HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: buttons, Head, run flat, brake fluid, alternator belt, coolant temperature, Mount

Page 1171 of 1681

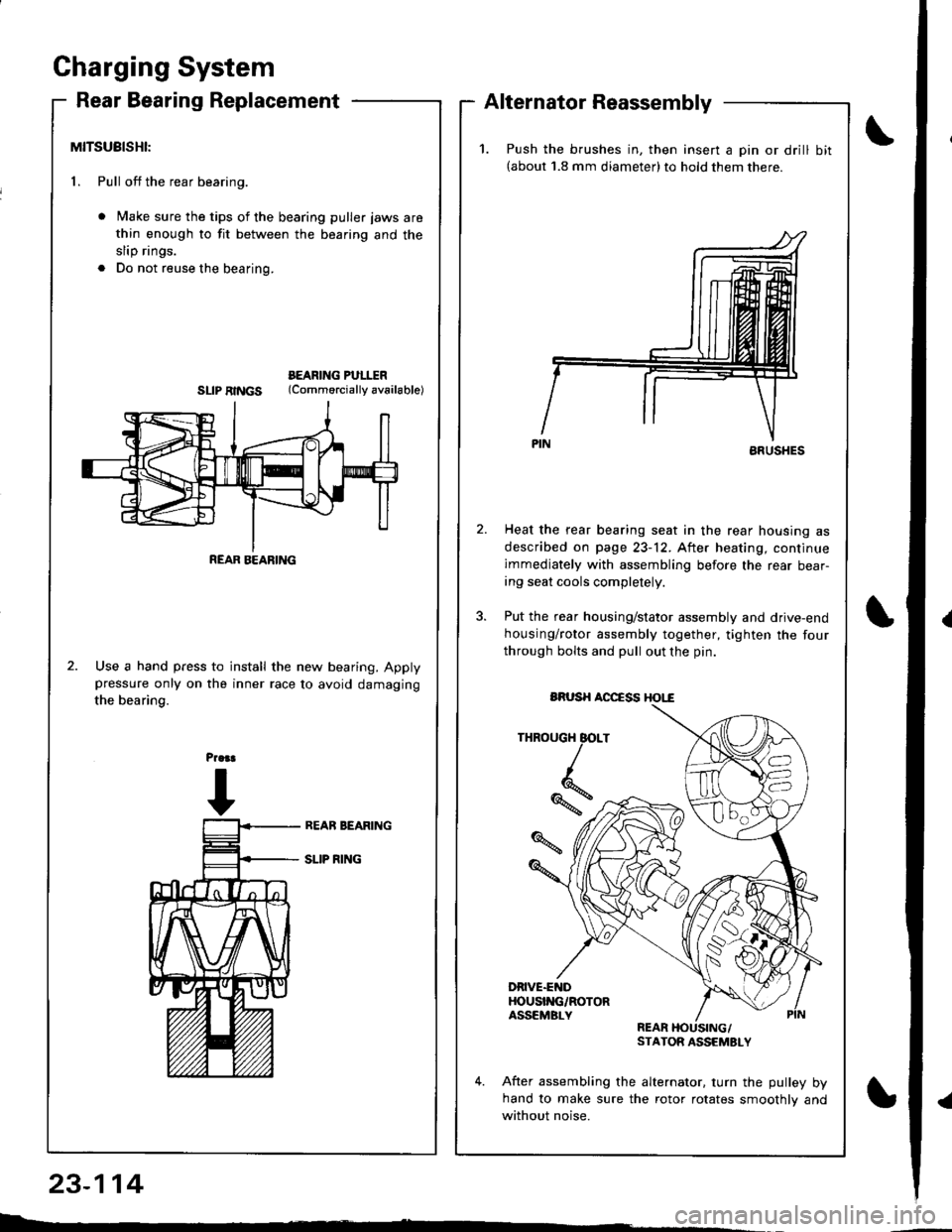

Gharging System

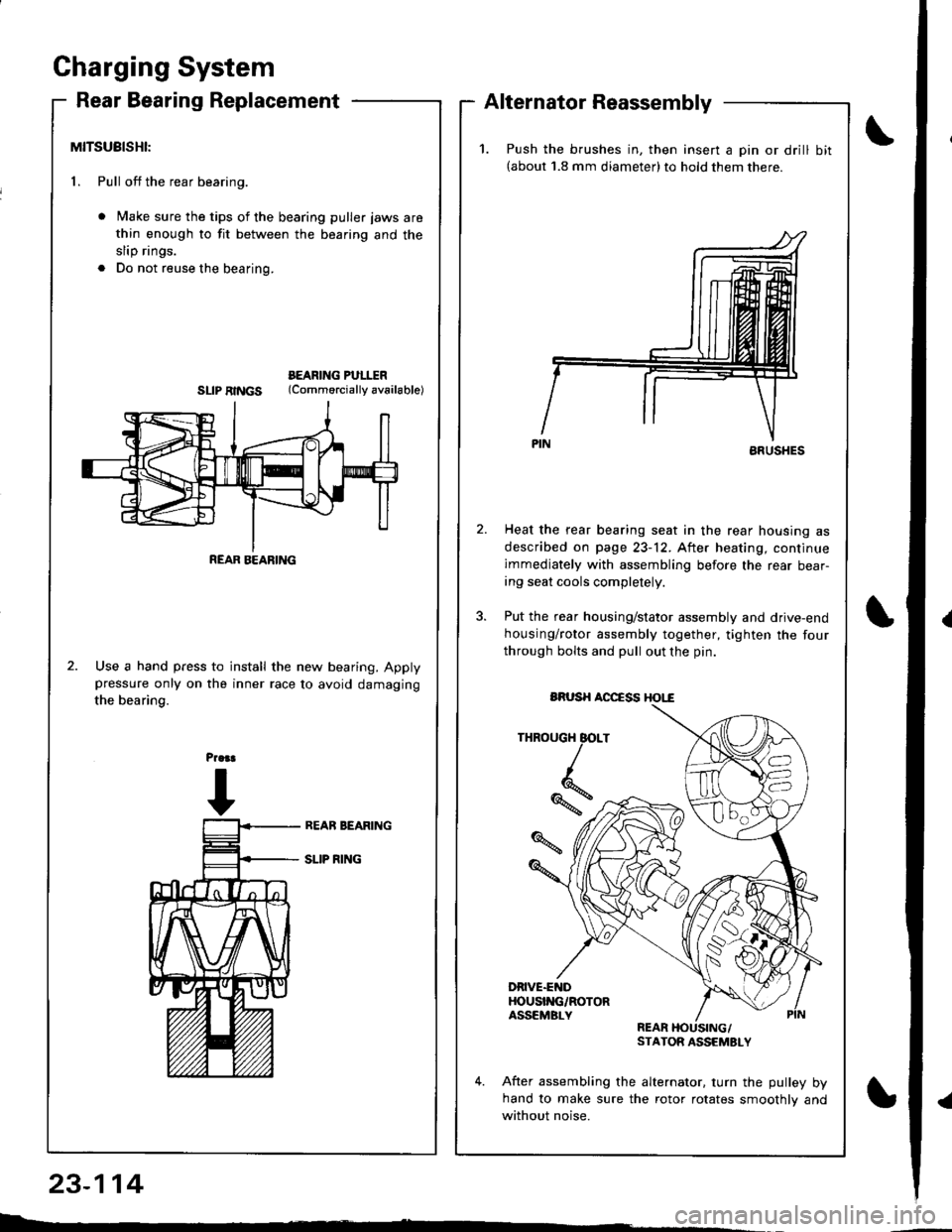

Rear Bearing ReplacementAlternator Reassembly

MITSUBISHI:

1. Pull off the rear bearing.

Make sure the tips of the bearing puller jaws are

thin enough to fit between the bearing and the

slip rings.

Do not reuse the bearing.

BEARING PULITRSLIPRINGS (Commorciallyav6ilable)

Use a hand press to install the new bearing. Applypressure only on the inner race to avoid damaging

the bearing.

23-114

L : -

REAR BEARING

1.Push the brushes in, then insert a pin or drill bit(about 1.8 mm diameter)to hold them there.

ARUSHES

Heat the rear bearing seat in the rear housing as

described on page 23-12. After heating, continue

immediately with assembling before the rear bear-ing seat cools completely.

Put the rear housing/stator assembly and drive-end

housing/rotor assembly together, tighten the four

through bolts and pull out the pin.

THROUGH BOLT

*,

DRIVE.ENDHOUSI'{G/ROTORASSEMBLYREARSTATOR ASSEMSLY

After assembling the alternator. turn the pulley byhand to make sure the rotor rotates smoothlv and

without noise.

BRUSH AOCCSS HOI,"€

Page 1172 of 1681

)

t

J

Altelnator ttelr Inspecuon ano Aol

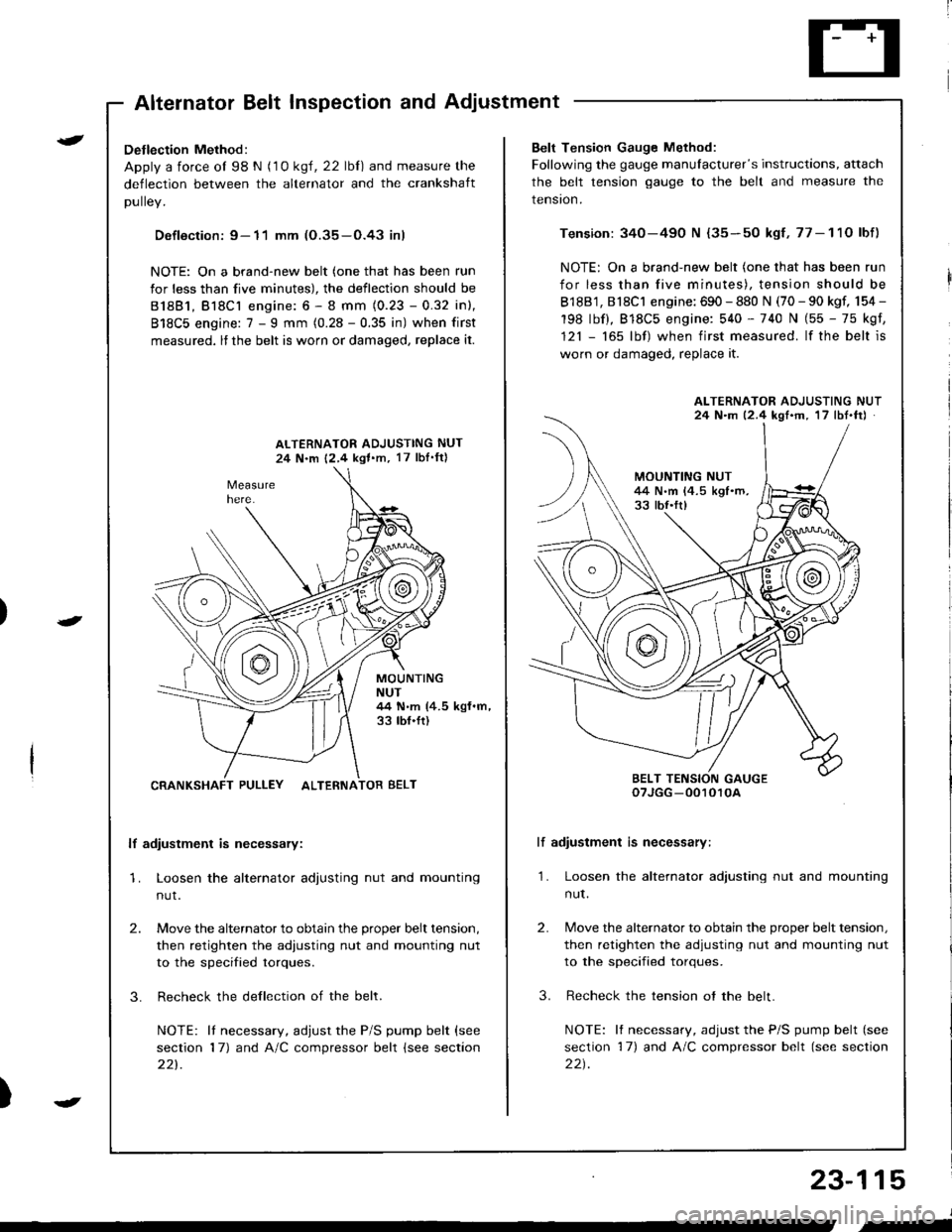

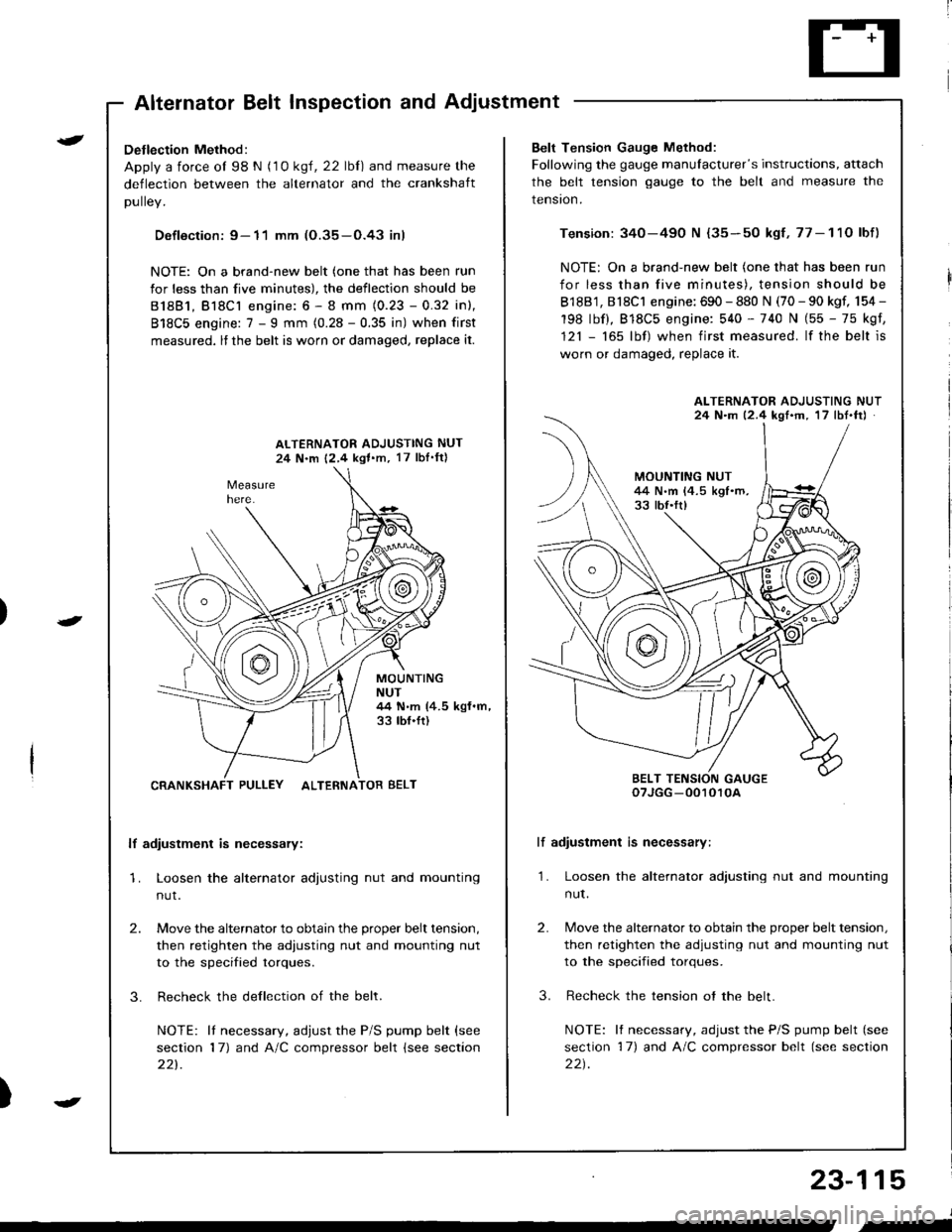

Detlection Method:

Apply a force ol 98 N (1 0 ksl, 22 lbl) and measure the

deflection between the alternator and the crankshaft

DUllev,

Defloction: 9- 11 mm (O.35-O.43 inl

NOTE: On a brand-new belt (one that has been run

for less than five minutes), the deflection should be

81881, Bl8Cl engine: 6 - 8 mm (0.23 - 0.32 inl,

818C5 engine: 7 - I mm (0.28 - 0.35 in) when first

measured, lf the belt is worn or damaged, replace it.

ALTERNATOR ADJUSTING NUT

24 N.m 12,4 kgl.m, 17 lbI'ftl

MOUNTINGNUT44 N.m (4.5 kgf.m,33 tbf.ft)

CRANKSHAFT PULLEY ALTERNATOR BELT

lf adiustment is necessary:

1. Loosen the alternator adjusting nut and mounting

nut.

2.

3.

Move the alternator to obtain the proper belt tension,

then retighten the adiusting nut and mounting nut

to the specified torques.

Recheck the dellection of the belt.

NOTE: lI necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

221.

Belt Tension Gauge Method:

Following the gauge manulacturer's instructions, attach

the belt tension gauge to the belt and measure the

tension.

Tension: 340-490 N {35-50 kgf,77-11O lbf)

NOTE: On a brand-new belt (one that has been run

for less than five minutes), tension should be

818B1, 818C1 engine: 690 - 880 N (70 - 90 kgf, 154 -

198 lbf), 818C5 engine: 540 - 740 N (55 - 75 kgf,

121 - 165 lbf) when first measured. lf the belt is

worn or damaged, replace it.

lf adiustment is necessary:

1. Loosen the alternator adjusting nut and mounting

nut.

2.

3.

Move the alternator to obtain the proper belt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

Recheck the tension ot the belt.

NOTE: It necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

22t.

ALTERNATOR ADJUSTING NUT24 N.m 12.4 kgf'm, 17 lbt.ftJ

BELT TENSION GAUGEoTJGG -0010r0A

23-115

J

,-

Page 1173 of 1681

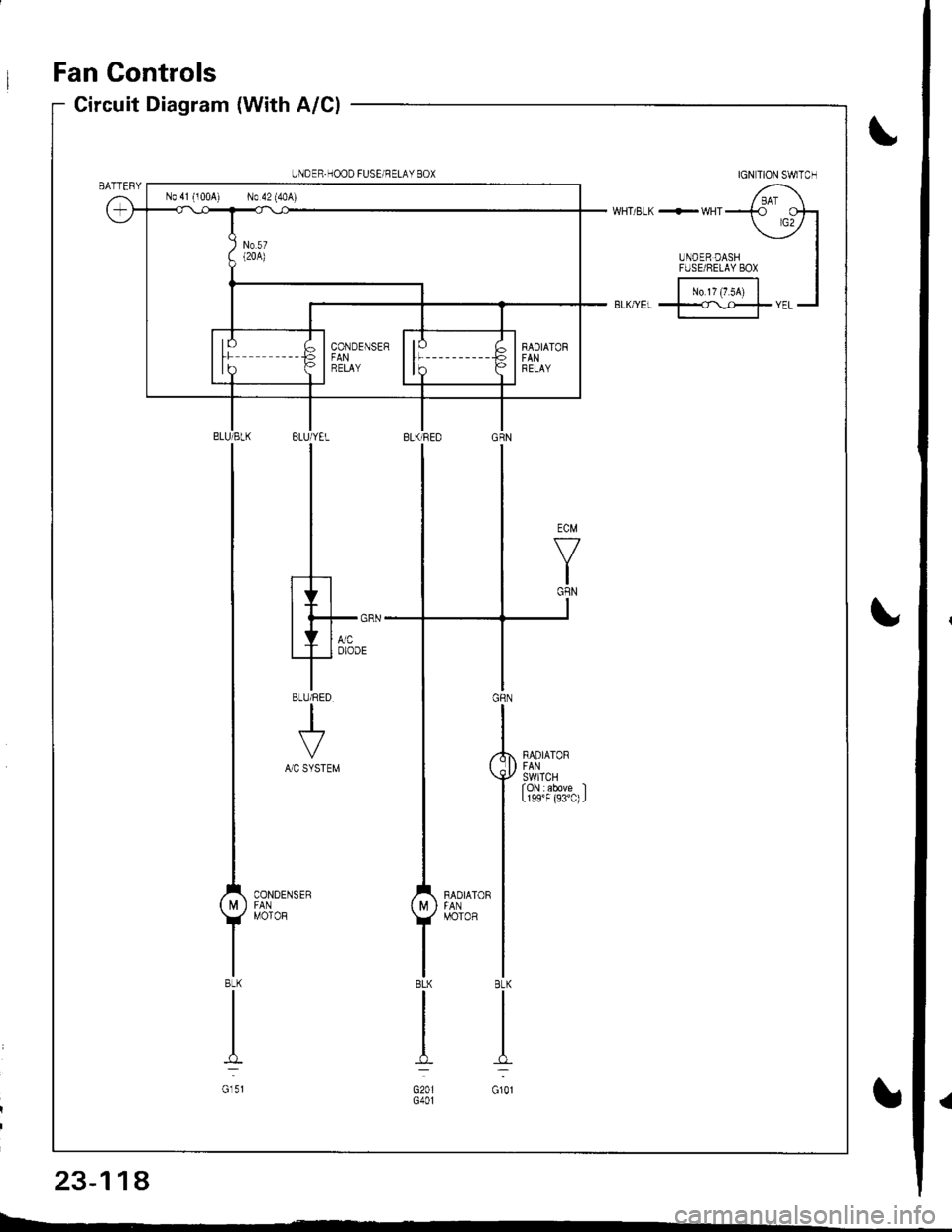

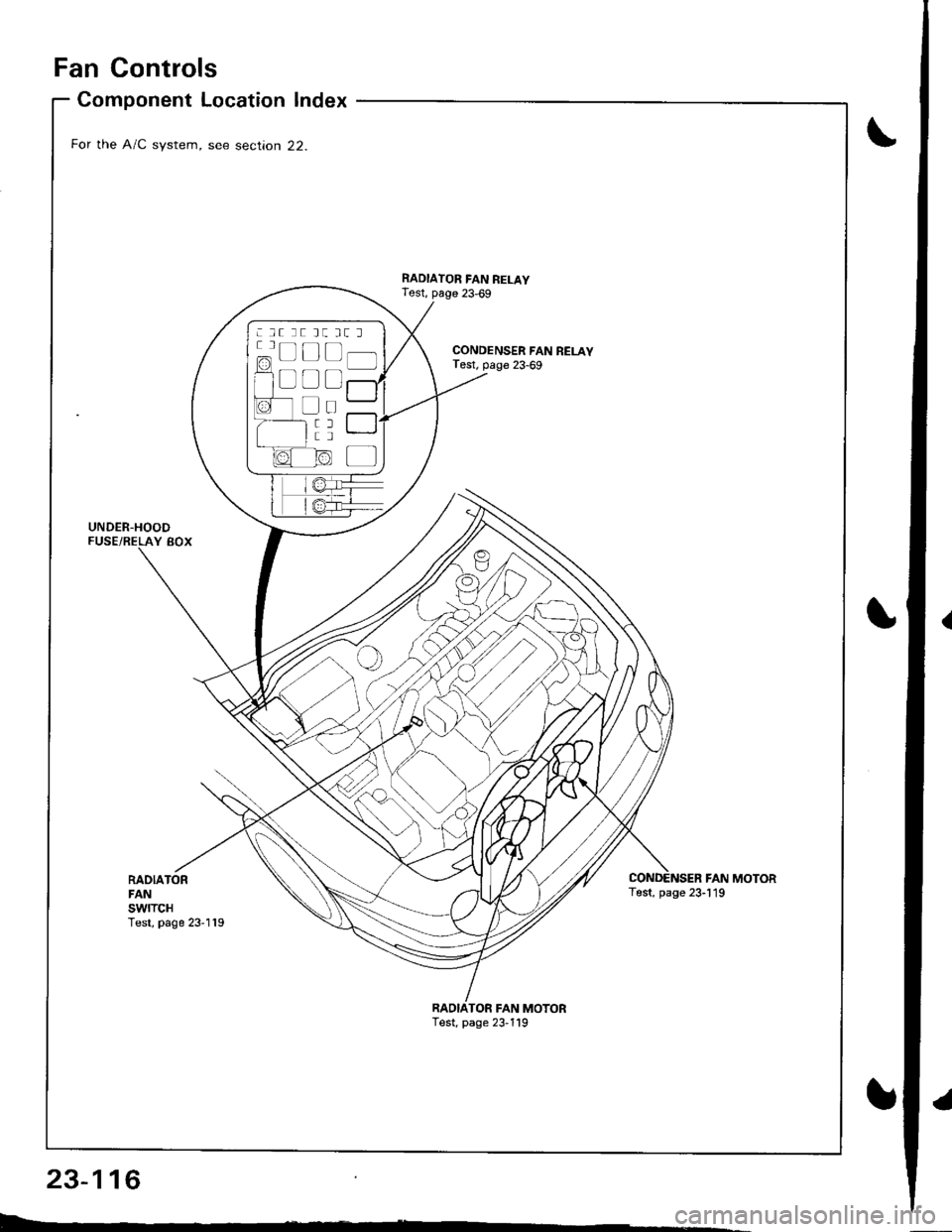

Fan Controls

RADIATORFANswtTcHTest, page 23-119

Component Location Index

For the A/C system, see section 22.

UNDER-HOODFUSE/RELAY BOX

CONDENSER FAN RELAYTest, page 23-69

RADIATOR FAN RELAYTest, page 23,69

FAN MOTORTest, page 23-119

TOR FAN MOTORTest, page 23,119

: lt tt tt tt l

c=, Ll L-t t lf l]-]l

f1 a l f -r a'r -

I i I r""""rlla-t fr -

a tL) | |Irt -

1/^ l/-\ltr.z{ N/ L

Page 1174 of 1681

Circuit Diagram (Without A/Cl

UNOEF.OASHFUSE,NELAY BOX

|-;ffi;I-YELf\-.rl]-t

BTK'EL -l

RAOIATORFANS\,YITCHfoN : above )(199'F (93'C)J

BLIVREO

BLK

I

G201G401

IGNITION SWITCH

N0.41 (lmAl No.42 (104)

RADIATORFANRELAY

23-117

.l

Page 1175 of 1681

Fan Controls

IGN TION SWITCH

/ BAI \WHT/ELK +-WHTT rcotr

UNDER DASH

-

IFUSE/8ELAY 8ox I

|-;;;l IBL(rYEL t==rYEL-l

BLUiYEL

I

I

I

.h

Ith*-'T'o'oo'

8LU/RED

+A/C SYSTEM

.,'l'**u.'

UNDER.HOOD FUSEi NELAY BOX

No 41 (100A) No 42 (40A)

23-114

Page 1176 of 1681

)

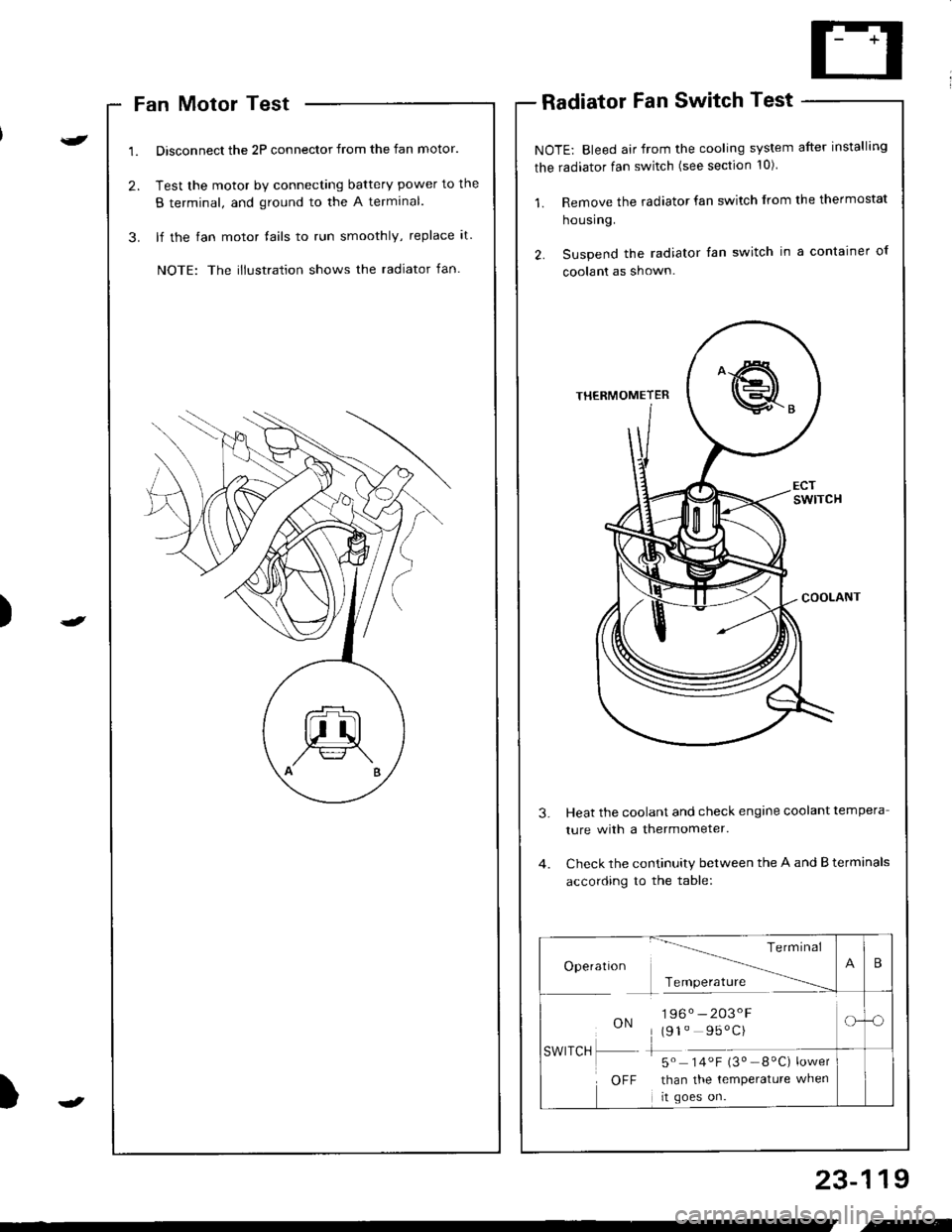

Fan Motor Test

Disconnect the 2P connector from the fan motor.

Test the motor by connecting battery power to the

B terminal, and ground to the A termlnal.

lf the fan motor fails to run smoothly, replace it.

NOTE: The illustration shows the radiator fan.

Radiator Fan Switch Test

NOTE: Bleed air from the cooling system after installing

the radiator fan switch (see section 10)

1. Remove the radiator fan switch from the thermostat

housing.

2. Suspend the radiator fan switch in a container ol

coolanl as shown.

Heat the coolant and check engine coolant tempera

ture with a thermometer.

Check the continuity between the A and B terminals

according to the table:

23-119

Te rm Inal

Operatlon -------\

Tcmoerature ------

ON196. -203'F

(91" 95'C)

-5" 14.F i3" _8"C) ;*,*

than the temperature when

rt goes on.

SWITCH

OFF

B

-o

.-

Page 1177 of 1681

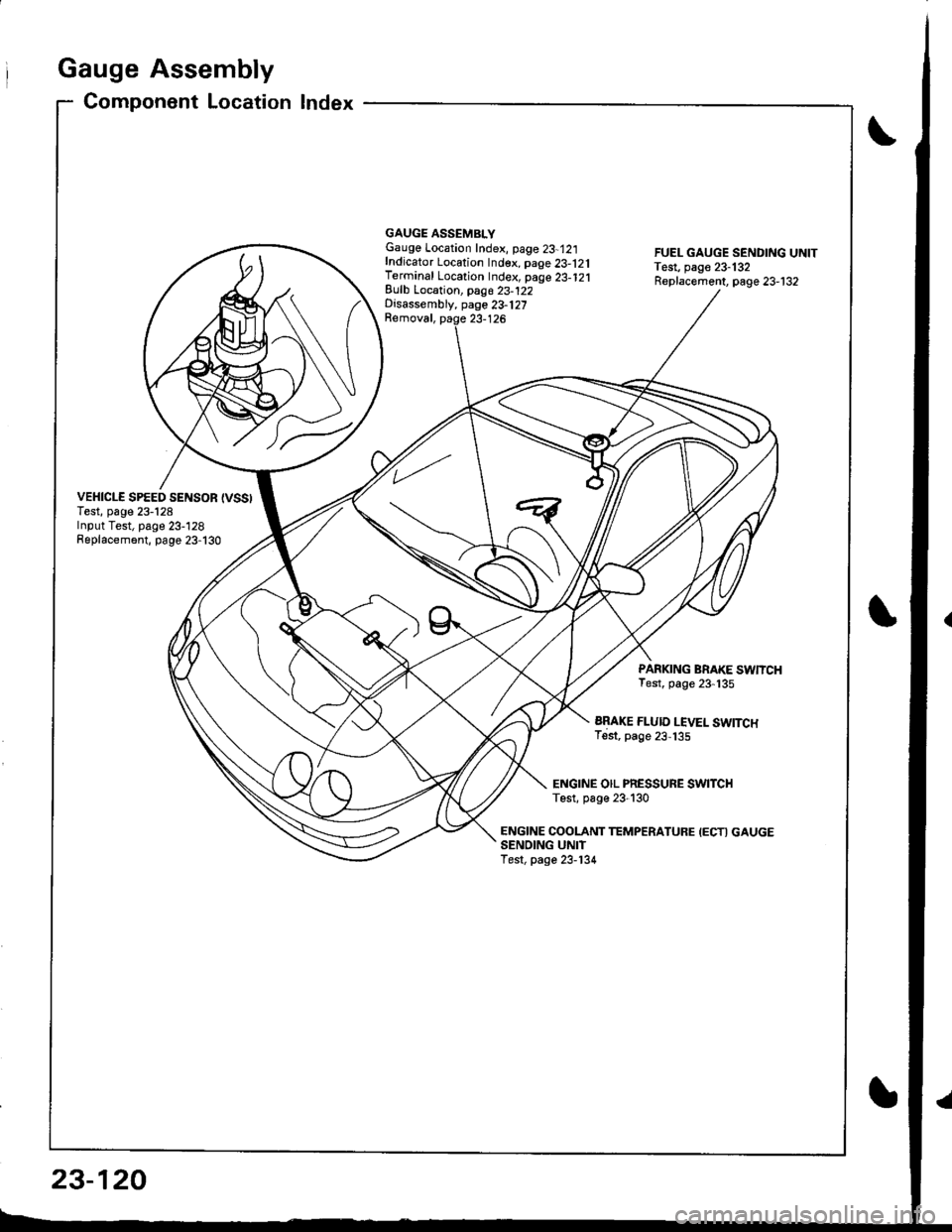

Gauge Assembly

Component Location Index

VEHICLE SPEED SENSOR {VSSITest, page 23-128Input Test, page 23-128Replacement, page 23-130

GAUGE ASSEMBLYGauge Location Index, page 23-12:|fndicator Location Index. page 23-121Terminal Location Index, page 23-121Eulb Location, pag6 23-122Disassembly, page 23-127Removal, paqe 23-126

FUEL GAUGE SENDING UNITTest, page 23-132Replacement, page 23-132

PARKING BRAKE SWNCHTest, page 23-135

ARAKE FLUID LEVEL SWITCHTest, page 23,135

ENGINE OIL PRESSURE SWITCHTest, p6ge 23-130

ENGINE COOLANT TEMPERATUFE IECTI GAUGESENOING UNITTest, page 23-134

23-120

Page 1178 of 1681

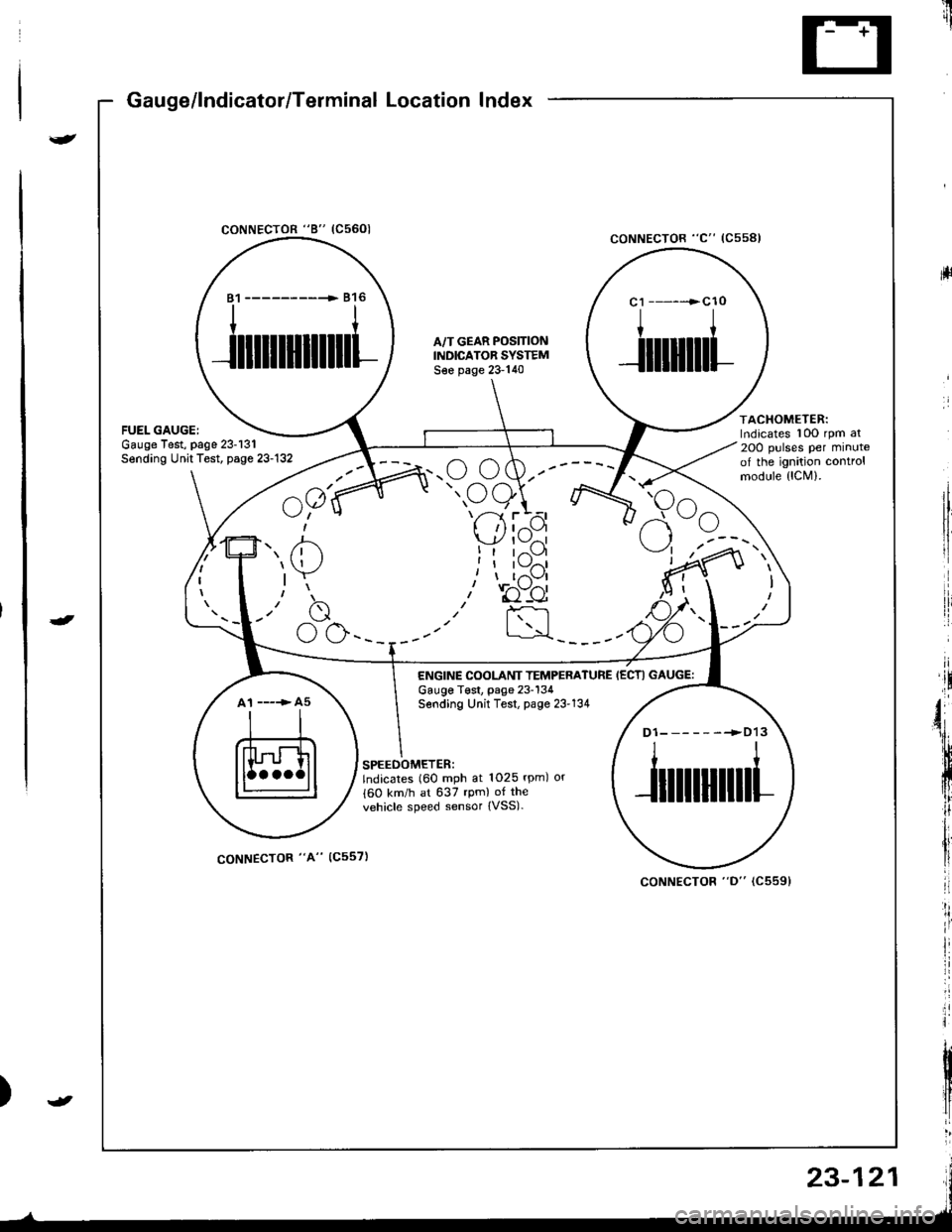

Gauge/lndicator/Terminal Location Index

coNNECTOR "8" (C5601

ltrii

rll

coNNECTOR "C" (Css8l

ACHOMETER:rdicates 10O rpm al

OO pulses per minutef the ignition controlrodule {lCM).

81 ------------ 816

ililllllilll

A,/T GEAR POS]TIONINDICATOR SYSTEMS€e page 23-140

c1 ------>cl0

I

Jilliltl

atespage 23-131t Test, page 23-132

^a1(

u;" u

7' /'- /n.u (,w.--

" oe)\r- -7 ttt'-1 r --

I 'l I z{.-a\y' | \-./^l

!t tr--',9I I l\-//11, I t,-\Jl

.r' to"-ei

I :rl

F<

elrle

ENGINE COOLANT TEMPERATUREGauge T€st, page 23-134Sending Unit Test, page 23'134

IECTI GAUGE:

A1 ----> A5

D1-------->D13

ililtl|illl

SPEEOOMETER:lndicates (60 mph at 1025 rpm) or

{60 km/h at 637 rpm) of the

vehicle speed sensor {VSS).

coNNECTOR "A" (C557)

coNNECTOR "D" (C5591

23-121

Page 1179 of 1681

I

rIGauge Assembly

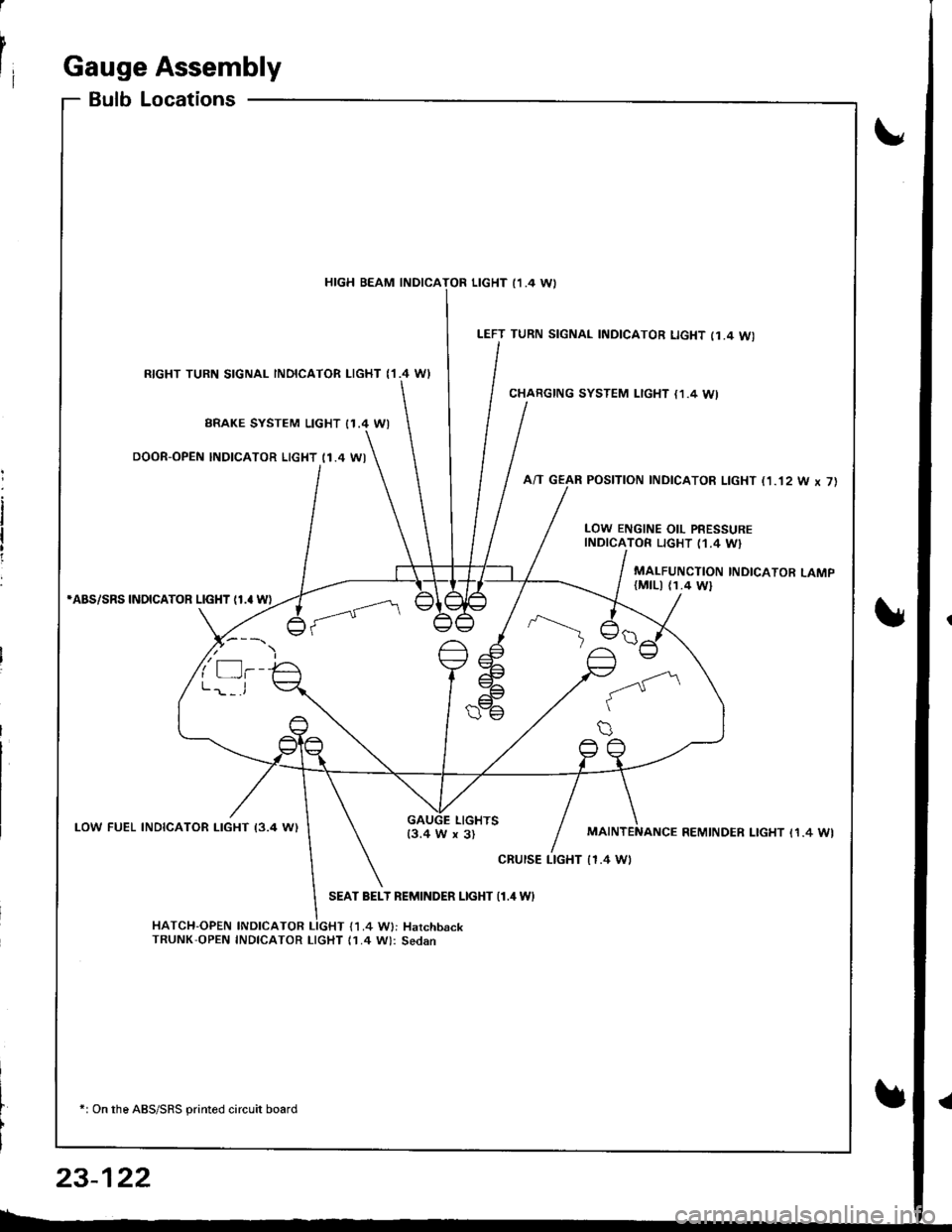

BulbLocations

RIGHT TURN SIGNAL INOICATOR LIGHT ('I.4 WI

BRAKE SYSTEM LIGHT I1.4 WI

DOOR-OPEN INDICATOR LIGHT (1.4 WI

*ABS/SRS INOICATOR LIGHT (1.' W)

LOW FUEL INDICATOR I-IGHT I3.4 W)

SEAT BELT REMINDER LIGHT {1.4 WI

HATCH-OPEN INDICATOR LIGHT {1.4 W}: HarchbackTRUNK'OPEN INDICATOR LIcHT (1.4 W): Sedan

+: On the ABS/SRS printed circuit board

LEFT TURN SIGNAL INDICATOR LIGHT (1.4 WI

CHARGING SYSTEM LIGHT {1,4 WI

A/T GEAR POSITION INDICATOR LIGHT (1.'t2 W x 7)

HIGH BEAM INDICATOR LIGHT I1 .4 \A,

LOW ENGINE OIL PRESSUREINDICATOR LIGHT (1.4 W}

MALFUNCTION INDICATOR LAMP(MtLl (1.4 Wl

LIGHTS13.4 W x 3)REMINDER LIGHT I1.4 WI

cRursE LTGHT | 1.4 Wt

23-122

Page 1180 of 1681

UNDER.DASHFUSE/RELAY 8OX

No.l5 (7.54)

No 2s (7 5A)

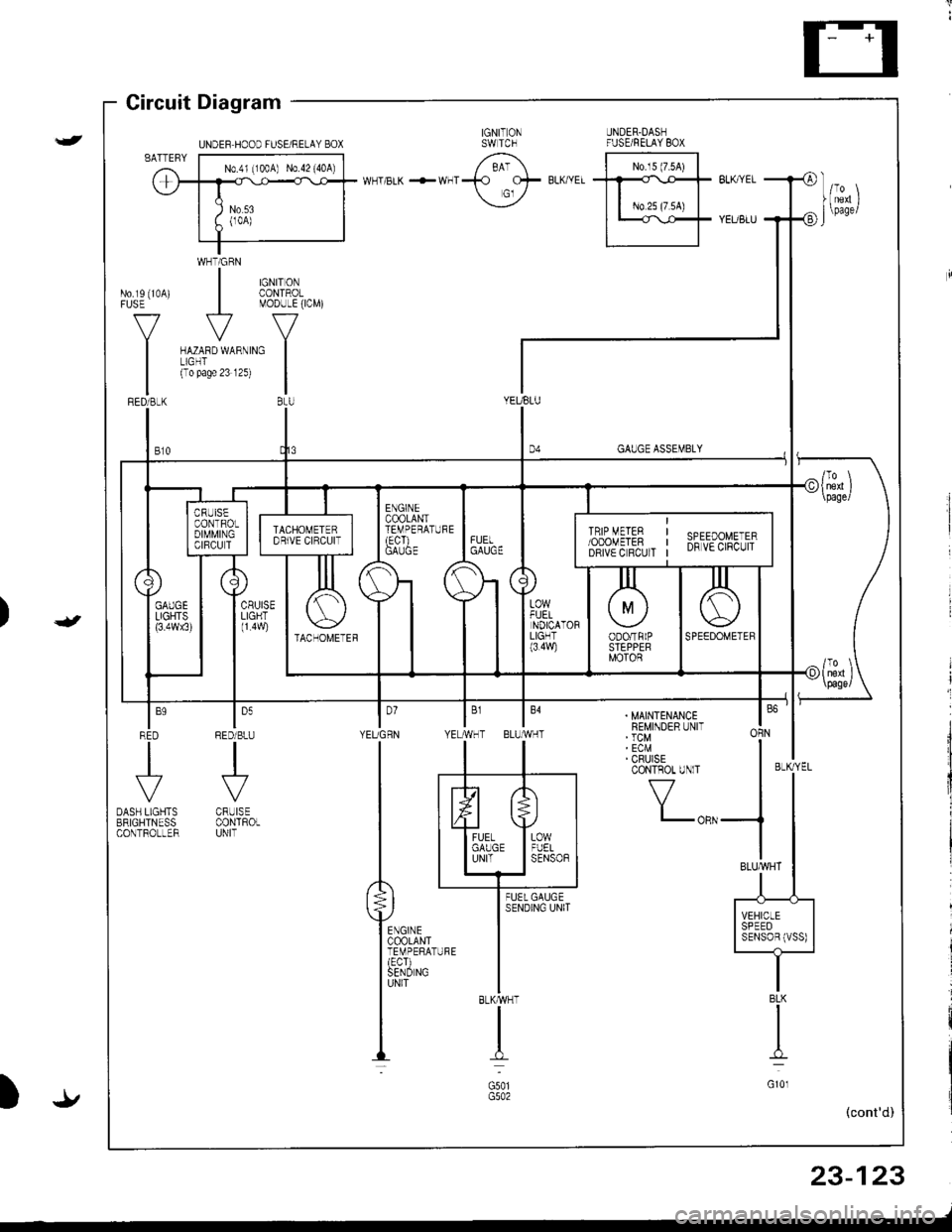

Gircuit Diagram

WHTiGRN

| $il,�4,

V

MODULE(ICM)

ru{no unrno I(To pase 23 12s)

|BtU

No.rs (10A)FUSE

V

I

GAUGE ASSEMBLY

YEUBLU

t,,

| ,,J,,

1l

|;;il'-II SPEED II SENSoBIVSS) |-t-

. MAINTENANCEREMINDER UNIT' TCM' ECM' CRUISECONTROT UNlT

f7

I-oRN

BLKMHT

I

G501

I'YEUGRN YE

ln

tl

P**,,,'

ffirxl-"

louRED/BLU

.J'-

CRUISECONTROLUNIT

BLK

I

G10l

23-123

-/

UNDEF HOOD FUSE/RELAY BOX

Trending: manual radio set, coolant capacity, tow bar, wheel, Starter, ignition, load capacity

![HONDA INTEGRA 1998 4.G Workshop Manual Circuit Diagram (Without A/Cl

UNOEF.OASHFUSE,NELAY BOX

|-;ffi;I-YELf\-.rl]-t

BTKEL -l

RAOIATORFANS\,YITCHfoN : above )(199F (93C)J

BLIVREO

BLK

I

G201G401

IGNITION SWITCH

N0.41 (lmAl No.42 (104)

RAD HONDA INTEGRA 1998 4.G Workshop Manual Circuit Diagram (Without A/Cl

UNOEF.OASHFUSE,NELAY BOX

|-;ffi;I-YELf\-.rl]-t

BTKEL -l

RAOIATORFANS\,YITCHfoN : above )(199F (93C)J

BLIVREO

BLK

I

G201G401

IGNITION SWITCH

N0.41 (lmAl No.42 (104)

RAD](/img/13/6069/w960_6069-1173.png)