HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: steering wheel adjustment, wheel torque, oil, checking oil, warranty, check transmission fluid, service

Page 1141 of 1681

Starting System

Armature Inspection and Test (cont'd)

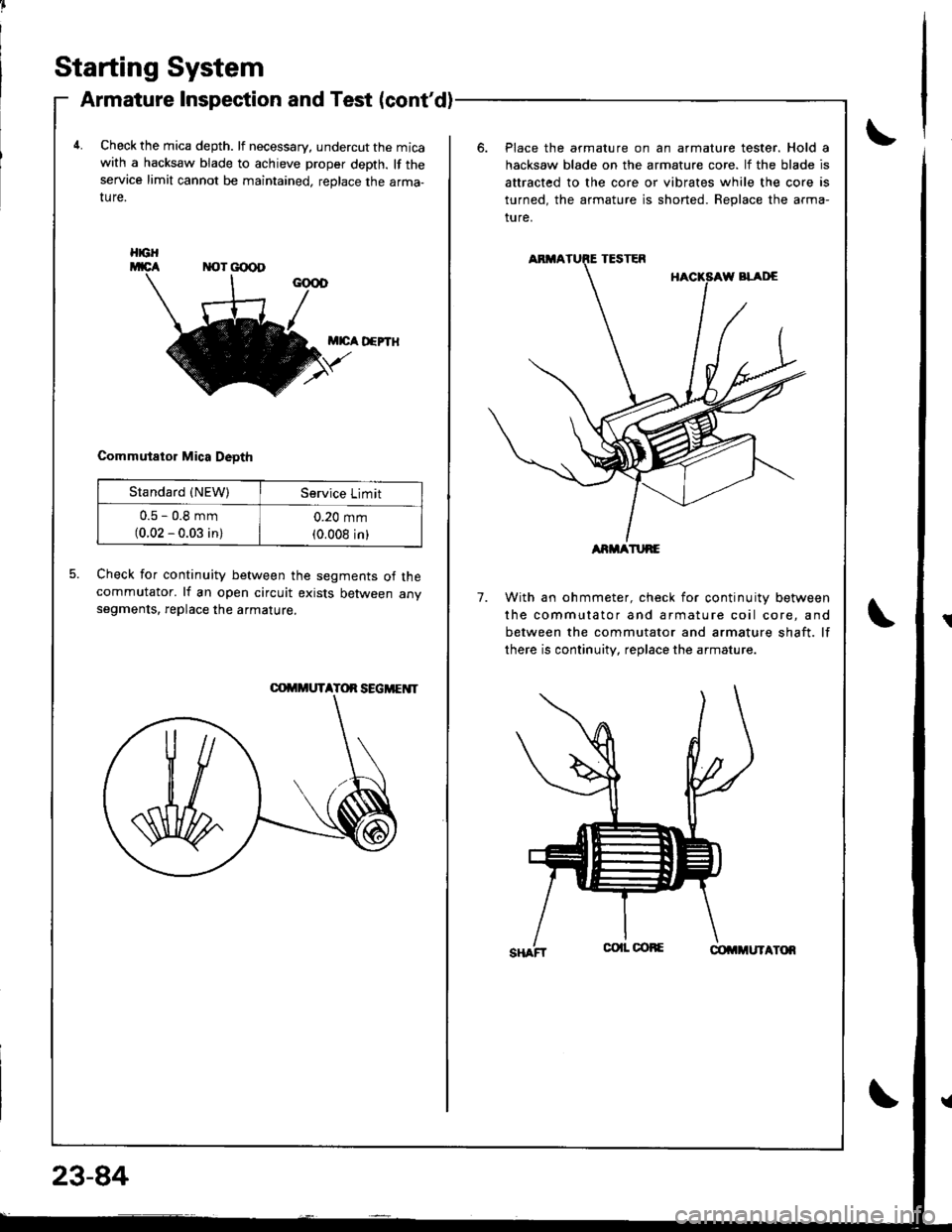

4.Check the mica depth. lf necessary, undercut the micawith a hacksaw blade to achieve proper depth. lf theservice limit cannot be maintained, replace the arma-ture.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. lf the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Beplace the arma-

ture.

M|cA D€PTH

Commutator Mica Deoth

5.Check for continuity between the segments of thecommutator. lf an open circuit exists between anvsegments, replace the armature.7.With an ohmmeter, check for continuity between

the commutator and armature coil core, and

between the commutator and armature shaft. lf

there is continuity, replace the armature.

HGH

Standard {NEW)Service Limit

u.5 - u,6 mm(0.02 - 0.03 in)

0.20 mm(0.008 inlARMATURE

Page 1142 of 1681

BRUSHES

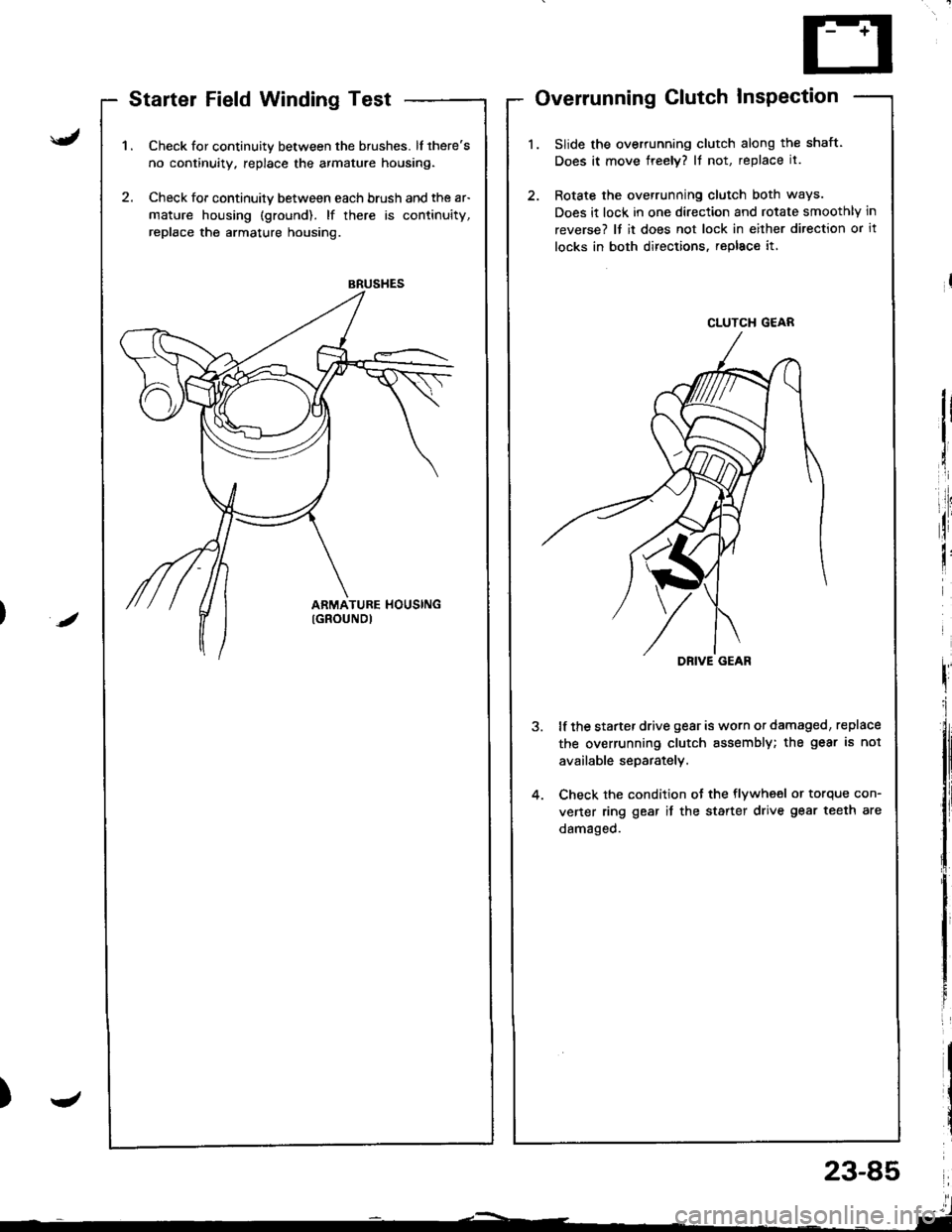

Startel Field Winding Test

Check for continuity between the brushes. lf there's

no continuity. replace the armature housing.

Check for continuily between each brush and the ar-

mature housing (ground). lf there is continuity,

replace the armature housing.

Overrunning Clutch InsPection

Slide the overrunning clutch along the shaft.

Does it move freely? It not, replace it.

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in

reverse? It it does not lock in either direction or it

locks in both directions, repl8c€ it,

lf the starter drive gear is worn or damaged, replace

the overrunning clutch assembly; the gear is not

available separately.

Check the condition ot the flywheel or torque con-

vener ring gear it the starter drive gear teeth are

damaged.

/

J

CLUTCH G€AR

DRIVE GEAR

23-85

l'l- ,-----_ -'l

Page 1143 of 1681

Starter Reassembly

Starting System

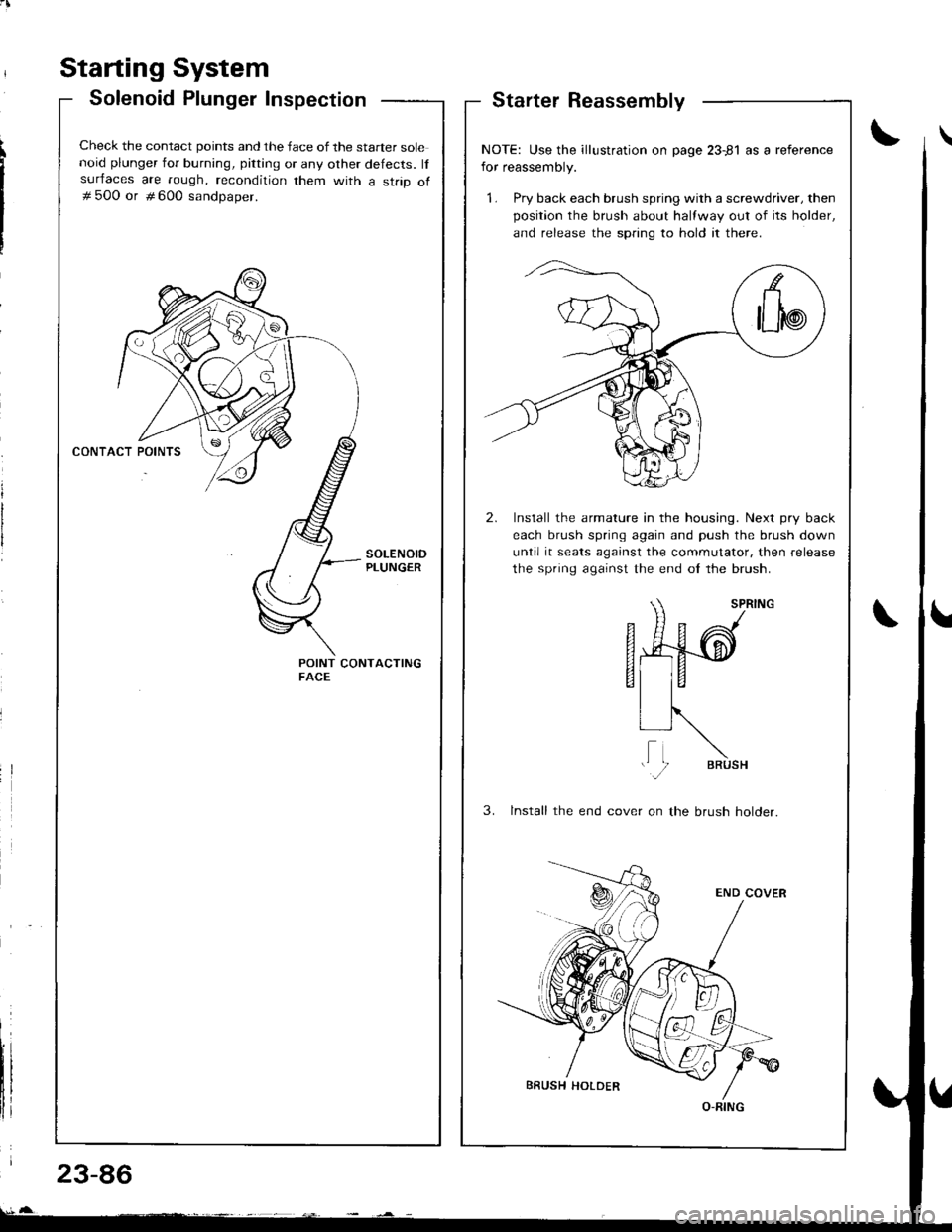

Solenoid Plunger Inspection

Check the contact points and the face of the starter solenoid plunger for burning, pitting or any other defects. lfsurfaces are rough, recondition them with a strip of# 500 or # 600 sandoaoer.

POINT CONTACTINGFACE

NOTE: Use the illustration on page 23-81 as a reference

for reassembly.

1. Pry back each brush spring with a screwdriver, then

position the brush about halfway out of its holder,

and release the spnng to hold it there.

2. Install the armature in the housing. Next pry back

each brush spring again and push the brush down

until it seats against the commutator. then release

the spring against the end ol the brush.

SPRTNG

fi49-d

EI

VIR, ,\

li N,."

3. lnstall the end cover on the brush holder.

O-RING

23-86

Page 1144 of 1681

J

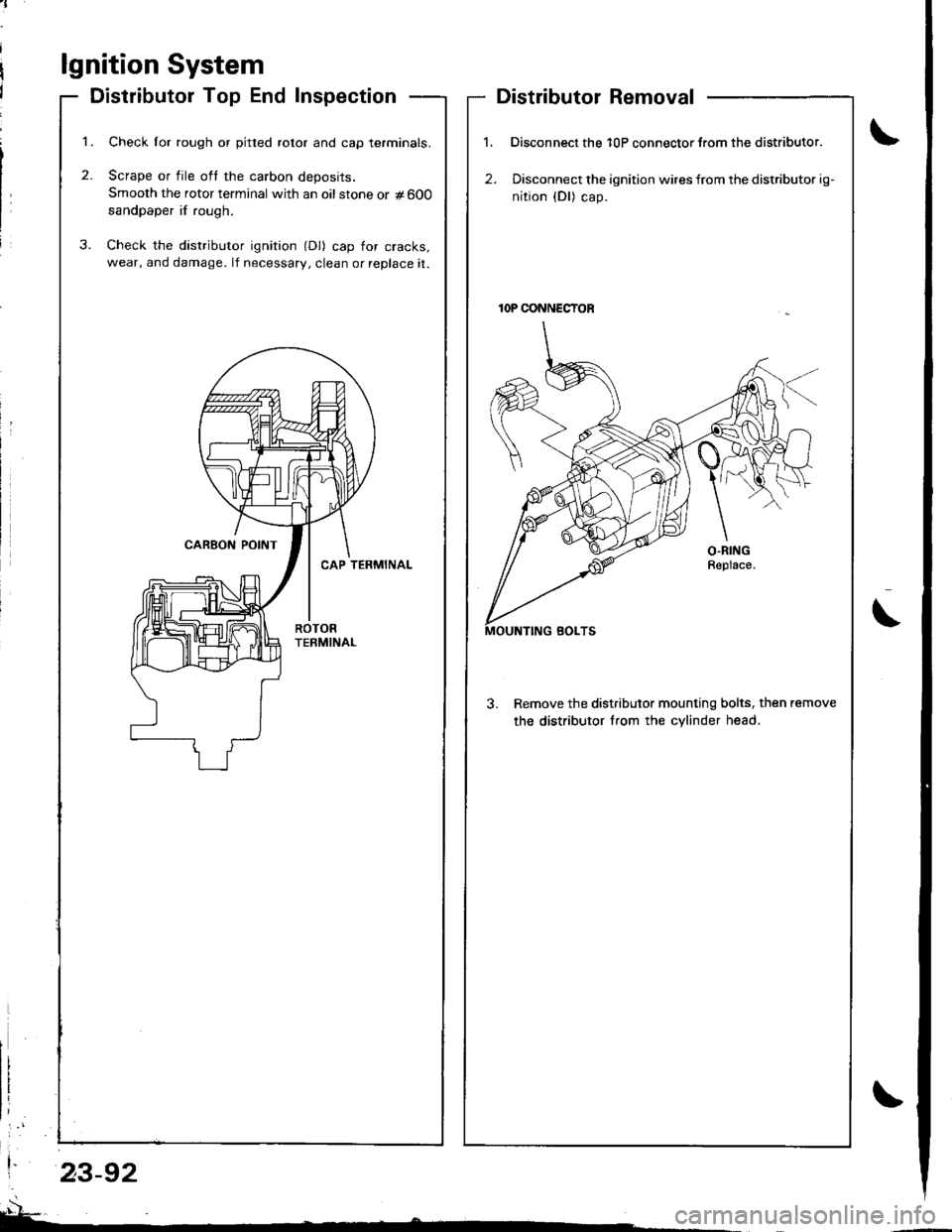

Starting System

Performance Test

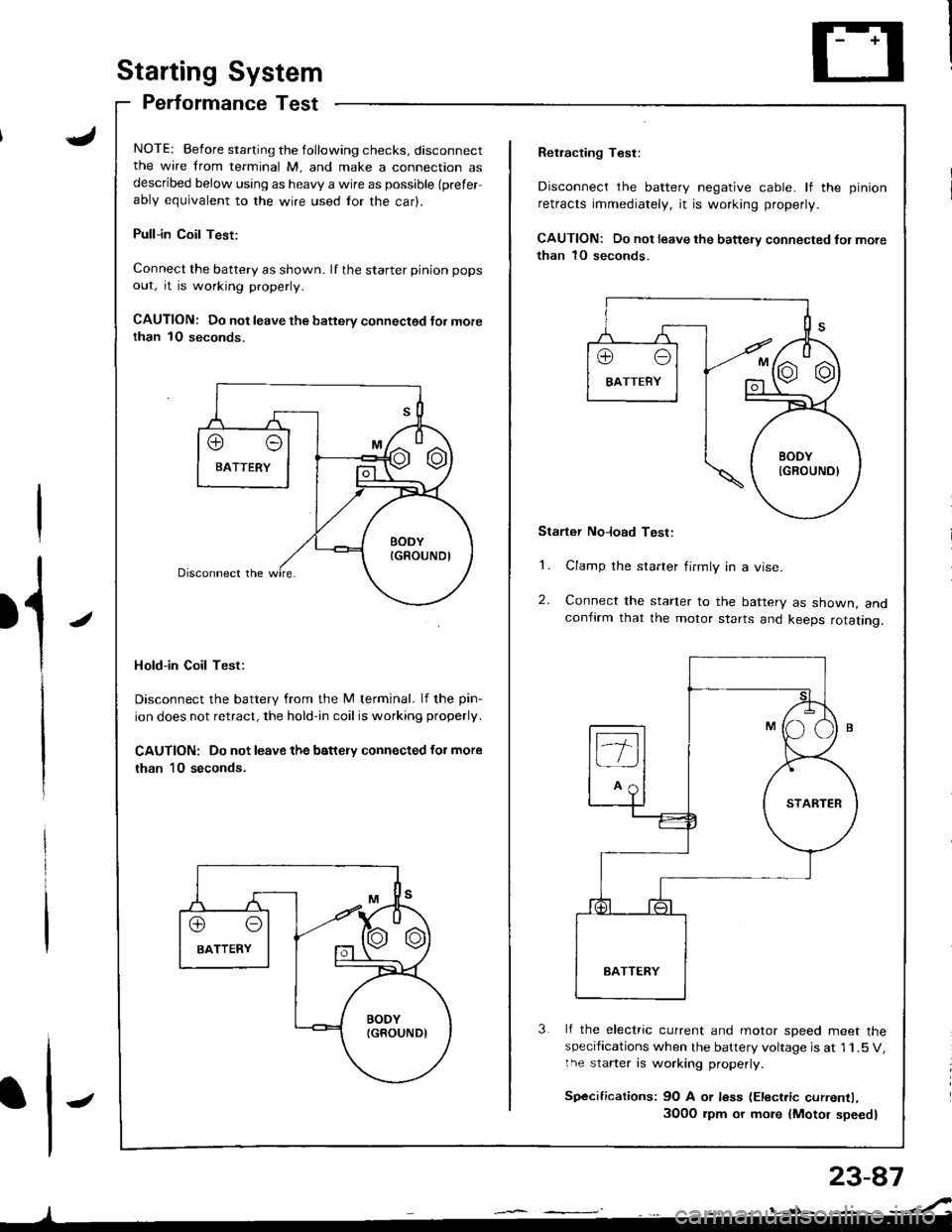

NOTE: Before starting the following checks, disconnectthe wire from terminal M, and make a connection asdescribed below using as heavy a wire as possible (prefer

ably equivalent to the wire used for the car).

Pull-in Coil Test:

Connect the battery as shown. If the starter pinion pops

out, it is working properly.

CAUTION: Do not leave the battery connectsd Jor morethan 1O seconds.

Hold-in Coil Test:

Disconnect the battery from the M terminal. lf the pin-

ion does not retract, the hold-in coil is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

J

Retracting Test:

Disconnect the battery negative cable. lf the pinion

retracts immediately, it is working properly.

CAUTION: Do not leave the battery connected fol more

than 1O seconds.

Starter No]oad Test:

1. Clamp the starter firmly in a vise.

2. Connect the starter to the battery as shown, andconfirm that the motor starts and keeps rotating.

3 lf the electric current and motor soeed meet thespecifications when the battery voltage is at 1 1.5 V,the starter is working properly.

Sp€cifications: 9O A or less (Electric currentl,

3O0O rpm or more {Motor speed}

Page 1145 of 1681

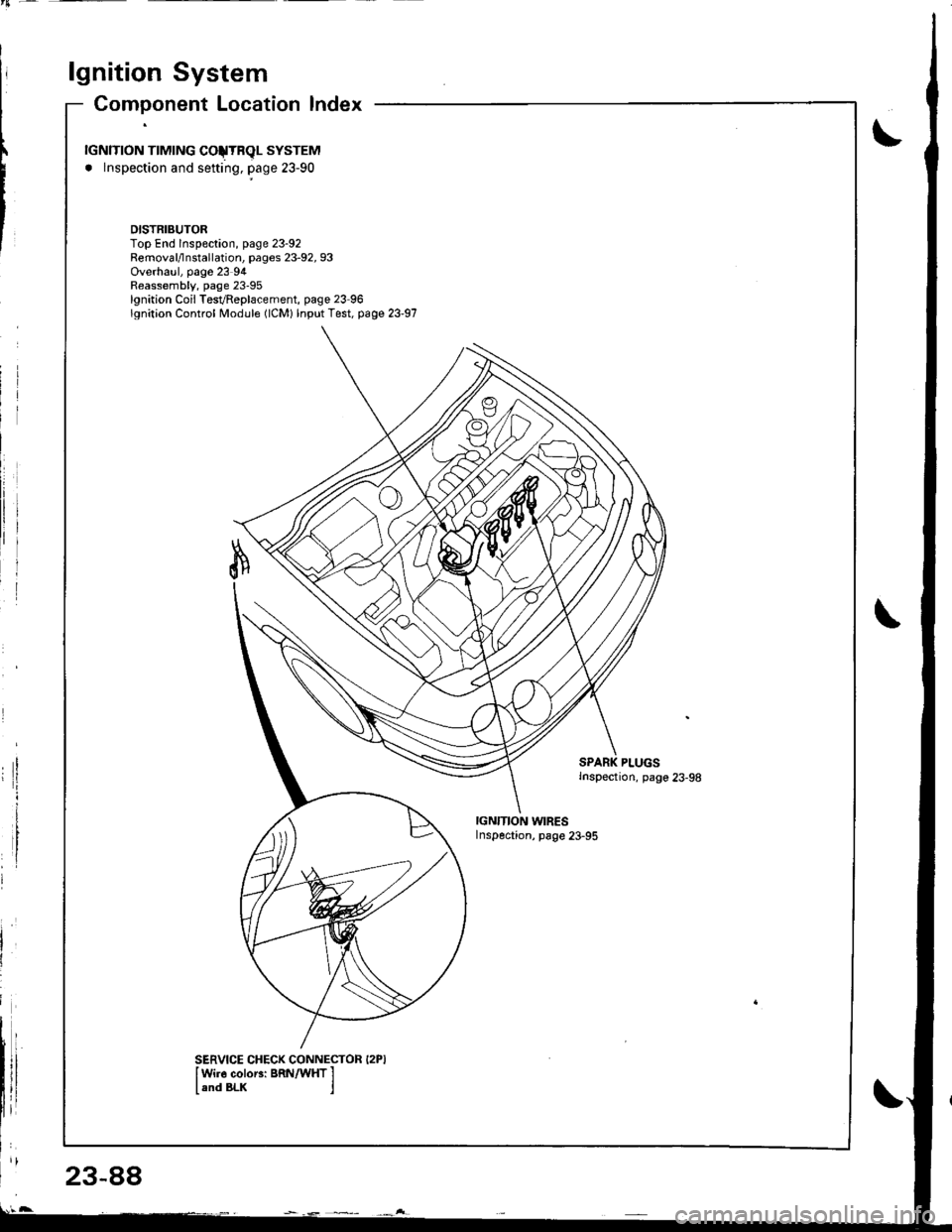

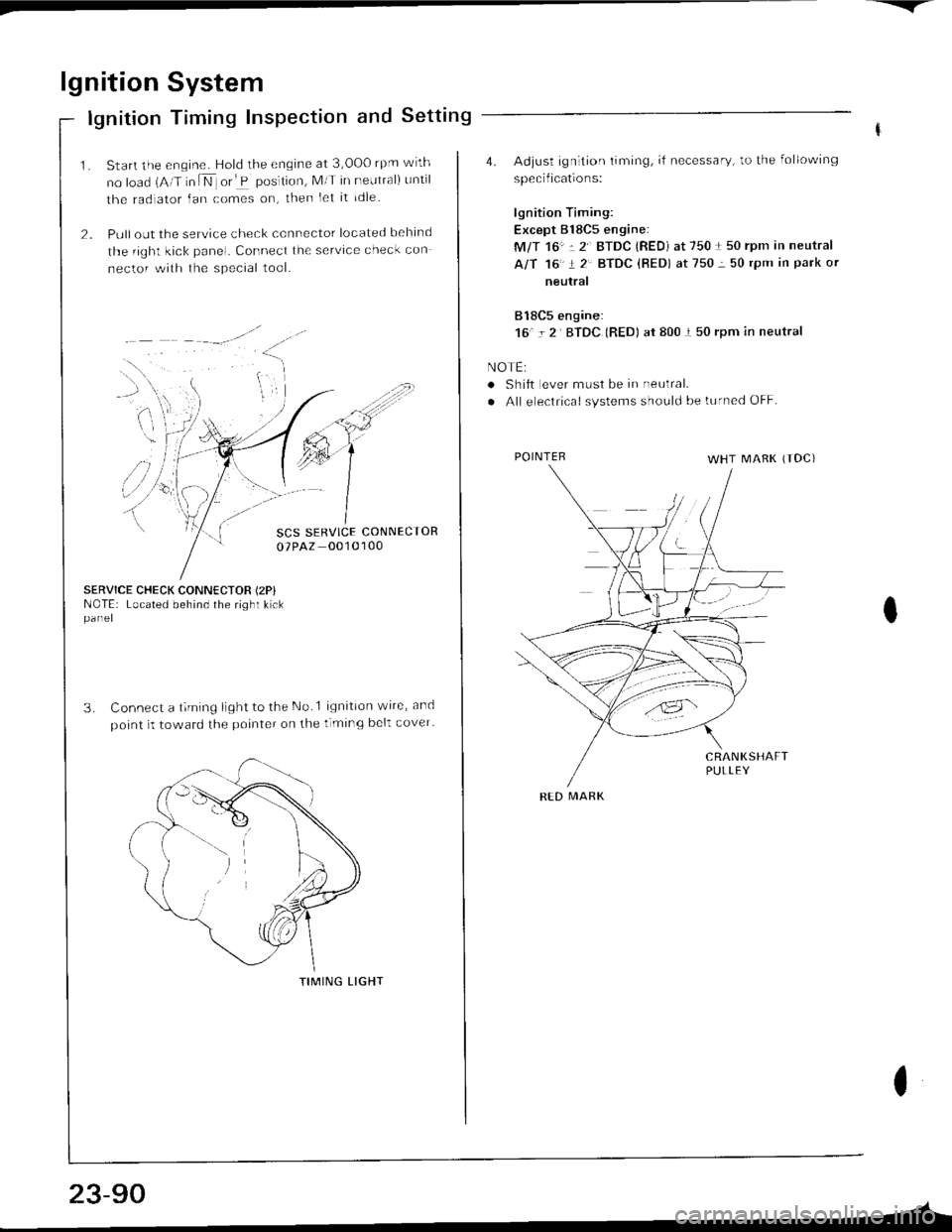

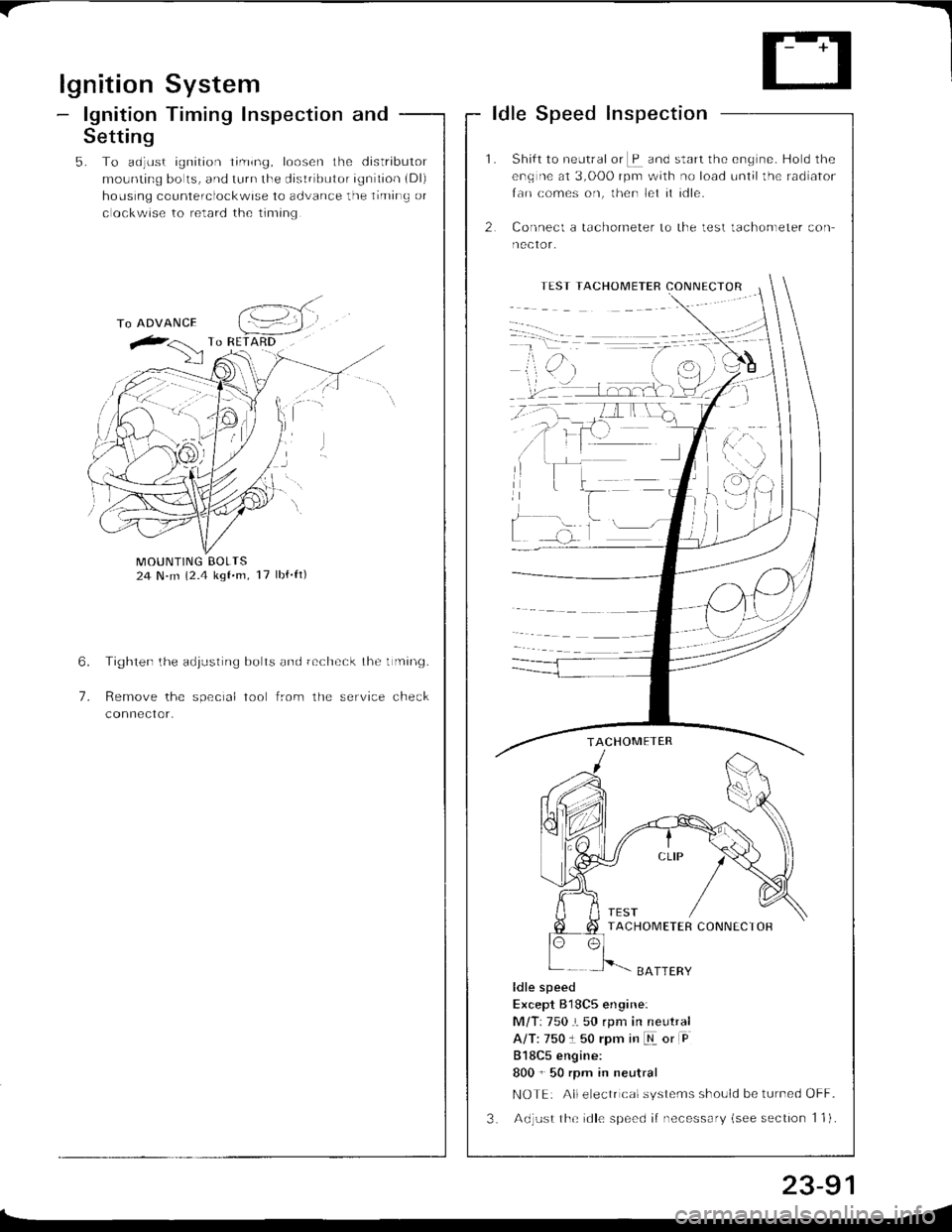

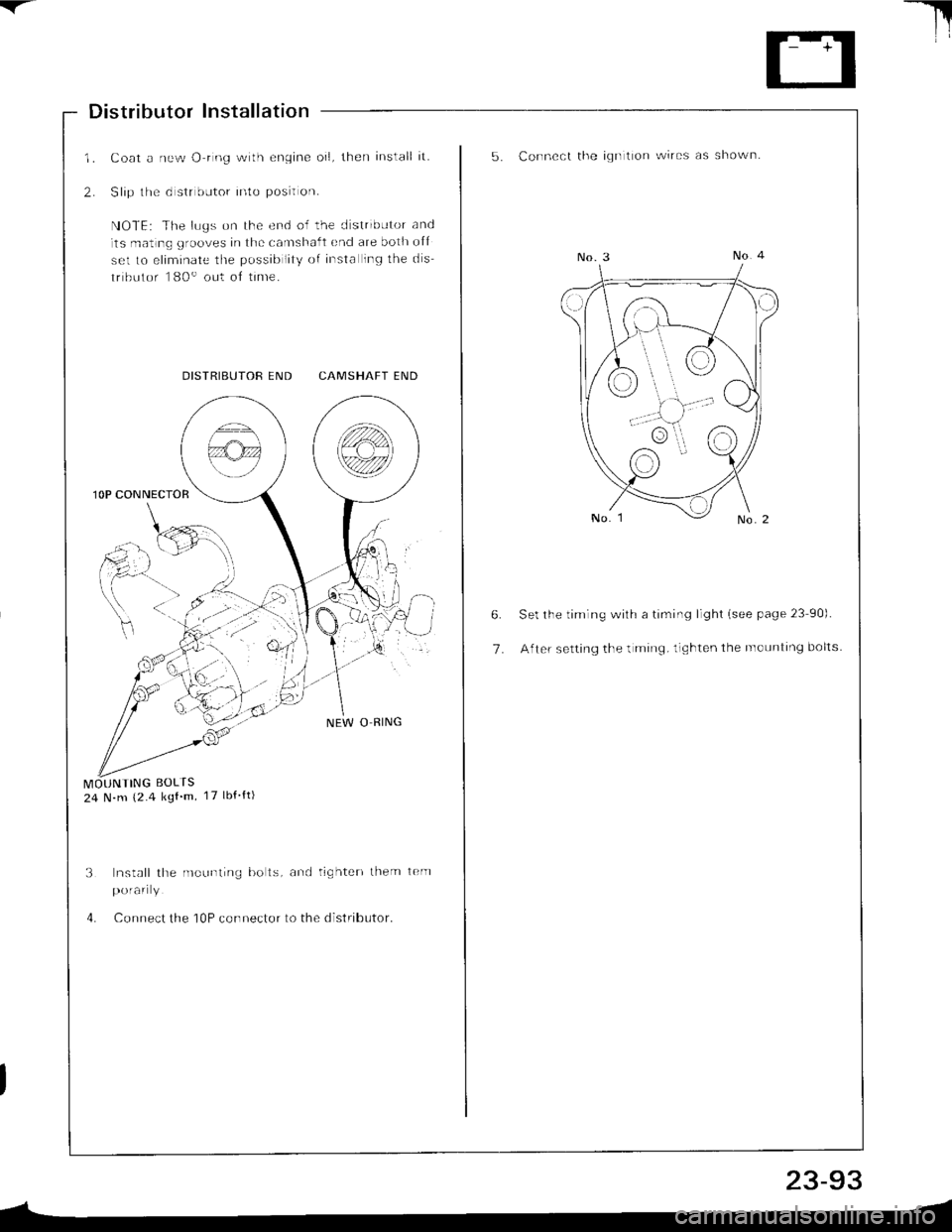

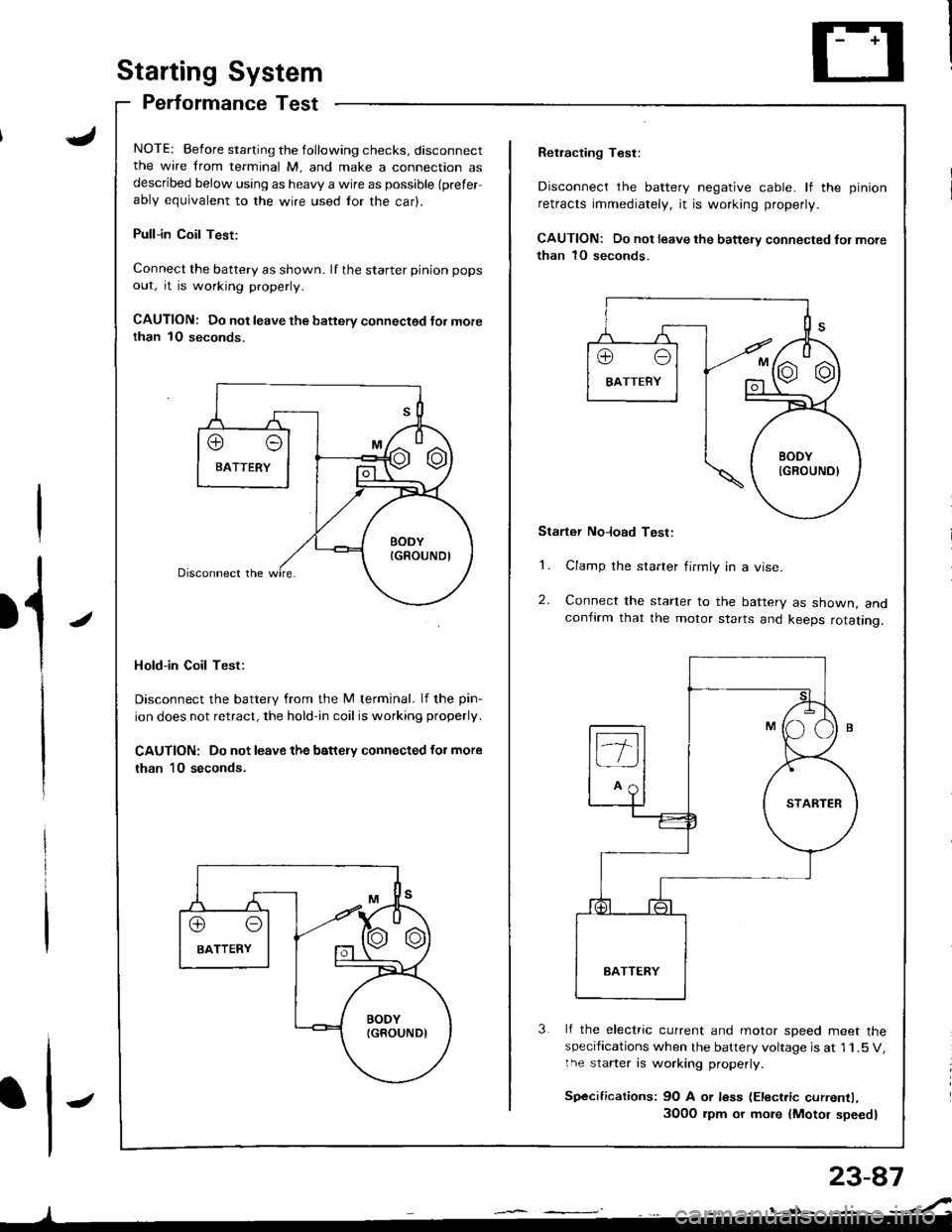

lgnition System

23-88

Component Location lndex

rGNlTroN TTMTNG COJTRqL SYSTEM

. lnspection and sefting, page 23-90

DISTRIBUTORTop End lnspeclion, page 23-92Removal/lnstallation, pages 23-92, 93Overhaul, page 23 94Reassembly, page 23-95lgnition Coil TesvReplacement, page 23 96lgnition Control Module (lCM) lnput Test, page 23-97

PLUGSInspection, pago 23-98

IGN'TION WIRESInspection, page 23-95

SERVICE CHECK CONNECTOR I2PIIWi]6 coloEi BRN/WHT I

land BLK j

Page 1146 of 1681

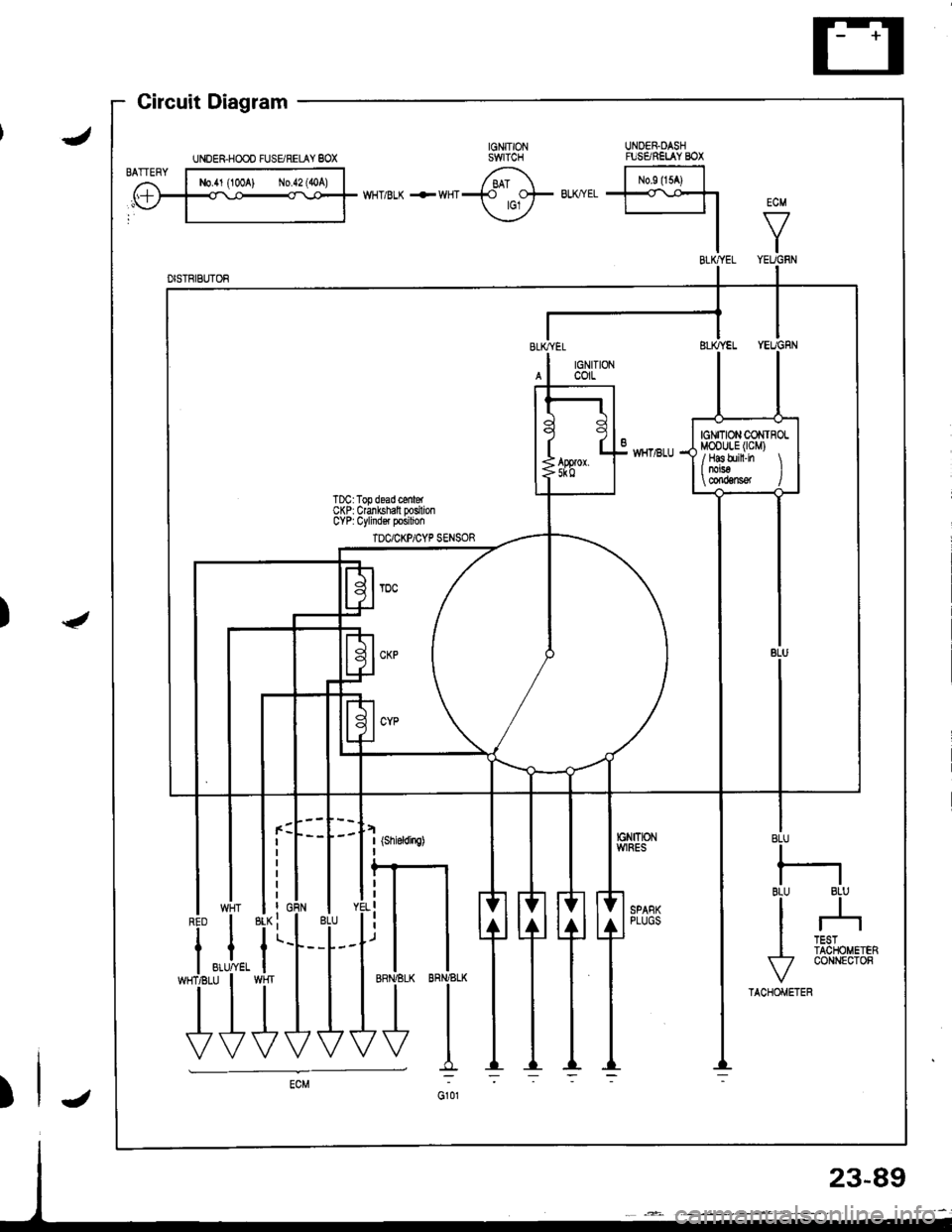

ECM

VI

BLU

I

BI.U 8LUll

I --r

I li3fou.'..

v

coNNEcroR

TACHOMETER

UNOER.DASHruSARELAY BOX

l-*",t^l

t*Tl-l

I

IGNTTIONWlRES

llI SPANKI PLUGS

t uragram -

UNDER.HOOO FUSgRELAY 8OX

-i.i,

T}

23-89

Page 1147 of 1681

Page 1148 of 1681

Page 1149 of 1681

Page 1150 of 1681

Trending: oil change, steering, jump start terminals, warning light, Photo c503, turn signal bulb, refrigerant type