battery HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1386 of 1681

)o

)a

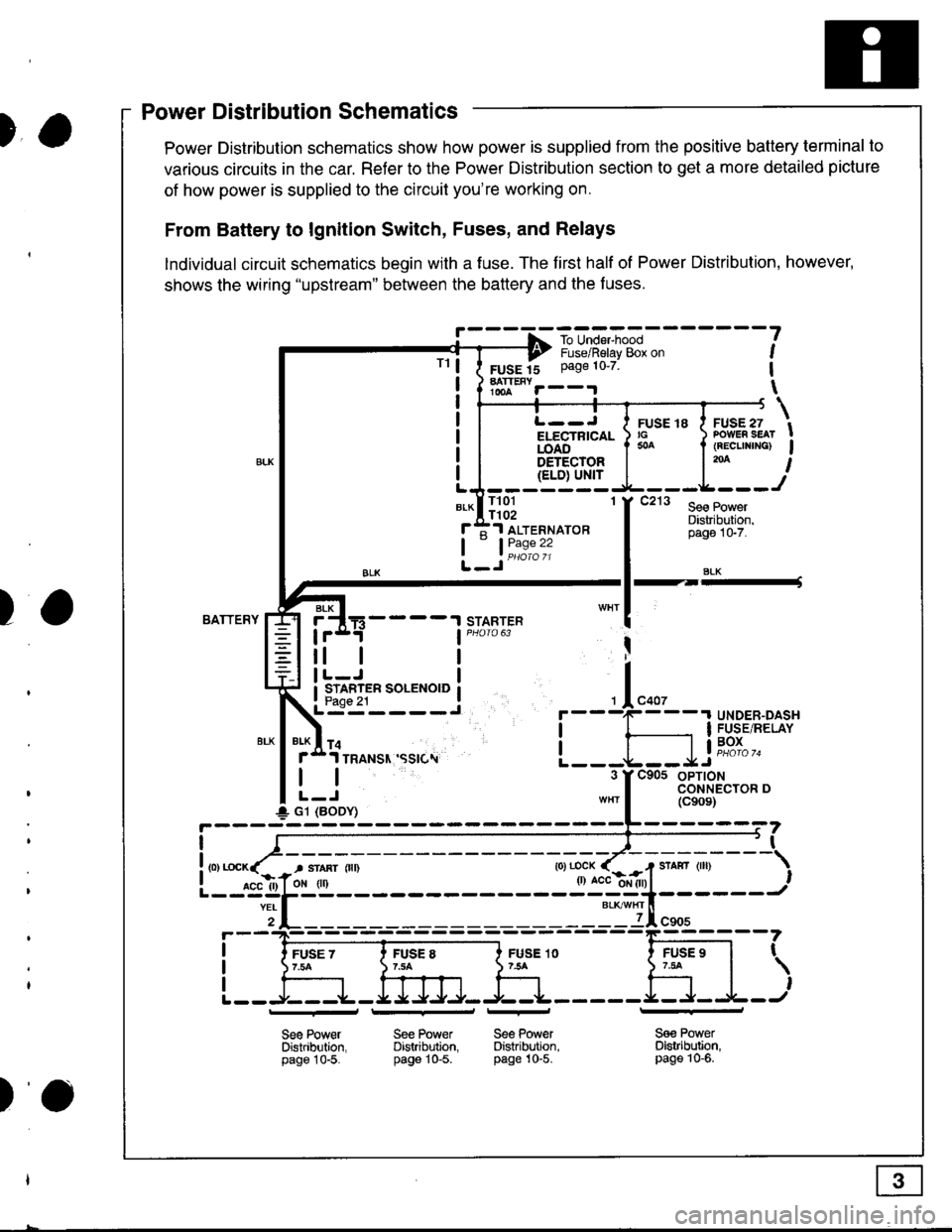

)wer IJrstnDullon Scnemallcs -

Power Distribution schematics show how power is supplied from the positive battery terminal to

various circuits in the car. Refer to the Power Distribution section to get a more detailed picture

of how power is supplied to the circuit you're working on.

From Battery to lgnition Switch, Fuses, and Relays

lndividual circuit schematics begin with a fuse. The first half of Power Distribution, however,

shows the wiring "upstream" between the battery and the f uses.

!' - - - -f -ro-unE,-"*l - - - - - - -

?---? i,"-")il"i"v-g& o" ,

FUSE 15 Page 10'7 1

hTt""r--.r \

TrL--J I ruse re I ruse zi/ ru:rE ro a .v-E., tELECTRTCAL ) rc ) PowER sEAr !iOA6".'-'- I * I (REcuNrNG) Igs-r-qqrg! | l'* I{ELD) Ul'{rLJ-------

*-lll3l 'f t"' l*.r:::f ;1 ALTERNAToR

tL_Jii1:"":

Distribuiion,pago 1G7.

SLK

BATTERYSTARTERBLK

4----t

tl

STARTER SOLENOID

I

I

+ G1 (BODY)

r

I

I

I

FUSE 1O754

Sge PowerDistribltion,page 10-5.

FUSE 97.tat

,

l---r+J

See Power Se€ PowerDistribution. Distribution.page 10-5. pag€ 10-5.

_l_

Sa€ PowerDistribution,page 10-6.

Power Distribution Schematics

tt

)o

Page 1394 of 1681

'l'

Five-Step Troubleshooting

1. Verify The Complaint

Turn on all the components in the problem

circuit to check the accuracy of the customer

complaint. Note the symptoms. Do not begin

disassembly or testing until you have

narrowed down the Problem area.

2. Analyze The Schematic

Look up the schematlc for the problem

circuit. Determine how the circuit is

supposed to work by tracing the current

paths from the power source through the

circuit components to ground. Also, trace

circuits that share wiring with the problem

circuit. The names of circuits that share the

same fuse, ground, or switch, and so on' are

referred to in each circuit schematic. Try to

operate any shared circuits you didn't check

in steo 1. lf the shared circuits work, the

shared wiring is OK, and the cause must be

in the wiring used only by the problem

circuit. lf several circuits fail at the same

time, the fuse or ground is a likely cause.

Based on the symptoms and Your

understanding of the circuit's operation,

identify one or more possible causes.

3. lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis

you made in step 2. Keep in mind that a

logical, simple procedure is the key to

eff icient troubleshooting. Test for the most

likely cause of failure f irst. Try to make tests

at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified,

make the repair. Be sure to use proper tools

and safe procedures.

5. Make Sure The Circuit Works

Turn on all components in the repaired

circuit in all modes to make sure you've

fixed the entife problem. lf the problem was

a blown f use, be sure to test all of the

circuits on that {use. Make sure no new

problems turn up and the original problem

does not recur.

Test Equipment

CAUTION:

Most circuits include solid-state devices.

Test the voltages in these circuits only with

a 1o-megaohm or higher impedance digital

multimeter. Never use a test light or analog

meter on citcuits that contain solid-state

devices. Damage to the devices may result.

Test Light and DVOM

On circuits without solid-state devices, use a

test light to check for voltage. A test light is

made up of a 12 volt bulb with a pair of leads

attached. After grounding one lead, touch the

other lead to various points along the circuit

where voltage should be present. The bulb

will go on i{ there is voltage at the point being

tested. lf you need to know how much

voltage is present, use a digital

volVohmmeter (DVOM).

Selt-Powered Test Light and DVOM

Use a self-powered test light to check for

continuity. This tool is made up of a light bulb,

battery, and two leads. To test it, touch the

leads together: the light should go on.

Use a self-powered test light only on an

unoowered circuit. First, disconnect the

battery, or remove the fuse that feeds the

circuit you are working on. Select two points

in the circuit between which you want to

check continuity. Connect one lead ol the

self-powered test light to each point. lf there

is continuity, the test light's circuit will be

completed, and the light will go on.

lo

I

SELF.POWERED TEST LIGHT

Page 1395 of 1681

How To Use This Manual

Test Equipment

lf, in addition, you need to know exactly how

much resistance there is between two ooints.

use a digital volVohmmeter (DVOM).

In the "oHMS" range, the DVOM will show

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting the measurement.

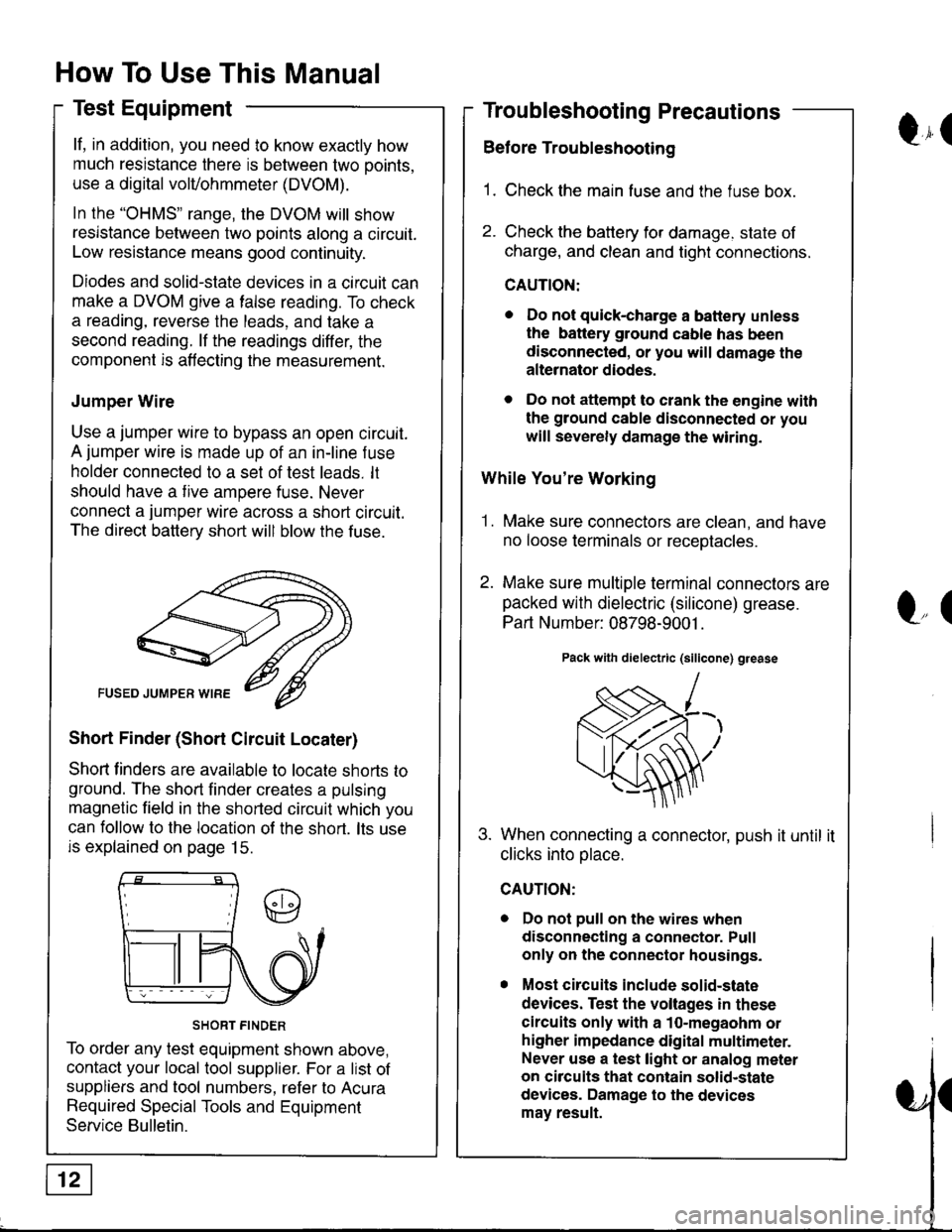

Jumper Wire

Use a jumper wire to bypass an open circuit.

A jumper wire is made up of an in-line f use

holder connected to a set of test leads. lt

should have a tive ampere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Shoft linders are available to locate shorts to

ground. The short finder creates a pulsing

magnetic field in the shorted circuit which you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To order any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Acura

Required Special Tools and Equipment

Service Bulletin.

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage. state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unless

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine with

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receotacles.

2. Make sure multiple terminal connectors are

packed with dielectric (silicone) grease.

Part Number: 08798-9001 .

Pack with dielectric (silicone) grease

When connecting a connector, push it until it

clicks into olace.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector housings.

Most circuits include solid-state

devices. Test the voltages in these

circuits only with a 1o-megaohm or

higher impedance digital multimeter.

Never use a test light or analog meter

on circuits that contain solid-state

devices. Damage to the devices

may result.

Qr(

l"(

Page 1396 of 1681

ra

Troubleshooting Tests

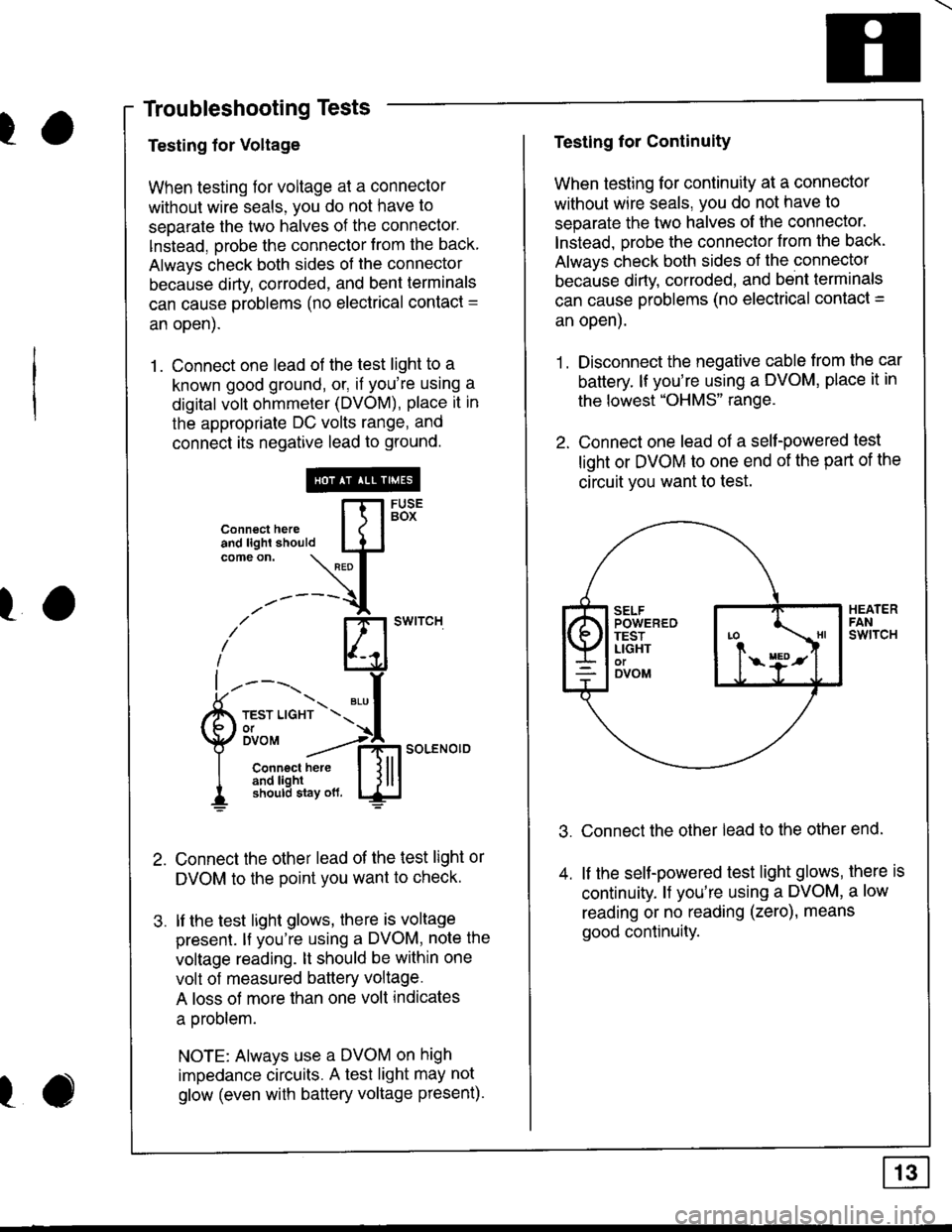

Testing for Voltage

When testing for voltage at a connector

without wire seals, you do not have to

seoarate the two halves of the connector.

lnstead. orobe the connector from the back

Always check both sides of the connector

because dirty, corroded, and bent terminals

can cause problems (no electrical contact =

an open).

1. Connect one lead of the test light to a

known good ground, or, if you're using a

digital volt ohmmeter (DVOM), place it in

the appropriate DC volts range, and

connect its negative lead to ground.

Connect the other lead of the test light or

DVOM to the point you want to checK.

lf the test light glows, there is voltage

presenl. lf you're using a DVOM, note the

voltage reading. lt should be within one

volt of measured battery voltage.

A loss of more than one volt indicates

a oroblem.

NOTE: Always use a DVOM on high

impedance circuits. A test light may not

glow (even with battery voltage present).

connecthe,e [fl5Bi'

:lL:'#*-'\L{.t

-'-----{

i' El'*''""

L----'t.r- ".,f

Qli'""'"":*soLENo,DI Connect here I l lll

I 3f,3JiEx\",* ljlu

ro

I

Testing for Continuity

When testing for continuity at a connector

without wire seals, you do not have to

separate the two halves of lhe connector'

lnstead. orobe the connector from the back.

Always check both sides of the connectol

because dirty. corroded. and bent terminals

can cause problems (no electrical contact =

an open).

1. Disconnect the negative cable from the car

battery. lf you're using a DVOM, place it in

the lowest "OHMS" range.

2. Connect one lead of a self-powered test

light or DVOM to one end of the part of the

circuit vou want to test.

Connect the other lead to the other end.

lf the seltpowered test light glows, there is

continuity. l{ you're using a DVOM, a low

reading or no reading (zero), means

good continuity.

Page 1397 of 1681

How To Use This Manual

Troubleshooting Tests

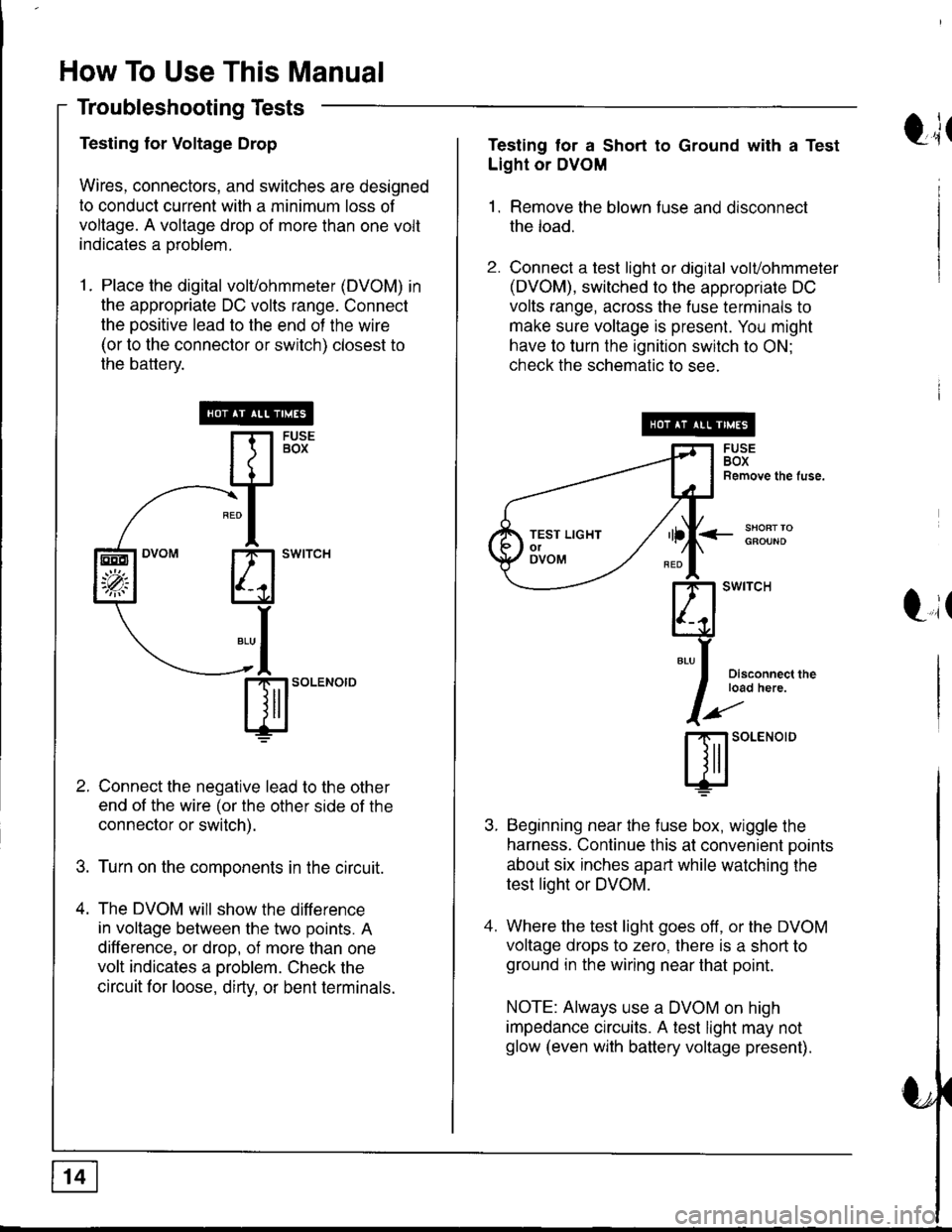

Testing for Voltage Drop

Wires, connectors, and switches are designed

to conduct current with a minimum loss of

voltage. A voltage drop of more than one volt

indicates a oroblem.

1. Place the digital volvohmmeter (DVOM) in

the appropriate DC volts range. Connect

the positive lead to the end of the wire

(or to the connector or switch) closest to

the battery.

Connect the negative lead to the other

end of the wire (or the other side of the

connector or switch).

Turn on the components in the circuit.

The DVOM will show the difference

in voltage between the two points. A

difference, or drop, of more than one

volt indicates a oroblem. Check the

circuit for loose, dirty, or bent terminals.

sl'o""o'o

EEO

'p;

t;tTesting tor a Short to Ground with a Test

Light or DVOM

1. Remove the blown fuse and disconnect

the load.

2. Connect a test light or digital volvohmmeter

(DVOM), switched to the appropriate DC

volts range, across the fuse terminals to

make sure voltage is present. You might

have to turn the ignition switch to ON;

check the schematic to see.

<_SHOFTTOGFOUND

t,it

I

Disconnect theload here.

SOLENOID

Beginning near the f use box, wiggle the

harness. Continue this at convenient ooints

about six inches apart while watching the

test light or DVOM.

Where the test light goes off, or the DVOM

voltage drops to zero, there is a short to

ground in the wiring near that point.

NOTE: Always use a DVOM on high

impedance crrcuits. A test light may not

glow (even with battery voltage present).

TEST LIGHTolOVOM

Page 1398 of 1681

I

I

I

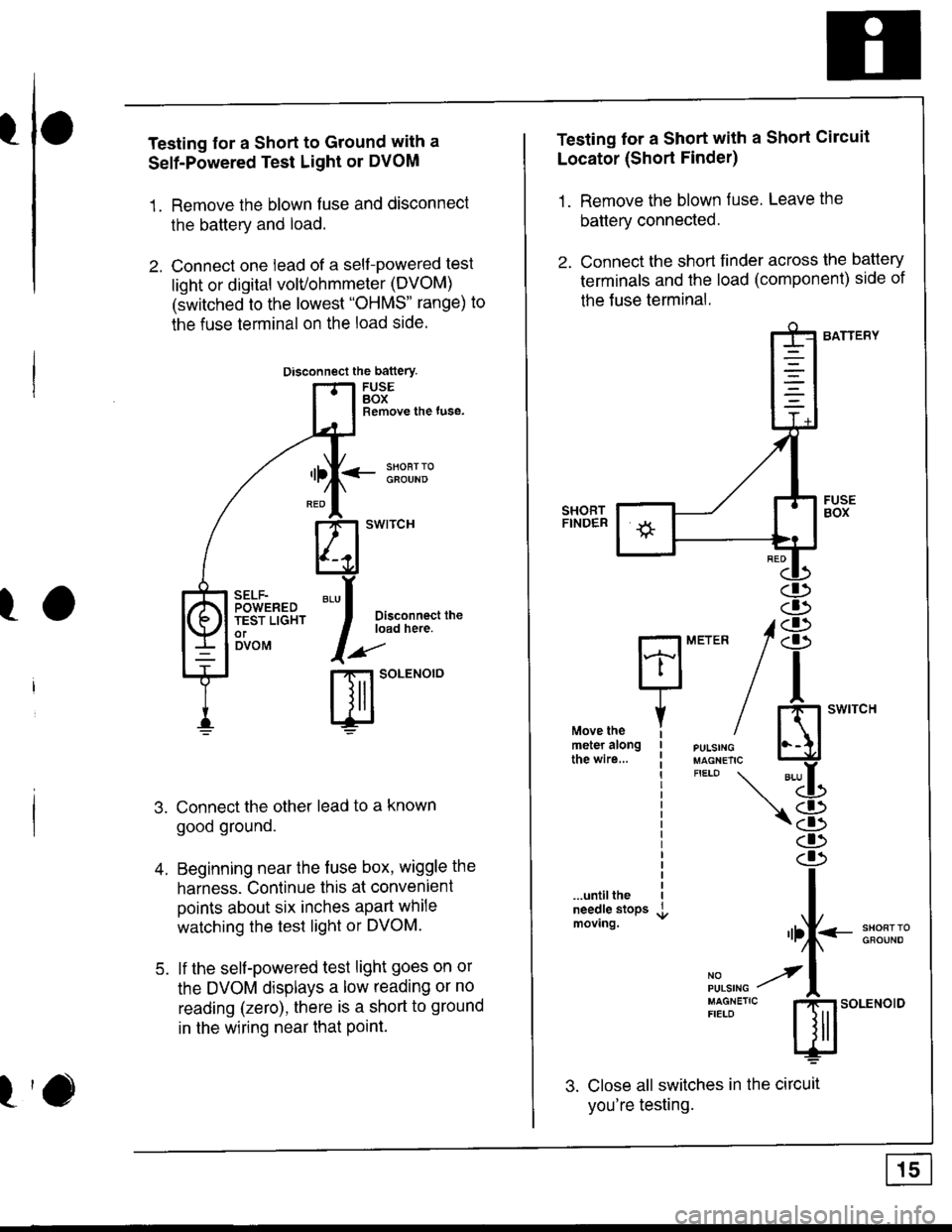

Testing for a Short to Ground with a

Self-Powered Test Light or DVOM

1. Remove the blown fuse and disconnect

the battery and load.

2. Connect one lead of a self-powered test

light or digital volvohmmeter (DVOM)

(switched to the lowest "OHMS' range) to

the fuse terminal on the load side.

Disconnect the battery

FUSEBOXRemove the tuse,

<- li9T:oGFOUND

Disconnect theload here.

.aa'

t-t SoLENOTO

Connect the other lead to a known

good ground.

Beginning near the fuse box, wiggle the

harness. Continue this at convenient

points about six inches apart while

watching the test light or DVOM.

lf the self-powered test light goes on or

the DVOM displays a low reading or no

reading (zero), there is a short to ground

in the wiring near that Point.

SELF-POWEREDTEST LIGHTorDVOM

A

5.

Testing lor a Short with a Short Circuit

Locator (Short Finder)

1. Remove the blown fuse. Leave the

battery connected.

2. Connect the short finder across the battery

terminals and the load (component) side of

the Juse terminal.

BATTERY

SHORTFINDER

...untiltheneedle stopsmoving.

3. Close all switches in the circuit

you're testing.

n

iH"#/ El'*"""'*"

"'-LL

\8

I

"rf--:*ll;"

il,",r. y'l

:[:J"'"

s;.o"*o'o

Page 1403 of 1681

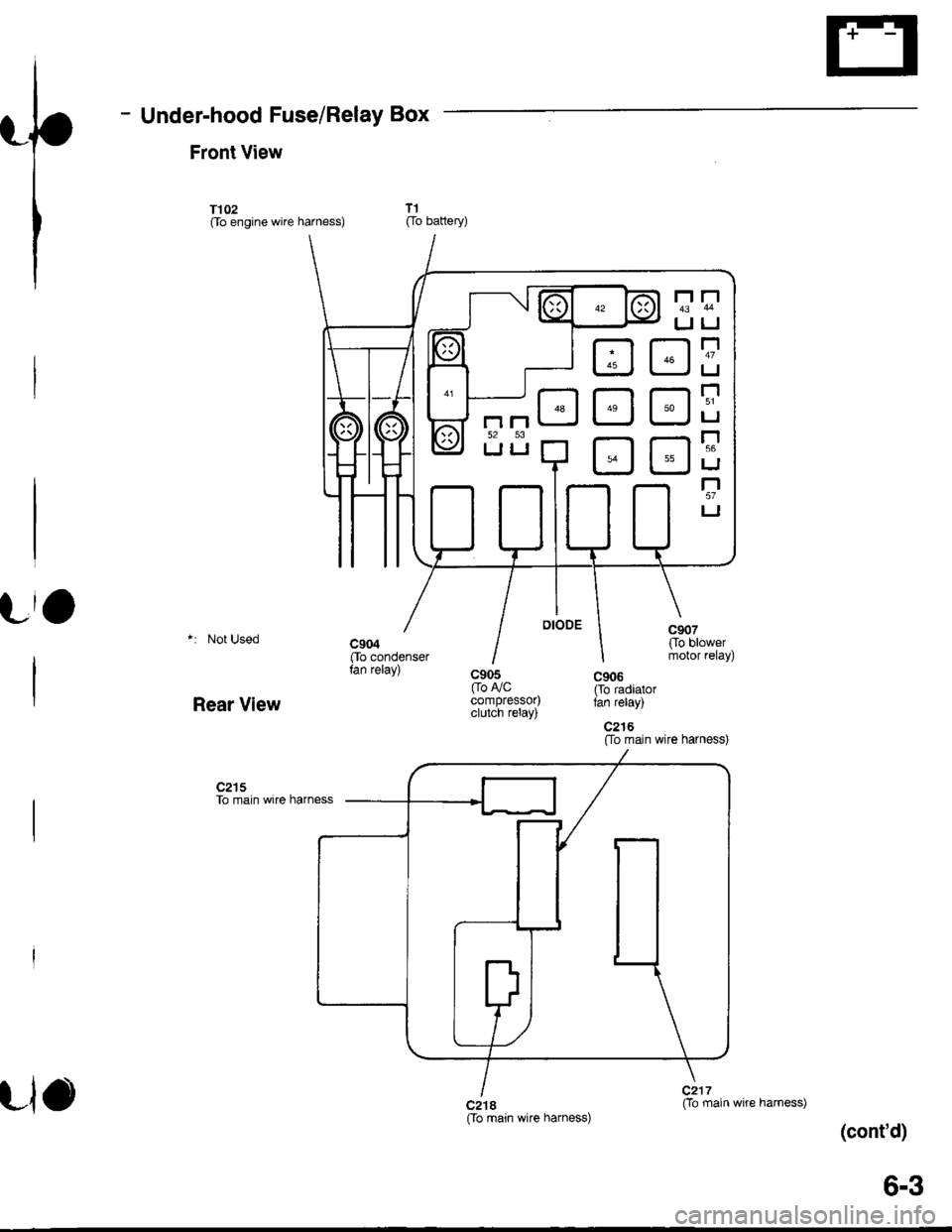

- Under-hood Fuse/Relay Box

Front View

T102Oo engine wire harness)

*: Not Used

Rear View

c2l5To main wire harness

T1[ro battery)

c905[ro F/Ccompressor)clutch relay)

c2t8[fo main wire harness)Oo main

(cont'd)

D3

tr

tr

[J

r'1

IJ

r-t

IJ

r'151

LI

r-156

IJ

r"l57

LI

Llowire harness)

6-3

Page 1404 of 1681

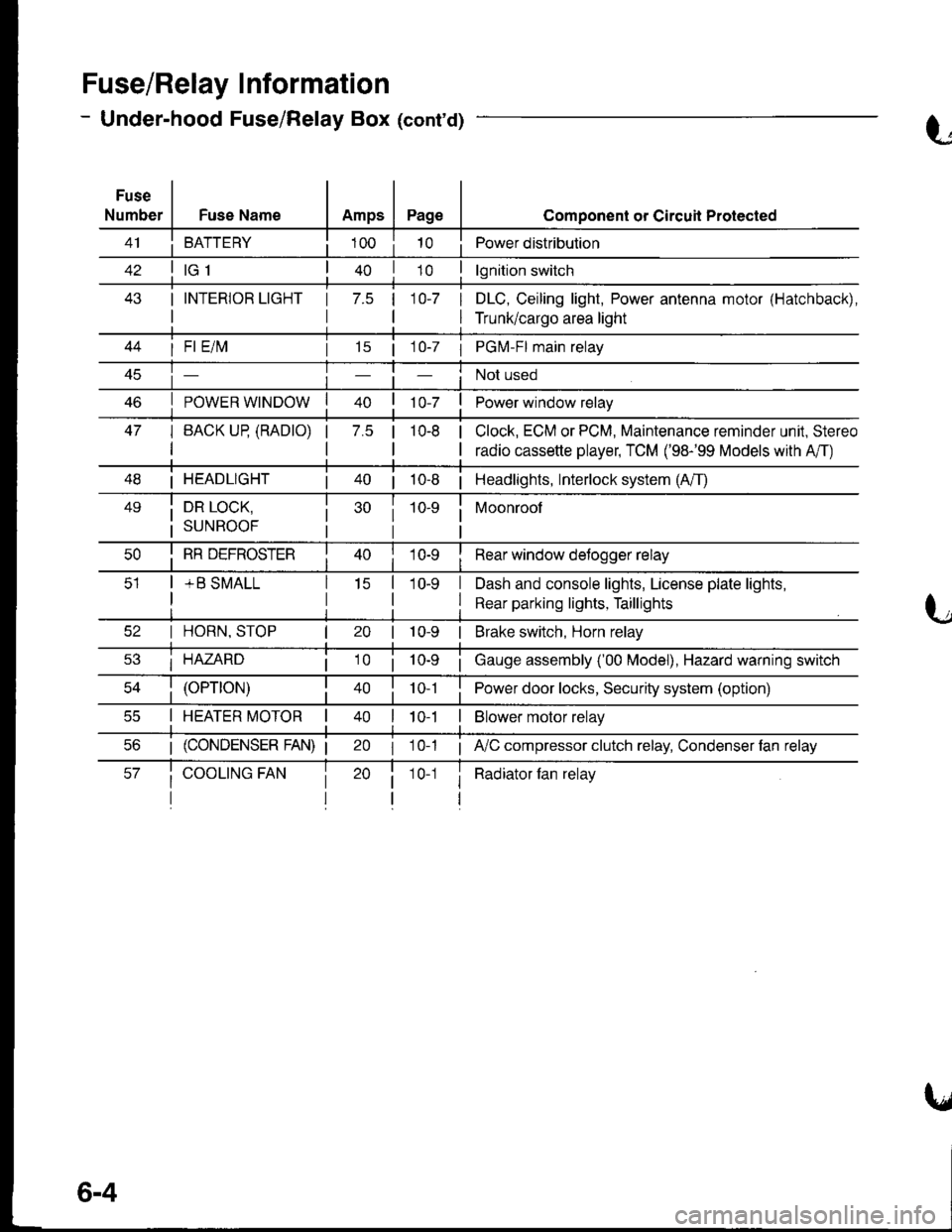

Fuse/Relay I nformation

- Under-hood Fuse/Relay Box (cont'd)

Fuse

NumberFuse NameAmpsPage

BATTERY

I INTERIOR LIGHT

I

1 7.5 110-7 I

I

Component or Circuil Protected

Power distribution

lgnition switch

DLC, Ceiling light, Power antenna motor (Hatchback),

Trunk/cargo area light

47

I Fl E/lvl

POWER WINDOW

I BACK UP (RADTO)

I

15 | 1 0-7 I PGM-FI main relay

Not used

Power window relay

Clock, ECM or PCM, Maintenance reminder unit, Stereo

radio cassette player, TCM ('98-'99 Models with A'/T)

7.5 |10-8

I HEADLIGHT| 40 | 10-8 | Headlights, Interlock system (A/T)

49i DR LOCK,

i suNRooF

10-9 i Moonroof

I

I RR DEFROSTER

+ B SMALL

I Rear window detogger relay

I Dash and console lights, License plate lights,

I Rear parking lights, Taillights

I HORN, STOP

i HAZARD

10-9 | Brake switch, Horn relay

i Gauge assembly ('00 Model), Hazard warning switch

40 | to t I Power door locks, Security system (option)

I HEATER MOTOR II t 0-1I Blower motor relay

20 I 10-1 ; A,/C compressor clutch relay, Condenser fan relay

i Radiator fan relay1 0-1

6-4

Page 1405 of 1681

rio

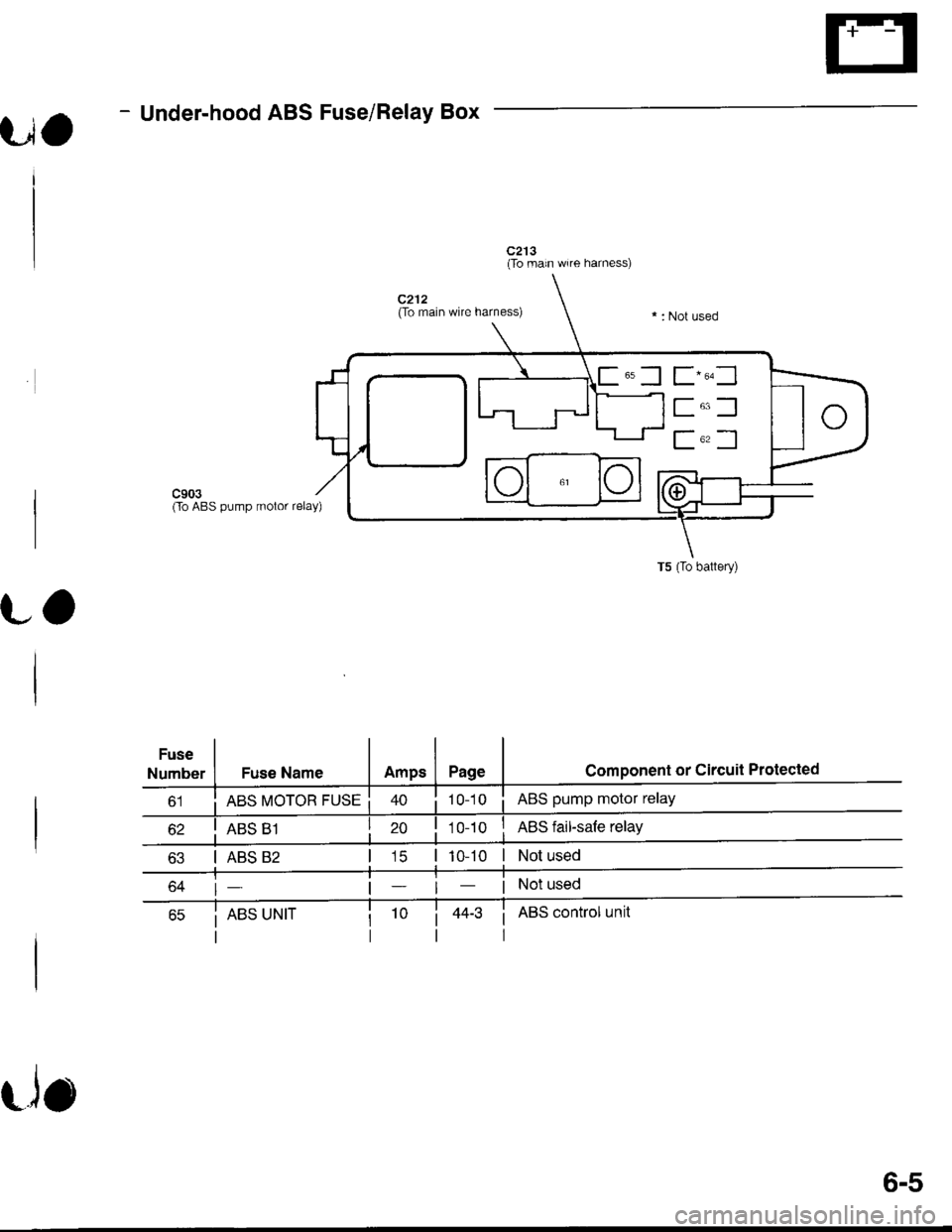

- Under-hood ABS Fuse/Relay Box

c213(To main wire harness)

Fuse

Number

c903Oo ABS pump rnotor relay)

Fuse Name

ABS MOTOR FUSE

ABS 82

ABS UNIT

Component or Circuit Protected

ABS pump motor relay

ABS fail-safe relay

| 10-10 | Not used

I Not used

i ABS control unit

*Il f.*l

f*-l

f*-l

CI .' IC

T5 (To battery)

rJO

6-5

Page 1406 of 1681

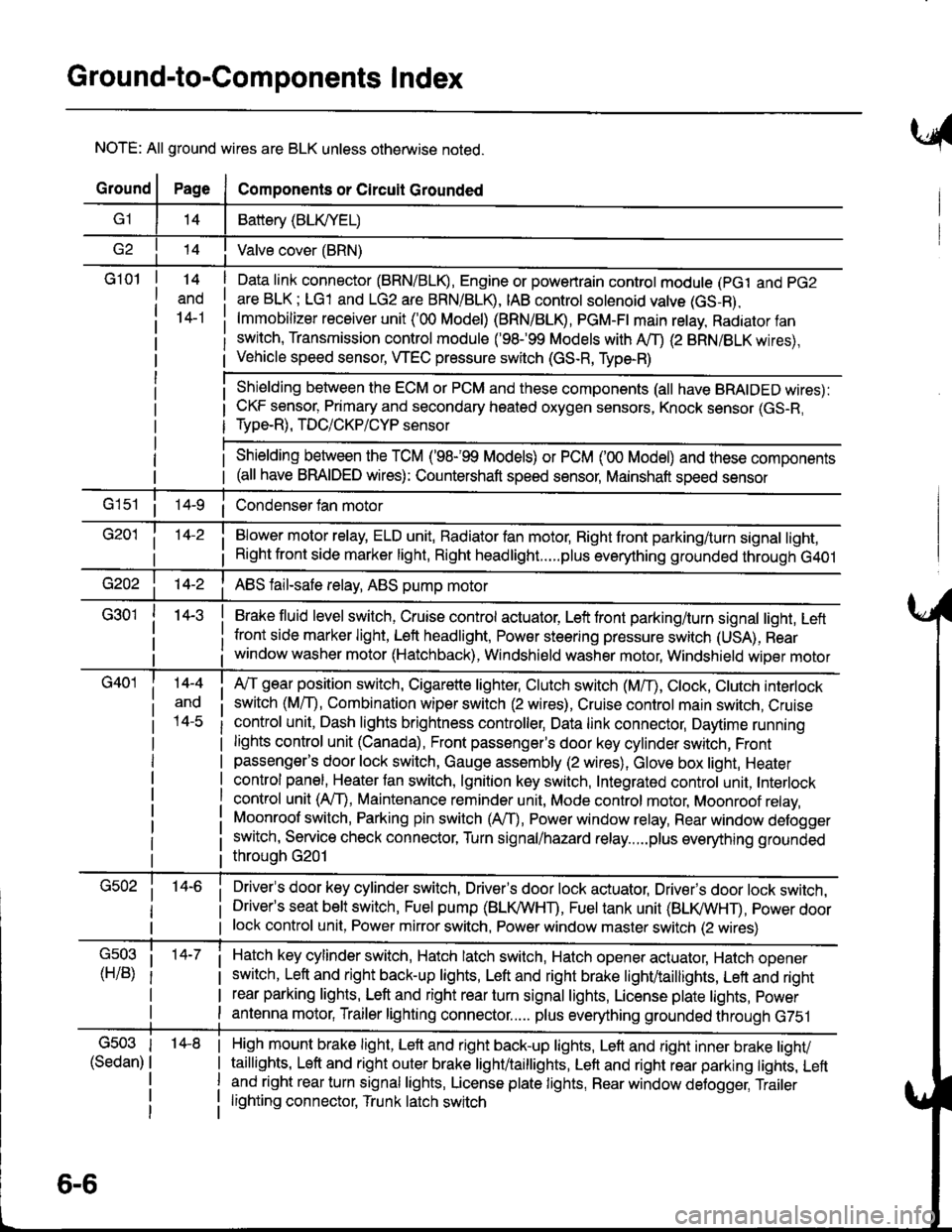

Ground-to-Components I ndex

NOTE: All ground wires are BLK unless otherwise noted.

GroundPageComponents or Circuit Grounded

Battery (BLIVYEL)

--t'I Valve cover (BRN)

G101t.+

and

14-1

Daia link connector (BRN/BLK), Engine or powertrain controt module (pct and pG2

are BLK; LG1 and LG2 are BRN/BLR, IAB controt solenoid valve (GS-B),

lmmobilizer receiver unit ('00 Model) (BRN/BLR, PGM-Ft main retay, Radiator fan

switch, Transmission control module ('98.�99 Models with MD (2 BRN/BLK wires),

Vehicle speed sensor, WEC pressure switch (GS-R, Type-R)

Shielding between the ECM or PCM and these components (all have BRAIDED wires):

CKF sensor, Primary and secondary heated oxygen sensors, Knock sensor (GS-R,

Type-R), TDC/CKP/CYP sensor

Shielding between the TCM ('98-'99 Models) or PCM ('00 Model) and these components(all have BRAIDED wires): Countershaft speed sensor, Mainshaft speed sensor

G1s1 ii Condenser fan motor

Brake fluid level switch, Cruise control actuator, Left front parking/turn signal light, Left

front side marker light, Left headlight, Power steering pressure switch (USA), Rear

window washer motor (Hatchback), Windshield washer motor, Windshield wiper motor

14-3

Blower motor relay, ELD unit, Badiator fan motor, Right front parking/turn signal light,

Right front side marker light, Right headlight.....plus everything grounded through G401

ABS fail-safe relay, ABS pump motor

G40114-4

ano

l4-c

A,/T gear position switch, Cigarette lighter, Clutch switch (M,/T), Ctock, Ctutch interlock

switch (MfD, Combination wiper switch (2 wires), Cruise control main switch, Cruise

control unit, Dash lights brightness controller, Data link connector, Daytime running

lights control unit (Canada), Front passenger's door key cylinder switch, Frontpassenger's door lock switch, Gauge assembly (2 wires), Glove box light, Heater

control panel, Heater tan switch, lgnition key switch, Integrated control unit, Interlock

control unit (AfI), Maintenance reminder unit, Mode control motor, Moonroof relay,

Moonroof switch, Parking pin switch (AfD, Power window relay, Rear window defogger

switch, Service check connector, Turn signal/hazard relay.....plus everything grounded

throuoh G201

Driver's door key cylinder switch, Driver's door lock actuator, Drivels door lock switch,Driver's seat belt switch, Fuel pump (BLI(/WHT), Fuel tank unit (BLI(/WHT), power doorlock control unit, Power mirror switch, Power window master switch (2 wires)

Hatch key cylinder switch, Hatch latch switch, Hatch opener actuator, Hatch ooener

switch, Left and right back-up lights, Left and right brake light/taillights, Lett and right

rear parking lights, Left and right rear turn signal lights, License plate lights, power

antenna motor, Trailer lighting connector..... plus everything grounded through G751

6-6

'14-8G503

(Sedan)

High mount brake light, Left and right back-up lights, Lett and right inner brake tighv

taillights, Left and right outer brake light/taittights, Left and right rear parking tights, Leftand right rear turn signal lights, License plate lights, Rear window detogger, Trailer

lighting connector, Trunk latch switch