check engine HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 163 of 1681

I

7.

8.

9.

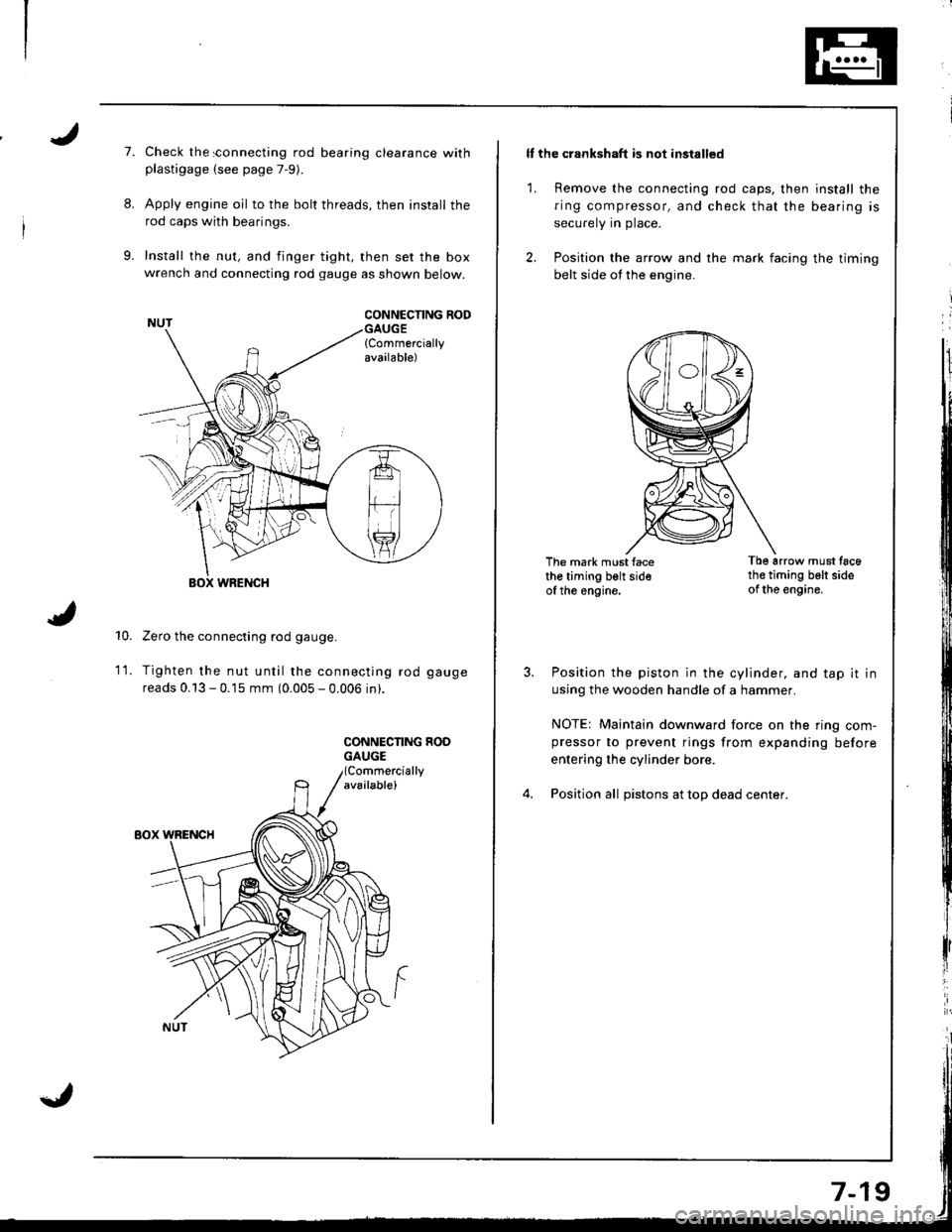

Check the sonnecting rod bearing clearance withplastigage (see page 7-9).

Apply engine oil to the bolt threads, then install the

rod caps with bearings.

Install the nut, and finger tight, then set the boxwrench and connecting rod gauge as shown below.

CONNCCNNG RODGAUGE{Commerciallyavailable)

10.

WRENCH

Zero the connecting rod gauge.

Tighten the nut until the connecting rod gauge

reads 0.13 - 0.15 mm (0.005 - 0.006 in).

CONNECNNG HOOGAUGE

1t.

ll the crankshaft is not installed

1. Remove the connecting rod caps, then install the

ring compressor, and check that the bearing is

securely in place.

2. Position the arrow and the mark facing the timing

belt side ot the engine.

The mark must facethe timing belt sideof the engine.

Tb6 arrow must tac6th€ timing belt sideof the engine.

Position the piston in the cylinder, and tap it in

using the wooden handle of a hammer.

NOTE: Maintain downward force on the ring com-pressor to prevent rings from expanding before

entering the cylinder bore.

Position all pistons at top dead center.

Page 164 of 1681

Piston Rings

Replacement

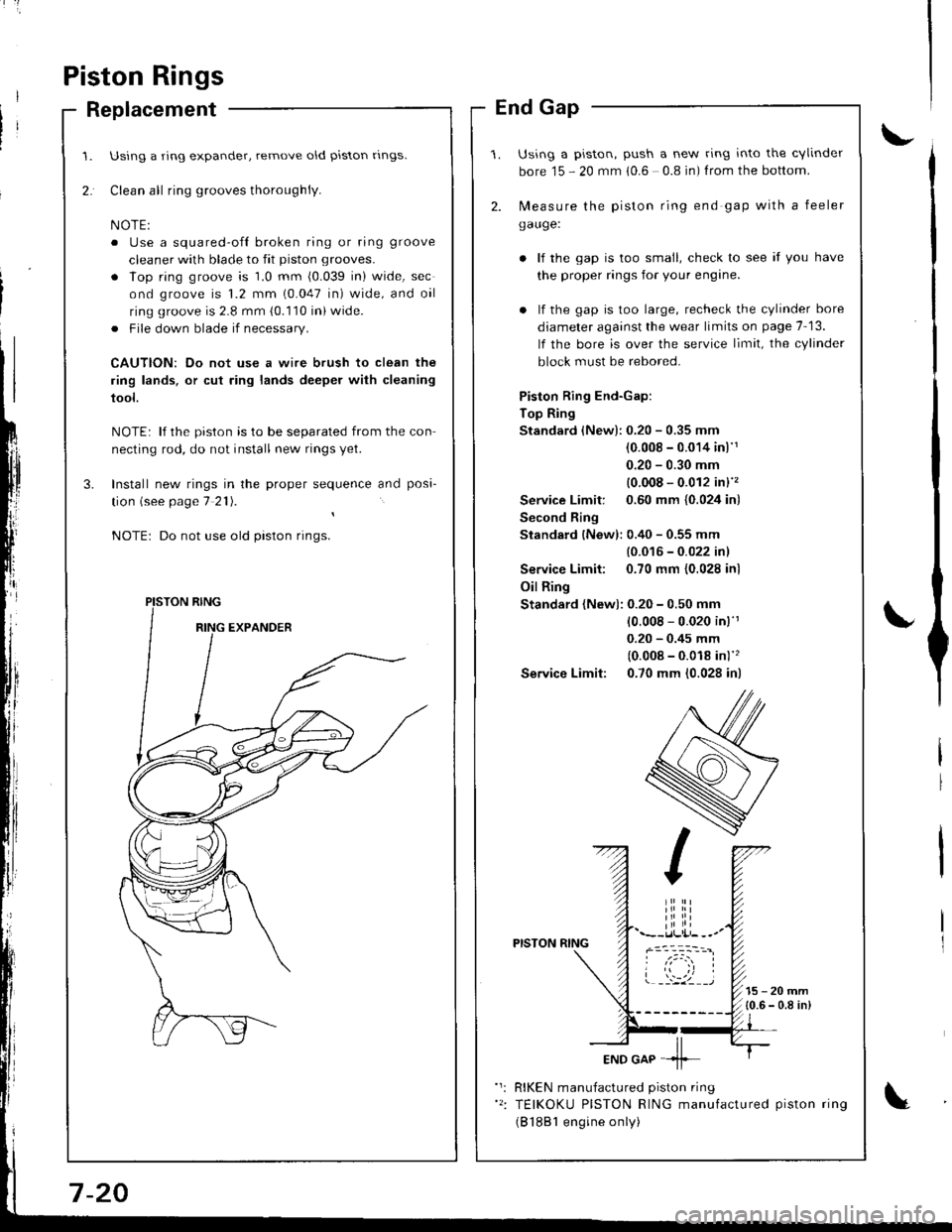

Using a ring expander, remove old piston rlngs.

Clean all ring grooves thoroughly.

o Use a squared-ofl broken ring or ring groove

cleaner with blade to fit piston grooves.

. lop ring groove is 1.0 mm (0.039 in) wide, sec

ond groove is 1.2 mm (0.047 in) wide, and oil

ring groove is 2.8 mm (0.110 in) wide.

. File down blade if necessary.

CAUTION: Do not use a wire brush to clean the

ring lands, or cut ring lands deeper with cleaning

tool.

NOTE: lf the piston is to be separated from the con

necting rod, do not install new rings yet.

Install new rings in the proper sequence and posa-

tion (see page 7 21).

Do not use old piston rings.

PISTON RING

End Gap

Using a piston, push a new ring into the cvlinder

bore 15 - 20 mm 10.6 0.8 in) f rom the bottom.

2. N,4easure the piston ring end gap with a feeler

gauge:

lf the gap is too small, check to see if you have

the proper rings for your engine.

. lf the gap is too large, recheck the cylinder bore

diameter against the wear limits on page 7-13.

lf the bore is over the service limit, the cylinder

block must be rebored.

Piston Ring End-Gap:

Top Ring

Standard (New):0.20 - 0.35 mm

(0.008 - 0.014 inl'1

0.20 - 0.30 mm

{0.008 - 0.012 in}''�

Service Limit: 0.60 mm {0.024 in)

Second Ring

Standard {New): 0.40 - 0.55 mm

{0.016 - 0.022 inl

Service Limit: 0.70 mm {0.028 inl

Oil Ring

Standard (New): 0.20 - 0.50 mm

10.008 - 0.020 in)'r

0.20 - 0.45 mm

(0.008 - 0.018 in)''�

Service Limit: 0.70 mm (0.028 in)

PISTON RING

15-20mm{0.6 - 0.8 in)

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured piston ring

(B 1881 engine only)

Page 168 of 1681

Inspection (cont'dl

3.

4.

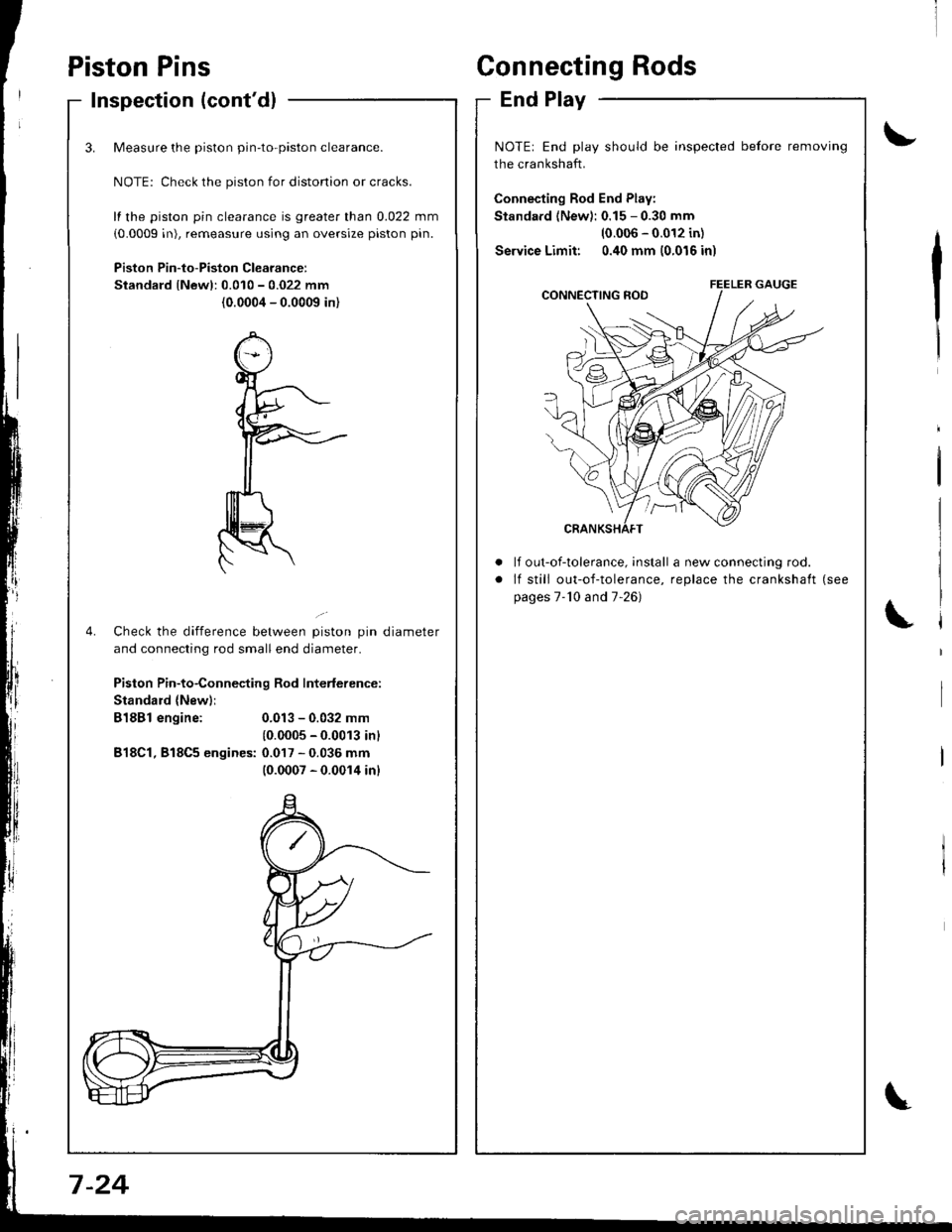

Measure the piston pin-to-piston clearance.

NOTE: Check the piston for distonion or cracks.

fl the piston pin clearance is greater than 0.022 mm

(0.0009 in), remeasure using an oversize piston pin.

Piston Pin-to-Piston Clearancer

Standard lNewl:0.010 - 0.022 mm

(0.0004 - 0.0009 in)

Check the difference between piston pin diameter

and connecting rod small end diameter.

Piston Pin-to-Connecting Rod Interlerence:

Standard {New)i

B18Bl engine:

B18Cl, 818C5 engines:

0.013 - 0.032 mm

10.0005 - 0.0013 inl

0.017 - 0.036 mm(0.0007 - 0.0014 inl

Piston PinsConnecting Rods

End Play

\,

\

t'

NOTE: End play should be inspected before removing

the crankshaft.

Connecting Rod End Play:

Standard (New): 0.15 - 0.30 mm

10.006 - 0.012 in)

Service Limit: 0.40 mm (0.016 in)

a

a

It out-of-tolerance, install a new connecting rod.

lf still out-of-tolerance, replace the crankshaft (see

pages 7-'10 and 7-26)

7 -24

Page 170 of 1681

t'

Crankshaft

lnstallation

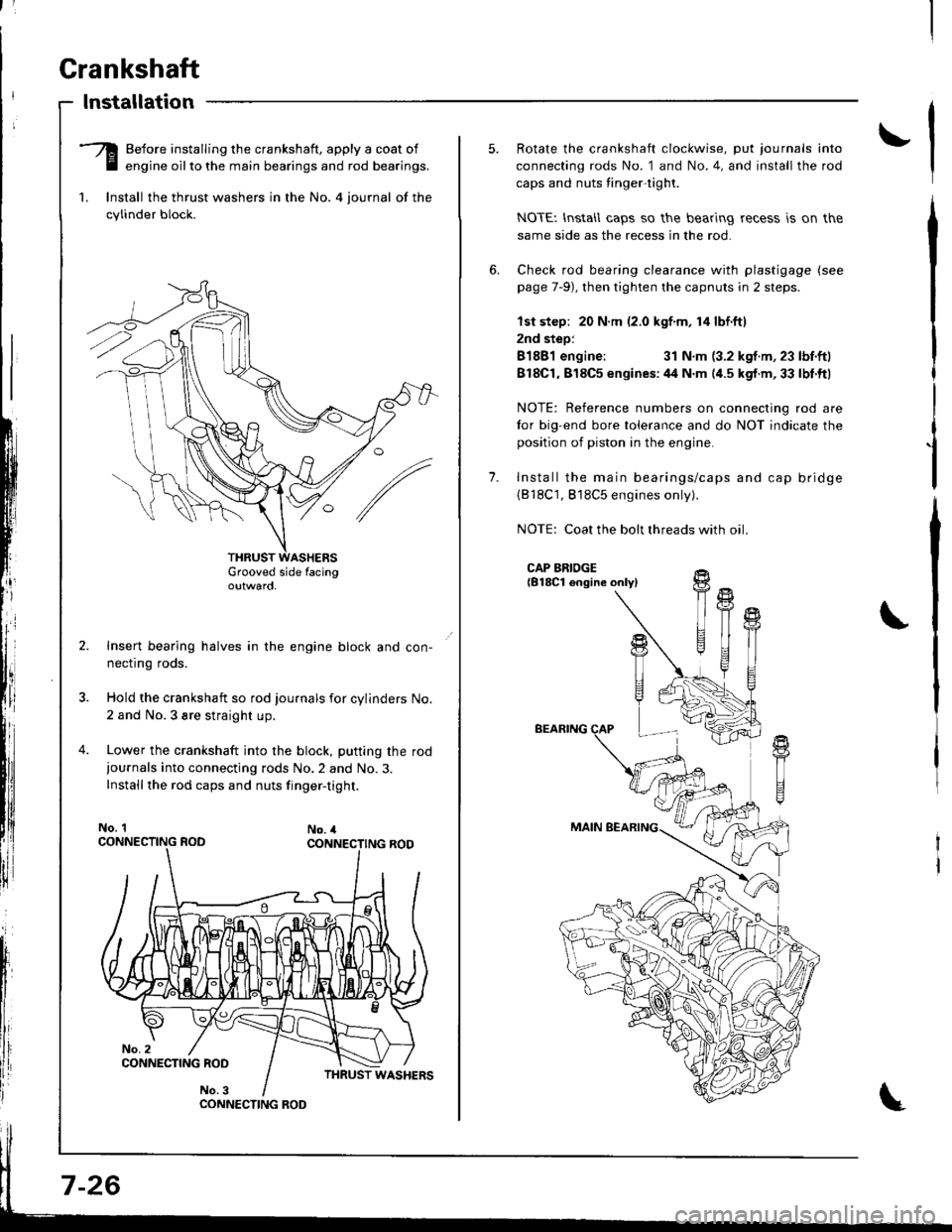

-Q Before installing the crankshaft, apply a coat of

E engine oilto the main bearings and rod bearings.

1. lnstall the thrust washers in the No. 4 iournal of the

cylinder block.

Grooved side facingoutwaro,

Insert bearing halves in the engine block and con-

necflng roos.

Hold the crankshaft so rod journals for cylinders No.

2 and No.3 sre straight up.

Lower the crankshaft into the block, putting the rod

iournals into connecting rods No.2 and No.3.

Installthe rod caps and nuts finger-tight.

No. 1No. 4

CONNECTING ROO

7-26

1.

Rotate the crankshaft clockwise, put journals into

connecting rods No. 1 and No.4, and install the rod

caps and nuts tinger-tight.

NOTEI lnstall caps so the bearing recess is on the

same side as the recess in the rod.

Check rod bearing clearance with plastigage (see

page 7-9), then tighten the capnuts in 2 steps.

lst step: 20 N.m (2.0 kgf m, 14 lbf.ftl

2nd step:

81881 engine:31 N.m (3.2 kgf.m, 23 lbf.ftl

818C1,818C5 enqines:44 N.m (4.5 kgf.m,33 lbt.ftl

NOTE: Reference numbers on connecting rod are

tor big-end bore tolerance and do NOT indicate the

position of piston in the engine.

Install the main bearings/caps and cap bridge(818C1, 818C5 engines only).

NOTE: Coat the bolt threads with oil

CAP BRIDGE{B18Cl engine onlyl

BEARING

MAIN BEARING

fi

U

t{

T

!+

T1

Page 171 of 1681

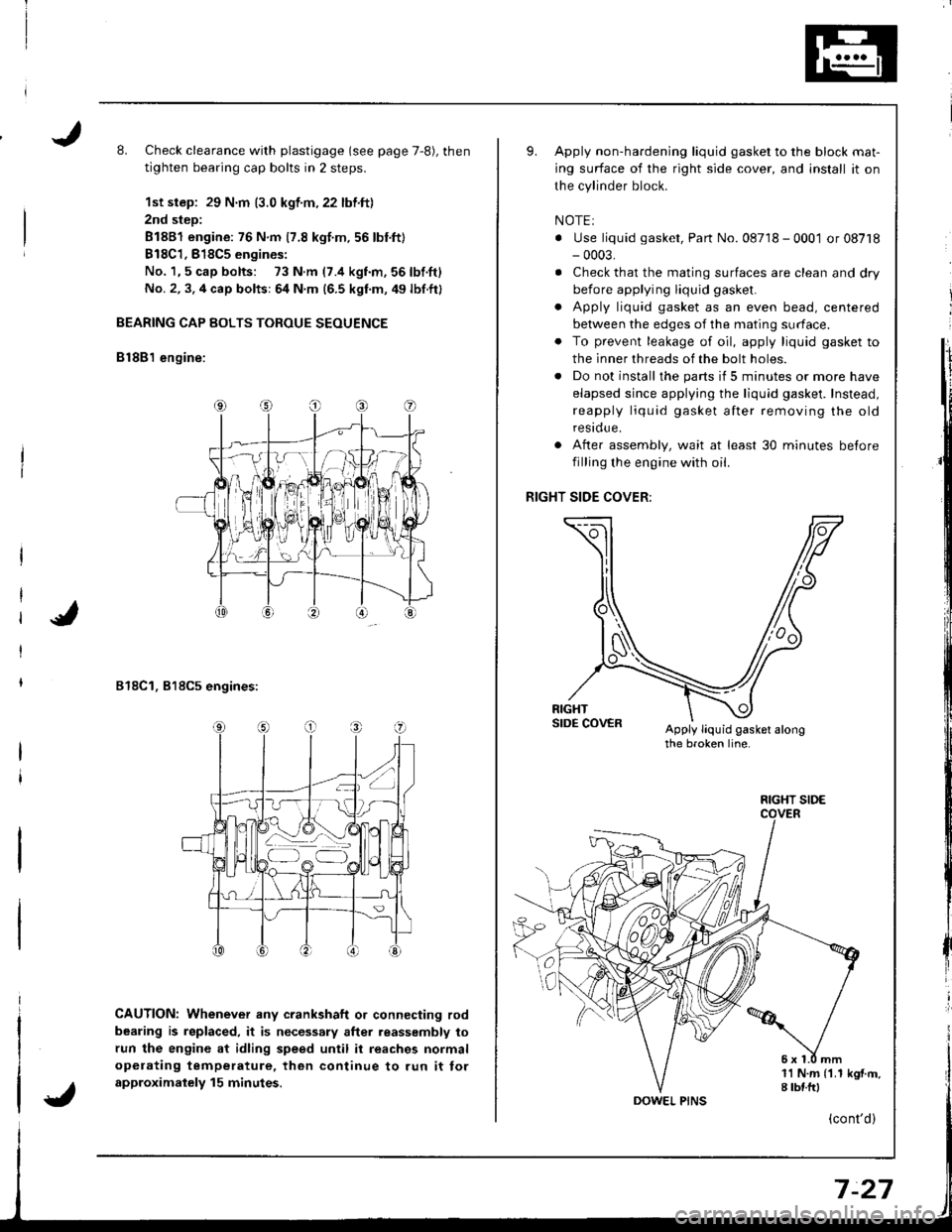

L Check clearance with plastigage (see page 7,8), then

tighten bearing cap bolts in 2 steps.

1st step: 29 N.m (3.0 kgf.m,22 lbf.ft)

2nd step:

81881 engine: 76 N.m 17.8 kgt.m.56 lbnft)

B18C1,818C5 engines:

No. 1,5 cap bolts: 73 N.m (7.4 kgnm,56lbf.ft)

No. 2, 3. 4 cap bolts: 64 N.m (6.5 kgf.m, 49 lbf.ft)

BEARING CAP BOLTS TOROUE SEOUENCE

B lSB'l engine:

818C1, 818C5 engines:

CAUTION: Whenever any crankshaft o. connecting rod

bearing is replaced, it is necessary after reassembly to

run the engine at idling speed until it reaches normal

opelating temperature, then continue to run it tor

approximalely 15 minutes.

Apply non-hardening liquid gasket to the block mat-

ing surface of the right side cover, and install it on

the cylinder block.

NOTEI

. Use liquid gasket, Part No. 08718 - 0001 or 08718- 0003,

. Check that the mating surfaces are clean and dry

before applying liquid gasket.

. Apply liquid gasket as an even bead, centered

between the edges of the mating surface.

. To prevent leakage of oil, apply liquid gasket to

the inner threads of the bolt holes.

. Do not install the parts if 5 minutes or more have

elapsed since applying the liquid gasket. Instead,

reapply liquid gasket after removing the old

residue.

After assembly, wait at least 30 minutes betore

filling the engine with oil.

RIGHT SIDE COVER:

Apply liquid gasket alongthe broken line.

o

a

1l N.m {1.1 kgf.m,I tbf.frl

FIGHT SIDE

(cont'd)

Page 173 of 1681

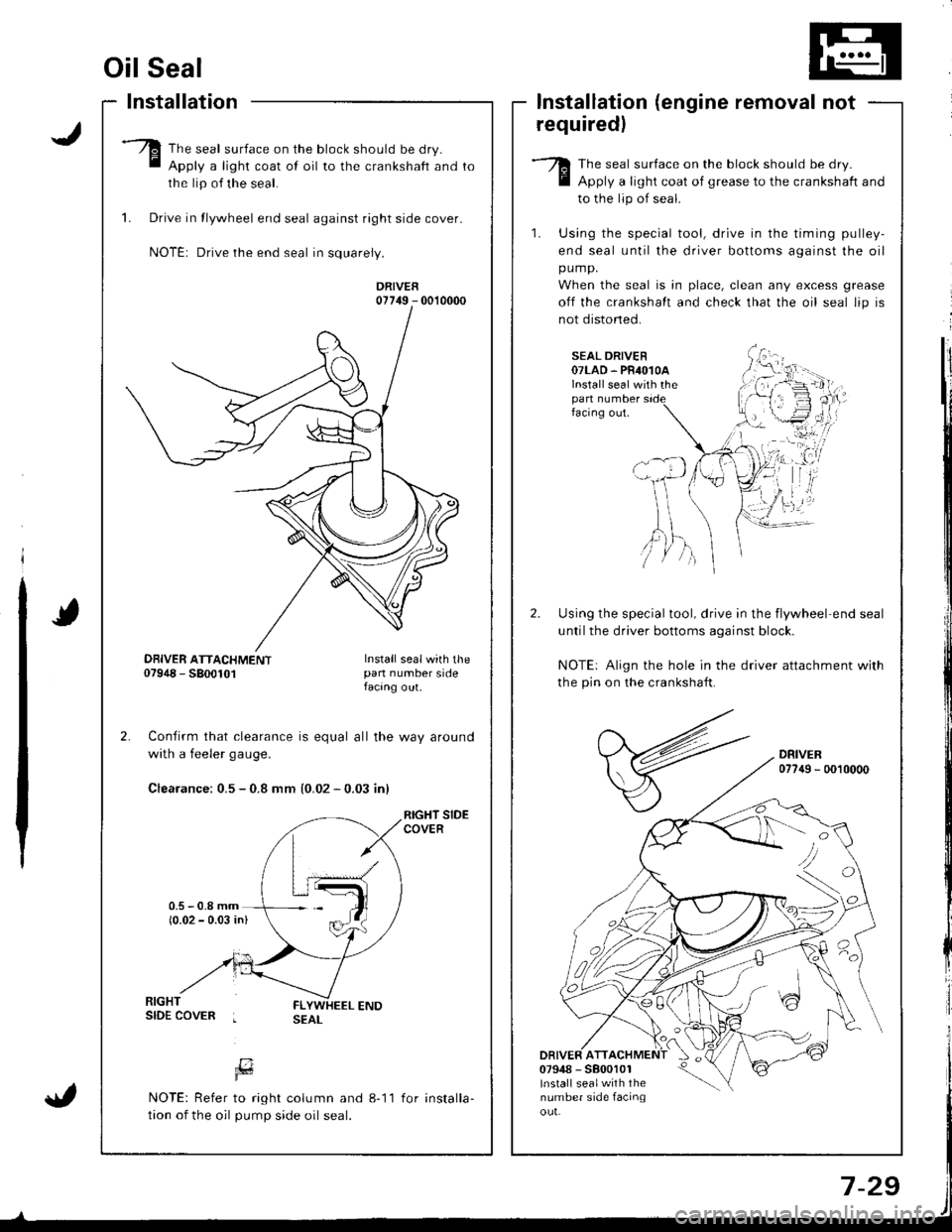

Oil Seal

Installation

The seal surface on the block should be dry.

Apply a light coat of oil to the crankshaft and

the lip of the seal.

1. Drive in tlywheel end seal against right side cover.

NOTE: Drive the end seal in squarely.

DRIVER07749 - 0010000

Confirm that clearance is equal all the way around

with a feeler gaug€.

Clearance: 0.5 - 0.8 mm {0.02 - 0.03 inl

RIGHT SIDECOVER

lnstallation (engine removal not

requiredl

The seal surface on the block should be dry.

Apply a light coat of grease to the crankshaft and

to the lip of seal.

1. Using the special tool, drive in the timing pulley-

end seal until the driver bottoms against the oil

pump.

When the seal is in place, clean any excess grease

off the crankshalt and check that the oil seal lip is

not distoned.

SEAL DRIVER07LAD. PR4O1OAlnstall seal with thepan numberfacing out.

Using the special tool, drive in the flywheel end seal

untilthe driver bottoms aqainst block.

NOTE: Align the hole in the driver attachment with

the pin on the crankshaft.

DRIVER077{9 - 0010000

DRIVER ATT07948 - 5800101lnstall sealwith thenumber side facinqou!.

'tvA,)/ )

DBIVER ATTACHMENT07948 - 5800101Install sealwith thepan number sidefacang out.

[7Fd

NOTE: Refer to right column and 8-11

tion of the oil pump side oil seal.

for installa-

Page 180 of 1681

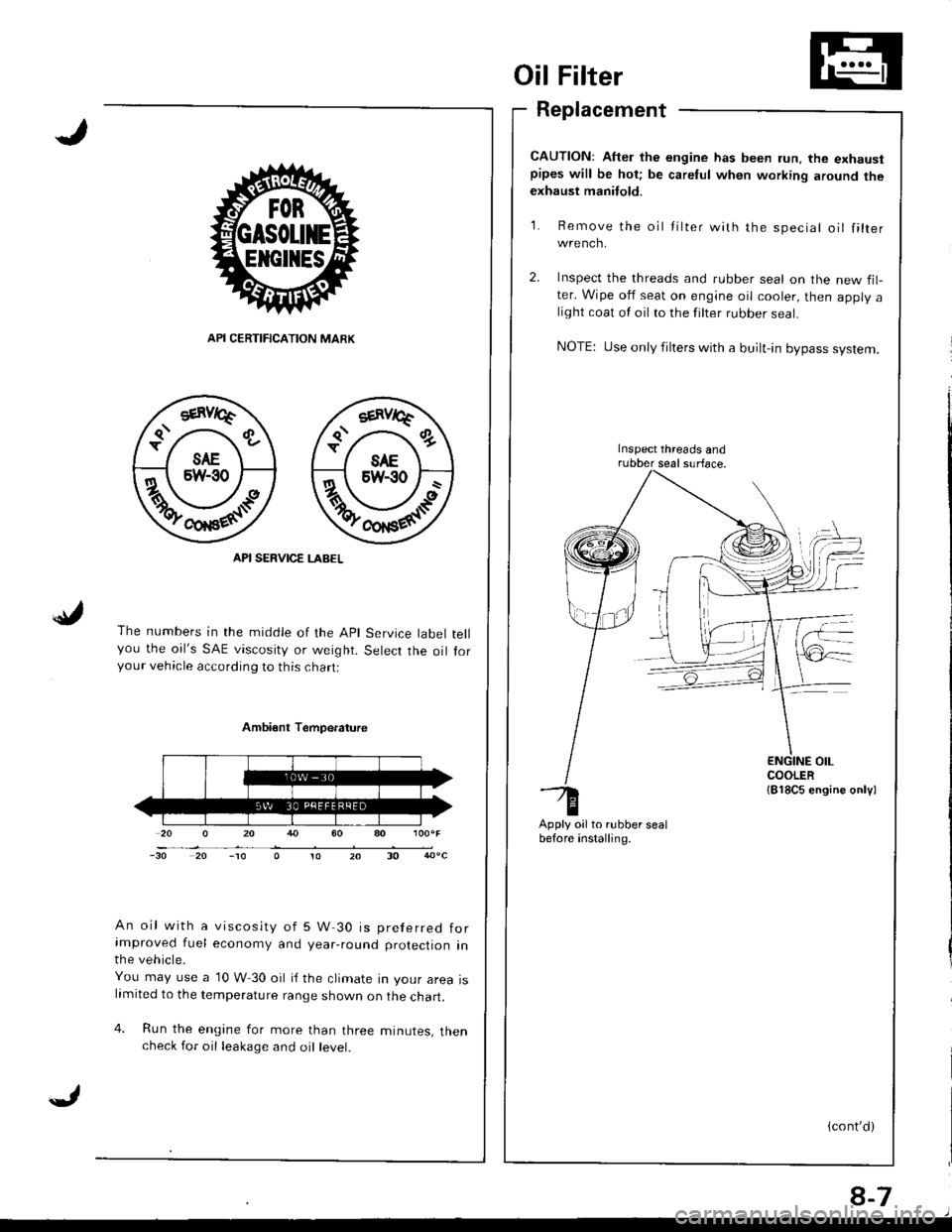

Oil Filter

Replacement

CAUTION: After the engine has been run, the exhaustpipes will be hot; be careful when working around theexhaust manitold.

Re m ove the

wrench.

Iilter with the speciallilter

API CERTIFICATION MARK

API SERVICE LABEL

The numbers in the middle of the Apl Service tabelyou the oil's SAE viscosity or weight. Selecr rhe oilyour vehicle according to this chart:

Inspect the threads and rubber seal on the new fil-ter. Wipe oif seat on engine oil cooler, then apply alight coat ol oil to the filter rubber seal.

NOTE: Use only filters with a built-in bypass system.

Inspect threads andrubber seal surface.

tell

for

Ambi€nt Temperature

An oil with a viscosity of 5 W 30 is preferred forimproved fuel economy and year-round protection inthe vehicle.

You may use a 10 W 30 oil if the climate in your area islimited to the temperature range shown on the chart.

4. Run the engine for more than three minutes, thencheck for oil leakage and oil level.

Apply oilto.ubber sealbefore installing.-to20-30

{cont'd)

8-7

Page 181 of 1681

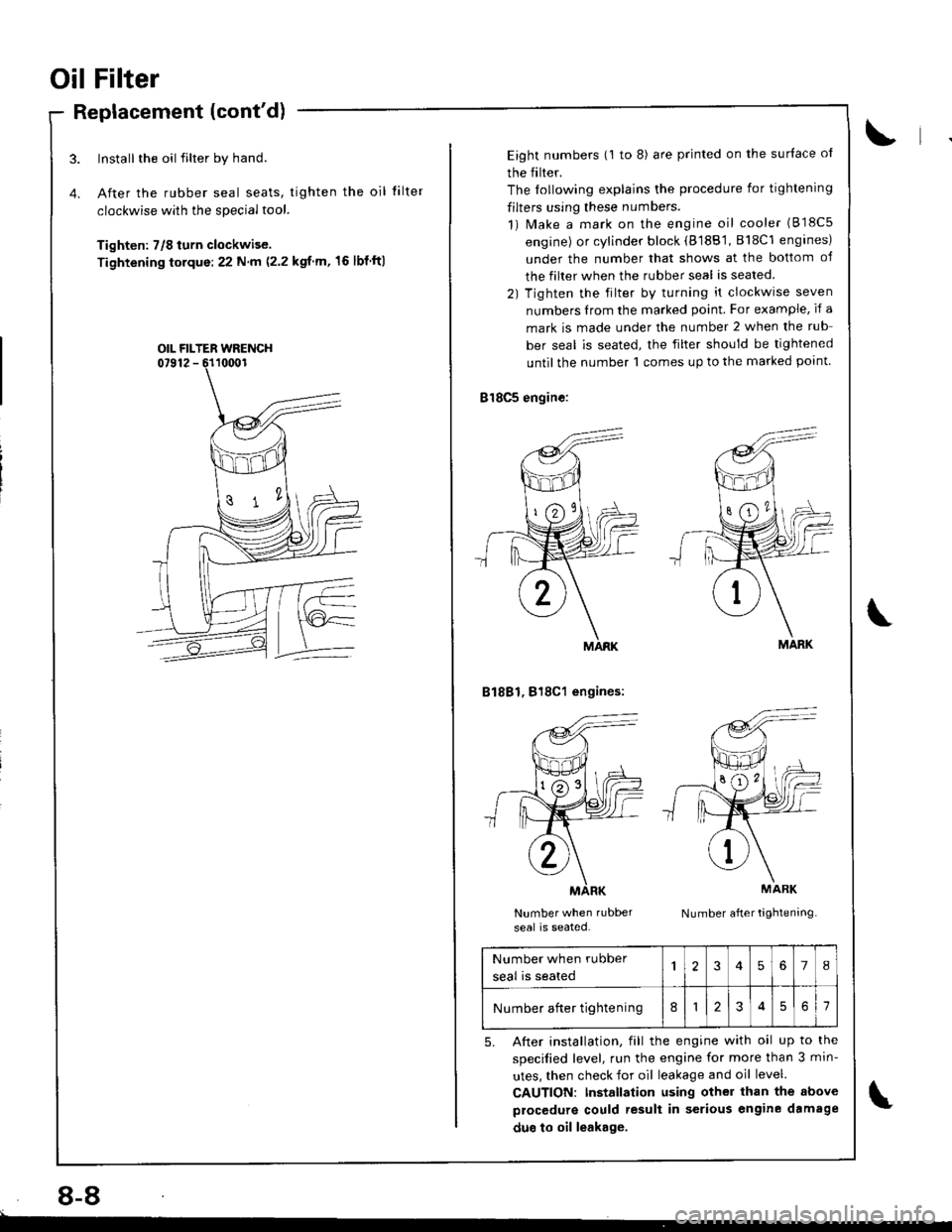

Oil Filter

Replacement (cont'd)

Install the oil filter by hand.

After the rubber seal seats, tighten the oil

clockwise with the special tool.

Tighten: 7/8 turn clockwise.

Tightening torque:22 N m (2.2 kgf m,'16 lbf ftl

tilte r

OIL FILTER WRENCH

8-8

Eight numbers (1 to 8) are printed on the surlace ol

the filter.

The lollowing explains the procedure for tightening

filters using these numbers.

1) Make a mark on the engine oil cooler (818c5

engine) or cylinder block (8188'1, 818C1 engines)

under the number that shows at the bottom of

the filter when the rubber seal is seated.

2) Tighten the filter by turning it clockwise seven

numbers Irom the marked point. For example, if a

mark is made under the number 2 when the rub

ber seal is seated, the filter should be tightened

until the number 1 comes up to the marked point

818C5 engine:

B1881, 818C1 engines:

Number when rubber

seal is seated.Number after tightening

MARK

MARK

Number when rubber

seal is seated

'I2345678

Number after tightening812561

5. After installation, fill the engine with oil up to the

specilied level, run the engine for more than 3 min-

utes, then check for oil leakage and oil level.

CAUTION: Installation using other than the above

procedure could result in serious engine damage

duo to oil leakage.

Page 182 of 1681

Oil Pressure

Testing

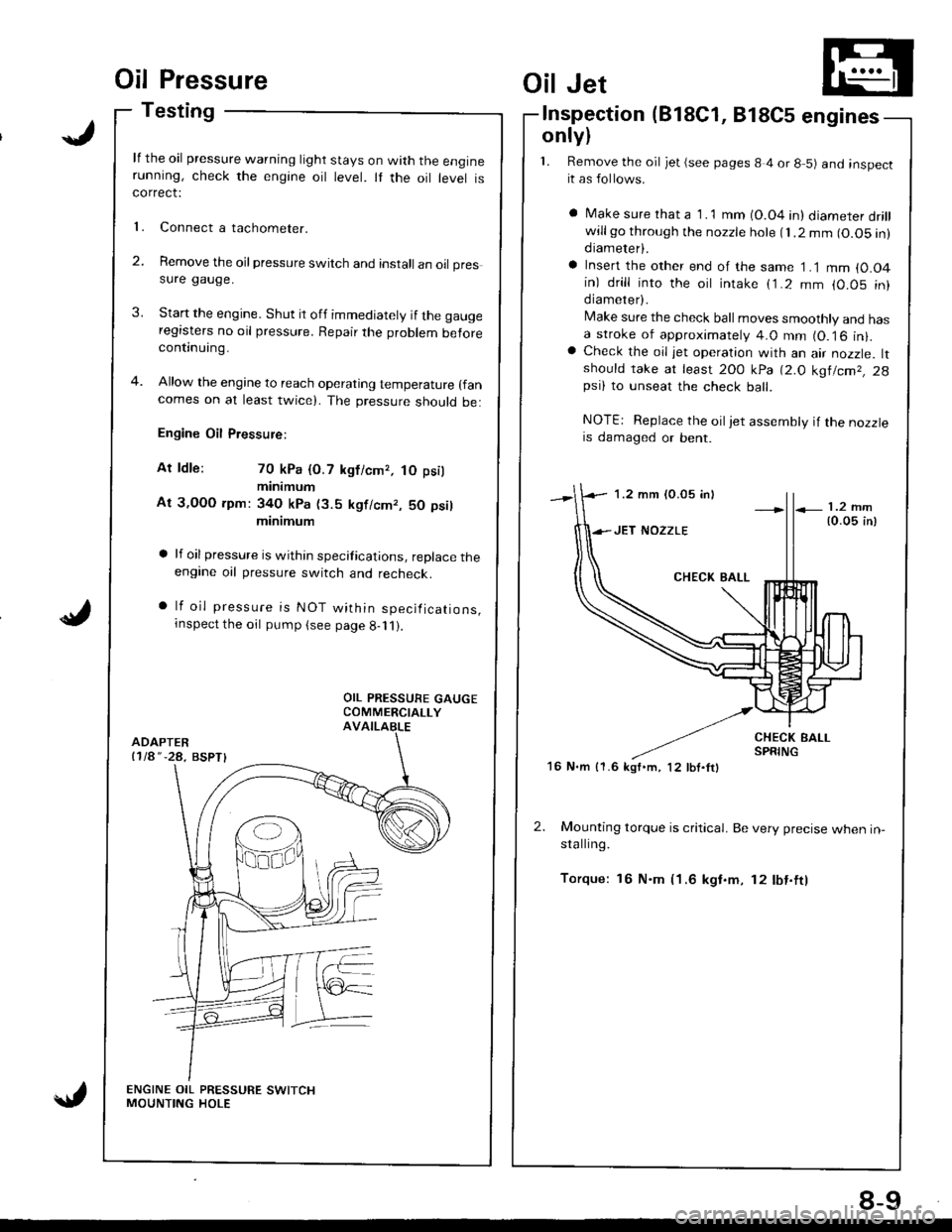

lf the oil pressure warning light stays on with the enginerunning, check the engine oil level. It the oil level iscorrect:

Connect a tachometer.

Remove the oil pressure switch and install an oil pressure gauge.

Start the engine. Shut it off immediately if the gaugeregasters no oil pressure. Repair the problem beforecontinuing.

Allow the engine to reach operating temperature (fan

comes on at least twicel. The pressure should be:

Engine Oil Pressure:

At ldle: 70 kPa {O.7 kgficmr, tO psil

minimum

At 3,OOO rpm: 34O kPa (3.5 kgf/cmr, 50 psil

minimum

a lf oilpressure is within specifications, replace theengine oil pressure switch and recheck.

a lf oil pressure is NOT within specifications,rnspect the oil pump (see page g-11).

l�

2.

Oil Jet

lnspection(818C1, 818C5 engines

only)

1. Remove the oil jet (see pages 8 4 or 8 5) and inspectit as follows.

a Make sure rhat a 1 .1 mm (O.04 in) diameter drillwillgo through the nozzle hole fl.2 mm (O.O5 in)diameter).

a Insert the other end of the same 1 .1 mm {0.O4in) drill into the oit intake (1.2 mm (0.05 in)diameter).

Make sure the check ball moves smoothly and hasa stroke of approximately 4.0 mm (O.16 in).a Check the oil jet operation with an air nozzle. ltshould take at least 2OO kPa 12.O kg|lcm2, 2gpsi) to unseat the check ball.

NOTE: Replace the oiljet assembly if the nozzleis damaged or bent.

2. Mounting torque is critical. Be very precise when in-stalling.

Torque: 16 N.m (1.6 kgf.m, 12 lbf.ftl

1.2 mm (0.05 inl

16 N.m {1.6 kgf'm, 12 lbf.ftl

8-9

Page 184 of 1681

3.

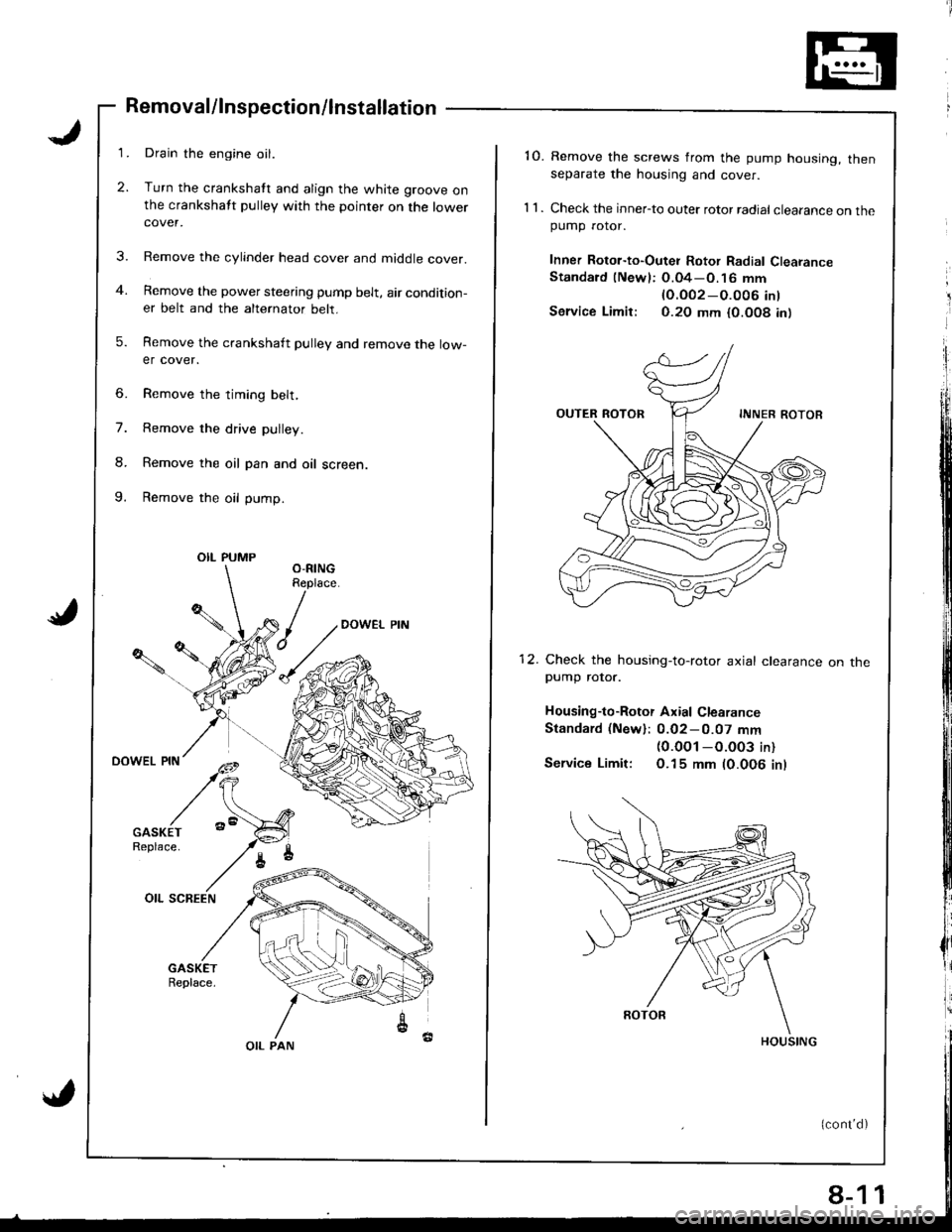

Removal/lnspection/lnstallation

Drain the engine oil.

Turn the crankshatt and align the white groove onthe crankshatt pulley with the pointer on the lowercover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condition-er belt and the alternator belt.

Remove the crankshaft pulley and remove the low-er cover.

6. Remove the timing belt,

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

OIL PUMP

OIL PAN

8-1

'10. Remove the screws from the pump housing, thenseparate the housing and cover.

1 1 . Check the inner-to outer rotor radial clearance on thepumD rotor.

Inner Rotor-to-Outei Rotor Radial ClearanceStandard (Newl: O.04-O.16 mm

lO.OO2-O.O06 int

Service Limir: 0.20 mm {0.O08 in)

12. Check the housing-to-rotor axial clearancepump rotor.

Housing-to-Rotor Axial Clearance

Standard (New): 0.02-0.07 mm(0.0O1 -O.003 in)

Service Limit: O.15 mm (0.006 inl

on tne

1