belt HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 659 of 1681

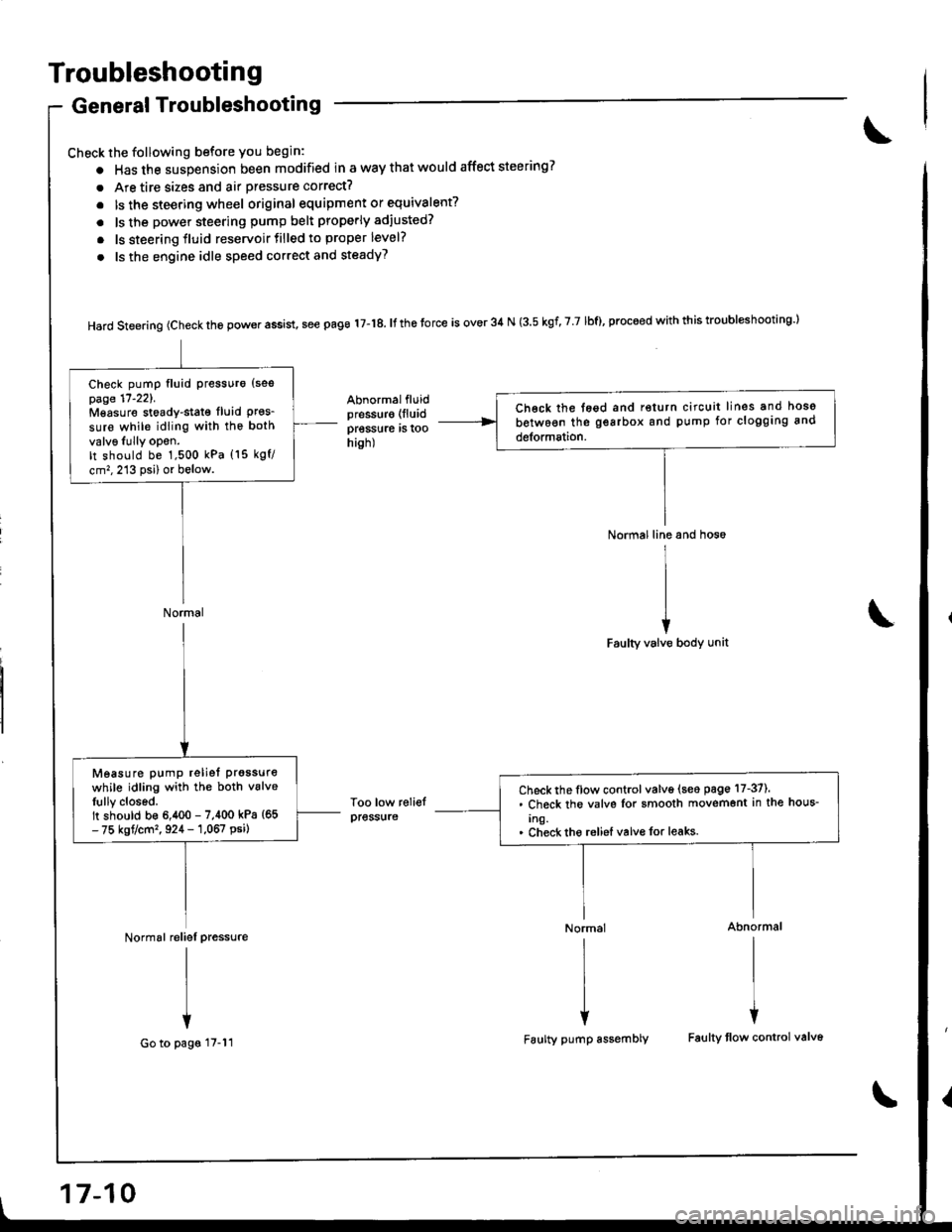

Troubleshooting

General Troubleshooting

Check the following before you begin:

o Has the suspension been modified in a way that would affect steering?

. Are tire sizes and air pressure correct?

. lsthe steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adiusted?

. ls steering fluid reservoirtilled to proper level?

. ls the engine idle speed correct and steadyT

Hard steering (check the power assist, see page 17-18. It the torce is over 34 N (3.5 kgf, 7 7 lbf), proceed with this troubl*hooting l

Abnormalfluidpressur€ (lluid

pressure rs roohish)

Too low reliefpress{ire

Normal line and hos6

I

II

iFaulty valve body unit

Normal Abnormal

rlrl

l{

Faulty pump assembly Faulty tlow control valv6

Ch€ck the tegd and return circuit lines and hoso

between the gearbox and pump for clogging and

detormation.

Check pump fluid Pressuro {sespage 17'221.Mgasure stoady-stat€ fluid Pres_sure while idling with the both

valv6Iully opon.It should be 1,500 kPa (15 kgf/

cm,,213 psi) or below.

Normal

Check the flow control valve (seo page 17-37).. Check the valvs Ior smooth movemont in the hous-

Ing.. Check tho reliel valvo for leaks.

Measure pump reliet prgssure

while idling with the both vslveIully closed.It should b€ 6,400 - 7,400 kPa {65- 75 kgt/cm'�, 924 - 1,067 psi)

Normal reliel pressure

I

I

+

Go to pags 17-11

17-10

Page 661 of 1681

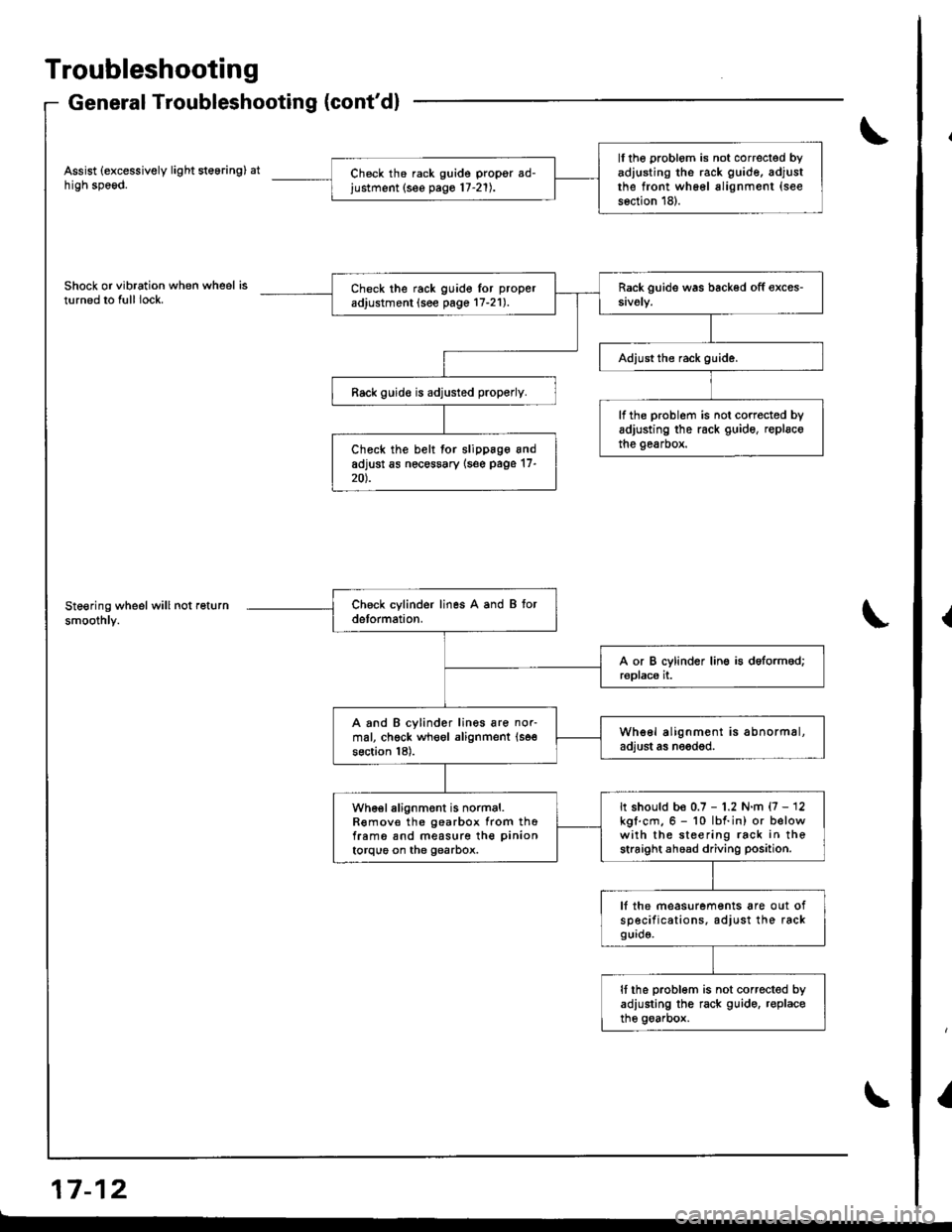

Troubleshooting

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speod.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not return

smoothly.

a-, aa GrI r- tz

ll the problom is not correcled byadiusting the rack guide, adjustthe front wh66l alignment (see

s6ction 18).

Ch6ck th6 rack guide propgr ad-justment (see pago 17-21).

Check the rack guido lor proper

adjustment (see page 17-21).

Rack guid€ is adjusted properly.

lf the problem is not corrected byadjusting the rack guide, replscothe gearbox.Check the belt for slippage andadjust as nec€ssary {s6e page 17-20).

A and B cylinder lines are nor-mal, chgck wheol alignment (se€

section 18).

Whe6l alignment is abnormal,adjust as needod.

It should be 0.7 - 1.2 N.m {7 - 12kgl.cm.6 - 10 lbf.in) or belowwith the steering rack in thestraight ahoad driving position.

wh€el alignment is normal.R€mov€ the gearbox from thofram6 snd measure the pinion

torque on the gearbox.

lf the measurements are out ofsp€cifications. adjust the rackgurd9.

It the problom is not corrected byadiusting the rack guido. r€placethe goarbox.

{

I

Page 667 of 1681

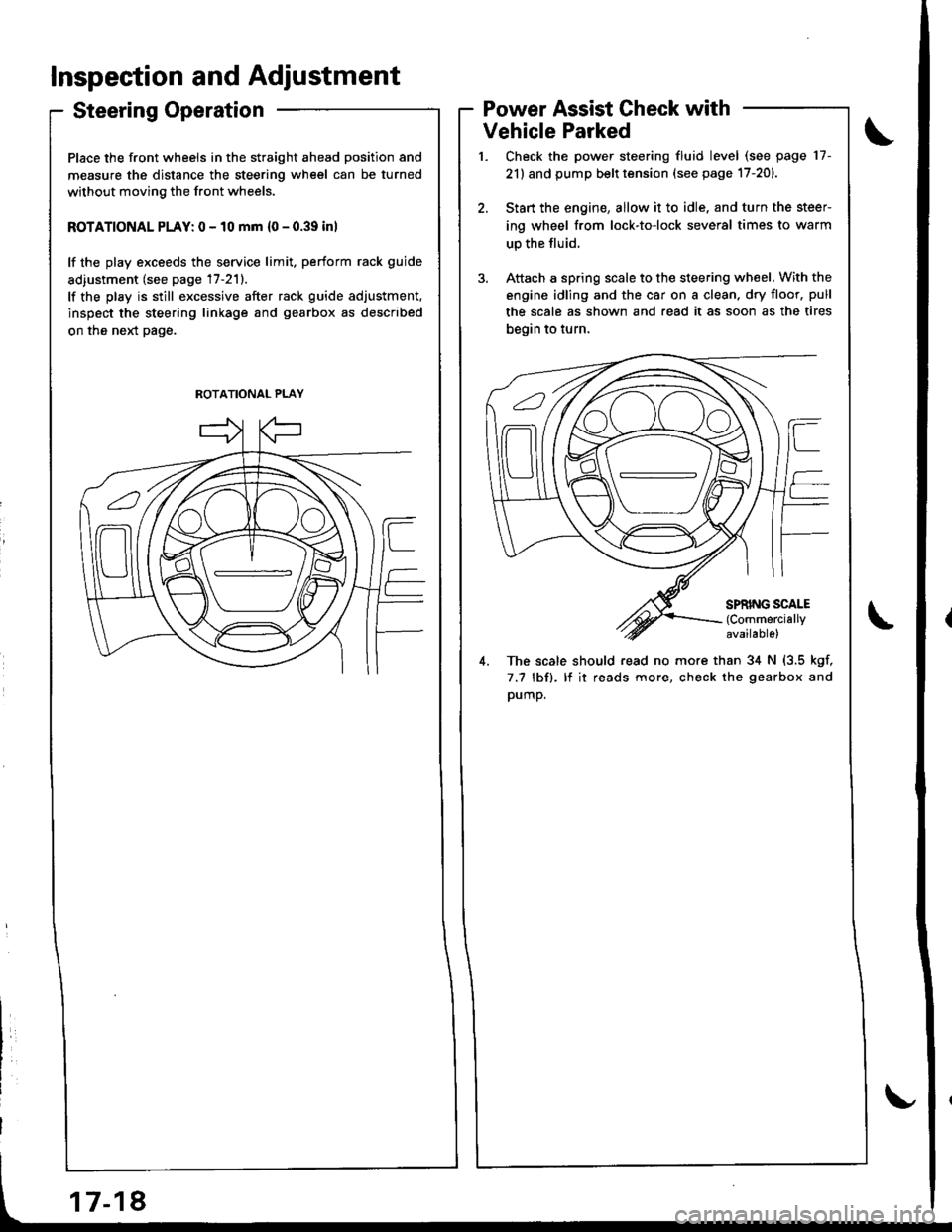

Inspection and Adjustment

Steering Operation

Place the front wheels in the straight ahead position and

measure the distance the steering wheel can be turned

without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm {0 - 0.39 inl

lf the play exceeds the service limit. perform rack guide

adiustment (see page 17-211.

lf the play is still excessive after rack guide adjustment.

inspect the steering linkage and gearbox as described

on the neld page.

Power Assist Check with

Vehicle Parked

Check the power steering fluid level (see page 17-

21) and pump belt tension (see page 17-201.

Start the engine, allow it to idle. and turn the steer

ing wheel from lock-to-lock several times to warm

up the fluid.

Attach a spring scale to the steering wheel. With the

engine idling and the car on a clean. dry floor. pull

the scale as shown and read it as soon as the tires

begin to turn,

4. The scale should read no more than 34 N (3.5 kgf,

7.7 lbf). lf it reads more, check the gearbox and

pump.

ROTATIONAL PLAY

Page 669 of 1681

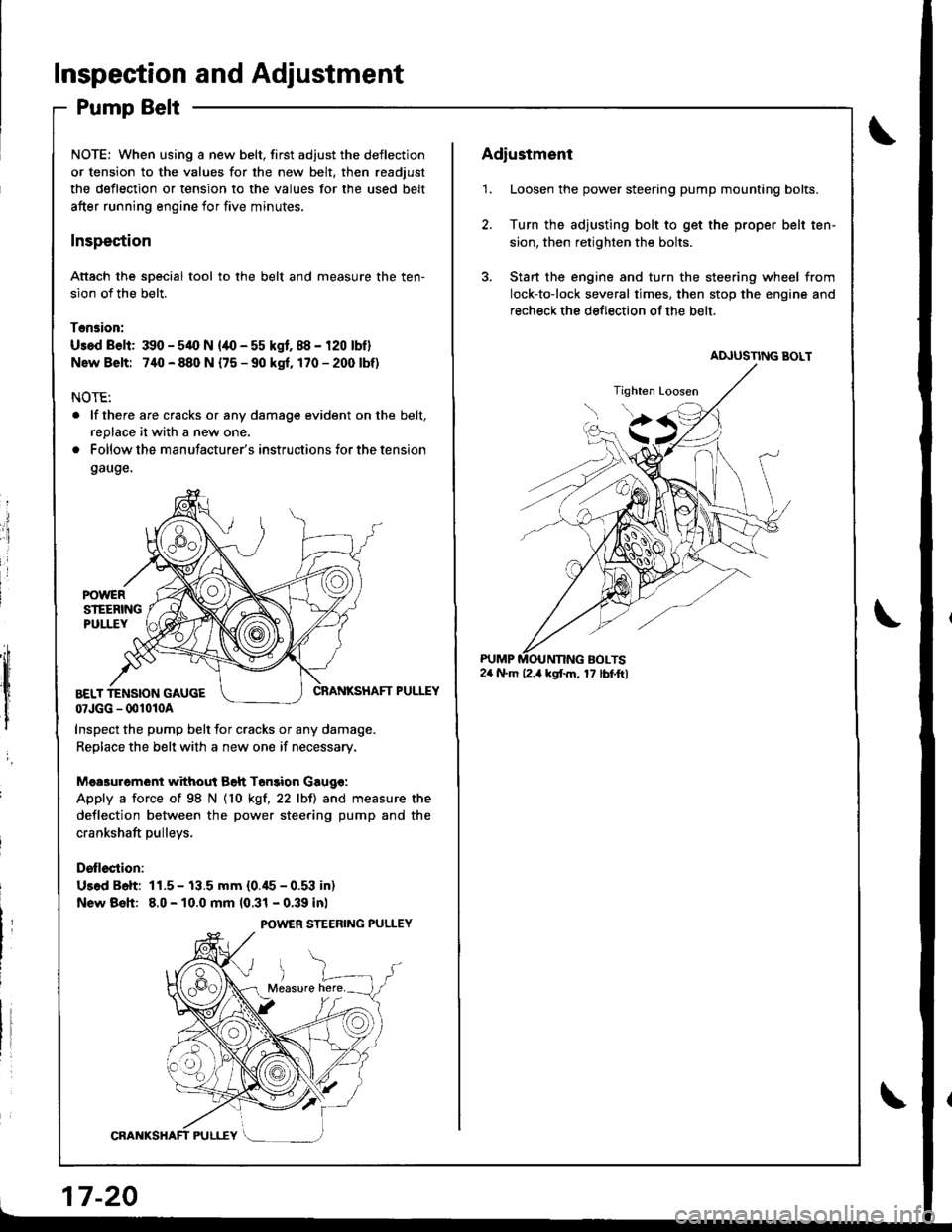

Inspection and Adjustment

Pump Belt

NOTE: When using a new belt, first adjust the deflection

or tension to the values for the new belt, then readjust

the deflection or tension to the values for the used belt

after running engine for five minutes,

Inspection

Attach the soecial tool to the belt and measure the ten-

sion of the belt.

Tension:

Usad Belt: 390 - 54O N {/10 - 55 kgf. 88 - 120 lbf}

Nsw Belt: 740 - 880 N {75 - 90 kgf. 170-2(X)lbf)

NOTE:

. lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions for the tension

gauge.

ii

:i

i

I

,;h

,lt l

I

i

CRANKSHAFT PULEYBELT TENSION GAUGE07JGG - 001010A

Inspect the pump belt for cracks or any damage.

Replace the belt with a new one if necessary.

Mea3urement without Bah Tonsion Gaugo:

Apply a force of 98 N {10 kgt,22 lbll and measure the

deflection between the power steering pump and the

crankshaft pulleys,

Drllection:

Us.d B6h: 11.5 - 13.5 mm (0.45 - 0.53 in)

New Bsh: 8.0 - 10.0 mm 10.31 - 0.39 inl

POWER STEERING PULLEY

17-20

Adiustment

1. Loosen the power steering pump mounting bolts.

2. Turn the adjusting bolt to get the proper belt ten-

sion, then retighten the bolts.

3. Stan the engine and turn the steering wheel from

lock-to-lock several times. then stop the engine and

recheck the deflection of the belt.

24 N.m l2.a kgf.m, 17 lbf.ftl

Page 671 of 1681

Inspection and Adjustment

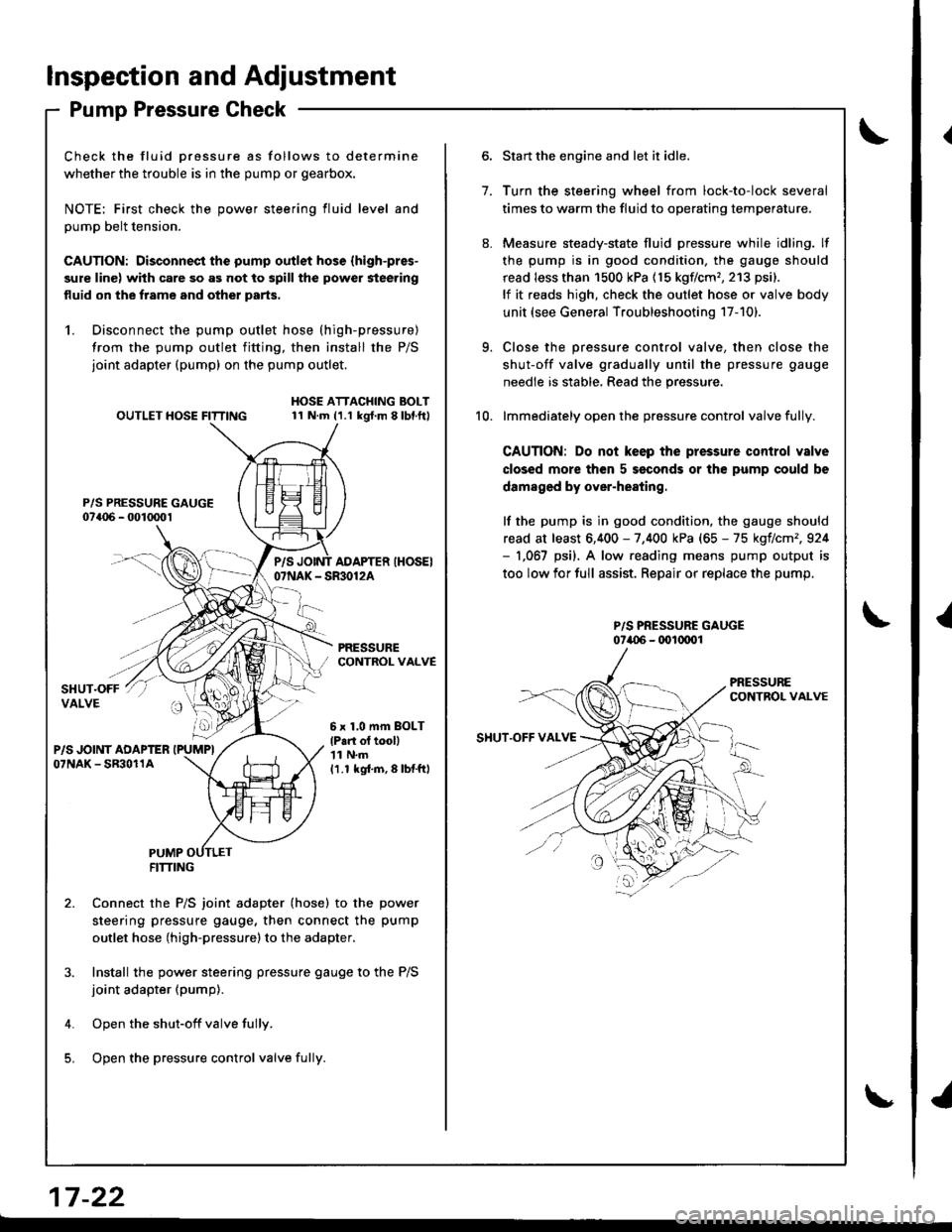

Pump Pressure Check

Check the fluid Dressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE; First check the power steering fluid level and

pump belt tension.

CAUTION: Disconnect the pump outlet hose (high-pres-

sure line) with care so as not to spill the power steering

fluid on the frame and other parts,

1. Disconnect the pump outlet hose (high-pressure)

from the pump outlet fitting, then install the P/S

joint adapter (pump) on the pump outlet.

P/S PRESSURE GAUGE07a06 - 001mo1

OUTLET HOSE FITTINGHOSE ATTACHING BOLT11 N.m (1.1 kgt.m 8lbl.ft)

PRESSURECONTROL VALVE

P/SAOAPTER IHOSEI07NAK - SR30124

6 x 1,0 mm BOLT

lP.n ol tooll'| 1 N.m

11.1 kgi.m,8lbtftl

PUMPFITTING

Connect the P/S joint adapter (hose) to the power

steering pressure gauge, then connect the pump

outlet hose (high-pressure)to the adapter.

Install the power steering pressure gauge to the P/S

joint adapter (pump).

Open the shut-off valve fully.

Open the pressure control valve fulli.

1.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. lf

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgflcm'�,213 psi).

lf it reads high, check the outlet hose or valve body

unit (see General Troubleshooting 17-101.

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable, Read the pressure.

lmmediately open the pressure control valve fully.

CAUTION: Do not keep the pressure control valve

closed more then 5 seconds or the pump could be

damaged by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm',924- 1,067 psi). A low.eading means pump output is

too low for full assist. Repair or replace the pump.

P/S PRESSURE GAUGE07i.{)6 - (x)l(xrol

9.

10.

SHUT.OFF VAI.VE

17 -22

{

I

Page 684 of 1681

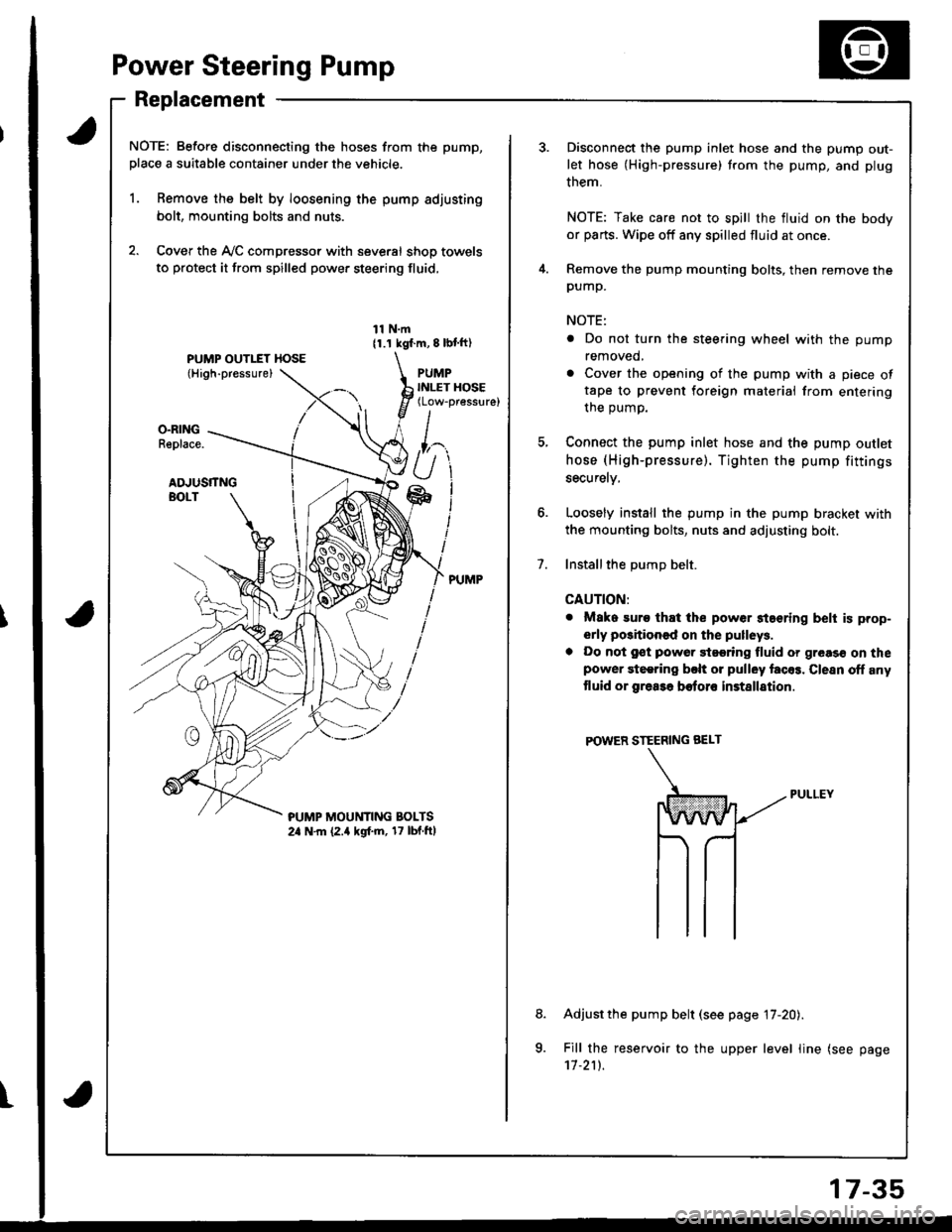

Power Steering Pump

Replacement

NOTE: Before disconnecting the hoses from the pump,

place a suitable container under the vehicle.

1. Remove the belt by loosening the pump adjusting

bolt, mounting bolts and nuts.

2. Cover the Ay'C compressor with several shop towels

to protect it from spilled power steering fluid,

11 N.m11.1 kgf.m, 8 lbl ft)

PUMPINLET HOSE(Low-pressure)

O.RINGReplace.

ADJUSTTNGBOLT

?UMP MOUt'lTlNG BOLTS2a N.m (2.a kgf.m, 17 lbf.ftl

t

7.

Disconnect the pump inlet hose and the pump out-

let hose (High-pressure) trom the pump, and plug

them.

NOTE: Take care not to spill the fluid on the body

or parts. Wipe off any spilled fluid at once.

Remove the pump mounting bolts, then remove thepump.

NOTE:

. Do not turn the steering wheel with the pump

removed,

. Cover the opening of the pump with a piece oftape to prevent foreign materiai from entering

the oumo.

Connect the pump inlet hose and the pump outlet

hose (High-pressure). Tighten the pump fittings

securelv,

Loosely install the pump in the pump bracket with

the mounting bolts, nuts and adjusting bolt.

Installthe DumD belt.

CAUTION:

. Mako suro that the power staering belt is prop-

erly positioned on the pulleys.

a Do not gst powor 9t99ring fluid or greas€ on thepower steering bclt or pulley facos. Clesn off any

tluid or grea3a botoro installation

POWER STEERING BEI-T

Adjust the pump belt (see page 17-20).

Fill the reservoir to the upper level line (see page'11.211.

8.

a

17-35

Page 816 of 1681

!

Body

Bumpers

Front Bumper Replacement ....................-..... 20-111

Rear Bumpar Replacemeni

Hatchback ................. 20-1/B

Sedan .................... ....20-111'Carpet

. Repfacemenl .,.,.,.,,..-....-.20-126

Consoles, Front and Rear

* Replacement ..................20-130

Dashboard

Component Removal/lnstallation ................ 20-133

Replacement Precautions ...........,................. 20-138

R€placement ....,.,...........20-139

Doors

Door Index Hatchback ................................... 20-2

Front Door Index Sedan .................,.,..,.,....,.. 20-18

Rear Door Index Sedan ........,.,........,.............. 20-30

Emblems

Installation .....................20-167

FenderwellTrim

+ Replacement., ................20.162

Fram€ Repair Chart .-..........20-170

Hatch

Replacoment .......,..........20-118

Adiustment .................... 20-150

Hatch Latch and Lock Cylinder

Replacement ..,.,..... ........ 20-158

Hstch Spoiler

Replacement ......... .......-.20.161

Hatch Weatherstrip/Trunk Lid Wsatherstrip

Replacement ..................20.163

Headliner

ReDlacement

Hatchbsck ,.,....,......,.. 20-98

Sedan .........................................................20-100

Hood

Replacsment ......... ......... 20.146

Adiustment ....................20-117

lnterior Trim

Reolacement

Hatchback ................. 20-91

Sedan .........................................................20-9,1

Mirrors

Power Mirror Reolacement ..........,................ 20-49

Mirrol Holder Removal ............................,..... 20.50

Mirror Holder Installation .............................. 20-50

Mirror Visor and Mirrot Covet

Replacement

Haichback ............20-51

Sedan .................................................... 20-51

Rearview Mirror Reolacement ..........-....-.-.... 20.52

Roof Molding Rep|acament ................................ 20.164

Door and Sid€ Moldings

Replacement .,..........,..... 20-165

Moonroot

lnd6x

Hatchback -................20-77

Sodan .........................................................20-8il

Opener and Latch

Replacement .......... ......,. 20-156

Opensr Cables

Replacamsnt .,.,...,.. ......., 20-154

Retainers and W€atherstrip

Replacement .................. 20-160

Seats

Front Seat Romoval ....................................... 20-103

Front Seat Replacement ...........................,.,.. 20-104

Front Soat Disassembly and Reassembly ...20-106

Torsion Bar ReDlacomant .....,...,......,.......,..,., 2O-1O7

Seat Eelt Switch Ha.ness Location ..,...,.,.,..,2O-1O7

Front Seat Cover Replacemont ..,....,..,..,.....,. 20-108

Rear Soat Roplscemont

Hatchback ................. 20.110

Sedan.........................................................20-112

R€al Seat Cover Replacomont ...................... 20-114

Seat Belts

Front Seat Beh Replacement

Hatchback..................20.117

Sedan20-r18

Rear S6at Bolt R€plac€ment

Hatchback .-......-.-......20-121

Sedan.......................-.-....-.-..........-.............20-122

fnspection ......-.-.,....-.-....20-121

Chifd Seat Anchor Plate ................................ 20-125

Side Sill Panol

Beplacom€nt .................. 20-166

Sub-frame ........................... 20.169

Trunk Lid

Replacement ......... ..,..,.,.20-151

Adiustmeni .................... 20-153

Trunk Lid Latch and Lock Cvlindot

Replac€ment ......... ......... 20-159

Trunk Trim

Replacement .,.,,.,........... 20-97

Windshield, Rear Window, Ouarter Glass

lndex

Hatchback ...........,,.20-53

!

S6dan ......................................................... 20.54

Page 908 of 1681

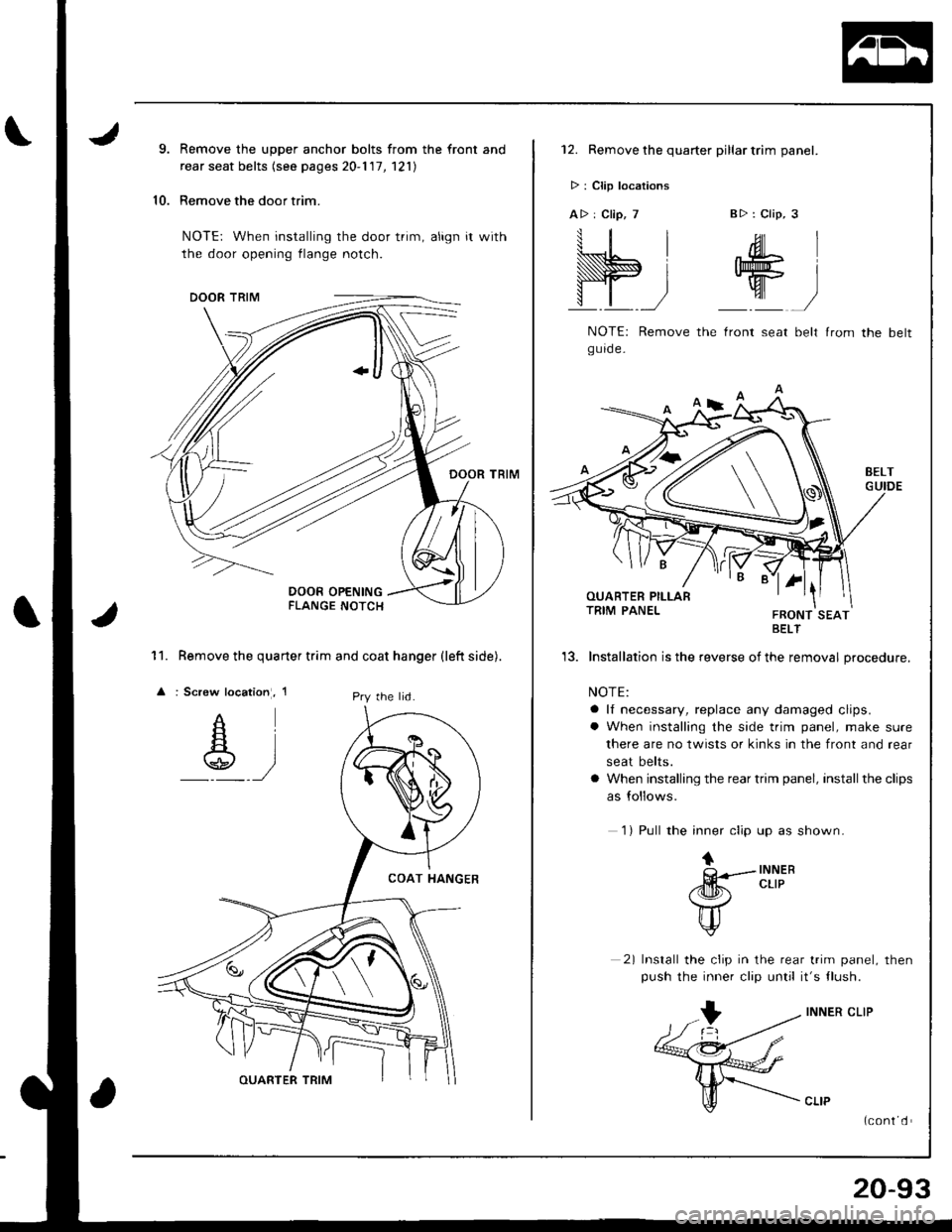

9.

10.

Remove the upper anchor bolts from the front and

rear seat belts (see pages 20-1 '17, 121)

Remove the door trim.

NOTE: When installing the door trim, align it with

the door opening flange notch.

Remove the quarter trim and coat hanger (left side).

: Screw location, 1

11.

lPry the lid.

12. Remove the quarter pillar trim panel.

> : Clip locations

A> : Clip, 7B>: Clip, 3

W;

.ML

W

NOTE: Remove the lront seat belt lrom the beltgurde-

BELT

'13. Installation is the reverse of the removal procedure.

NOTE:

a lf necessary, replace any damaged clips.

a When installing the side trim panel, make sure

there are no twists or kinks in the front and rear

seat belts.

a When installing the rear trim panel, install the clips

as follows.

1) Pull the inner clip up as shown.

tQ---INNER

/dm!r. cLrP

\7

u

2) Install the clip in the rear trim panel, then

push the inner clip until it's tlush.

INNER CLIP

(cont d

20-93

Page 909 of 1681

lnterior Trim

II

I

)

,/lCENTER PILLARLOWER TRIM

w

Replacement (cont'dl

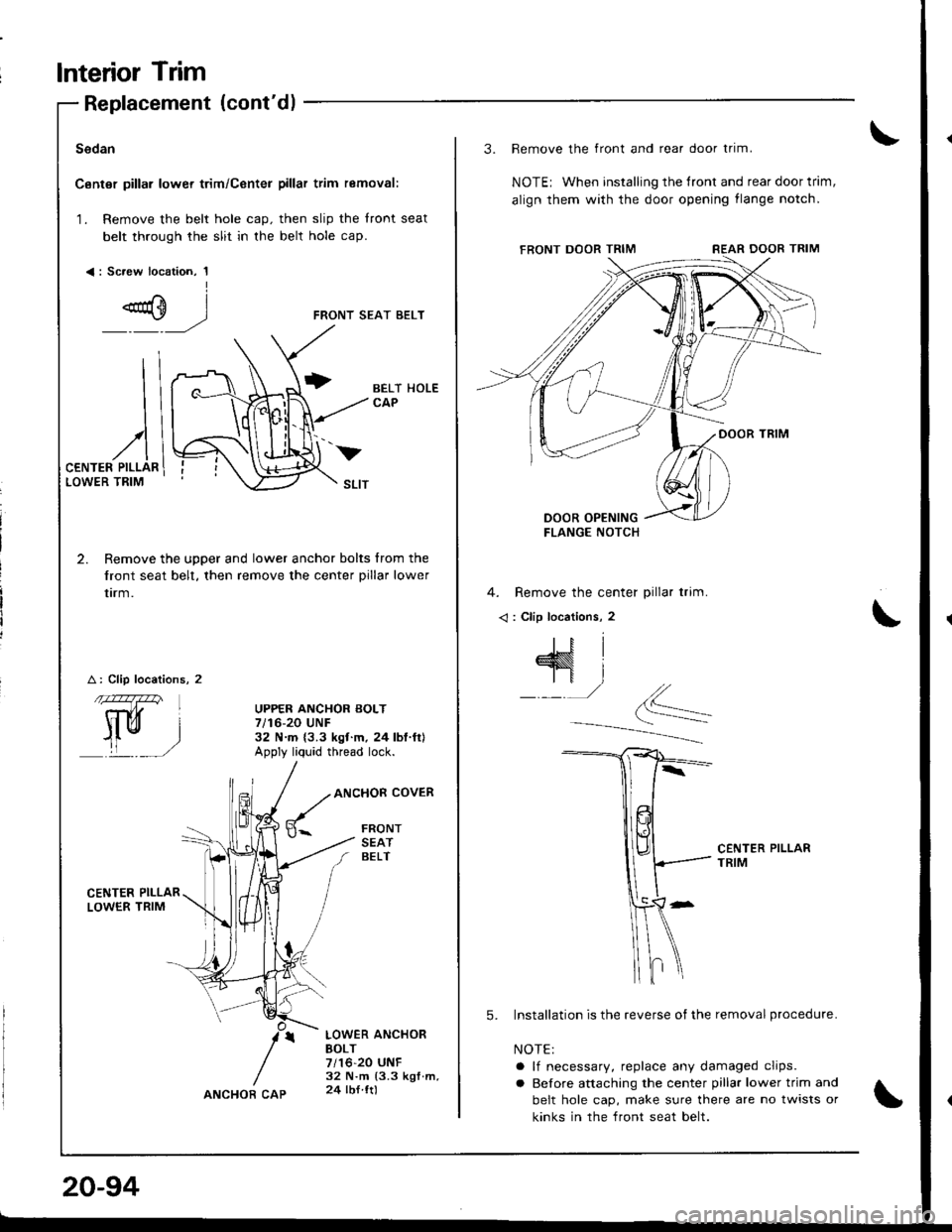

Sedan

Canter pillar lower trim/Center pillar trim removal:

1. Remove the belt hole cap. then slip the front seat

belt through the slit in the belt hole cap.

<: Sc.ew location, 1I

FRONT SEAT BELT

2. Remove the upper and lower anchor bolts from the

front seat belt, then remove the center pillar lower

trrm.

A: Clip locations, 2

CENTER PII-LARLOWER TRIM

BELT HOLECAP

UPPER ANCHOR BOLT7/16-20 UNF32 N.m {3.3 ksf.m. 24lbl.ft}Apply liq'rid thread lock.

ANCHOR COVER

FRONTSEATBELT

LOWER ANCHOBBOLT7/16-20 UNF32 N.m (3.3 kgf.m,24 lbl ttl

v

20-94

ANCHOR CAP

3. Remove the front and rear door trim.

NOTEr When installing the tront and rear door trim,

align them with the door opening flange notch,

4. Remove the center pillar trim.

< : Clip locations, 2

CENTER PILLARTRIM

5. Installation is the reverse of the removal procedure.

NOTE:

a lf necessary, replace any damaged clips.

a Before attaching the center pillar lower trim and

belt hole cap, make sure there are no twists or

kinks in the front seat belt.

Page 910 of 1681

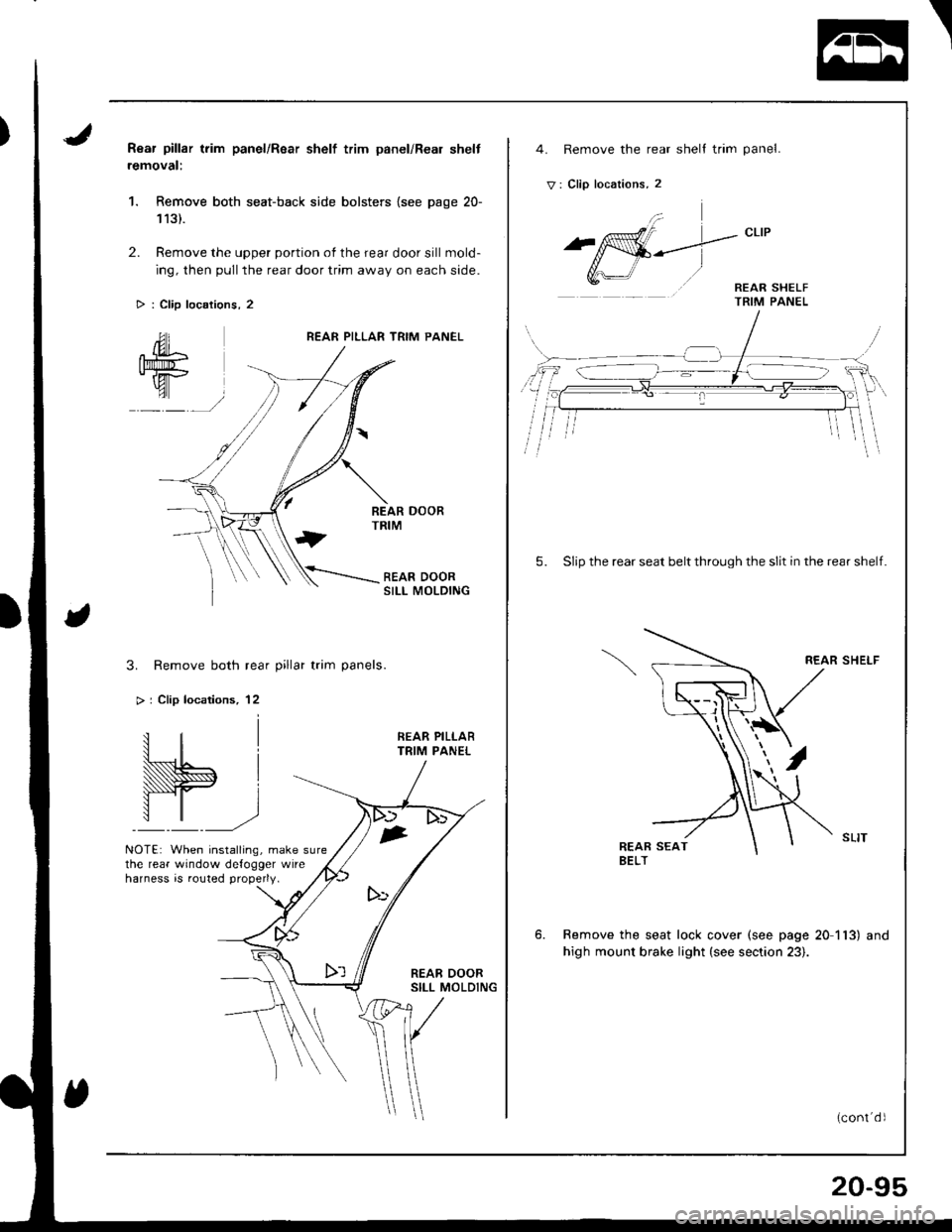

Rear pillar trim panel/Rsar shelf trim panel/Real shelt

removal:

1. Remove both seat-back side bolsters {see page 20-

113).

2. Remove the upper portion of the rear door sill mold-

ing, then pull the rear door trim away on each side.

> : Clip locations, 2

REAR PILLAR TRIM PANEL

SII-I MOLDING

3. Remove both rear pillar trim panels.

> | Clip locations, 12

NOTE: When installing, make surethe rear window defogger wireharness is routed properly.

1

I

,

4. Remove the rear shell trim panel.

V: Clip locations, 2

5. Slip the rear seat belt through the slit in the rear shelf.

REAR SHELF

Remove the seat lock cover (see page 20 113) and

high mount brake light (see section 23).

20-95