lock HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 173 of 1681

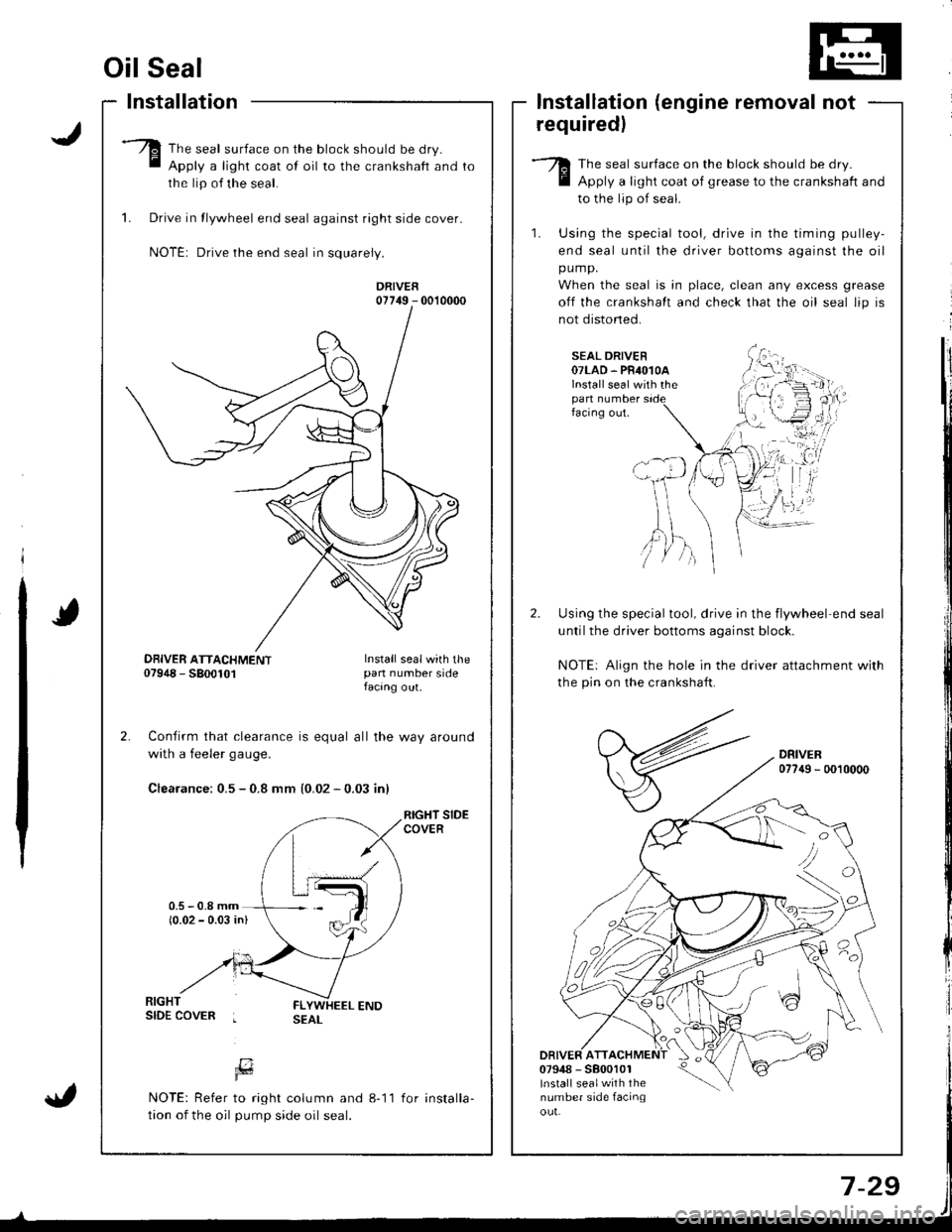

Oil Seal

Installation

The seal surface on the block should be dry.

Apply a light coat of oil to the crankshaft and

the lip of the seal.

1. Drive in tlywheel end seal against right side cover.

NOTE: Drive the end seal in squarely.

DRIVER07749 - 0010000

Confirm that clearance is equal all the way around

with a feeler gaug€.

Clearance: 0.5 - 0.8 mm {0.02 - 0.03 inl

RIGHT SIDECOVER

lnstallation (engine removal not

requiredl

The seal surface on the block should be dry.

Apply a light coat of grease to the crankshaft and

to the lip of seal.

1. Using the special tool, drive in the timing pulley-

end seal until the driver bottoms against the oil

pump.

When the seal is in place, clean any excess grease

off the crankshalt and check that the oil seal lip is

not distoned.

SEAL DRIVER07LAD. PR4O1OAlnstall seal with thepan numberfacing out.

Using the special tool, drive in the flywheel end seal

untilthe driver bottoms aqainst block.

NOTE: Align the hole in the driver attachment with

the pin on the crankshaft.

DRIVER077{9 - 0010000

DRIVER ATT07948 - 5800101lnstall sealwith thenumber side facinqou!.

'tvA,)/ )

DBIVER ATTACHMENT07948 - 5800101Install sealwith thepan number sidefacang out.

[7Fd

NOTE: Refer to right column and 8-11

tion of the oil pump side oil seal.

for installa-

Page 176 of 1681

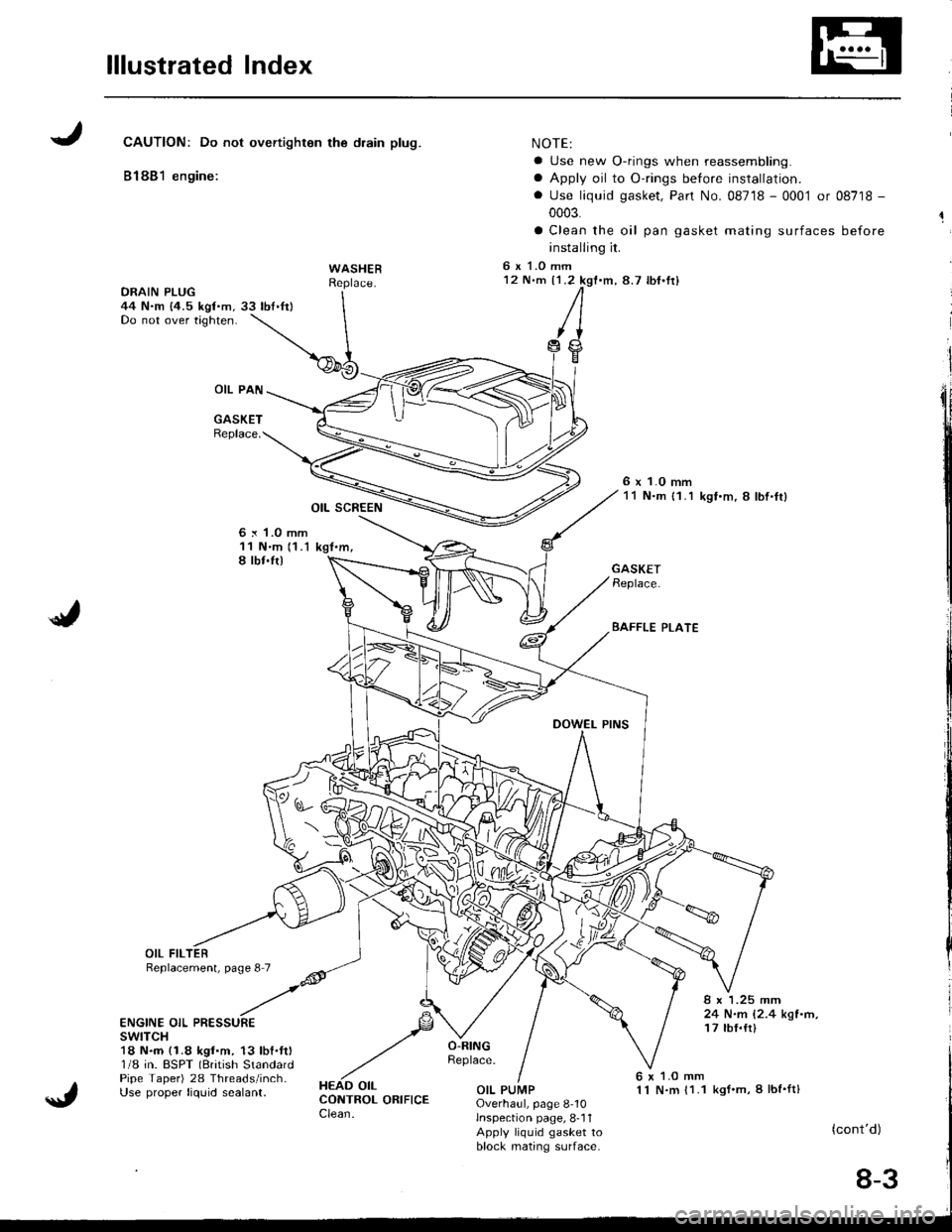

lllustrated Index

JCAUTION: Do not overtighton the drain plug.

81881 engine:

WASHER

OIL PAN

GASKETReplace.

OIL SCREEN

6 x 1.0 mm11 N'm 11.1 kgt.m,I lbt.ft)

NOTE:

a Use new O-rings when reassembling.

a Apply oil to O-rings before installation.

. Use liquid gasket, Pan No. 08718 - 0001 or 08718 -

0003.

a Clean the oil pan gasket mating surfaces before

installing it.

6 x 1.O mm12 N'm {1.2 kgf.m,8.7 lbf'fr)

/I

,trg

6 x 1.0 mm11 N.m {1.1 kgf.m, 8 lbl.ft}

./

GASKETReplace.

BAFFLE PLATE

8 x 1.25 mm24 N.m 12.4 kgl.n,17 tbf.tt)ENGINE OIL PRESSUREswtTcH18 N.m (1.8 kgf.m. 13 lbf.ft)1/8 in. BSPT (British StandardPipe Taper) 28 Threads/inch-Use proper liquid sealant.

6 x 1.O mm1 l N.m {1.1 kgt.m, I lbf'ft}OIL PUMPOverhaul, page 8-10lnspection page, 8-11Apply liquid gasket toblock mating s(]lrface-

(cont'd)

8-3

Page 177 of 1681

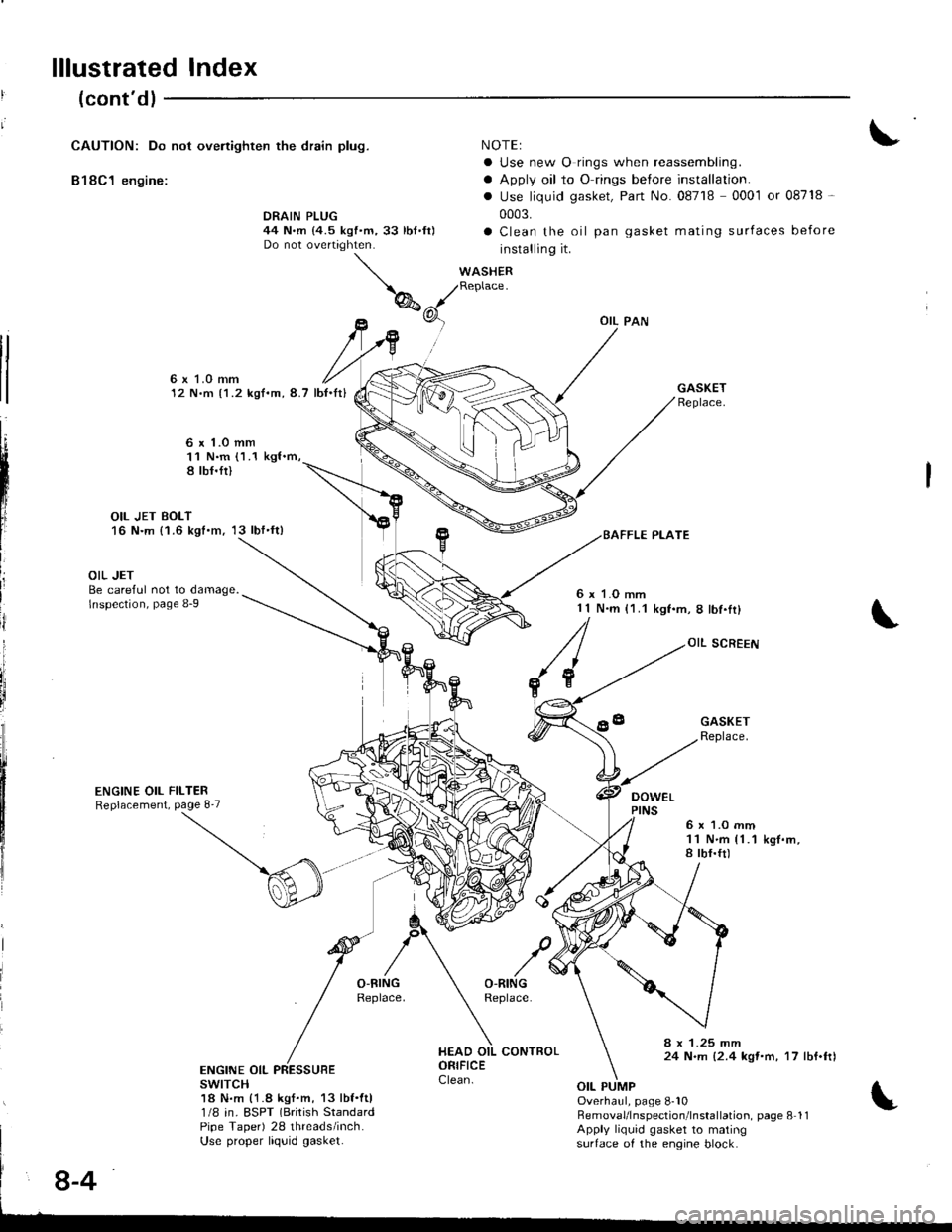

lllustrated Index

(cont'dl

CAUTION: Do not ovenighten the drain plug.

B18C1 engine:

NOTEI

a Use new O rings when reassembling.

a Apply oil to O rings before installation.

. Use liquid gasket, Part No. 08718 0001 or 08718 -

0003.

a Clean the oil pan gasket mating surfaces before

installing it.

WASHERReplace.

DRAIN PLUG44 N.m {4.5 kgf.m,33 lbf.ft)Do not overtighten.

tl

tl

6x LO mm12 N.m {1.2 kgf.m, 8.7 lb{.It}

6 x 1.o mm11 N.m (1.1 kgl.m,8 tbf.fi)

OIL JET BOLT16 N.m {1.6 kgt.m, 13 lbf'ft)

L

III

ij

i

OIL JETBe careful not to damage.lnspection, page 8-9

ENGINE OIL FILTERReplacement, Page 8'7

6 x 1.O mm1 1 N.m (1.1kgf.m,8lbf.Ir)

OIL SCREEN

DOWEL

GASKETReplace.

6x 1.O mm11 N.m {1.1a tbf.ft)k9f.m,

8 x 1.25 mm24 N.m {2.4 kqt'm, 17 lbf.ftlENGINE OIL PRESSUBEswrTcH18 N.m {1.8 kgf.m, 13 lbf.ftl1/8 in. ESPT (Brirish StandardPipe Taper) 28 threads/inch.Use proper liquid gasket.

Overhaul, page 8-10RemovaUlnspection'lnstallation. page 8 11Apply liquid gasket to matingsurtace of the engine block.

8-4

Page 178 of 1681

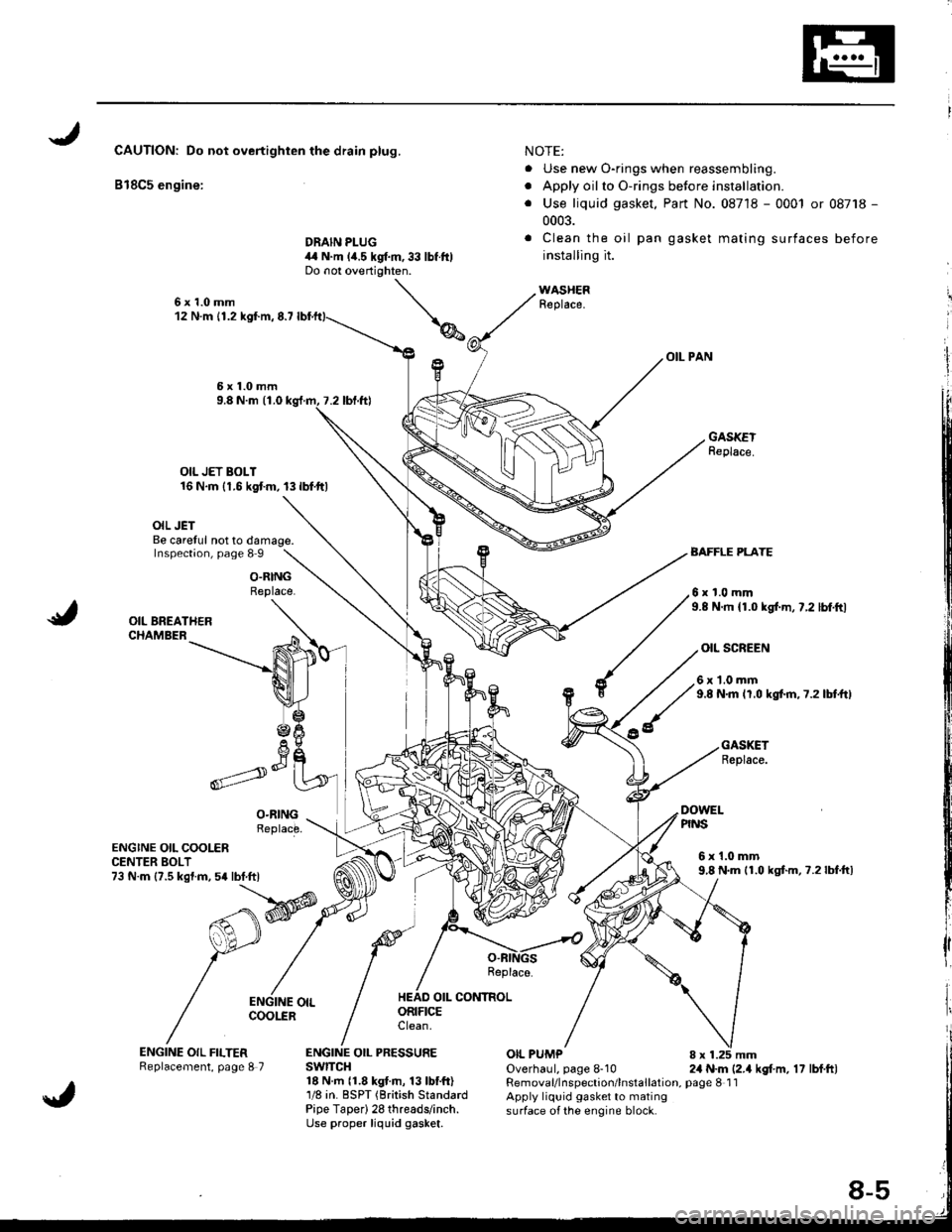

CAUTIONT Do not overtighten the drain plug,

B18C5 engine:

DRAIN PLUG

NOTE:

. Use new O-rings when reassembling.

. Apply oilto O-rings betore installation.

. Use liquid gasket, Part No. 08718 - 0001 or 08718 -

0003.

. Clean the oil pan gasket mating surfaces before

installing it.

WASHERReplace.

OIL PAN

GASKEIReplace.

4,r N.m lia.s kgt m, 33 lbf ftlDo not overtighten.

6x1.0mm12 N.m {1.2 kgI.m,8.7

OIL JET BOLT16 N.m {1.6 kgtm, 13lbf.ttl

\

7.2 tbl.ttl

OIL JETBe carelul not to damage.Inspect;on, page 8 9AAFFLE PLATE

6x1.0mm9.8 N.ft 11.0 kgl.m, 7.2 lbt.ftl

O.RINGReplace.

OIL SCREEN

ENGINE OIL COOLERCENTER BOLT73 N.m {?.5 kgf.m,5a lbt.ftl

ENGINE OIL FILTERReplacement, page I7

Replace.

OIL CONTROL

6x1.0mm9.8 N.m lr.0 kgt ft,7.2lbtftl

GASKETReplace.

8 x 1.25 mm2,1 N.m (2.1 kgt m, 17 lbf.ftl

DOWELPINS

6x1.0mm9,8 N.m 11.0 kgtm,7.2lbf.ftl

ORIFICEClean.

ENGINE OIL PRESSUREswrTcH18 N.m 11.8 kgt.m, 13 lbtft)1/8 in. BSPT (British StandardPipe TaDer) 28 threads/inch.Use proper liquid gasket.

OIL PUMPOverhaul, page 8-10Removal/lnspection/lnstallation, page 8 1 1Apply liquid gasket to matingsurface of the engine block.

Page 181 of 1681

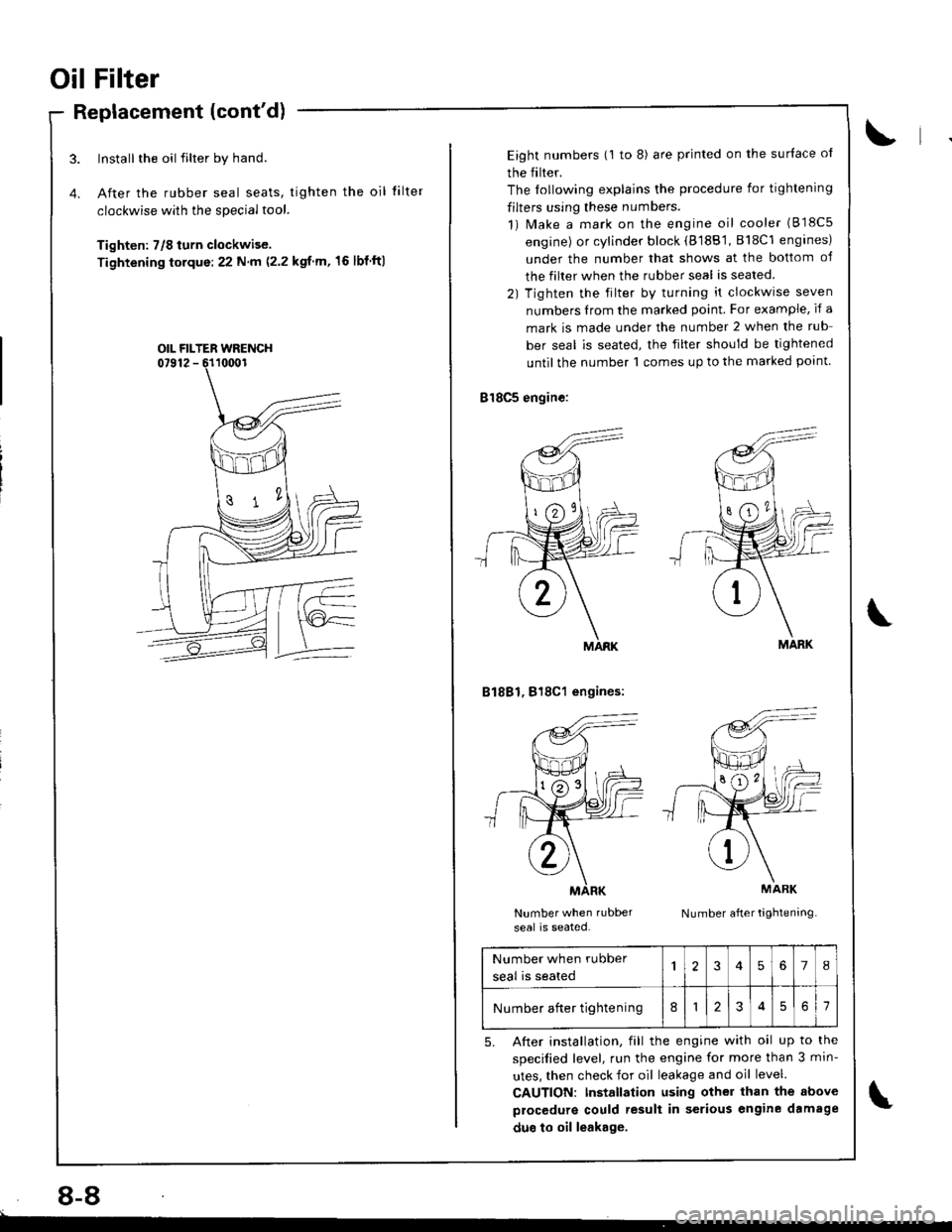

Oil Filter

Replacement (cont'd)

Install the oil filter by hand.

After the rubber seal seats, tighten the oil

clockwise with the special tool.

Tighten: 7/8 turn clockwise.

Tightening torque:22 N m (2.2 kgf m,'16 lbf ftl

tilte r

OIL FILTER WRENCH

8-8

Eight numbers (1 to 8) are printed on the surlace ol

the filter.

The lollowing explains the procedure for tightening

filters using these numbers.

1) Make a mark on the engine oil cooler (818c5

engine) or cylinder block (8188'1, 818C1 engines)

under the number that shows at the bottom of

the filter when the rubber seal is seated.

2) Tighten the filter by turning it clockwise seven

numbers Irom the marked point. For example, if a

mark is made under the number 2 when the rub

ber seal is seated, the filter should be tightened

until the number 1 comes up to the marked point

818C5 engine:

B1881, 818C1 engines:

Number when rubber

seal is seated.Number after tightening

MARK

MARK

Number when rubber

seal is seated

'I2345678

Number after tightening812561

5. After installation, fill the engine with oil up to the

specilied level, run the engine for more than 3 min-

utes, then check for oil leakage and oil level.

CAUTION: Installation using other than the above

procedure could result in serious engine damage

duo to oil leakage.

Page 183 of 1681

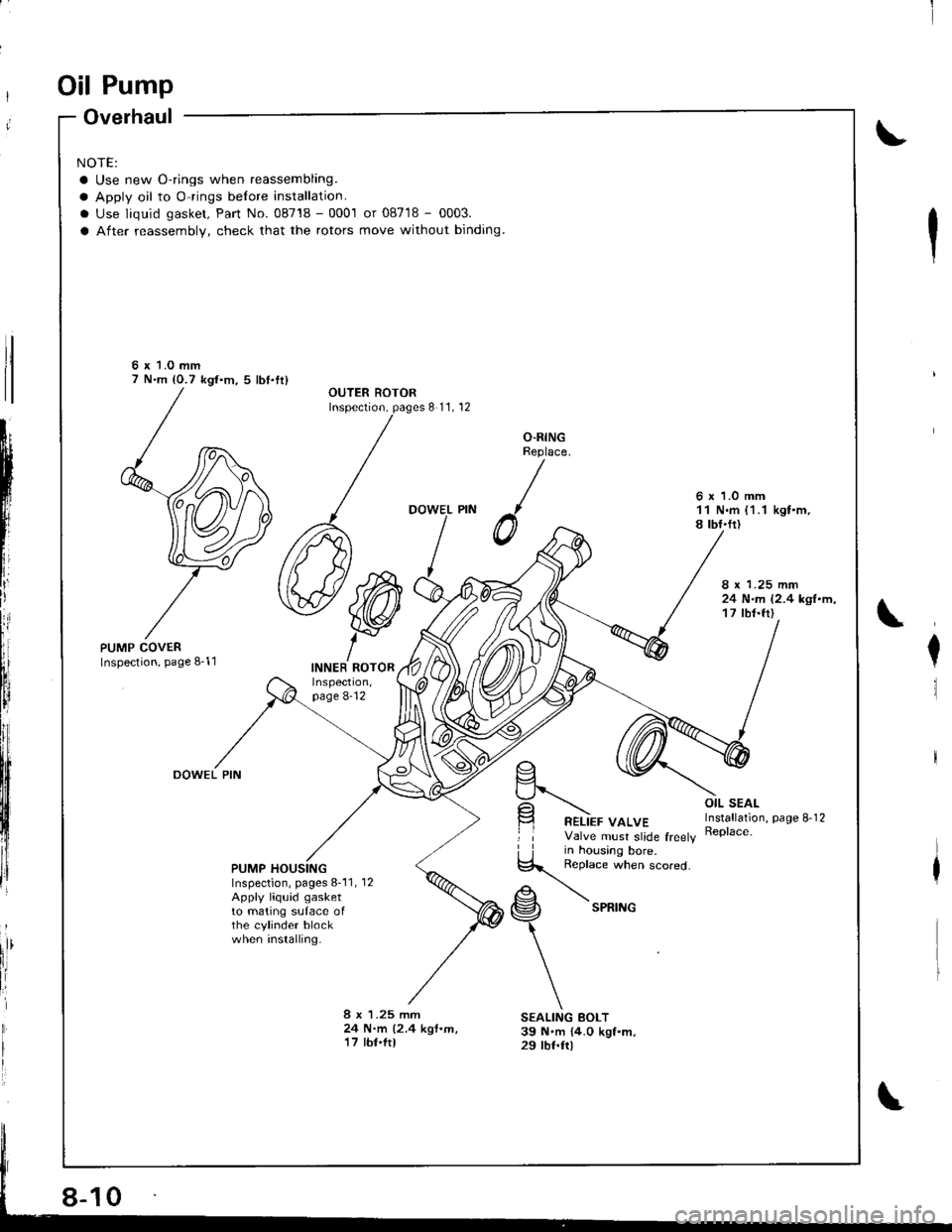

Oil Pump

Overhaul

NOTE:

a Use new O-rings when reassembling.

a Apply oil to O-rings belore installation.

. Use liquid gasket, Pan No. 08718 - 0001 or 08718 - 0003.

a After reassembly, check that the rotors move without binding.

6 x 1.0 mm7 N.m 10.7 kg{.m, 5 lbf.fr}OUTER ROTORInspection, pages 8 11, 12

SEALING BOLT39 N.m {4.0 kgf.m,29 rbf.ftl

t

n

I'

F'

ii

[]lir

ffi

O.RINGReplace

/6 x 1.0 mm11 N.m (1.1 kgt.m.8 tbf.fr)

8 x 1.25 mm24 N.m 12.4 kgl.m.17 lbt.fr)

DOWEL PIN

PUMP HOUSINGInspection, pages 8-'11, 12Apply liquid gasketto mating suface ofthe cylinder blockwhen installing.

8 x 1.25 mm24 N.m (2.4 kgf.m,17 tbt.ftl

Page 185 of 1681

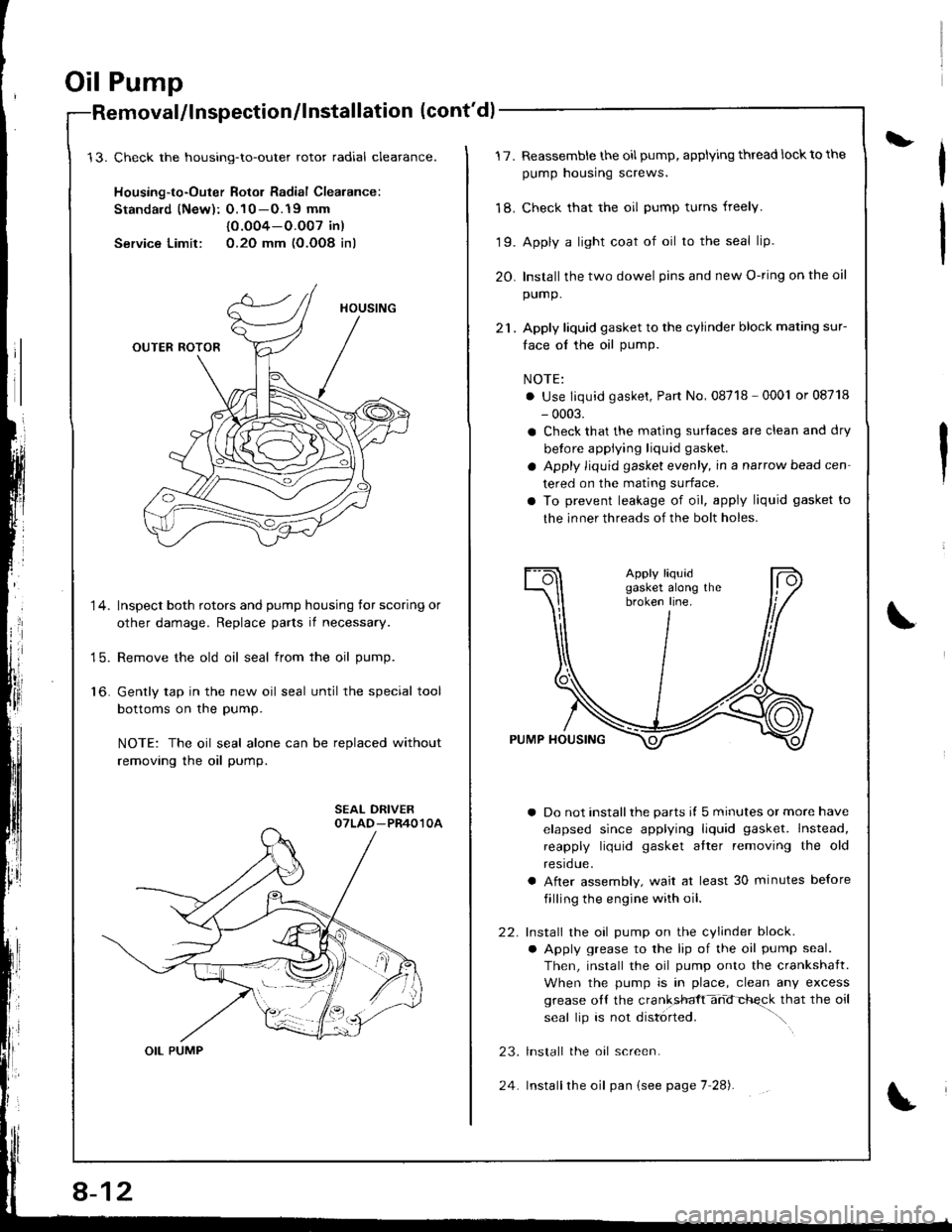

Oil Pump

Check the housing-to-outer rotor radial cleatance.

Housing-to-Outer Rotor Radial Clearance:

Standald (New): O.10 -O.19 mm

{0.O04-O.O07 in)

Service Limit: 0.2O mm (O.OO8 inl

Inspect both rotors and pump housing tor scoring or

other damage. Replace parts if necessary.

Remove the old oil seal from the oil pump.

Gently tap in the new oil seal until the special tool

bottoms on the pump.

NOTE: The oil seal alone can be replaced without

removing the oil pump.

alllnspection/lnstallation (cont'd)

14.

15.

to.

OIL PUMP

8-12

24

L17.

'18.

19.

20.

Reassemble the oil pump, applying thread lock to the

pump housing screws.

Check that the oil pump turns freely.

Apply a light coat of oil to the seal lip.

Install the two dowel pins and new O-ring on the oil

pump.

Apply liquid gasket to the cylinder block mating sur-

face ol the oil pump.

NOTE:

. Use liquid gasket, Part No, 08718 - 0001 or 08718

- 0003.

a Check that the mating surlaces are clean and dry

betore applying liquid gasket.

a Apply liquid gasket evenly, in a narrow bead cen

tered on the mating surface.

a To prevent leakage of oil, apply liquid gasket to

the inner threads of the bolt holes.

a Do not installthe parts il 5 minutes or more have

elapsed since applying liquid gasket. Instead,

reapply liquid gasket atter removing the old

resrdue.

a After assembly, wait at least 30 minutes before

filling the engine with oil.

Install the oil pump on the cylinder block.

a Apply grease to the lip of the oil pump seal.

Then, install the oil pump onto the crankshaft.

When the pump is in place, clean any excess

grease oll the cranksfft-hd-chqck that the oil

seal lip is not disl6rted. ".\

lnstall the oal screen.

Installthe oil pan (see page 7 28).

22.

23.

Page 190 of 1681

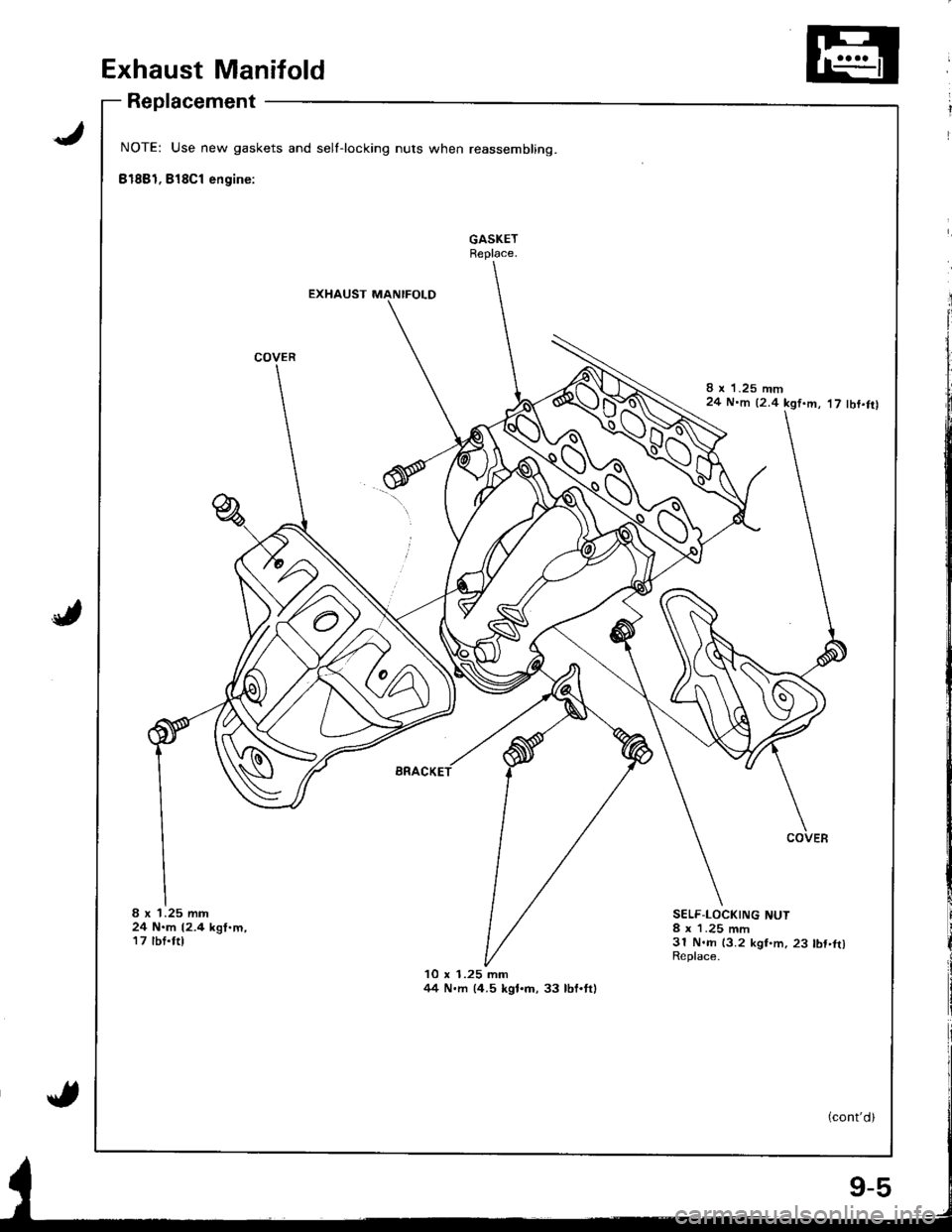

Exhaust Manifold

Replacement

NOTE: Use new gaskets and sell-locking nuts when reassembling.

81881, 818C1 engine:

EXHAUST MANIFOI-D

8 x 1.25 mm24 N.m (2.4 kgf.m, 17 tbt.trl

,t

8 x '1.25 mm24 N.m 12.4 kgt.m,17 lbt.ftl

SELF-LOCKING NUT8 x 1.25 mm31 N.m 13.2 kgf.m.23 tbl,fr)Replace.

10 x 1.25 mmrt4 N.m (4.5 kgl.m,33 lbf.ttl

N

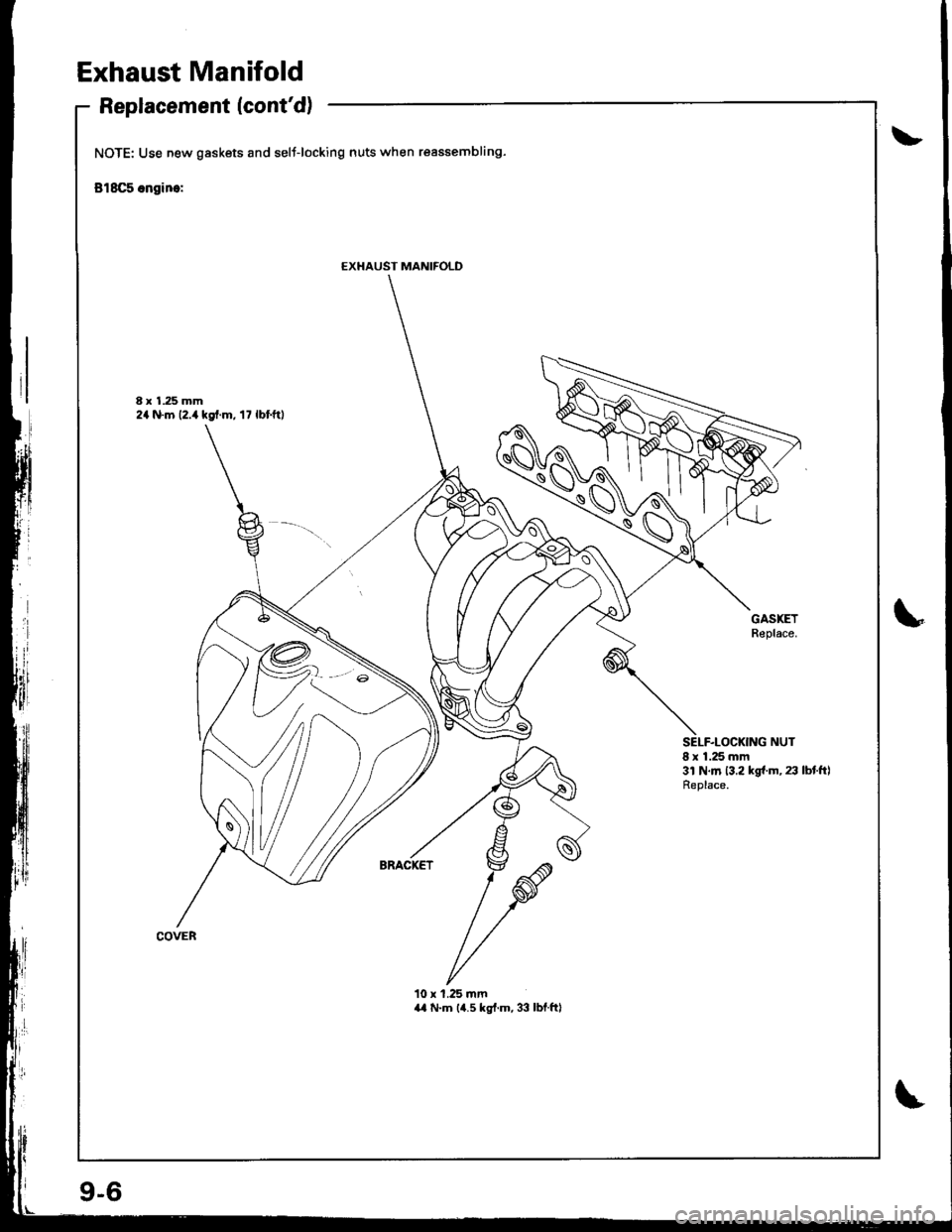

Page 191 of 1681

I

Exhaust Manifold

Replacement (cont'd)

NOTE: Use new gaskets and selt-locking nuts when reassembling-

818C5 ongine:

8 x 1.25 mm2a N.m 12.,r kgf.m, 17 lbf.ftl

GASKETReplace.

8 x 1.25 mm3l N.m 13.2 kgf.m, 23 lbtftlReplace.

10 x 1.25 mma,l N.m (4.5 kg{.m, 33 lbf.ftl

EXHAUST MANIFOLD

\A

9-6

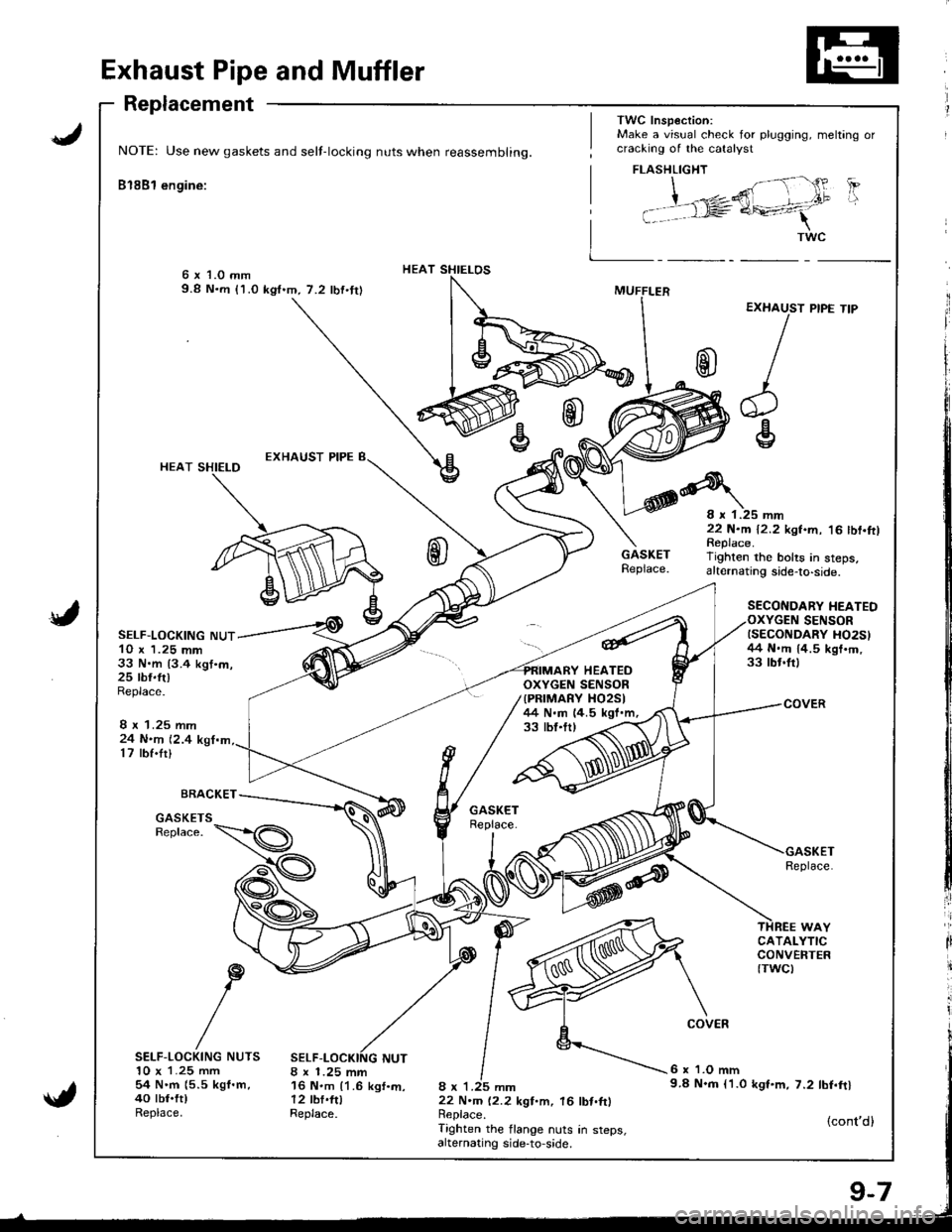

Page 192 of 1681

J

Exhaust Pipe and Muffler

Replacement

NOTE: Use new gaskets and self-locking nuts when reassembling.

Bl8Bl engine:

HEAT SHIELOS6 x 1.0 mm9.8 N.m (1.0 kgf.m,7.2 lbf.tr)

{

HEAT SHIELD

SELF-LOCKING NUT10 x 1.25 mm33 N.m {3.4 kgt.m,25 rbr.ft)Replace.

24 N.n 12.417 rbf.tr)

BRACKET

8 x 1.25 mm16 N.m {1.6 kgf.m,12 tbf.fttReplace.

33 tbt.tr,

8 x 1.25 mm22 N.m 12.2 kgf.m. 16 lbt.ftlReplace.Tighten the flange nuts in steps,alternating side-to,side.

Replace.

6 x 'l.O mm9.8 N.m l'1.0 kgt.m, 7.2 tbf.ftl

{cont'd}

GASKETSReplace.

ir

li

it

SELF-LOCKING NUTS10 x 1.25 mm54 N.m {5.5 kgf.m,40 tbt.ft)Replace.

TWC Insp€ction:Make a visual check for plugging, meltang orcracking of the catalyst

EXHAUST

/

r

HEATEDOXYGEN SENSOR{PRIMARY XO25I/+4 N.m 14.5 kgf.m,

FLASHLIGHT

| ;"1- {' 'PI i ,"*,2ffi - .t"

i t rl= a+-41

I _ _*"

PIPE TIP

8 r 1.25 mm22 N.m 12.2 kgf.m, '16 tbf.ftlReplace.Tighten rhe bolts in steps,altelnating side-to-side.

SECONDARY HEATEDSENSORISECONDARY HO2S}/+4 N.rn 14.5 kgt'm,33 tbr.frl

9-7