ignition HONDA INTEGRA 1998 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 295 of 1681

PGM-FI System

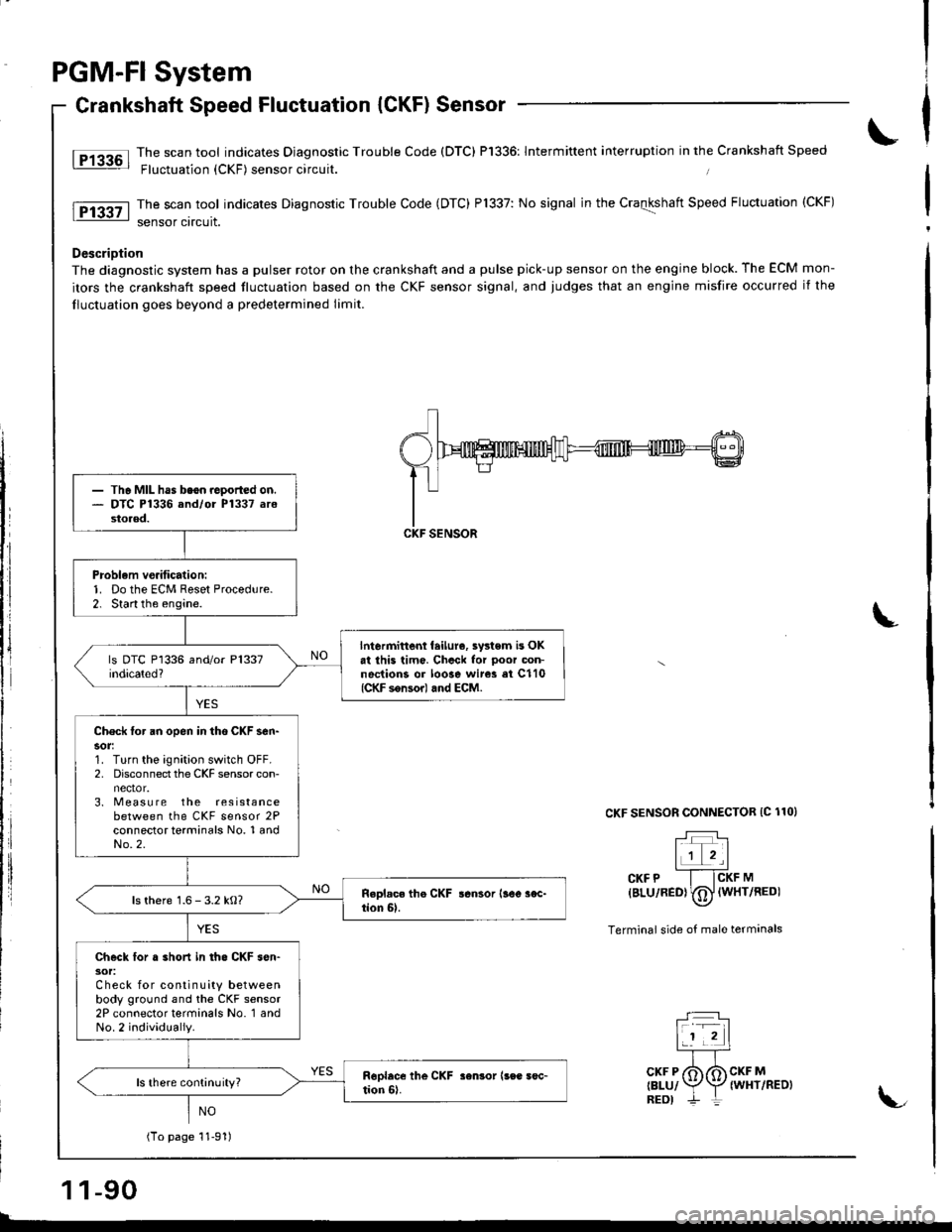

Crankshaft Speed Fluctuation {CKF) Sensor

lT13a6l Tje scan tool indicates Diagnostic Trouble Code (DTC) P'1336: lntermittent interruption in the Crankshaft Speed: Fluctuation {CKF) sensor orcurt.

The scan tool indicates Diagnostic Trouble Code (DTC) P1337: No signal in the Craqkshatt Speed Fluctuation (CKF)

sensor circuit.

DescriDtion

The diagnostic system has a pulser rotor on the crankshaft and a pulse pick-up sensor on the engine block. The ECM mon-

itors the crankshaft speed tluctuation based on the CKF sensor signal, and judges that an engine misfire occurred it the

lluctuation goes beyond a predetermined limit.

CKF SENSOR CONNECTOR IC 110)

T:lr+T

IJI',Icrr e -f-fcxr na

{BLU/RED} (D lwHr/REDI

Terminal side of male termanals

- The MIL has beon.ooorted on.- DTC P1336 and/or P1337 arostoaed.

Problem vo.itication:1. Do the ECM Reset Proced!re.2. Start the engine.

lntermittent feilure, swtem is OKat ihis timo. Chcck for ooor oon-noctions or loose wir* ei C110(CKF sonsor) and ECM.

Check for an open in tho CKF sen-sor:1. Turn the ignition switch OFF.2, Disconnect the CKF sensor con-

3. Measu re the resistancebetween the CKF sensor 2Pconnector terminals No. 1 andNo.2.

ls there 1.6 - 3.2 kO?

Check lor . short in tho CKF sen-30t:Check for continuity betweenbody ground and the CKF sensor2P connector terminals No. 1 andNo.2 individually.

ls there continuity?

(To page 11-91)

1 1-90

T:]lf -rl11 2|

TTcKF P /6 6 CKF M

relul Y\Z twxvneotneot ,-- | L

Page 297 of 1681

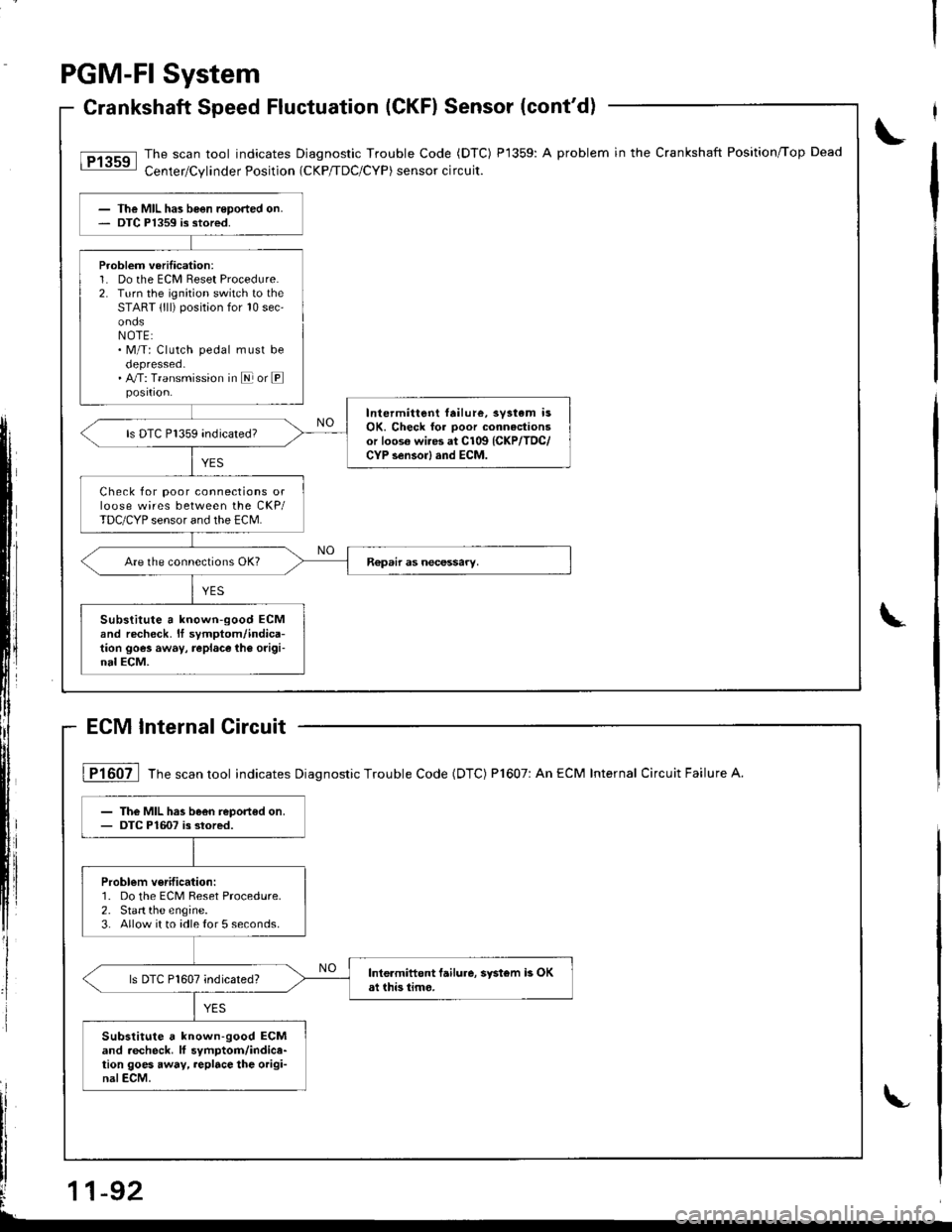

nsnan upeeo rlucruauon lunF, Densor lconr q,

The scan tool indicates Diagnostic Trouble Code (DTC) P1359: A problem in the Crankshaft Position,Top Dead

Cenler/Cylinder Position (cKP/TDC/CYP) sensor circuit.tPr3ssl

The MIL has been reported on.DTC P1359 is stored.

Problem verilication:1. Do the ECM Reset Procedure.2. Turn the ignition switch to theSTART {lll) positaon for 10 sec'

NOTE:. M/T: Clutch pedal must be

. A/T: Transmission in E or E

Intermittent failure, svstem isOK. Check for ooor connactionsor loos€ wi.es at C109 {CKP/TDC/CYP sensorl and ECM.

ls DTC P1359 indicated?

Check for poor connections orloose wires between the CKP/TDC/CYP sensor and the ECM.

Substitute a known-good ECMand recheck. It symptom/indica-tion goes away, replace ih6 origi-nal ECM.

PGM-FI System

Crankshaft Speed Fluctuatio(CKFI Sensor (cont'd)

ECM lnternal Circuit

\

L

I P1607 Tfre scan tool indicates Diagnostic Trouble Code (DTC) Pl607: An ECM Internal Circuit Failure A.

The MIL has been reported on.DTC P16O7 is stored.

Problem verification:1. Do the ECM Reset Procedure.2. Start the engine.3. Allow it to idle {or 5 seconds.

Inte.miftent failure, systom L OKst this iimo.ls DTC P1607 indicated?

Substitute a known-good ECMand .echeck. lf symptom/indica-tion goes away, replace the origi-nalECM.

-92

Page 298 of 1681

J

a

I

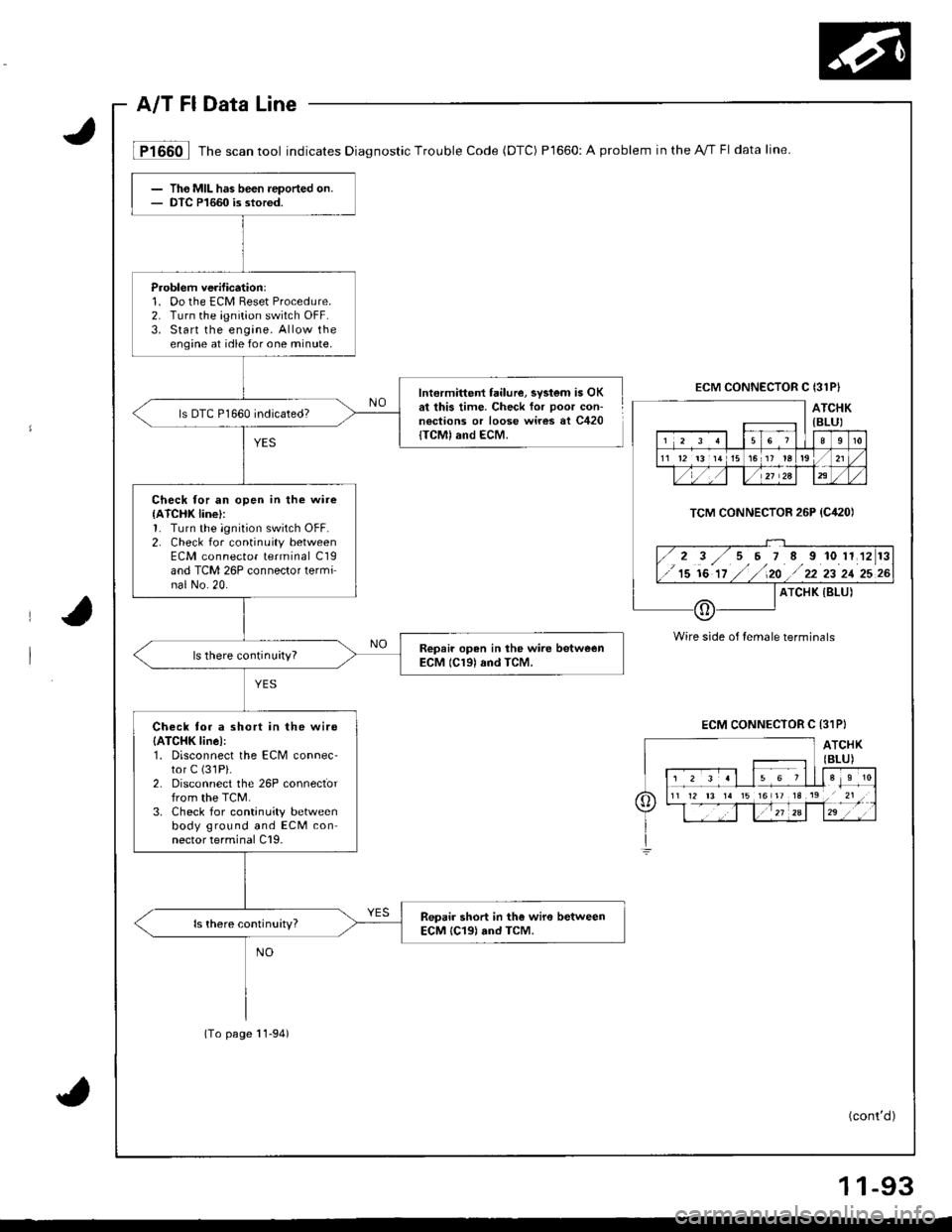

lF1660l Th"""untool indicates Diag nostic Trou ble code (DTC) P1660:Aproblem in theA./rf Fl data line.

Wire side of temale terminals

(conr'd)

ECM CONNECTOR C I31P}

ATCHK{BLUI

1 2 3 1l 15 6 710

11 t2 131r t5 16 1? t8'tg /21

././I l/nzex)

TCM CONNECTOR 26P (C,r2ol

7 r-T7 s 6 ;i-g-io-rrJzlil

15 16 17 / /.20 22 23 21 25 26

ATCHK IBLU)

o

ECM CONNECTOR C {31PI

Th6 MIL has been reported on.DTC P16GO is stored.

Problem verificationl1. Oo the ECM Reset Procedure.2. Turn the ignition switch OFF.3. Start the engane. Allow theengine at idle for one minute,

lntermittent failure, swtem is OKat lhis time. Check lor poor con-n€ctions or loose wires at C420ITCMI and ECM.

ls DTC P1660 indicated?

Check for an open in the wire

{ATCHK line}:1. Turn the ignition switch OFF.2. Check for continuity betweenECM connecto. terminal C19and TCM 26P connector terminal No.20.

Repair open in the wire betweenECM (Cl9) and TCM.ls there continuity?

Check tor a short in the wire{ATCHK line):1. Disconnect the ECM conoec'tor C (31P).

2- Disconnect the 26P connectorfrom the TCM.3. Check for continuity betweenbody ground and EcM connector terminal Cl9-

Repair short in the wire betweenECM lC19) and TcM.

(To page 11-94)

11-93

Page 300 of 1681

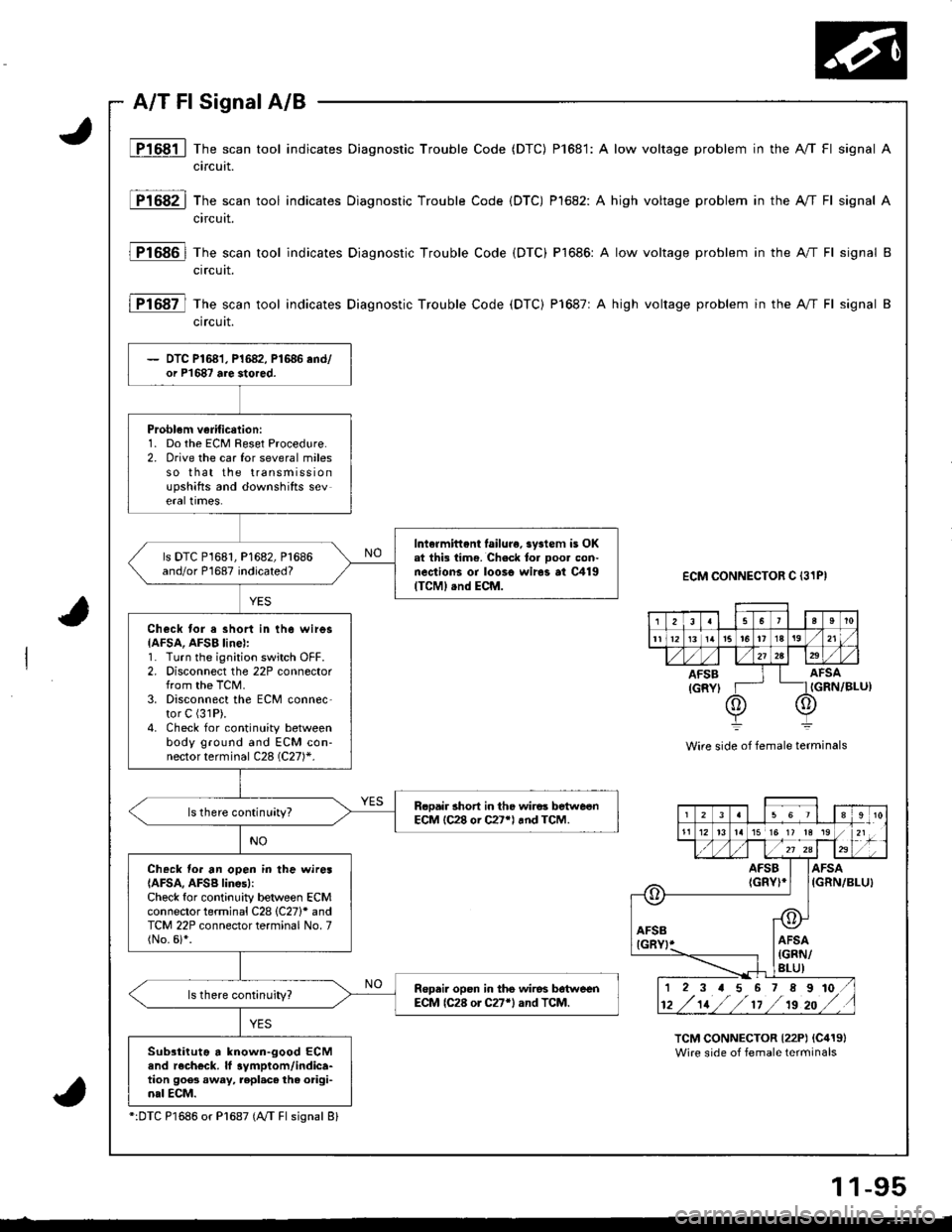

JP1681 | The scan tool indicates Diagnostic Trouble Code (DTC) P1681: A low voltage problem in the A/T Fl signal A

circuit.

P1682 | The scan tool indicates Diagnostic Trouble Code {DTC) Pl682: A high voltage problem in the A//T Fl signal A

circuit.

]TtOgOl fh" scan tool indicates Diagnostic Trouble Code (DTC) P1686: A low voltage problem in the A"/T Fl signal B

ctrcutt.

lFt Ogt-l fh" scan tool indicates Diagnostic Trouble Code (DTC) P1687: A high voltage problem in the A"/T Fl signal B

crrcurt.

ECM CONNECTOR C {31PI

IGRN/BLU)

Wire side of female terminals

TCM CONNECTOR {22P) {C419}Wire side of female terminals

2!a5't0

tl1213 tatat6It1a19 ,/

AFSB I I AFSA

{GRYI T- _IIGRN

@)o

2311to21 ;'15 15 17 13 13

E./ zl za

G-\

AFSIGR

\-

a

AFlGl

I

sBl

L]

r@!I AFSA

| {GRN/lRt ltl

iFSGRIA[/BLUt

12 3 a 5 6 7 89

tz /'tt //t't /ts zo

to ,/

DTC P1681, P1682, P1686 end/or P'1687 are stored.

Problem verificetion:1. Do the ECM Reset Procedure.2. orive the car for several milesso that the transmissionupshifts and downshifts severarlrmes.

Intormittent lailure. system is OKat thi3 tim€. Check tor ooo. con-nections or loo3o wir6s al C419{TCM} .nd ECM.

ls DTC P1681, P1682, Pl686and/or P1687 indicated?

Check tor a short in th6 wires{AFSA, AFSB linel:1. Turn the ignition switch OFF.2, Disconnect the 22P connectorfrom the TCM.3. Disconnect the ECM conn6c-tor C (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C28 (C27)*.

Rcoair 3hort in tho wiros betweenECM lC28 or C27*l rnd TCM.ls there continuity?

Check fo. an open in the wiresIAFSA, AFSB lines):Check for continuity between ECMconnector terminal C28 (C27)* andTCM 22P connector terminal No. 7(No.6i*.

Repai. opsn in the wiros bdtweenECM lC28 or C27'l and TCM.

Subsiiiutg a known-good ECMend r6ch€ck. lf 3ymptom/indica-tion goes away, repl.c6 the origi-nal ECM.

":DTC P1686 or Pl687 (NT Fl sisnal 8l

1 1-95

Page 304 of 1681

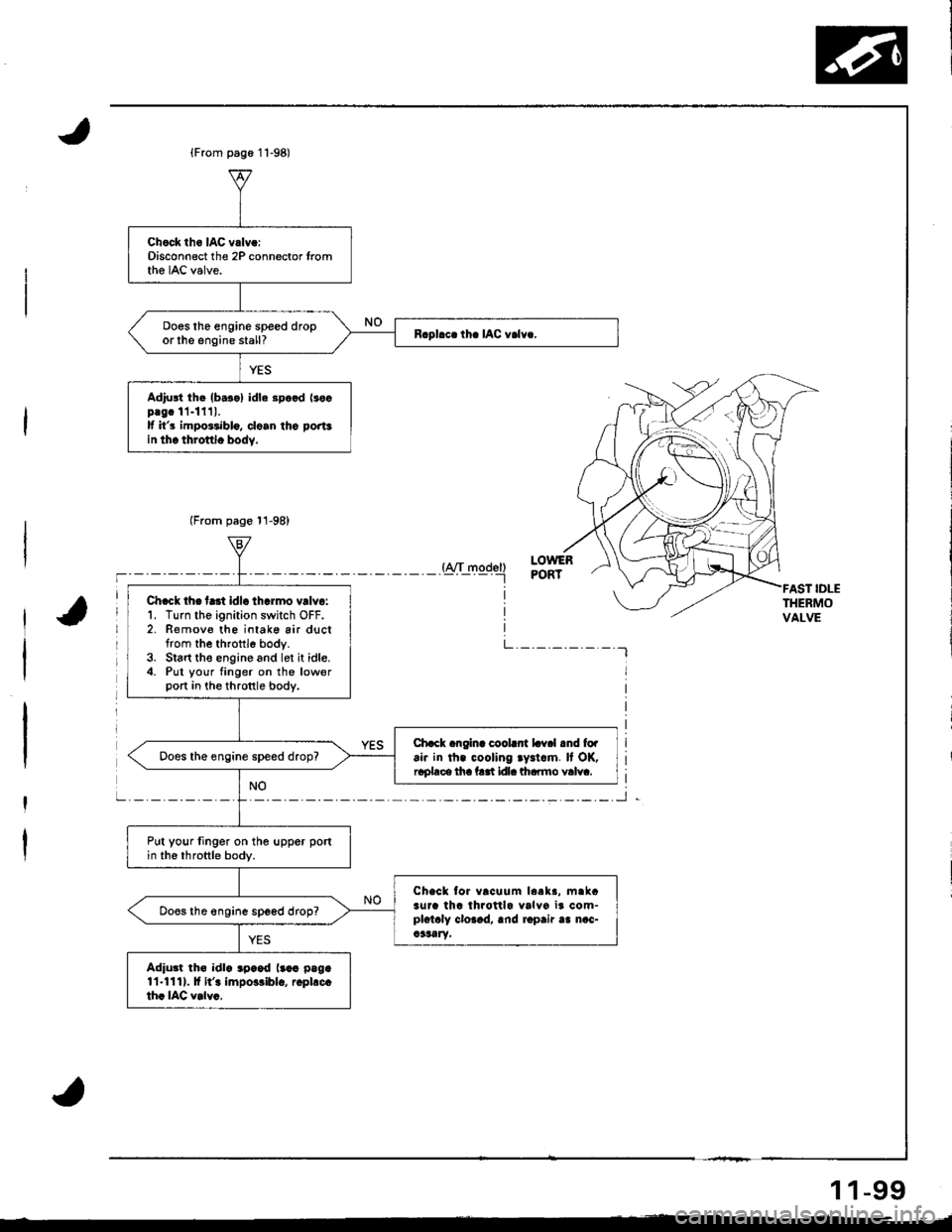

Chock th6 IAC vrlv.:Disconnect the 2P connector tromthe IAC valve.

ooes lhe engine speed droporlhe engine stall?

Adiu3t th. lb.r.l idle Bp..d lrocplgc 11-1111.lf it's impo3.iblo, clo.n tho portsin thc throftlc body.

Ch.ck th€ frtt idl. th.rmo vrlv.:1, Turn the ignition switch OFF.2. Remov€ th6 intake air ductfrom the throttle body.3. Slart the engine and let it idle.4. Put your finger on the lowerport in the thronle bodv.

Chack angina coobnt Lv.l and fo.ai. in th. cooling ry.l.m. It OK,r.place tha fatt ldla lftarmo valva.Does the engine speed drop?

Put your linger on the uppor portin the throttle body.

Chacl tor vrcuum leek3, m.lcilJa th6 throttlo valvo ir com-plotaly cloaad, rnd ropair aa nac-a3aatY,

ooes ihe engin6 speed drop?

Adiutt th€ idl. .p..d l..r p.g.11-1111. lf it'. impo3riblo, rcpl.c.thc IAC v.lvc.

{A/T model)----tLOWERPORT

L. _. _._. _. _. _.-l

IDLETHERMOVALVE

1 1-99

Page 305 of 1681

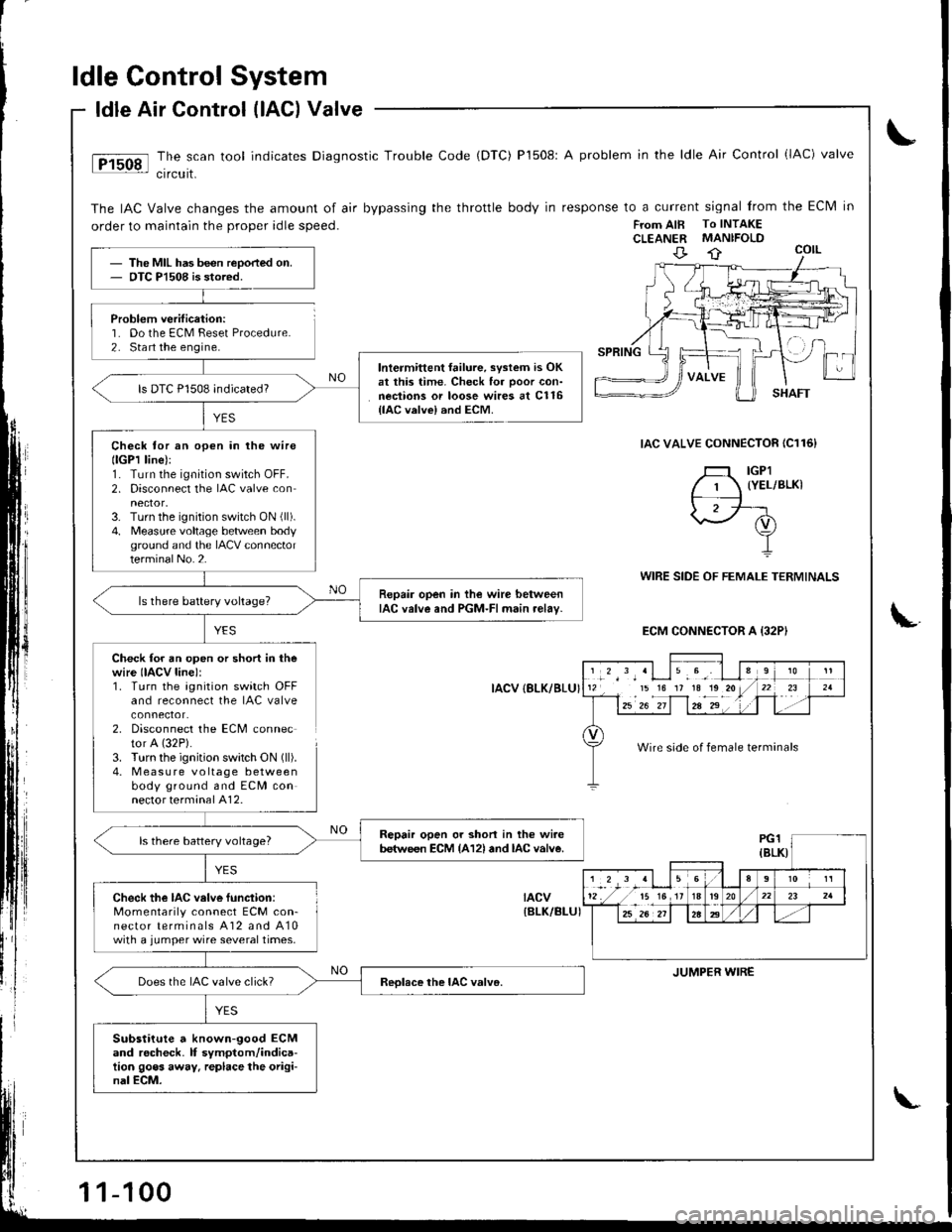

ldle Control System

Problem verification:'1. Do the ECM Feset Procedure.2. Sta rt the engine.

ldle Air Control (lAG) Valve

The scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Control (lAC) valve

crrcurt.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the Eclvl in

order to maintain the proper idle speed.FTom AIB To INTAKECLEANER MANIFOLD

IAC VALVE CONNECTOR IC116}

YES

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR A {32PI

Check for an open or short in thewire IIACV line):1. Turn the agnition switch OFFand reconnect the IAC valve

2. Disconnect the ECM connector A (32P).

3. Turn the ignition swatch ON (ll).

4. M easu re voltage betweenbody ground and ECM connector terminal A12.

IACV {8LK/BLU}

tacv{BLK/BI-UI

The MIL has been reoorted on.OTC Pl508 is stored.

lntermittent failure, svstem is OKat this time. Check for ooor con-nections or loose wires at C116{lAC valvel and ECM.

ls DTC P1508 indicated?

Check tor an open in lhe wirellGPl line):1. Turn the ignition switch OFF.2. Disconnect the IAC valve con

3. Turn the ignition switch ON (ll).

4. Measure voltage betlveen bodyground and the IACV connectorterminalNo.2.

Repair open in the wire betweenIAC valve and PGM-FI main relav-ls there battery voltage?

Repair open or shon in the wi.ebetween ECM {A12l and lAc valve.ls there battery voltage?

Check the IAC velve function:Momentarily connect ECM con-nector terminals A12 and A10with a jumper wire several times.

Does the IAC valve click?

Substitute a known-good ECMand rocheck. lf symptom/indica-tion goes away. replace the origi-nal ECM.

','*',,'Llu.9', I l112 15 16 17 1a1o20/

l--12u1 z"-if1za-2"' . '1 .

910

t-r '21

Wire side of female terminals

JUMPER WIRE

1-100

Page 306 of 1681

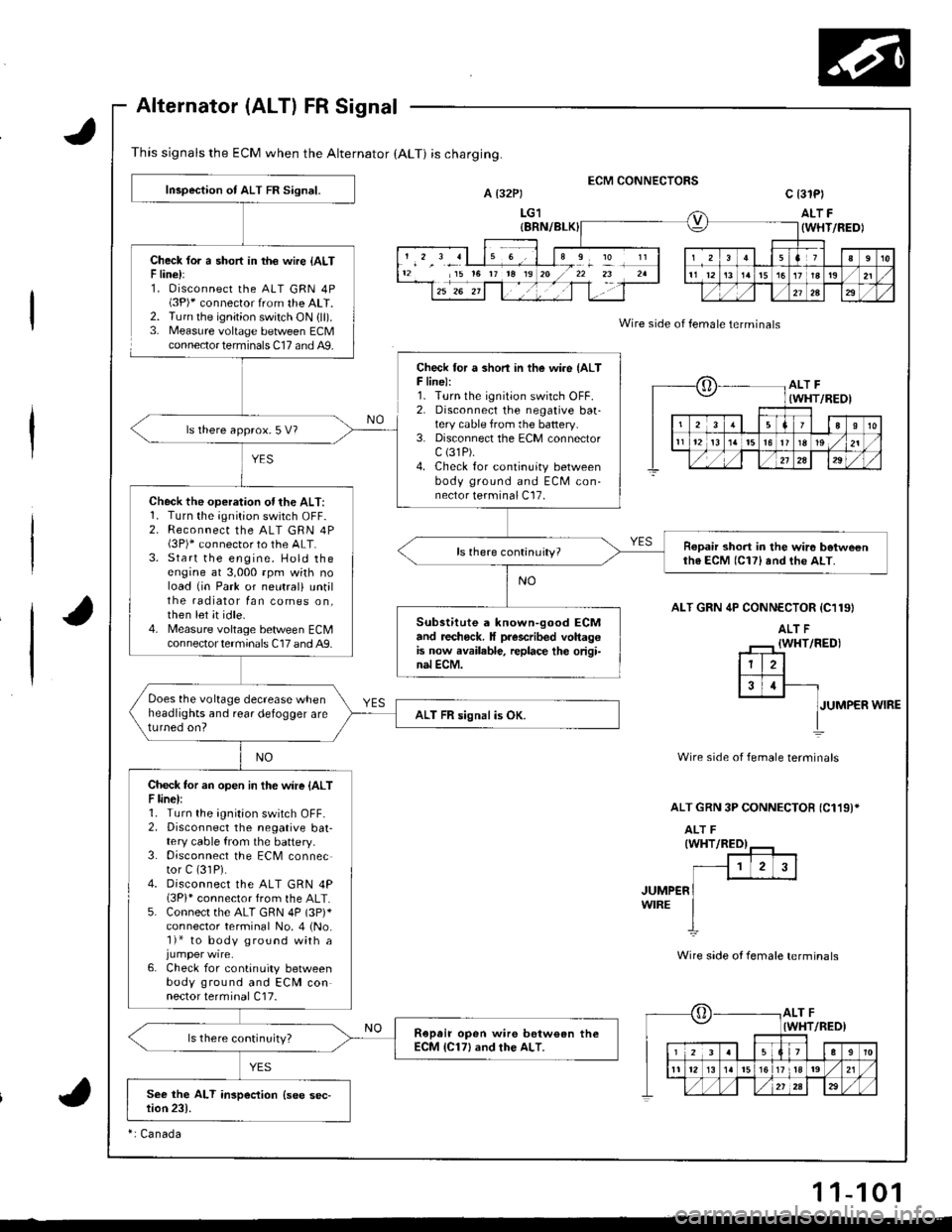

This signals the ECM when the Alternator (ALT) is charging.

Alternator (ALT) FR Signal

Check lor a short in th€ wire {ALTF line):1. Oisconnect the ALT GRN 4P(3P)* connector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECMconnector terminals C17 and A9.

ECM CONNECTORSA t32Pt

LG1

c 13lPl

ALT F(WHT/FEDI

Wire side of female terminals

ALT GRN 4P CONN€CTOR {C119}

JUMPER WIRE

Wire side of female terminals

ALT GRN 3P CONNECTOB {C119)*

JUMP€RWIRE

Wire side ot female terminals

12 15 t6 rr t8 19I

?

oALT F(WHT/REOI

23aI10

t112t3t5l6r819 ,/21

./,/,/2a29

[,ALT FIWHT/RED)

12339

11 12l517 tla19 ,/21

Inspection of ALT FR Signal.

Check for a shon in the wire {ALTF line):1. Turn the ignition switch OFF.2. Disconnecl the negative baatery cable from the battery.3. Disconnect the ECM connectorc (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C17.

ls there approx.5 V?

Check the operation ofthe ALT:1. Turn the;Onition switch OFF-2. Reconnect the ALT GRN 4P(3P)* connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm wkh noload {in Park or neutral) untilthe radiator fan comes on,then let it idle.4. Measure voltage bet/veen ECMcon nector termina ls C17 and A9.

Ropair short in the wir6 betweenth6 ECM (C17) and the ALT.

Substitute a known-good ECMand recheck. It prescribed voltagGis now available, replace th€ origi-nal ECM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire {ALTF line):1. Turn the ignition switch OFF-2. Disconnect the negative bat-tery cable from the battery.3. Disconnect the ECM connector C (31P).

4. Disconnect the ALT GRN 4P(3Pi* connector from the ALT.5. Connect the ALT GRN 4P (3p)*

connector terminal No. 4 (No.'l)* to body ground with a

6. Check for continuity betweenbody ground and ECM connector terminal C17.

Ropair open wire bstw€an theECM {C17} and rhe ALT.ls there continuity?

ri Canada

11-101

Page 307 of 1681

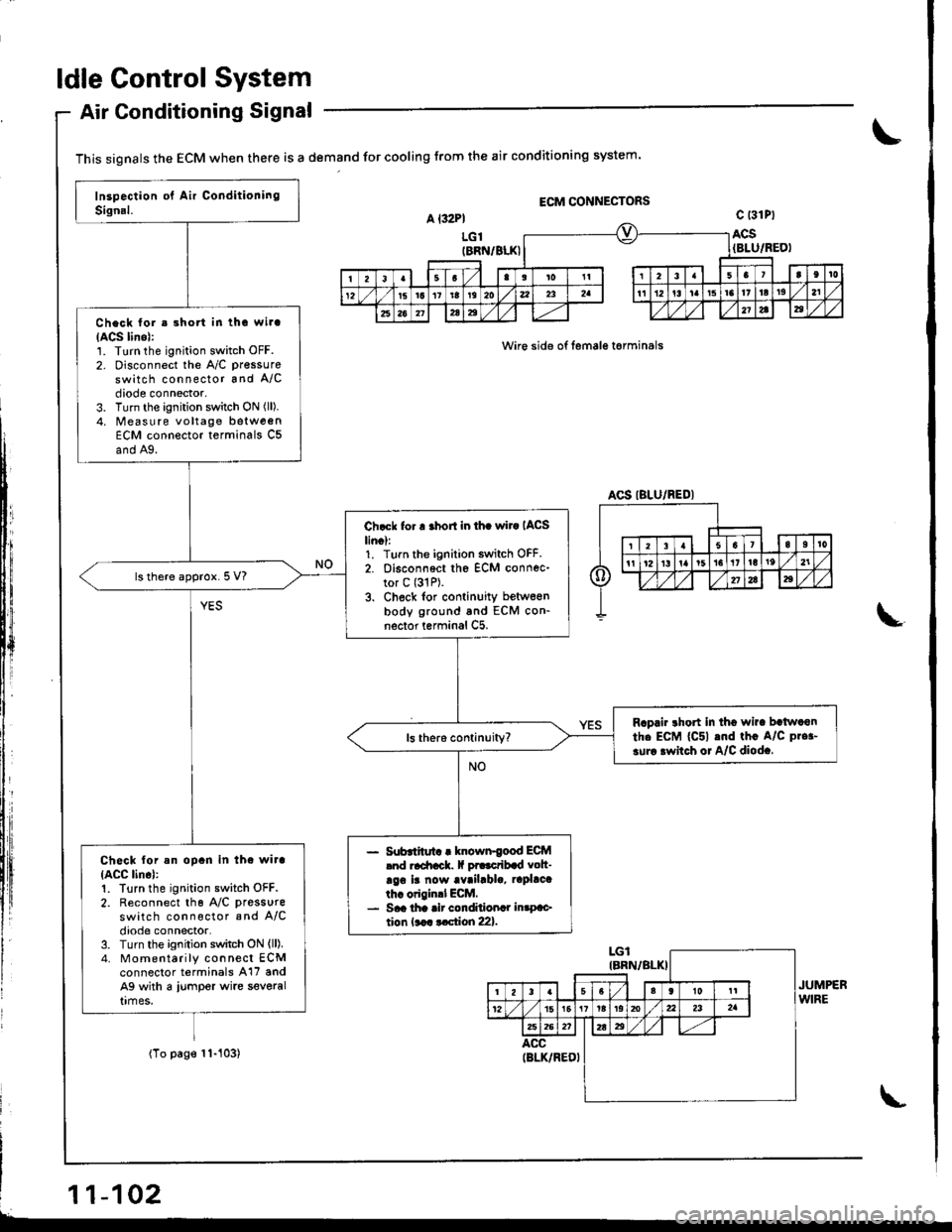

ldle

Air

Gontrol System

Gonditioning Signal

\

This signals the ECM when there is a demand for cooling from the air conditioning system'

ECM CONNECTORS

a l32Pl

LGl(BRN/BLKI

c t31Pt

ACSIBLU/REDI

wire side of femal€ torminals

;

L

LGI

JUMPERWIRE

ACS IBLU/REDI

Check lor.3hort in thG wira(ACS lino):1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch connector and A/Cdiode connector,3. Turn the ignition switch ON (ll).

4. Measu re voltage betwo€nECM connector terminals C5and A9.

Ch.ck to.. rhorl in th. wir. IACSlincl:1. Turn the ignition switch OFF.2. Disconnect the ECM connec-tor C (31P).

3. Ch6ck {or continuity betwe€n

body ground tnd ECM con-nector terminal C5.

lsthere approx.5 V?

Rapair rhort In tho wira batwaon

th. EcM {c5l and thc A/c pre.-

sur. rwitch ot A/C diod.,

- Subtlilut I known{ood Ecttllnd raahack. lf prtactibad voft-

rgo ir now avaihbla, tcplacalh. originll ECM.- Saa tha air condhiond in.plction 1... r.ction 221.

Check lor an opan in th€ wi.a(ACC lin.l:'1. Turn the ignition switch OFF.2. Reconnect th6 A,/C pressure

switch connector and A/Cdiode connector.3. Turn the ignilion switch ON (ll).

4. Momentarily connect ECMconnector terminals A'17 andAg wkh a iumper wire severaltimes,

(To page 11"103)

IBRN/BLKI

Ial,/l l8 I r0 I rl

12't516 11alrslzo ,/ l4l a3 | 2.

aa2621zel dt

IBLK/REDI

11-102

\

Page 310 of 1681

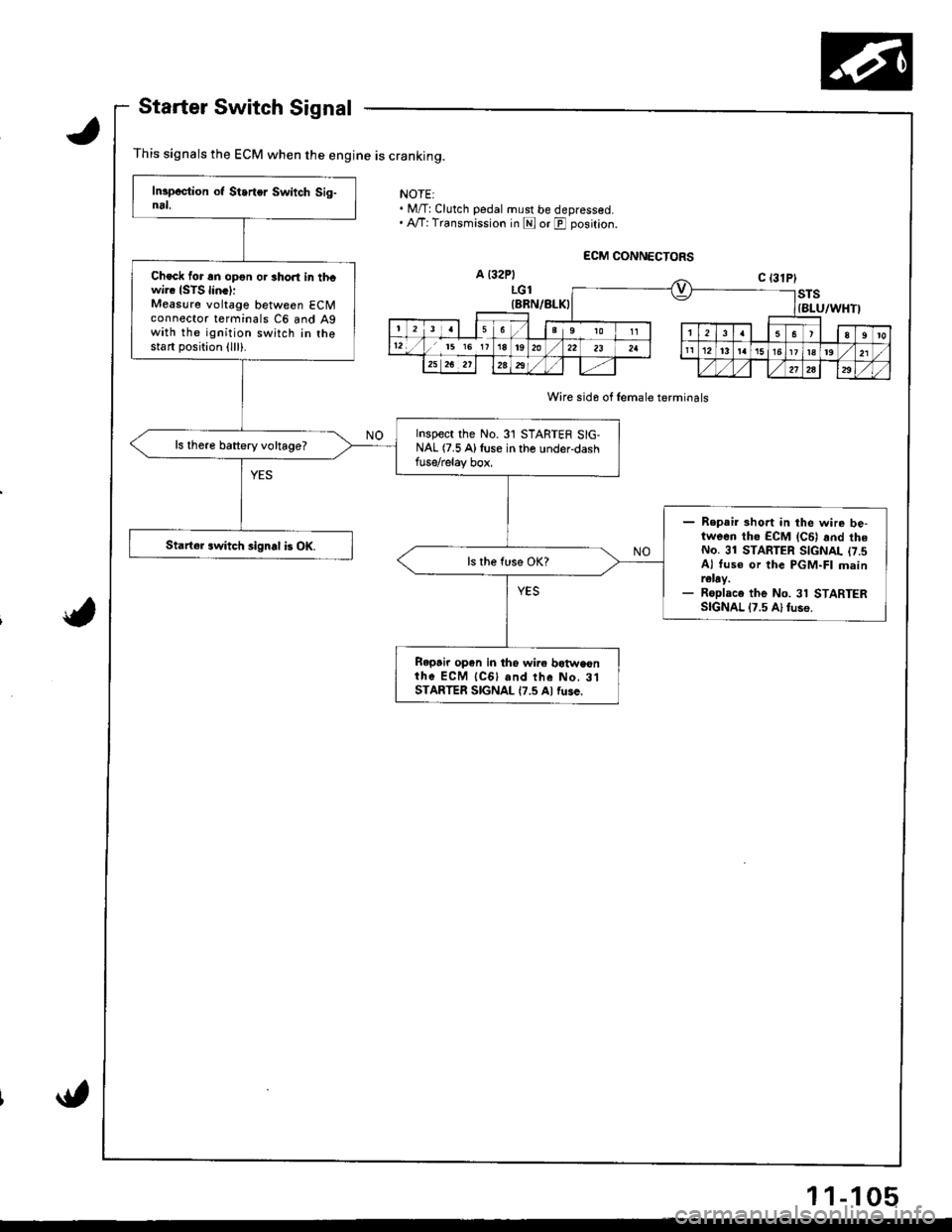

Starter Switch Signal

This signals the ECM when the engine is cranking.

NOTEI. M/T:Clutch pedal must be depressed.. A,/T: Transmission in E or E position.

Wire sida of female terminals

Check for an opon or short in thcwi.. ISTS lin.l:Measure voltage between ECMconnector terminals C6 and Agwith the ignition switch in thostart position (lll).

Inspect the No.31 STARTER SIG-NAL (7.5 Alluse in the under-dashfuse/relay box,

ls there battery voltage?

- Repair 3hort in the wire be-tween tho ECM lc6l rnd theNo. 31 STARTER SIGNAL (7.sAl tus€ or the PGM-FI mainr€lay.- Roplace the No. 31 STARTERSIGNAL 17.5 Al fuso.

Starter switch signal b OK.

Ropair open in tho wire botwaonih6 ECM {CGl and the No, 3lSTARTER SIGNAL {7.5 Al fuse.

11-105

Page 311 of 1681

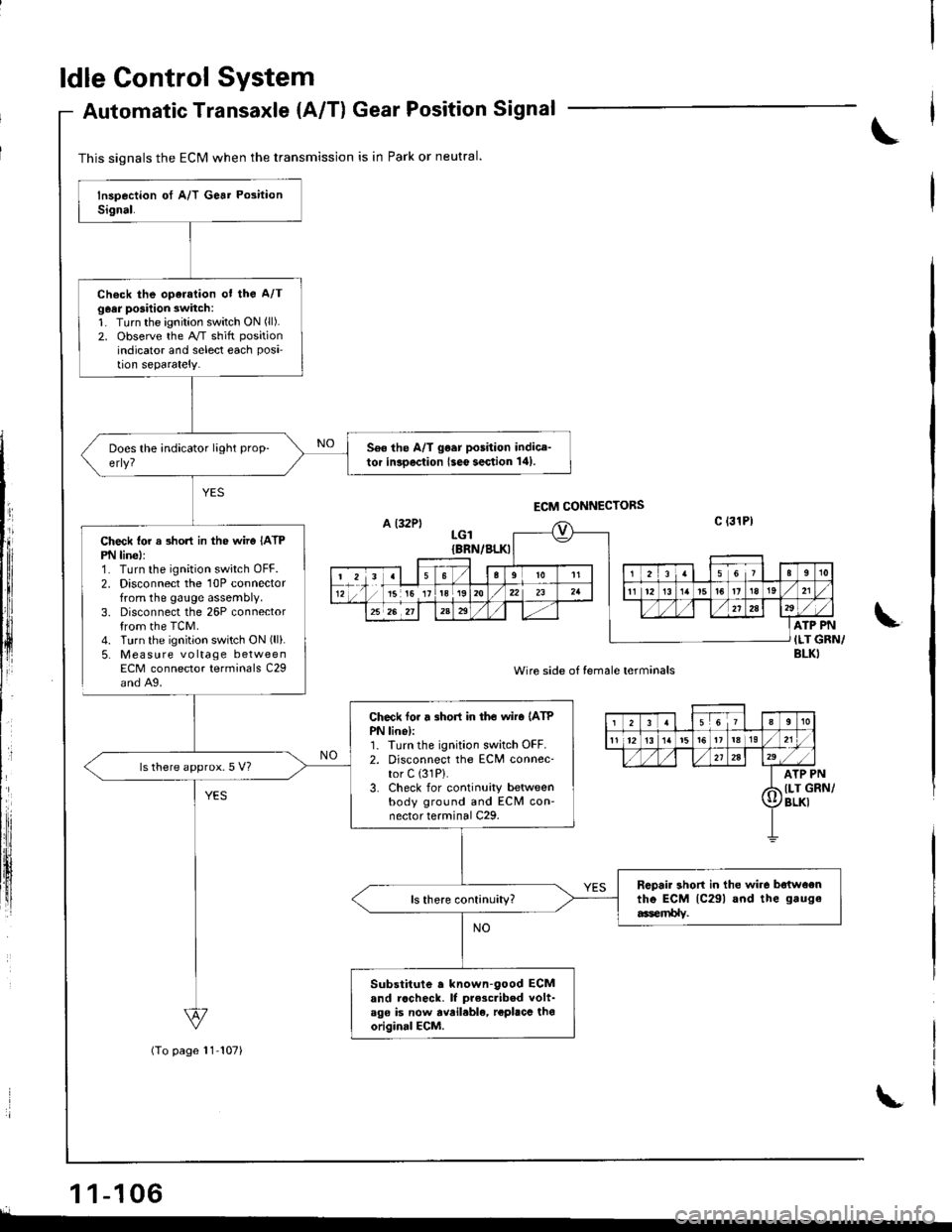

ldle Control System

Check lor a 3hon in the wiro IATPPN linel:1. Turn the ignition switch OFF.2. Disconnect the 10P connectorfrom the gauge assembly.3. Disconnect the 26P connectorfrom the TCM.4. Turn the ignition switch ON (ll).

5. Mea su re voltage betweenECM connector terminals C29and A9.

Automatic Transaxle {A/T) Gear Position Signal

1 1-106r.

This signals the ECM when the transmission is in Park or neutral.

(To page 11-107)

Check the oparation ot the A/Tg6ar posilion switch:1. Turn the ignition switch ON (ll).

2. observe the A/T shitt position

indicator and select each Posi'tion separately.

560 the A/T go.r position indice-tor inroection lseo section 141.

Check tor r 3hort in tho wiro (ATP

PN lino):1. Iurn the ignition switch OFF.2. Disconnect the ECM connec-tor C (31P).

3. Check for continuity betweenbody ground and ECM con'nector terminal C29.

ls there approx.5 V?

Rcpair short in the wir6 batwoentho ECM lc29l and the gauge

6er$lv.

Substitute a known-90od ECMand rccheck. lf prescribed volt-ago is now avail.ble, rcplacc thooriginal ECM.

,PN

GRN/

LGIIBRN/BLKI

ATP PN

ILT GRN/BLKI

Wire side of temale terminals

12355It0

11 1213t319

2A29/,a

I ArP

d llr (

Il/BLKI