ignition HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 355 of 1681

fIr

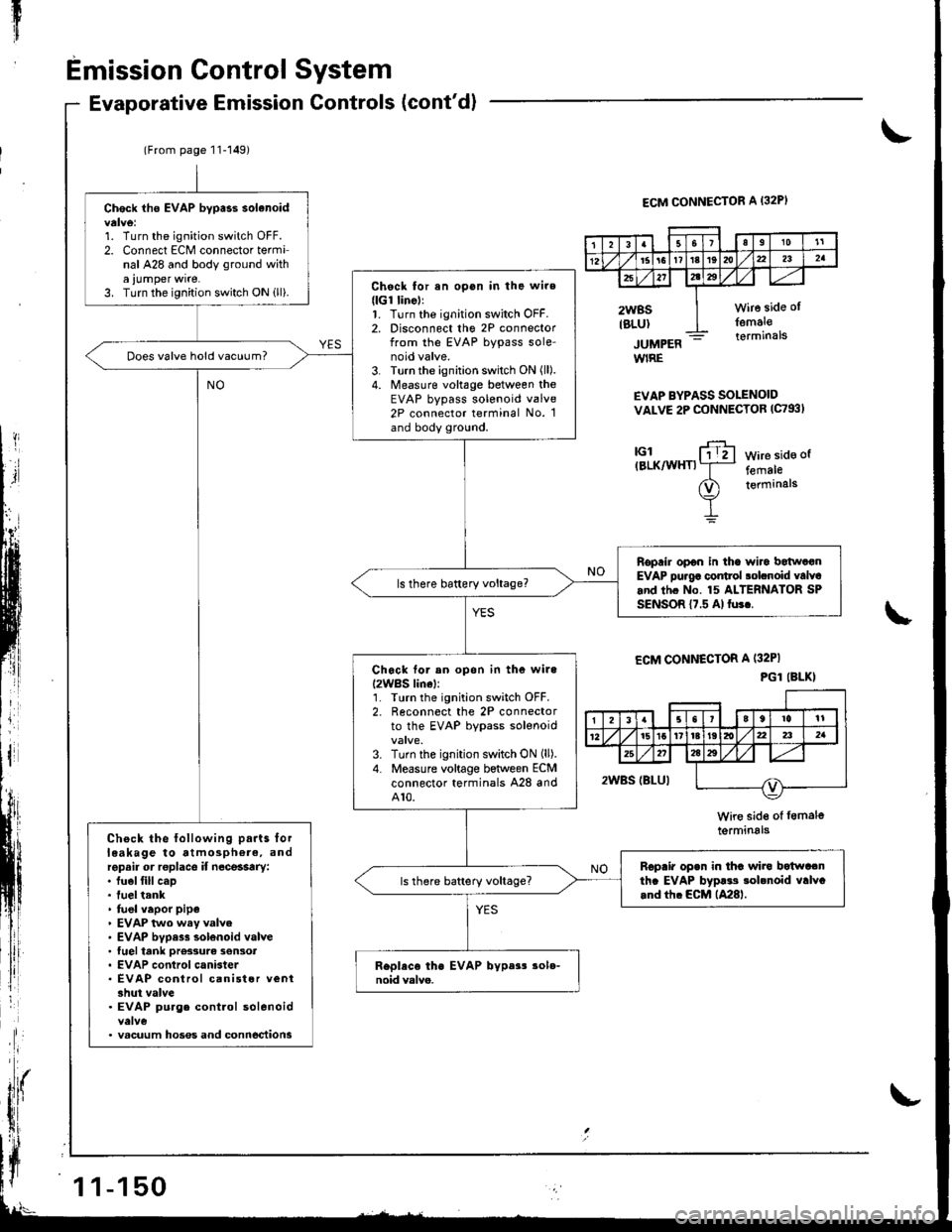

Emission Control System

Evaporative Emission Controls (cont'dl

t

ECM CONNECTOR A I32PI

JUMPERWIRE

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOB (C793I

tGl(BLK/WHTIWire side of

femaleterminals

\

ECM CONNECTOR A (32PI

PGl (BLKI

Wire side of lem6l6termrnals

(From page 11-149)

Check iho EVAP bypass solanoid

1. Turn the ignitioo switch OFF.2. Connect ECM connector terminal A28 and body ground witha ,umper wrre.3. Turn the ignition switch ON ill).Chock for an opon in the wire(lGr linell1. Turn the ignition switch OFF.2. Disconnect tho 2P connectorfrom the EVAP bypass sole-noid valve.3. Turn the ignition switch ON (ll).

4. Measure voltage between theEVAP bypass solenoid valve2P connector terminal No. 1and body ground.

Does valve hold vacuum?

Roprir opon in tha wiro batwatanEVAP pu.g6 control solcnoid valvcand thc No. 15 ALTERNATOR SPSENSOR {7.5 Al fu3..

Ch6ck tor an opon in the wile

I2WBS lin6l:'L Tlrrn the ignition switch OFF.2. Reconnect the 2P connectorto the EVAP bypass solenoid

3. Turn the ignition switch ON (ll).

4. Measure voltage between ECMconnector terminals A28 andA10.

Check the following parts lorleakage to atmosphere, andrepsir or roplace if n6ce$try:. fuel fill cap. fuel tank' fuel vapor pipe. EVAP two wsy valve. EVAP bvpess solenoid valve. tuel tank ore33urc son3ot. EVAP control canister. EVAP control canist6r veni3hut valve. EVAP purg. control solenoid

. vacuum hoses and conn6ctions

Rcpair opan in thc wira botwa.nth. EVAP byp!.s sobnoid valvc.nd tfi. ECM lA28l.

3Ia10't1

12l61611t8t9dta22a2a

x272tz3

2WBSIBLUI

wire side ol

femal€terminals

1 1-150

Page 439 of 1681

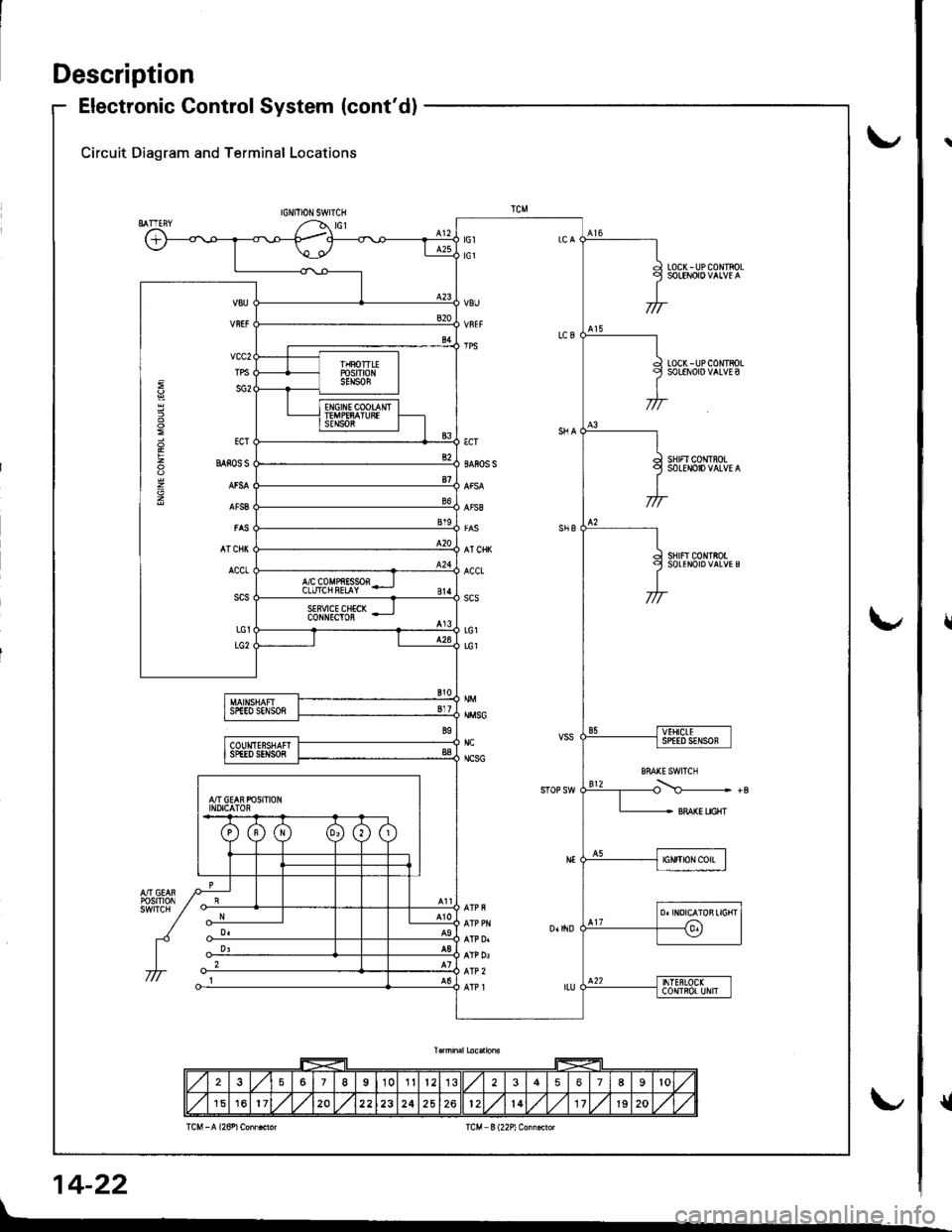

Description

Electronic Control System (cont'd)

Circuit Diagram and Terminal Locations

IGNITIONSWITCH

LOC(-UPCONTFOL

LOCK - UP COIITBOLSOLENOIO VALVE B

SHIFI CONTROLSOLENOID VALVE A

sHrFtc0NtRotSOLENOIDVALVES

€cT

SAFOS S

AT CHK

ACCt

scs

LG1

LG1

NMSG

NC

NCSG

vcc2

TPS

sG2

ECT

BAios s

AT CNI(

ACCt

LG1

LG2

257I10112356789lo

151620222324252612l417lg20

14-22

r

{

Page 465 of 1681

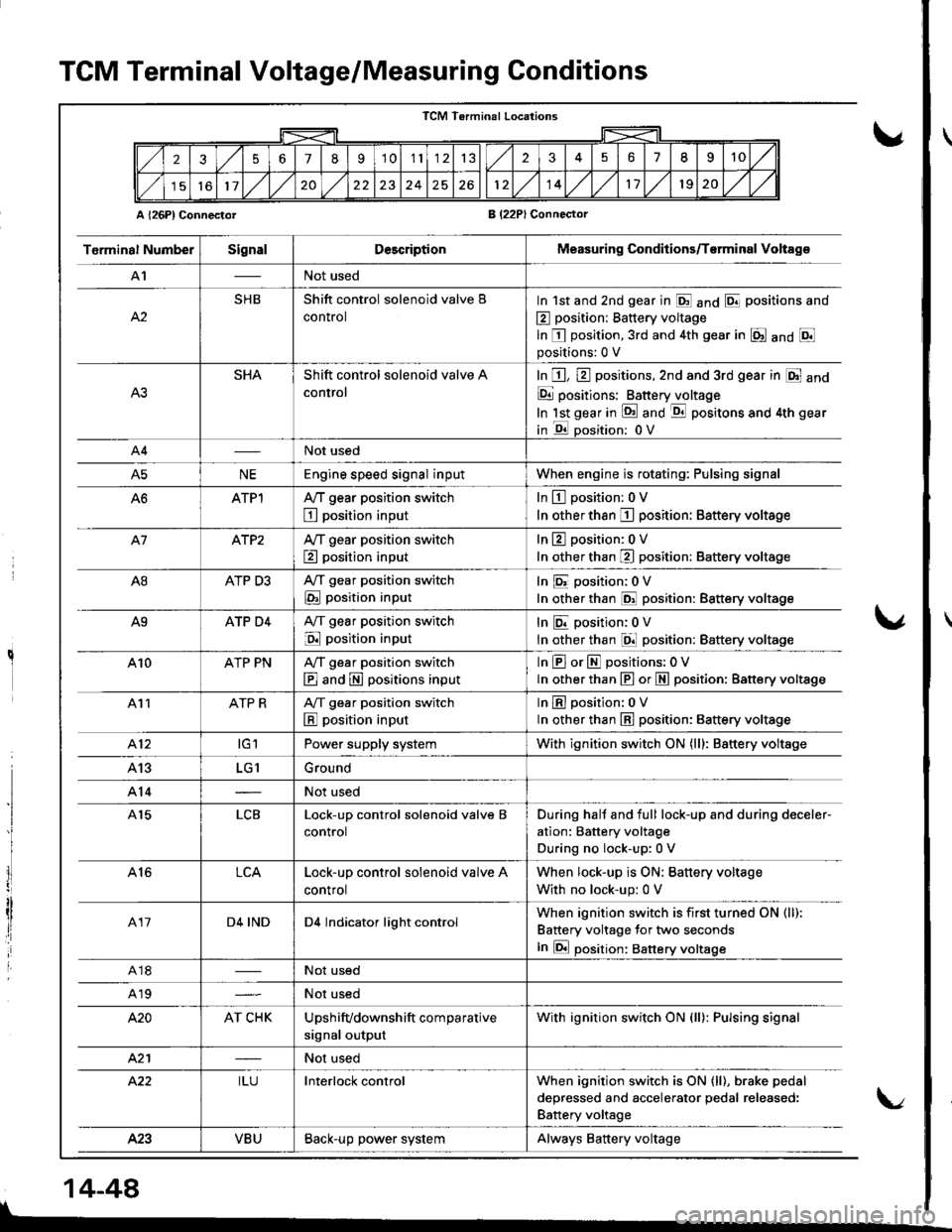

TCM Terminal Voltage/Measuring Conditions

A l26Pl ConnectorB (22PlConnector

TCM Terminal Locations

256789'1011132351II10

11,/l/2024261214,/l/1120,/1,/

T6rminal NumberSignalDescriptionMeasuring Conditions/T€rminal Voltag€

A'INot used

A2

SHBShift control solenoid valve B

control

In 1st and 2nd gear in E anO E positions and

E position: Battery voltage

ln E position,3rd and 4th gear in E anO Epositions:0 V

SHAShift control solenoid valve A

control

In E, E positions,2nd and 3rd gear in E and

E positions: Batteryjloltage

In lst gear in !d and -qtl positons and 4th gear

in E oosition: 0V

A4Not used

A5NEEngine speed signal inputWhen engine is rotating: Pulsing signal

ATPlA,/T gear position switch

E position input

In L!-l position: 0 V

In other than I position: Battery voltage

A7ATP2Ay'T gear position switch

E position input

In 13 position:0 V

In other than E position: Battery voltage

A8ATP D3A,/T gear position switch

E position input

In E position:0V

In other than @ position: Battery voltage

A9ATP D4A,/T gear position switch

E position input

InEposition;0V

In other than El position: Battery voltage

410ATP PNA,/T gear position switch

E and E positions input

InEorEpositions:OV

In other than E or N position: Battery vottage

411ATP RA/T gear position switch

E position input

lnEposition: oV

ln other than E position: 8attery voltage

412tGlPower supply systemWith ignition switch ON (lll: Battery voltage

413LG1Ground

A14Not used

A15LCBLock-up control solenoid valve B

control

During hall and full lock-up and during deceler-

ation: Battery voltage

During no lock-up:0 V

A16LCALock-up control solenoid valve A

control

When lock-up is ON; Battery voltage

With no lock-up: 0 V

417D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltsge

A18Not used

A19Not used

420AT CHKUpshifvdownshift comparative

signal output

With ignition switch ON (ll): Pulsing signal

421Not used

422ILUInterlock controlWhen ignition switch is ON (ll), brake pedal

deoressed and accelerator oedal released:

Battery voltage

423VBUBack-up power systemAlways Battery voltage

I

lI

I

14-44

\/

Page 466 of 1681

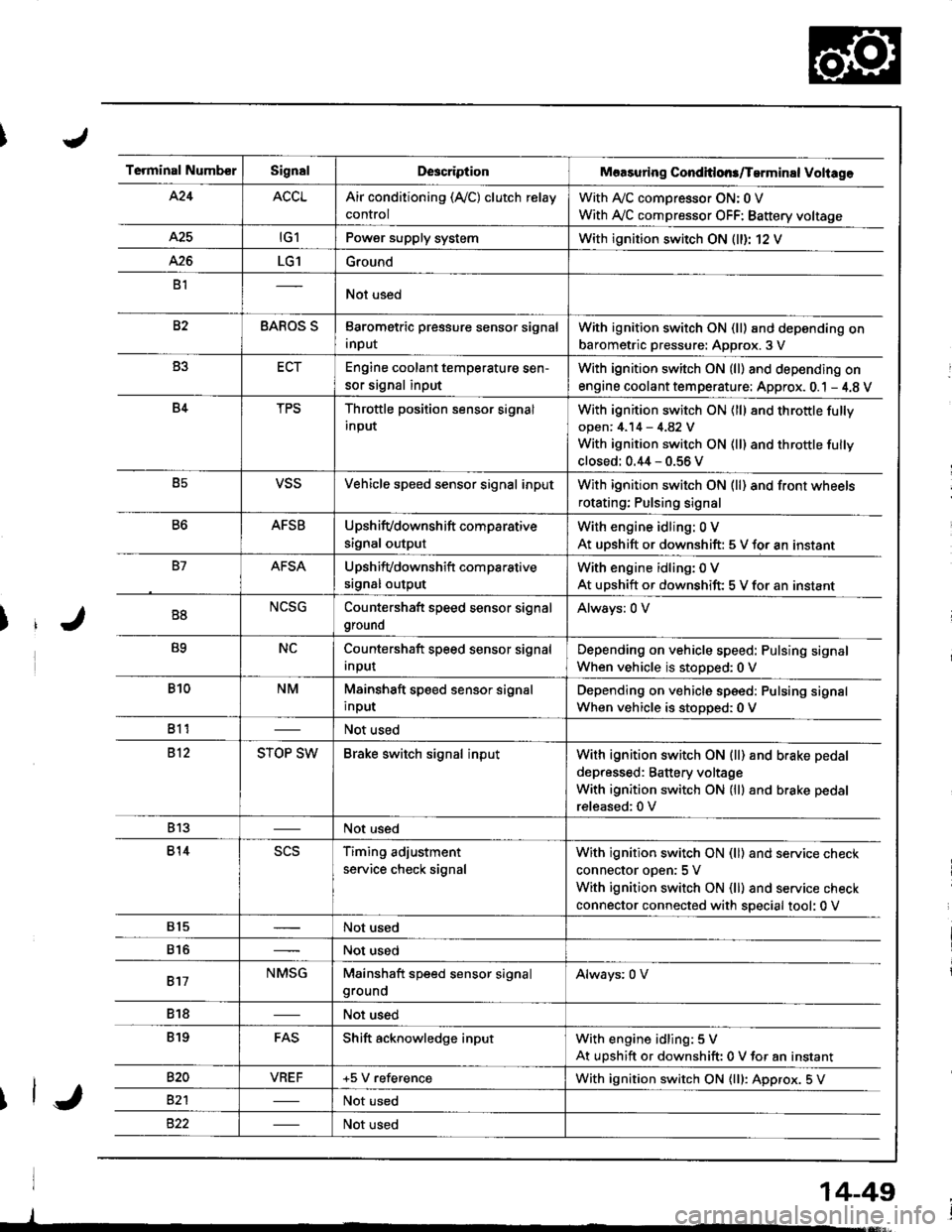

Terminal NumberSignalDescriptionMaasuring Conditlons/Tarminal Voliage

424ACCLAir conditioning (Ay'C) clutch relay

control

With A,/C comDressor ON: 0 V

With Ay'C compressor OFF: Battery voltage

A25tG1Power supply systemWith ignition switch ON (ll)r 12 V

426LG1Ground

B1Not used

82BAROS SBarometric pressure sensor signal

input

With ignition switch ON (ll) and depending on

barometric pressure: Approx. 3 V

B3ECTEngine coolant temperature sen-

sor signal input

With ignition switch ON (ll) and depending on

engine coolant tem perature: Approx. 0.1 - 4.8 V

B4TPSThrottle position sensor signal

input

With ignition switch ON (ll) 8nd throttle fully

open: 4.14 - 4.82 V

With ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

B5VSSVehicle speed sensor signal inputWith ignition switch ON (ll) and front wheels

rotating; Pulsing signal

B6AFSBUpshifvdownshift comparative

signal output

With engine idling: 0 V

At uDshift or downshift: 5 V for an instant

B7AFSAUpshifvdownshift com parative

srgnal output

With engine idling: 0 V

At upshift or downshift: 5 V for an instant

B8NCSGCountershaft speed sensor signal

ground

Always: 0 V

B9NCCountershaft speed sensor signal

Input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped:0 V

B10NMMainshaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stoDoed: 0 V

811Not used

812STOP SWBrake switch signal inputWith ignition switch ON {ll) and b.ake pedal

depressed: Battery voltage

With ignition switch ON (lll and brake pedal

released:0 V

813Not used

814scsTiming adjustment

service check signal

With ignition switch ON (ll) and service check

connector oDen:5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

815Not used

816Not used

817NMSGMainshaft speed sensor signalgroundAlways: 0 V

818Not used

819FASShift acknowledge inputWith engine idling: 5 V

At upshift or downshift: 0 V for an instant

820VBEF+5 V referenceWith ignition switch ON {lll: Approx. 5 V

82'lNot used

Not used

14-49

Page 467 of 1681

![HONDA INTEGRA 1998 4.G Manual PDF Troubleshooting Procedures

Checking the Diagnostic Trouble Code (DTC)

with an OBD ll Scan Tool or th€ Honda PGM Tester

When the TCM senses an abnormality in the input or output systems, the lD,] ind HONDA INTEGRA 1998 4.G Manual PDF Troubleshooting Procedures

Checking the Diagnostic Trouble Code (DTC)

with an OBD ll Scan Tool or th€ Honda PGM Tester

When the TCM senses an abnormality in the input or output systems, the lD,] ind](/img/13/6069/w960_6069-466.png)

Troubleshooting Procedures

Checking the Diagnostic Trouble Code (DTC)

with an OBD ll Scan Tool or th€ Honda PGM Tester

When the TCM senses an abnormality in the input or output systems, the lD,] indicator light in the gauge assembly will

blink. When the 16p Data Link Connector (DLC) (located under the dash on the passenger side) is connected to the OBD ll

Scan Tool or Honda PGM Taster as shown, the scan tool or tester will indicate the Diagnostic Trouble Code (DTC) when

the ignition switch is turned ON {ll}.

When the !r indicator light has been reported on, connect the OBD ll Scan Tool confirming to SAE J1978 or Honda PGM

Tester to the DLC (16P) behind the ashtray. Turn the ignition switch ON (ll) and observe the DTC on the screen ofthe OBD

ll Scan Tool or Honda PGM Tester. After determining the DTC, refer to the electrical system Symptom-to-Component

Chart on pages 14-54 and 14-55.

NOTE: SeetheOBDll ScanTool orHonda PGM Tester user's manual for specific instructions.

OBD-IlSCAN TOOL orHONDA PGM TESTER

Some PGM-Fl problems will also make the lol indicator light come on. After repairing the PGM-Fl system. disconnect the

BACK Up fuse (7.5 A) in the under-hood fuse/relay box for more than 10 seconds to reset the TCM memory, then recheck.

NOTE: Disconnecting the BACK UP fuse also cancels the radio anti-theft code, preset stations and the clock setting. Get

the customer's code number, and make note of the radio presets before removing the fuse so you can reset them

uJ trr

ulu

ai

14-50L

DATA LINK CONNECTOR (16P)

I

il

lt

rJq

Page 468 of 1681

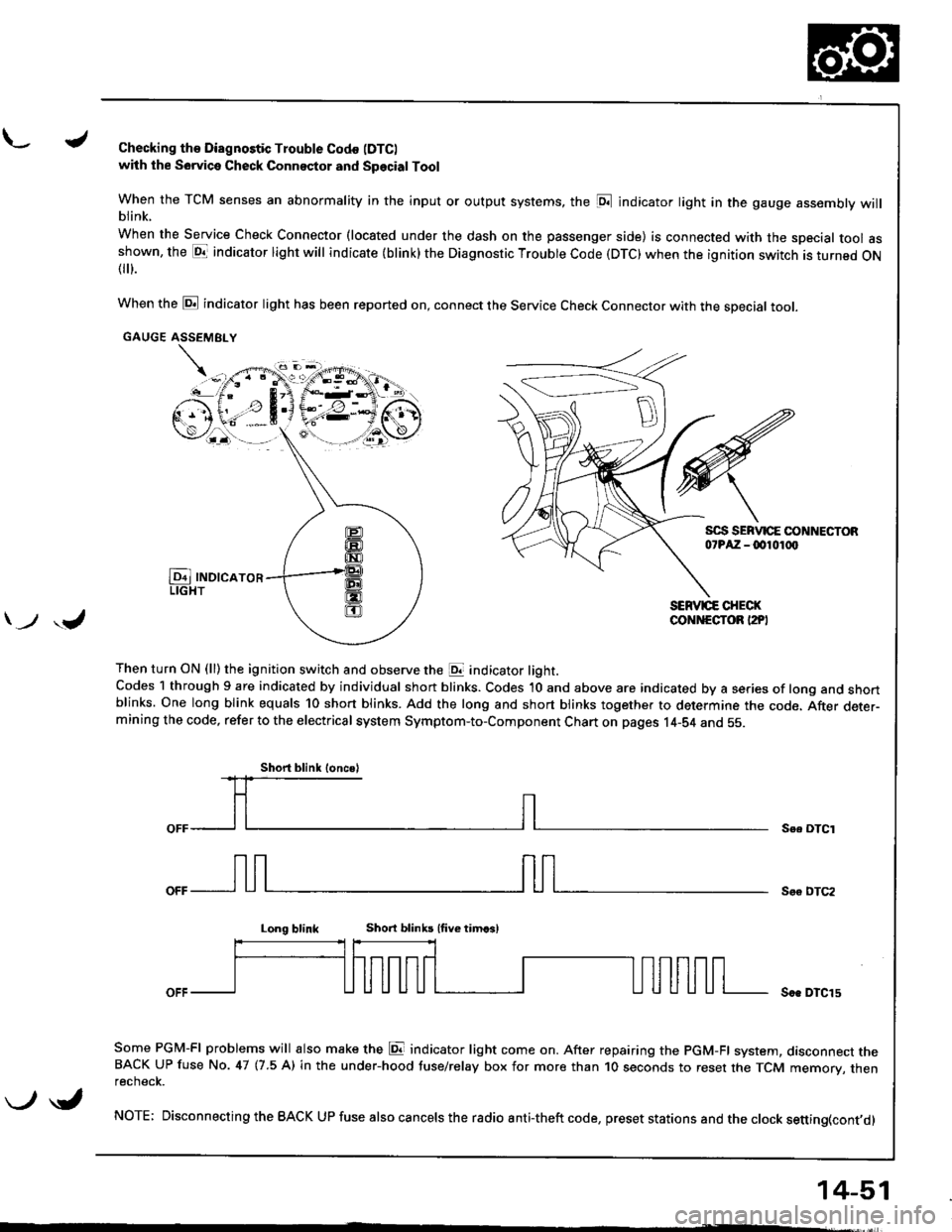

L./Checking th€ Diagnostic Trouble Codo (DTC)

with the Sowica Check Connector and Special Tool

When the TCM senses an abnormality in the input or output systems, the [D;l indicator light in the gauge assembly willblink.

When the Service Check Connector (located under the dash on the passenger side) is connected with the special tool asshown, the E1T indicator light will indicate (blink) the Diagnostic Troubte Code (DTC) when the ignition switch is turned ON{

}.

When the @ indicator light has been reported on, connect the Service Check Connector with the special toot.

GAUGE ASSEMEI.Y

Then turn ON (ll) the ignition switch and observe the E indicator light.Codes 1 through 9 are indicated by individual short blinks. Codes 1O and above are indicated by a series of long and shortblinks. One long blink equals 10 short blinks. Add the long and short blinks together to determine the code. After deter-mining the code, refer to the electrical system Symptom-to-Component Chart on pages 14-S4 and 55.

\-F;ii^r

) ,J

Se. OTCI

Soo DTC2

Long blinkShort blinb lfive timcsl

Soe DTCl5

Some PGM-FI problems will also make the E indicator light come on. After repairing the PGM-FI system, dasconnect theBACK UP fuse No. 47 (7.5 A) in the under-hood tuse/relay box for more than 1O seconds to reset the TCM memory, thenrecnecK.

NOTE; Disconnecting the BACK UP fuse also cancels the radio anti-theft code, preset stations and the clock setting(cont,d)

Short blink loncsl

\-/ \i,

14-51

Page 470 of 1681

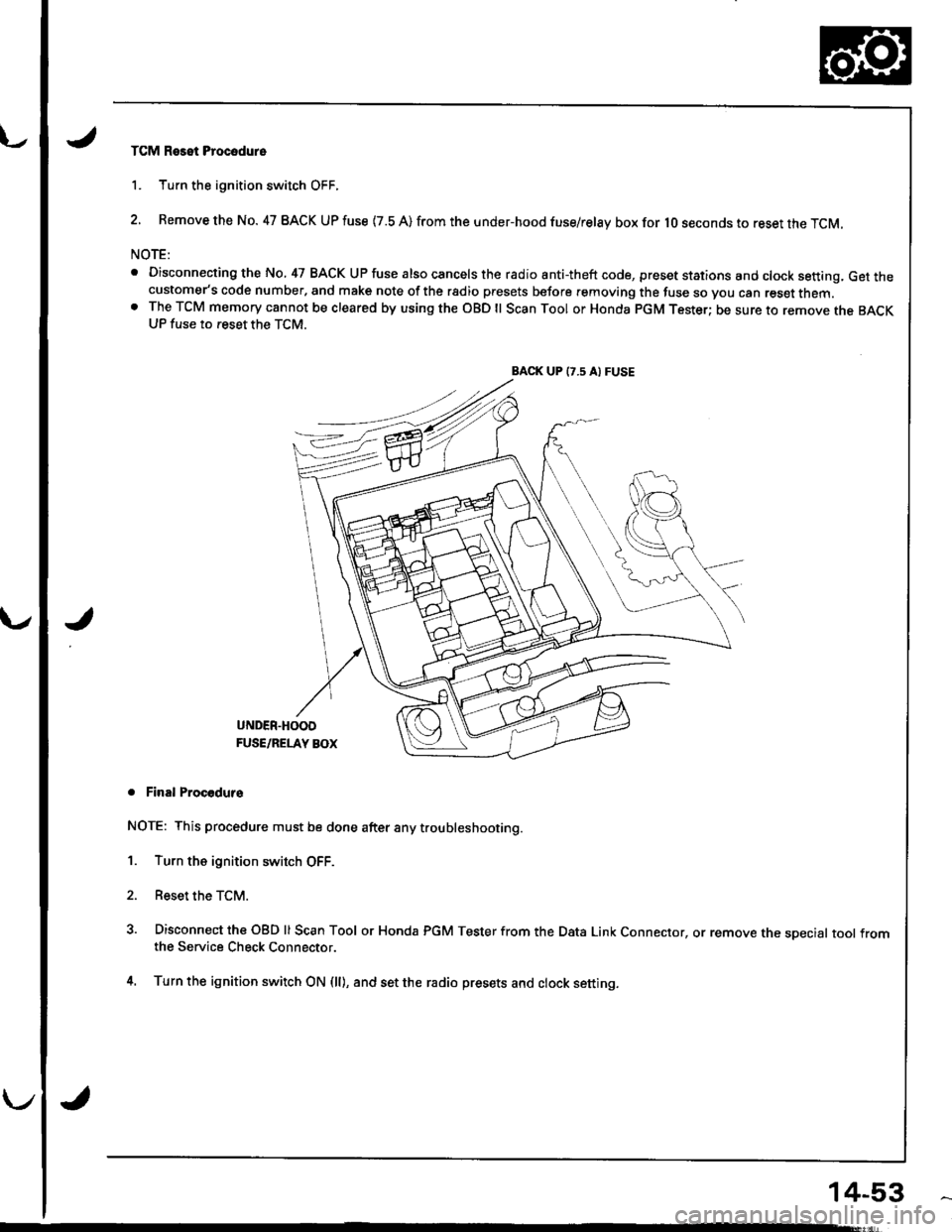

TCM Reset Procodure

1. Turn the ignition switch OFF.

2. Remove the No. 47 BACK UP fuse {7.8 A) from the under-hood fuse/relay box for lO seconds to reset the TCM.

NOTE:

. Disconnecting the No, 47 BACK UP fuse also cancels the radio anti-theft code, preset stations and clock setting, Get thecustomer's code number, and make note of the rsdio presets before removing the fuse so you can reset them.o The TCM memory cannot be cleared by using the OBD ll Scan Tool or Honda pGM Tester; be sure to remove the BACKUP fuse to reset the TCM.

BACK UP (7.5 A) FUSE

J

UNDER.HOOD

FUSE/RELAY BOX

. Final Procodurs

NOTE: This procedure must be done after any trou bleshooting.

1. Turn the ignition switch OFF.

2. Reset the TCM.

3. Disconnect the OBD ll Scan Tool or Honda PGM Tester from the Data Link Connector, or remove the sDecial tool fromthe Service Check Connector.

4. Turn the ignition switch ON (ll), and set the radio presets and clock setting.

14-53

Page 471 of 1681

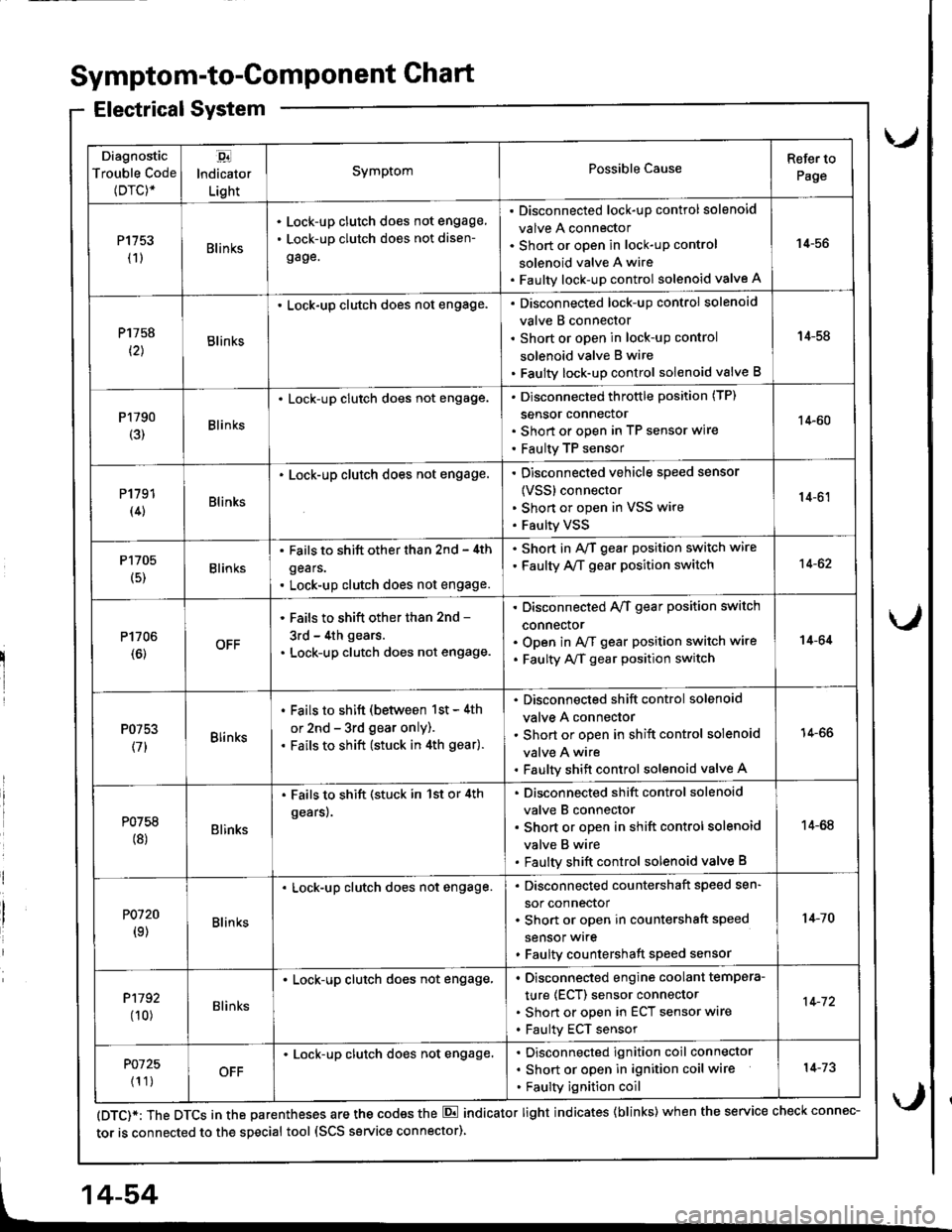

Diagnostic

Trouble Code(Drc)*

,94

lndicator

Light

SymptomPossible CauseRefer to

Page

P1153(1)Blin ks

Lock-up clutch does not engage,

Lock-up clutch does not disen-

gage.

Disconnected lock-up control solenoid

valve A connector

Short or open in lock-uP control

solenoid valve A wire

Faulty lock-up control solenoid valve A

14-56

P1758

t2lBlinks

. Lock-up clutch does not engage.Disconnected lock-up control solenoid

valve B connector

Short or open in lock-uP control

solenoid valve B wire

Faulty lock-up control solenoid valve B

14-58

P1790(3)Blinks

. Lock-up clutch does not engage.Disconnected throttle position (TP)

sensor connector

Short or open in TP seflsor wire

Faulty TP sensor

14-60

P1191(4)Blinks

. Lock-up clutch does not engage.Disconnected vehicle speed sensor

{VSS} connector

Shon or open in VSS wire

Faulty VSS

14-61

P1705

(5)Blinks

. Fails to shift other than 2nd - 4th

gears.

. Lock-up clutch does not engage.

. Shod in AvT gear position switch wire

. Faulty A,/T gear position switch14-62

P1706(6)OFF

' Fails to shift other than 2nd -

3rd - 4th gears.

. Lock-up clutch does not engage.

Disconnected A/T gear position switch

connector

Open in A/f gear position switch wire

Faulty A/f gear position switch

14-64

P0753

(71Blinks

. Fails to shift (between 1st - 4th

or 2nd - 3rd gear only).. Fails to shift (stuck in 4th gear).

Disconnected shift control solenoid

valve A connector

Short or open in shift control solenoid

valve A wire

Faulty shift control solenoid valve A

14-66

P0758(8)Blinks

. Fails to shift (stuck in 1st or 4th

gears).

Disconnected shift control solenoid

valve B connector

Short or open in shift control solenoid

valve B wire

Faulty shift control solenoid valve B

14-68

P0120(9)Blin ks

Lock-up clutch does not engage.Disconnected countershaft speed sen-

sor connector

Short or open in countershaft speed

sensor wrre

Faulty countershaft speed sensor

1+10

P1192

00)Blinks

. Lock-up clutch does not engage,Disconnected engine coolant tempera-

ture (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

14-72

P0725

{1 1)OFF

Lock-up clutch does not engage.Disconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

14-73

Symptom-to-ComPonent Chart

Electrical System

(DTC)*: The DTCS in the parentheses are the codes the E indicator light indicates {blinks) when the service check connec-

tor is connected to the special tool (SCS service connector)

4-54

Page 472 of 1681

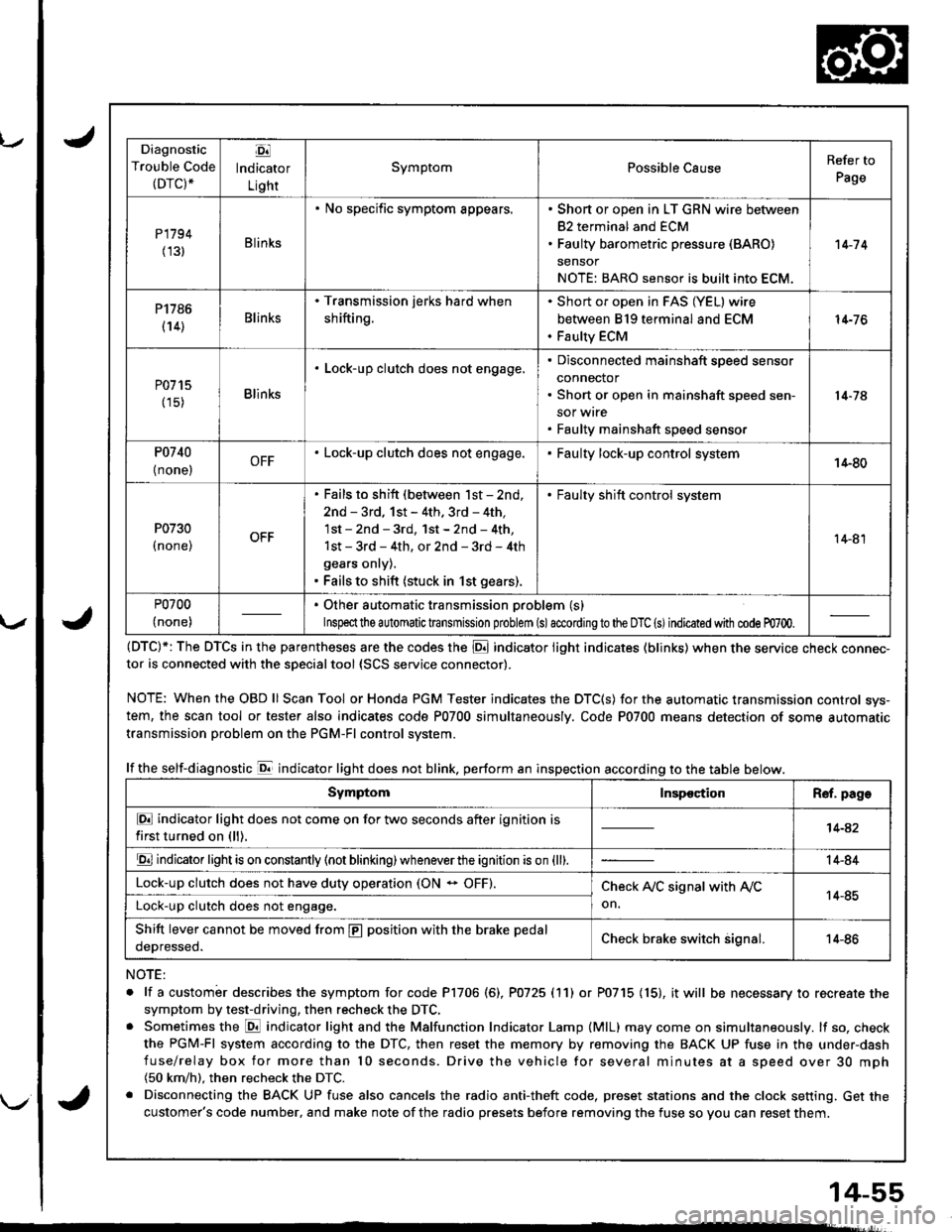

u.drrf,,

J

J

J

14-55

Diagnostic

Trouble Code(DTC).

Ej

lndicator

Light

SymptomPossible CauseRefer to

Page

P1794

(131Blinks

. No specific symptom appears.. Short or open in LT GRN wire between

82 terminal and ECM. Faulty barometric pressure (BARO)

sensor

NOTE: BARO sensor is built into ECM.

't 4-7 4

P1786

(14)Blinks

. Transmission jerks hard when

shifting.

Short or open in FAS (YEL) wire

between 819 terminal and ECM

Faulty ECM

14-76

P0715

(15)Blinks

. Lock-up clutch does not engage,Disconnected mainshaft speed sensor

connector

Short or open in mainshaft speed sen-

sor wrre

Faulty mainshaft speed senso.

14-74

P0740

{ none,OFF. Lock-up clutch does not engage.Faulty lock-up control system14-80

P0730

I none,

. Fails to shift (between lst - 2nd,

2nd - 3rd, 1st - 4th. 3rd - 4th,

1st - 2nd - 3rd, 1st - 2nd - 4th,

1st - 3rd - 4th, or 2nd - 3rd - 4th

gears onry).. Fails to shift (stuck in 1st gears).

. Faulty shift control system

14-81

P0700

(none)

. Other automatic transmission problem (s)

Inspeclthe a utomatic transmission problem (s)accordingto the DTC (s)indicated with code m700.

(DTC)*: The DTCS in the parentheses are the codes the E indicator light indicates (blinks) when the service cnecK connec-tor is connected with the sDecialtool {SCS service connector).

NOTE: WhentheOBDll Scan Tool orHonda PGM Tester indicates the DTC(S) for the automatic transmission control sys-

tem, the scan tool or tester also indicates code P0700 simultaneously. Code P0700 means detection of some automatic

transmission problem on the PGM-Fl control system.

lf the self-diagnostic E indicator light does not blink. perform an inspection according to the table below.

NOTE:

. lf a custombr describes the symptom for code P1706 (6), P0725 (11) or P0715 (15), it will be necessary to recreate the

symptom by test-driving, then recheck the DTC,. Sometimes the E indicator light and the Malfunction Indicator Lamp (MlL) may come on simultaneously. lf so, check

the PGM-Fl system according to the DTC, then reset the memory by removing the BACK UP fuse in the under-dash

fuse/relay box for more than l0 seconds. Drive the vehicle for several minutes at a speed over 30 mph(50 km/h). then recheck the DTC.

. Disconnecting the BACK UP fuse also cancels the radio anti-theft code, preset stations and the clock setting. Get the

customer's code number, and make note of the radio presets before removing the fuse so you can reset them.

SymptomInspectionR€f. page

E indicator light does not come on for two seconds after ignition is

first turned on (ll).14-42

E indicator light is on constantly (not blinking) wheneverthe ignition is on {ll).14-84

Lock-up clutch does not have duty operation (ON - OFF).Check A,/C signal with Ay'C

on.14-85Lock-up clutch does not engage.

Shift lever cannot be moved from E position with the brake pedal

oeDresseo.Check brake switch signal.14-86

Page 473 of 1681

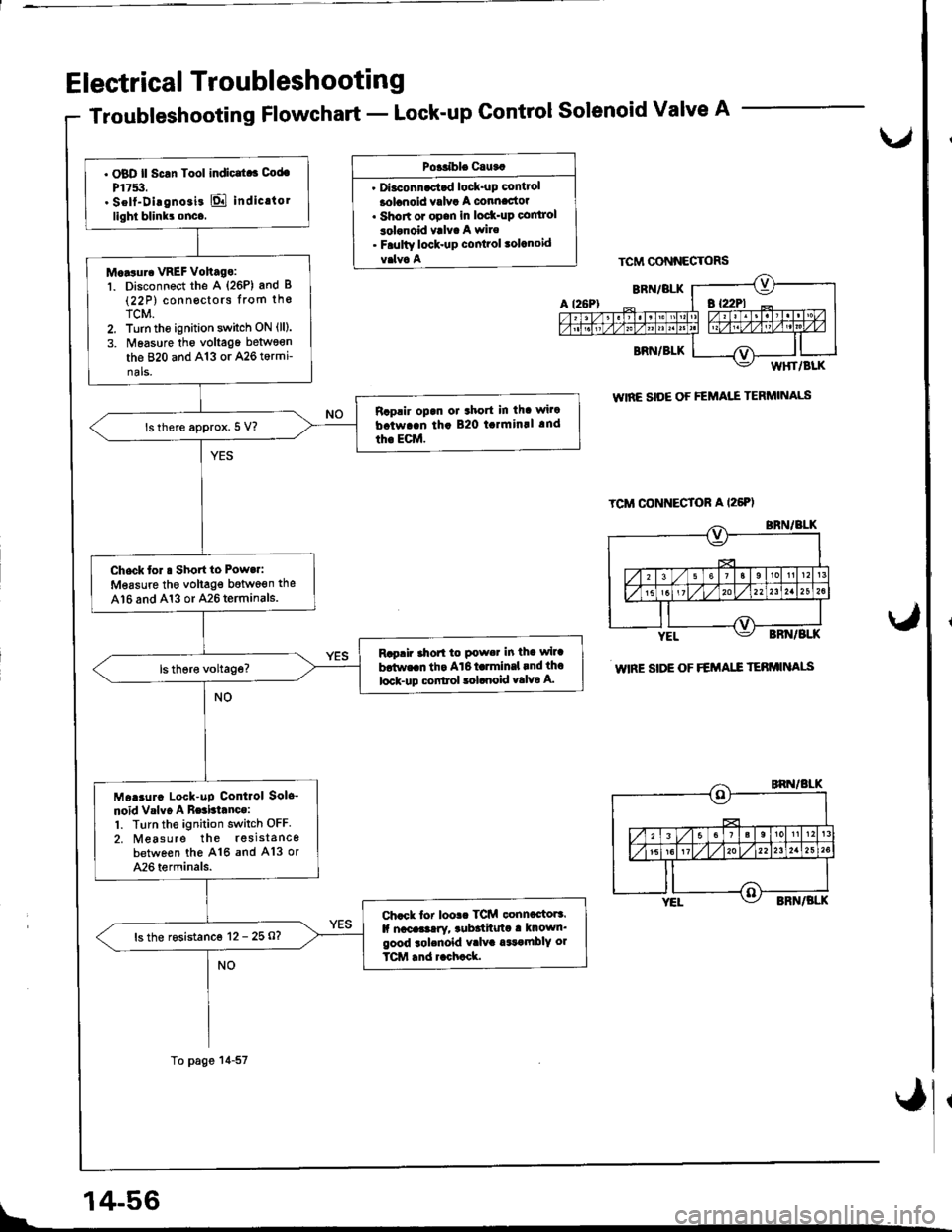

Electrical Troubleshooting

Troubleshooting Flowchart - Lock-up Control Solenoid Valve A

Po+tible Cauta

' Diaconnac'tad lock-up control

lolanoid valva A connac'toa. Shon or opan in lod(-up co|ltrol

3olonoid valva A wire. Faulty lock-up cont?ol lolanoid

TCM CONNECTORS

WIRE SIOE OF FEMAI."E TERMINALS

WIRE SIDE OF FEMA.E TEBMINAIS

L/

. OBD ll Scrn Tool indic|t.3 Cod.

P17!i:t.. Self-Dirgnoii! E indic.torlight blinkr onco.

M.Nur. VREF Voh.go:'t. Disconnect the A (26P) and B(22 P) conn€ctors lrom th€

TCM.2. Turn tho ignition switch ON (ll).

3. Nleasure tho voltage betwson

the 820 and A13 or A26 tormi-nals.

Raplir opan or 3hort in tha wi.a

b.twa.n th. B20 t.lmin!l .nd

th€ EcM.lsthere approx. 5 V?

Check tor a Short to Powa.i

Measure tho voltag€ botwoen the

A16 and A13 or A26 terminals.

Rap!fu ahorl to Pow.t in tha wlra

b!tw..n th. A16 t rmln.l rnd tho

lock-up c!filtol lolaooid valvo A.

Moaaurc Lock-uP Contlol Sole-

noid Vrlvo A Be3bianco:1. Ttrrn the ignition switch OFF.

2. Measure the rssistancebetween the A16 and A13 or

A26 terminals.

Chack tor loolc TCM conncctora.lf naca!3!ry, rub3tftuta a known'good rolcnold v.lva a$amblY ol

TCM .nd r.ch.ck.

ls the rosistanco 12 - 25 O?

To page 14-57

\

14-56