torque HONDA INTEGRA 1998 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 528 of 1681

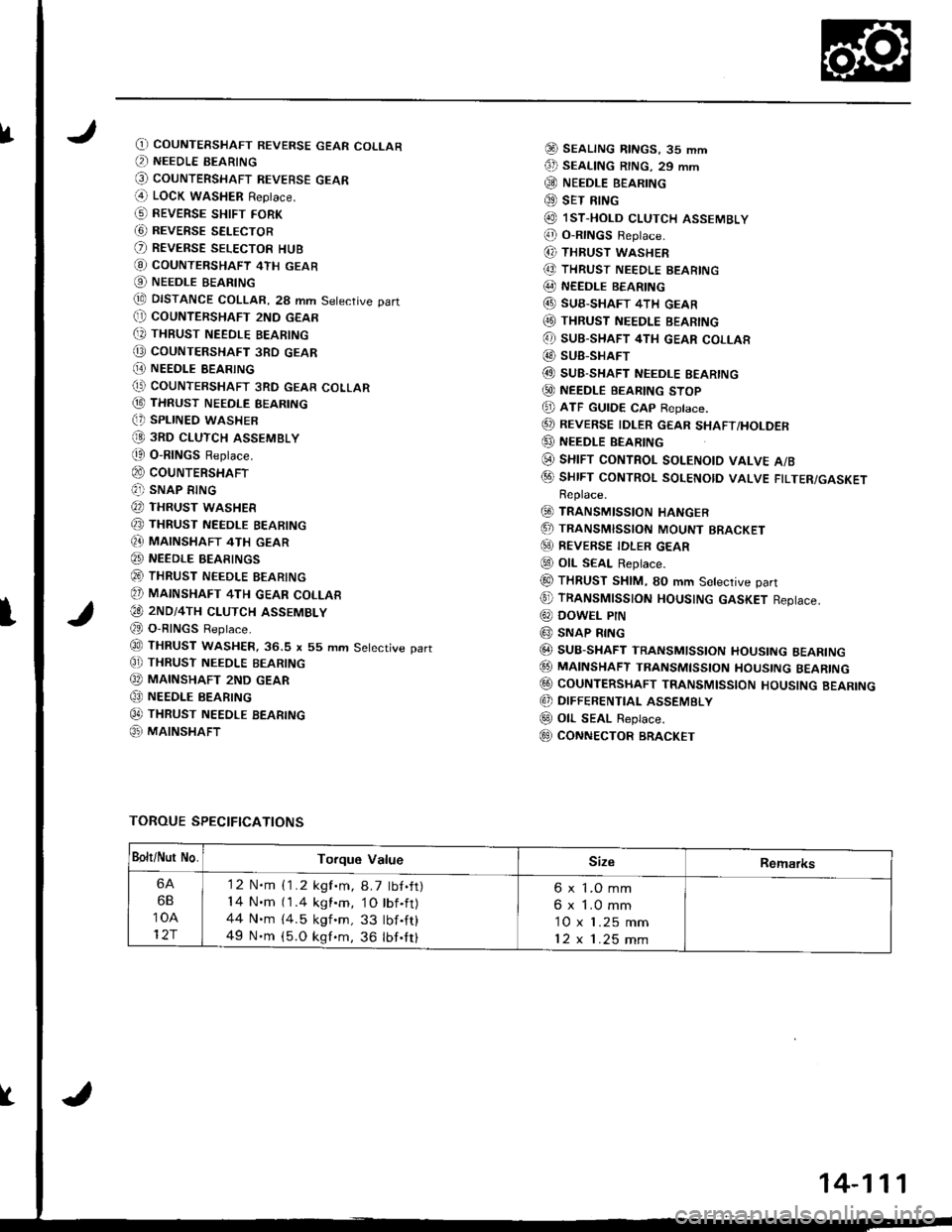

fO) COUNTERSHAFT REVERSE GEAR COLLAR(, NEEDLE BEARING

@ couNTERSHAFT REVEBsE GEAR(4 LOCK waSHER Replace.

G) REVERSE sHtFr FoRK

G) REVERSE SELECTOR

O REVERSE SELEcToR HUB

@ coUNTERSHAFT 4TH GEAR

O NEEDLE BEARING

tE DISTANCE COLLAR, 28 mm Setective part(} COUNTERSHAFT 2ND GEAR

[, THBUST NEEDLE BEARING

@ coUNTERSHAFT 3RD GEAR

[E NEEDI.E BEARING(' COUNTERSHAFT 3RD GEAR COLLAR

@ THRUST NEEDLE BEARING(, SPLINED WASHER

@ 3RD cLUTcH ASSEMBLY

t0 O-RINGS Replace.

@ couNTERSHAFT(?]) SNAP RING

@ THRUST WASHER

@ THRUST NEEDLE BEARING

Q} MAINSHAFT 4TH GEAR

@ NEEDLE BEARINGS

@ THRUST NEEDLE BEARING

@ MAINSHAFT 4TH GEAR coLLAR

€O 2ND/4TH cLUTcH ASSEMBLY

@ O-RINGS Reptace.

@ THRUST WASHER.36.S x 55 mm Setective part

C]) THRUST NEEoLE BEARING

@ MAINSHAFT 2ND GEAR

@ NEEDLE BEARING

0t THRUST NEEDLE BEARTNG

@ MAINSHAFT

@ SEALTNG RtNGs, 35 mm

€D SEAL|NG R|NG. 29 mm

@ NEEDLE B€ARING

@ sET RING

@ lsT.HoLD cLUTCH ASSEMBLY

@ o-RtNGs Reptace.

(, THRUST WASHER

@ THRUST NEEDLE BEARING

@ NEEDLE BEARING

@ SUB-SHAFT 4TH GEAR(O THRUST NEEDLE BEARING

@ sUB-SHAFT 4TH GEAR coLLAR

@ SUB-SHAFT

@ SUB-SHAFT NEEDLE EEARING

@ NEEDLE BEARTNG sToP

@ ATF GUTDE cAp Reptace.

@ REVERSE IDLER GEAR sHAFT/HoLDER

@ NEEDLE BEARING

(i) sHrFT coNTRoL soLENotD vALvE A/B

@ sHrFT coNTRoL soLENotD vALVE FTLTER/GASKETReplace.

@ TRANSMISSIoN HANGER

.5, TRANSMISSIoN MoUNT BRACKET

@) REVERSE TDLER GEAR

@ otL SEAL Replace.

@ THRUST SHIM, SO mm Setective part

@ TRANSMTSSTON HOUSTNG GASKET Reptace.

@ DowEL PtN

@ SNAP RING

@ SUB-SHAFT TRANSMlsstoN HoustNG BEARTNG

@ MA|NSHAFT TRANsMtssroN HoustNG BEARTNG

@ CoUNTERSHAFT TRANSMIssloN HoUsING BEARING

@ DIFFERENTIAL ASSEMBLY

@ oll- SEAL Replace.

E9 CONNECTOR BRACKET

TOROUE SPECIFICATIONS

I

Bolt/Nur No.Torque ValueSizeRemarks

6A

6B

10A

12r

'12 N.m {1.2 kgf.m, 8.7 tbf.ft)14 N.m (1.4 kgl.m, 1O tbf.ft)44 N.m {4.5 kgf 'm, 33 tbf .ft}

49 N.m (5.O kgf.m, 36 lbf.tt)

6 x 1.O mm

6 x 1.0 mm

10 x 1.25 mm

12x1.25mm

14-111

Page 529 of 1681

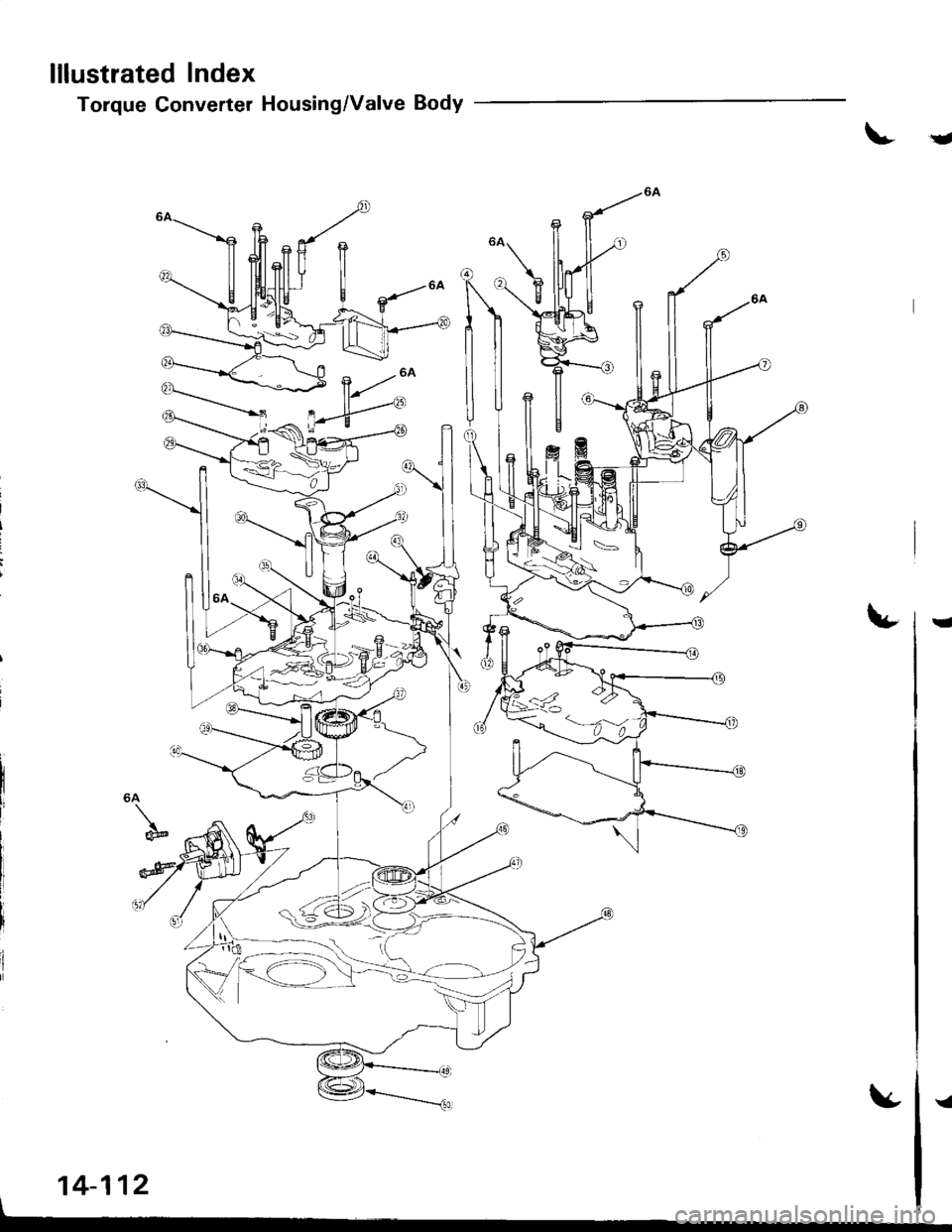

lllustrated Index

Torque Converter Housing/Valve Body

14-112I

\-{

\.,

6A

x

Page 530 of 1681

IfD ATF FEED PIPE

O AccUMULAToR covER

@ o-RING Reptace.(O ATF FEED PIPES

(!) ATF FEED PIPE

@ sERvo DETENT BASE

O LocK WASHER Reptace.

[8) ATF STRAINER

@ sucTroN ptpE coLLAR

@ sERVO EODY(, THRoTTLE coNTRoL SHAFT(t E R|NG

Q9 SERVO SEPARATOR PLATE(D 1ST ACCUMULAToR cHoKE

C' CHECK EALL

@ sToP SHAFT STAY

@) SECONDARY VALVE BODY

OO DOWEL PIN

(t SEcoNDARY SEPARAToR PLATE

@ LUBRICAToR PTATE

8] ATF FEED PIPE

@ LocK-uP vALvE BoDy

@ DowEL PrN

@ LocK-uP SEPARAToR PLATE

E TORoUE CoNVERTER cHEcK VALVE SPRING

€0 ToRouE CoNVERTER cHEcK vALvE

Q) COOLER CHECK VALVE SPRING

@ cooLER cHEcK VALVE

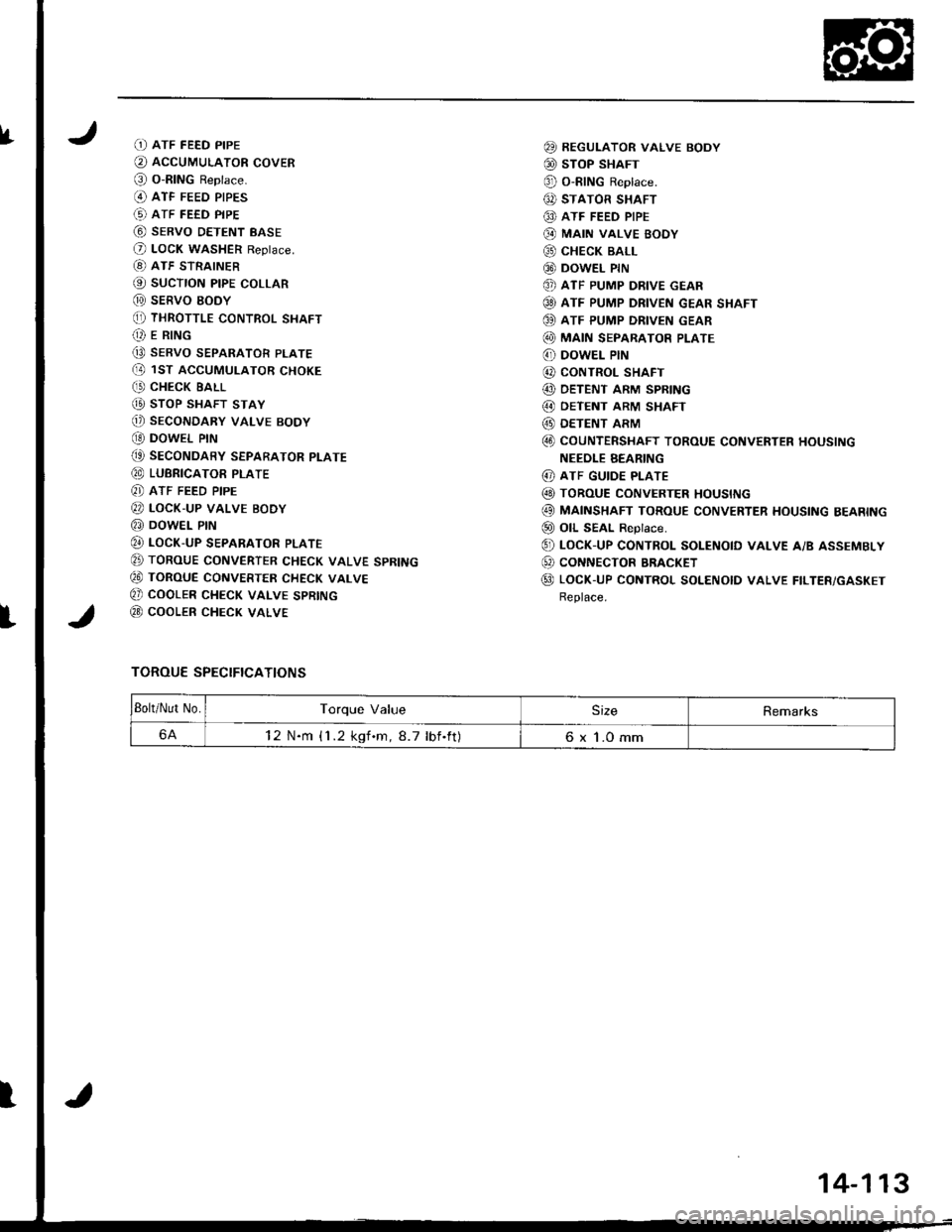

TOROUE SPECIFICATIONS

@ REGULAToR vALvE BoDY

@ sToP SHAFT

@ o-RING Reptace.

6, STATOR SHAFT

@ ATF FEED PIPE

@ MA|N VALVE BOOY

@ cHEcK BALL

@ DowEL PrN

@ ATF PUMP DRIVE GEAR

@ ATF PUMP DRIVEN GEAR SHAFT

OO ATF PUMP DRIVEN GEAR

@ MA|N SEPARAToR PLATE

6' DowEL PIN

@ CONTROL SHAFT

@ DETENT ARM SPRING

@ OETENT ARM SHAFT

@ DETENT ARM

@ coUNTERSHAFT ToRoUE coNVERTER HoUSING

NEEOLE BEARING

@ ATF GUIDE PLATE

@ ToRouE coNvERTER HoustNG

@ MAINSHAFT ToRoUE coNvERTER HousING BEARING

@ oll SEAL ReDtace.

@ LocK-up coNTRoL soLENotD vALvE A/B ASSEMBLy

@ coNNEcToR BRACKET

@ LocK-UP coNTRoL SoLENoID vALvE FILTER/GASKET

Replace.

Bolt/Nut No.Torque ValueSizeRemarks

6A12 N.m {1 .2 kgf.m,8.7 lbf.ft)6 x 1.0 mm

I

14-113

Page 535 of 1681

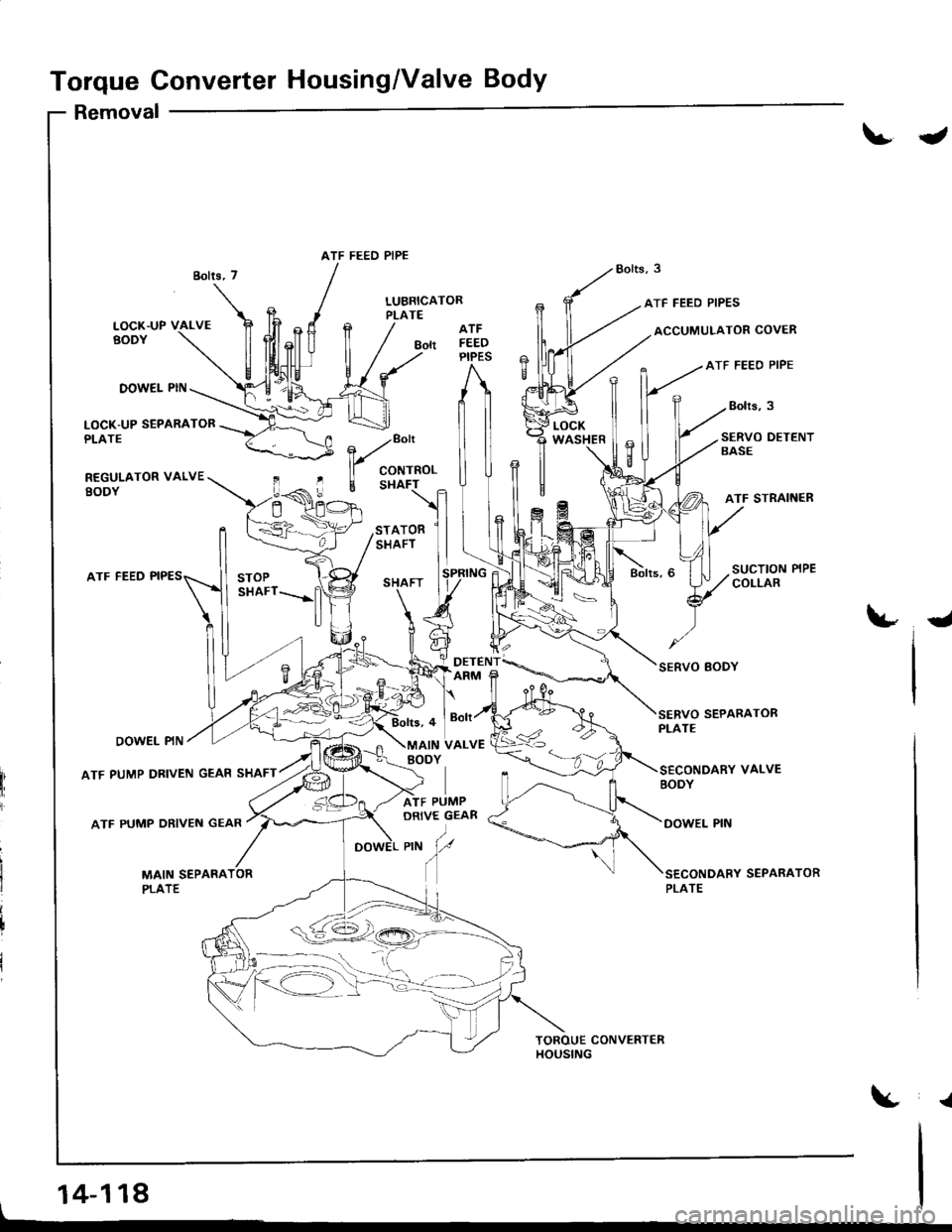

Torque Converter Housing/Valve Body

Removal

t

LUBRICATORPLATEATF FEED PIPES

ACCUMULATOR COVER

ATF FEEO PIPE

Bolrs,3

ATF

Bott FEEDPIPES

DOW€I- PIN

LOCK-UP SEPARATORPLATE

REGULATOR VALVEEODY

SERVO DETENTSASE

ATF STRAINER

LOCKWASHER

ATF FEED

DOWEL PIN

ATF PUMP DRIVEN GEAR SHAFT

ATF PUMP ORIVEN GEAR

-

SEPARATOR

.a

ATF FEED PIPE

, ./"o"

ll coNrRoL

E Sl{AF-r

ATOR

PLATE

_ro-rr!_

Page 536 of 1681

I

l"

I

J

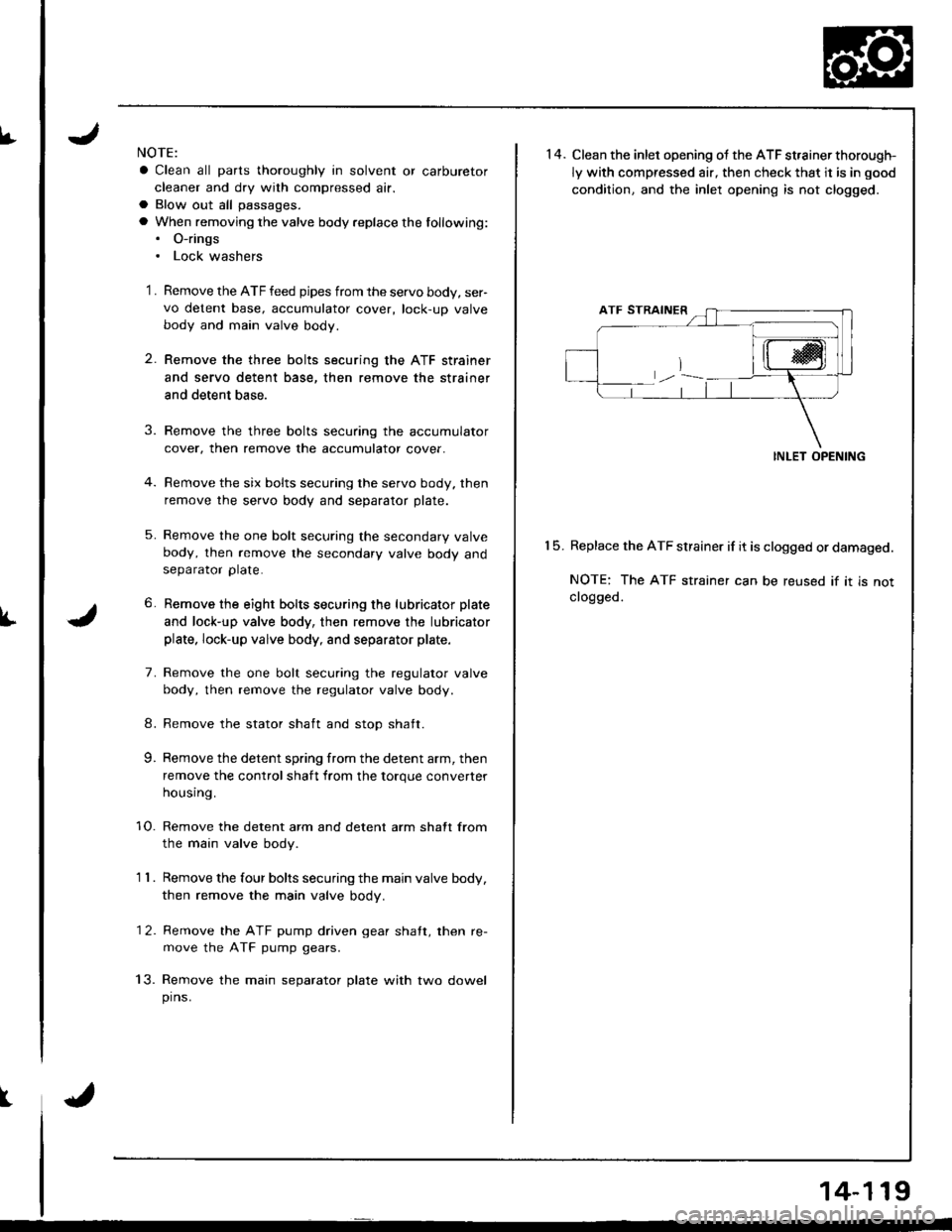

NOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.

a Blow out all passages.

a When removing the valve body replace the lollowing:. O-rings. Lock washers

1 . Remove the ATF feed pipes from the servo body, ser-vo detent base, accumulator cover, lock-up valve

body and main valve body.

2. Remove the three bolts securing the ATF strainer

and servo detent base, then remove the strainer

and detent base.

3. Remove the three bolts securing the accumulator

cover, then remove the accumulator cover.

4. Remove the six bolts securing the servo body. then

remove the servo body and separator plate.

5. Remove the one bolt securing the secondary valvebody, then remove lhe secondary valve body andseparator plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remov€ th€ lubricator

plate. Iock-up valve body, and separator plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body.

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

housrng.

1O. Remove the detent arm and detent arm shatt from

the main valve body.

1 'l . Remove the four bolts securing the main valve body,

then remove the main valve body.

'I2. Remove the ATF pump driven gear shatt, then re-

move the ATF pump gears.

13. Remove the main separator plate with two dowel

pins.

15.

14. Clean the inlet opening ot the ATF st,ainer thorough-

ly with compressed air, then check that it is in good

condition. and the inlet opening is not clogged.

INLET OPENING

Replace the ATF strainer if it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclogged.

14-119

Page 543 of 1681

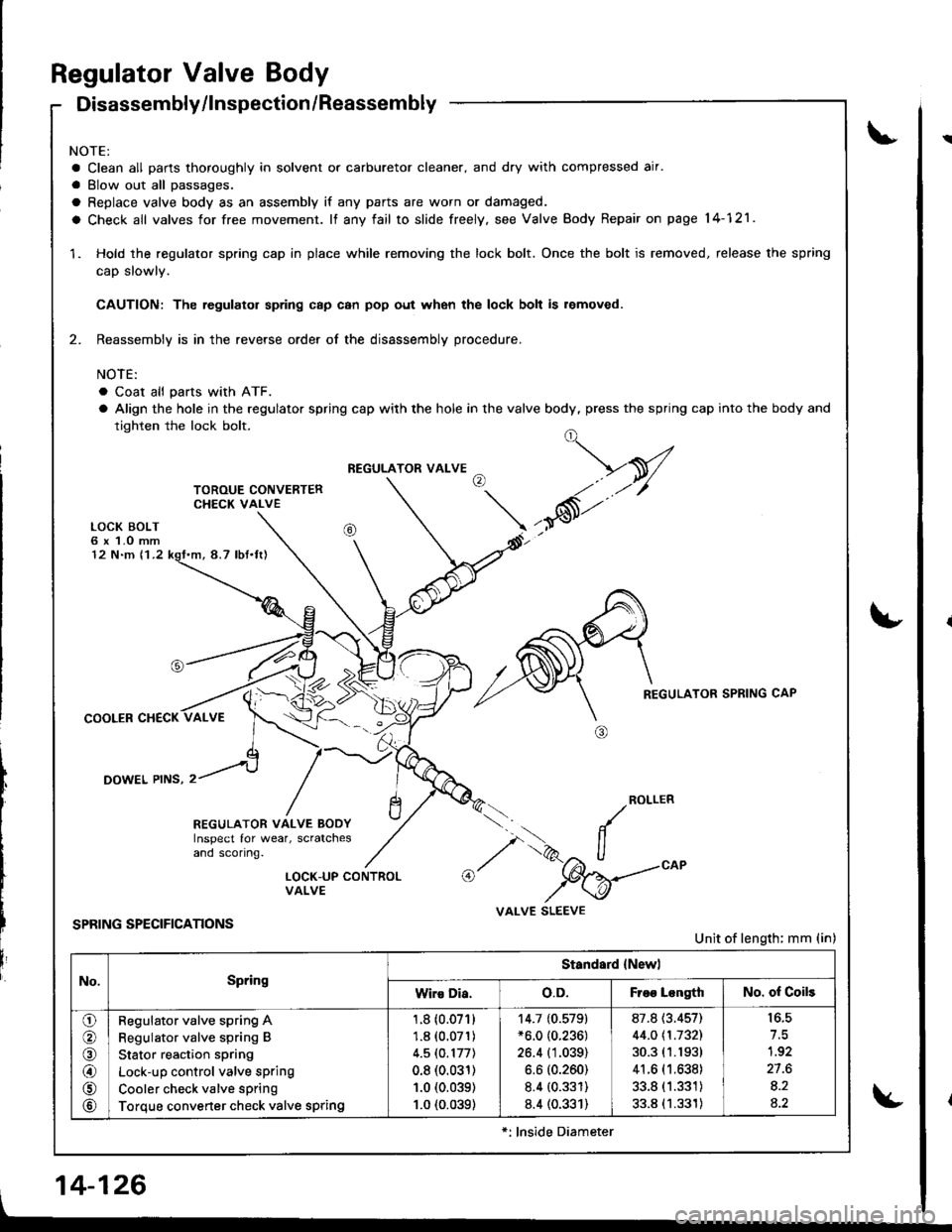

Regulator Valve Body

Disassembly/lnspection /Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner. and dry with compressed air.

a Blow out all passages.

a Replace valve body as an assembly if any parts are worn or damaged.

a Check all valves for free movement. lf any fail to slide freely, see Valve Body Repair on page 14-121.

1. Hold the regulator spring cap in place while removing the lock bolt. Once the bolt is removed. release the spring

cap slowly.

CAUTION: The regulator sp ng c8p can pop out when the lock bolt is r€moved.

2. Reassembly is in the reverse order of the disassembly procedure.

NOTE:

. Coat all pans with ATF.

a Align the hole in the regulator spring cap with the hole in the valve body, press the spring cap into the body and

tighten the lock bolt.

LOCK BOLT6 x 1.O mm12 N.m 11.2

COOLER CHECK

DOWEL PINS, 2

REGULATOR SPRING CAP

ROLLER

REGULATOR VALVE BODYInspect for wear, scratchesand sconng.

oi.

.. /

,/ i>, ll

,/ "W_-

VALVE SLEEVE

@LOCK-UP CONTROLVALVE

SPRING SPECIFICATIONSUnit of length; mm (in)

No.Spring

Standard {Newl

Wiro Dia.o.D.Froo LongthNo. of Coils

o

@

@

@rA

@

Regulator valve spring A

Regulator valve spring B

Stator reaction spring

Lock-up control valve sprlng

Cooler check valve spring

Torque converter check valve spring

1.8 (0.071)

1.8 (0.071)

4.5lO.177l

0.8 (0.031)

1.0 (0.039)

1.0 (0.039)

14.7 {0.579}*6.0 (0.236)

26.4 (1.039)

6.6 (0.260)

8.4 (0.331)

8.4 (0.331)

87.8 (3.457)

44.0 \1.1321

30.3 (1.1931

41.6 (1.638)

33.8 (1.331)

33.8 (1.331)

to.c

1.92

27.6

8.2

4.2

*: lnside Diameter

, 14-126

!

Page 551 of 1681

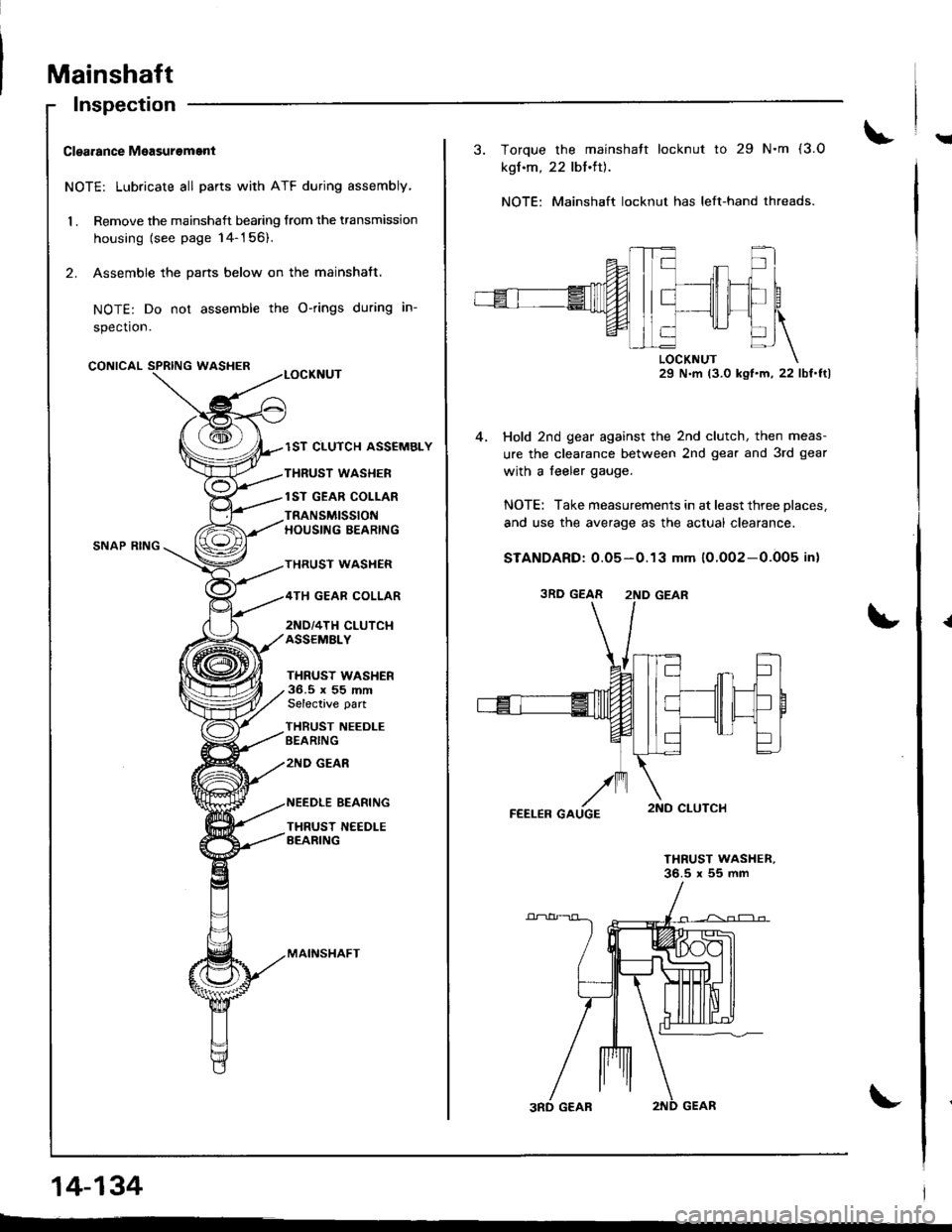

Mainshaft

!Clgarance Measurement

NOTE: Lubricate all parts with ATF during assembly,

1 . Remove the mainshaft bearing from the transmission

housing {see page 14-156).

2. Assemble the pans below on the mainshaft.

NOTE: Do not assemble the O-rings during in-

spection.

CONICALWASHER

Inspection

SNAP RING

lST CLUTCH ASSEMBLY

THRUST WASHER

lST GEAR COLLAR

TRANSMISSIONHOUSING BEARING

THRUST WASHER

TH GEAR COLLAR

2ND/4TH CLUTCI{ASSEMALY

THRUST WASHER36.5 x 55 mmSelective part

THRUST NEEDLEBEARING

zND GEAR

BEARING

THRUST N€EDLEBEARING

MAINSHAFT

14-134

3. Torque the mainshatt locknut to 29 N.m (3.O

kgf.m, 22 lbt.tt).

NOTE: Mainshaft locknut has left-hand threads.

29 N.m (3.0 ksl'm,22 lbf'ftl

Hold 2nd gear against the 2nd clutch, then meas-

ure the clearance between 2nd gear and 3rd gear

with a feeler gauge.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: 0.05-0.13 mm 10.002-0.005 in)

THRUST WASHER,36.5 x 55 mm

3RD GEAR 2ND GEAR

Page 556 of 1681

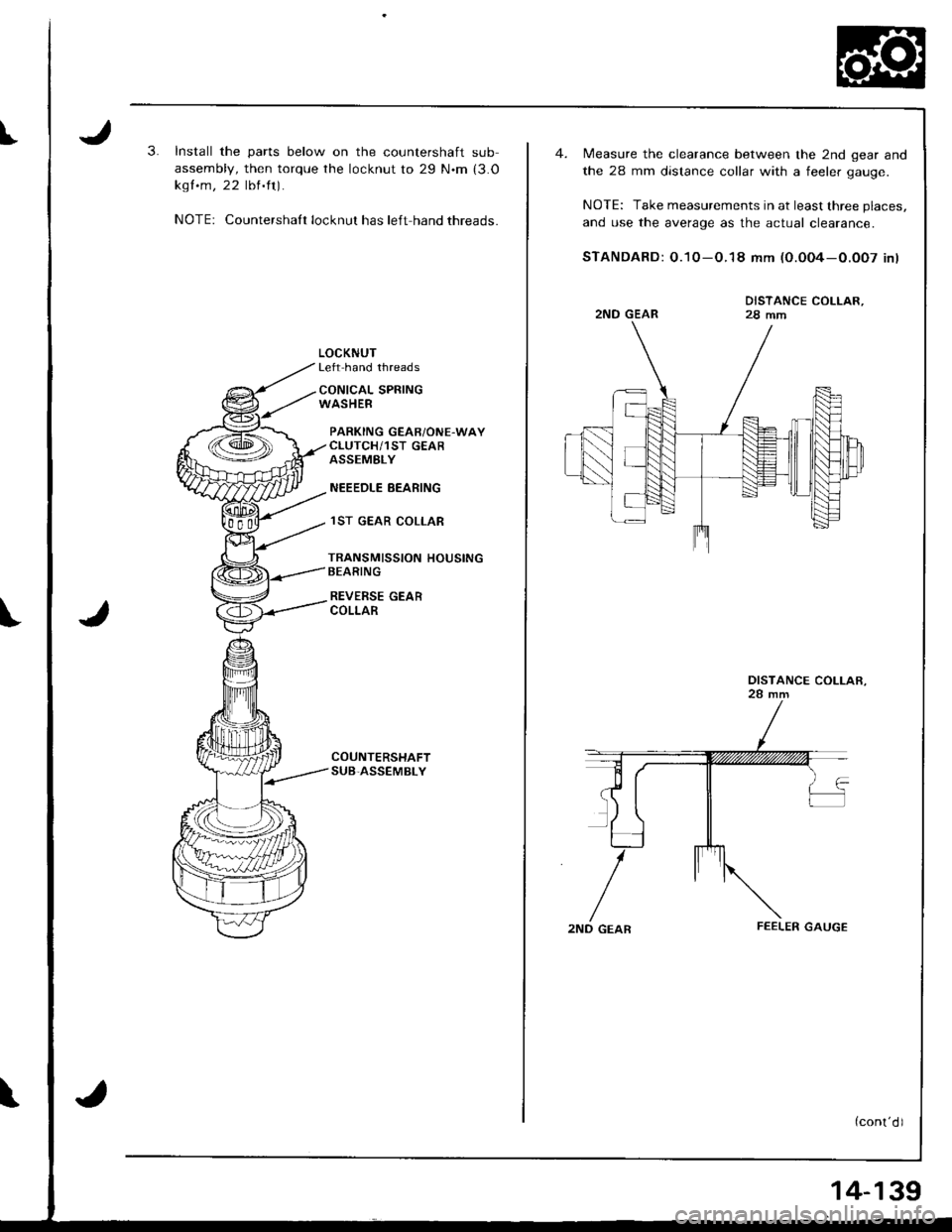

I3.Install the parts below on the countershaft sub

assembly, then torque the locknut to 29 N.m (3.O

kgf .m, 22 lbl'ft).

NOTE: Countershalt locknut has left hand threads.

LOCKNUTLeft hand threads

CONICAL SPRINGWASHEB

PARKING GEABiONE.WAYCLUTCH/1ST GEARASSEMELY

NEEEDLE EEARING

lST GEAR COLLAR

TRANSMISSION HOUSINGBEARING

REVERSE GEARCOLLAR

COUNTERSHAFTSUB,ASSEMBLY

Measure the clearance between the 2nd gear and

the 28 mm distance collar with a feeler oauoe.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: O.10-O.18 mm (O.0O4-O.OO7 inl

2ND GEARFEELER GAUGE

DISTANCE COLLAR,

DISTANCE COLLAR.

14-139

Page 571 of 1681

Torque Converter Housing Bearings

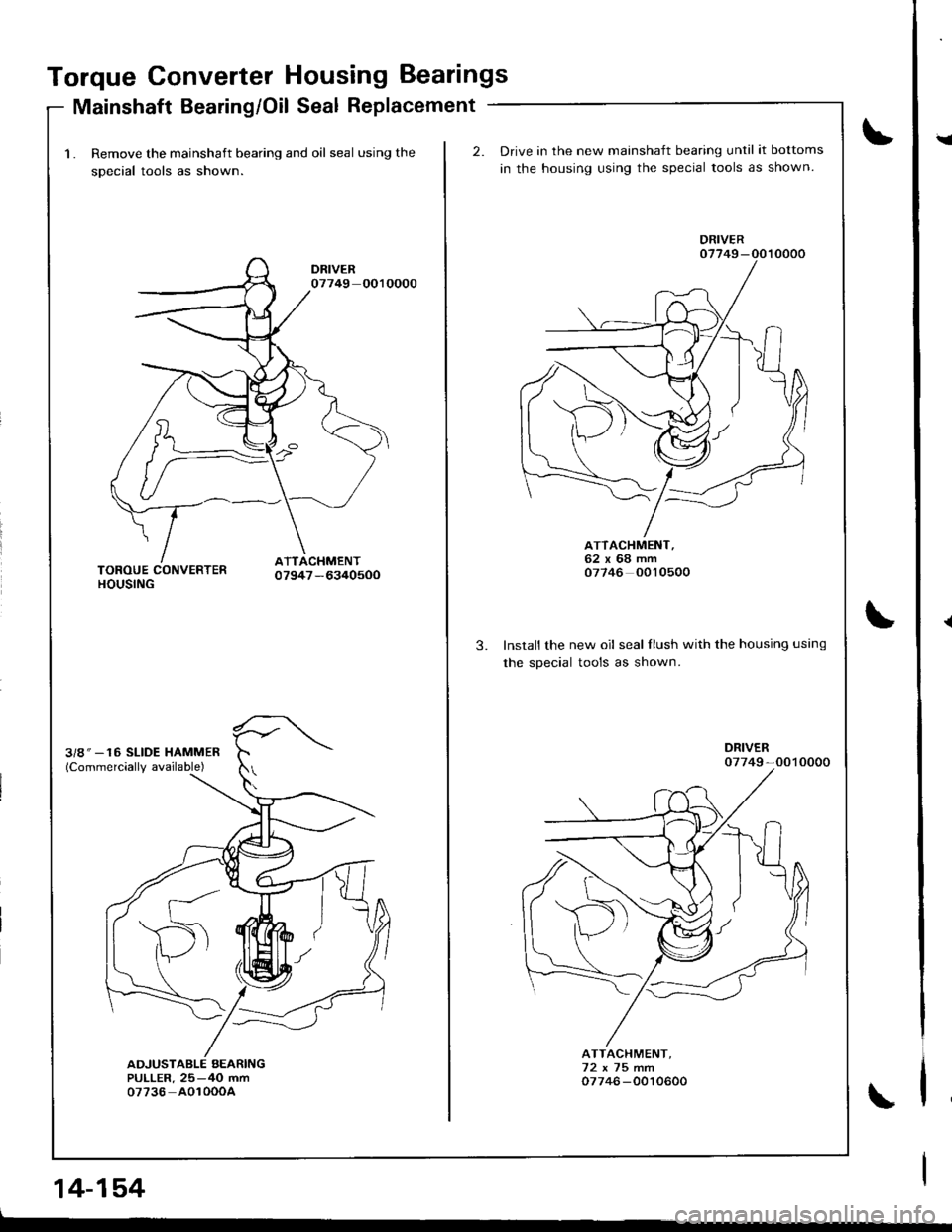

Mainshaft Bearing/Oil Seal Replacement

1. Remove the mainshaft bearing and oil seal using the

sDecial tools as shown.

14-154

2.Drive in the new mainshaft bearing until it bottoms

in the housing using the special tools as shown.

3.Install the new oil seal flush with the housing using

the soecial tools as shown.

ATTACHMENT,62x68mm07746 0010500

ATTACHMENT,72x75m.m07746 -0010600

I

Page 577 of 1681

)

)

A

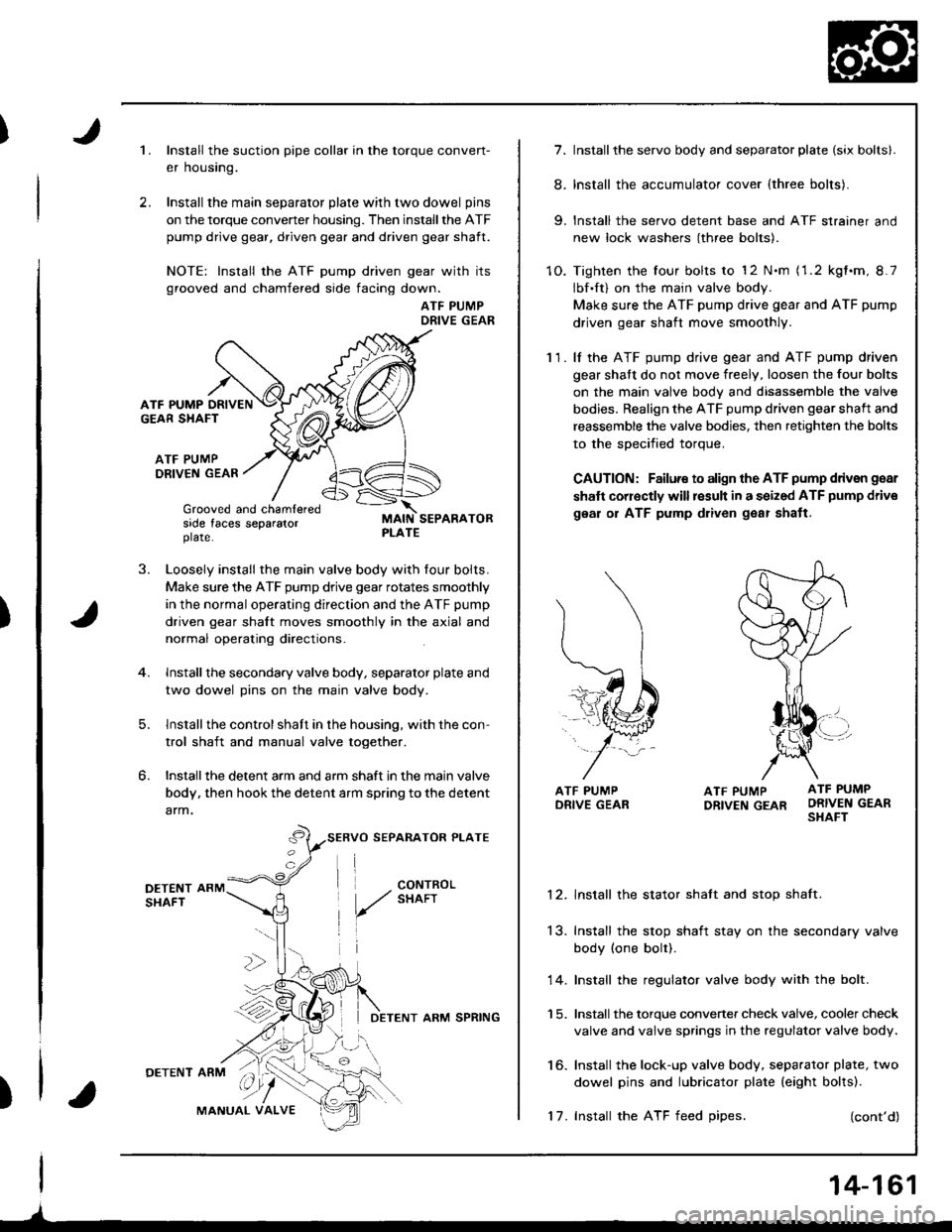

1.

ATF PUMP DRIVENGEAR SHAFT

ATF PUMPDRIV€N GEAR

J.

6

Grooved and ch6mleredside faces separatorplate.

Install the suction pipe collar in the torque conven-

er housing.

Install the main separator plate with two dowel pins

on the torque convener housing. Then install the ATF

pump drive gear, driven gear and driven gear shaft.

NOTE: Install the ATF pump driven gear with its

grooved and chamfered side facing down.

ATF PUMPDRIVE GEAR

Loosely install the main valve body with four bolts.

Make sure the ATF pump drive gear rotates smoothly

in the normal operating direction and the ATF pump

driven gear shalt moves smoothly in the axial and

normal operating directions.

Install the secondary valve body, separator plate and

two dowel pins on the main valve body.

lnstallthe control shaft in the housing, with the con-

trol shaft and manual valve together.

Installthe detent arm and arm shaft in the main valve

body, then hook the detent arm spring to the detent

arm.

SERVO SEPARATOR PLATE

I

DETENT ARM SPRING

'17. Install the ATF feed oipes.

14-161

7. Install the servo body and separator plate (six bolts|.

8. Install the accumulator cover (three bolts).

9. Install the servo detent base and ATF strainer and

new lock washers (three bolts).

1O. Tighten the four bolts to '12 N.m (1.2 kgt.m, 8.7

Ibf.ft) on the main valve body.

Make sure the ATF pump drive gear and ATF pump

driven gear shaft move smoothly.

11. lf the ATF pump drive gear and ATF pump driven

gear shaft do not move freely, loosen the four bolts

on the main valve bodv and disassemble the valve

bodies. Realign the ATF pump driven gear shaft and

reassemble the valve bodies, then retighten the bolts

to the soecified toroue.

CAUTION: Failure to align the ATF pump ddven gear

shaft corr€ctly will result in a seized ATF pump driv€

gear or ATF pump dliven g€ar shatt,

ATF PUMP ATF PUMP

DRtvEN GEAR ORIVEN GEARSHAFT

12. lnstall the stator shatt and stop shaft.

13. Inslall the stop shaft stay on the secondary valve

body (one bolt).

14. Install the regulator valve body with the bolt.

1 5. Install the torque converter check valve, cooler check

valve and valve springs in the regulator valve body.

16. Install the lock-up valve body, separator plate, two

dowel pins and lubricator plate (eight bolts).

(cont'd)