torque HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 579 of 1681

![HONDA INTEGRA 1998 4.G Repair Manual 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in HONDA INTEGRA 1998 4.G Repair Manual 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in](/img/13/6069/w960_6069-578.png)

18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

'19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in the torque con

verter housrng.

21. Assemble the mainshaft and countershaft sub-

assembly, then install them together in the torque

converler noustng.

22. Turn the shilt fork so the large chamlered hole is fac-

ing the fork bolt hole, then installthe shift tork with

the reverse selector and torque the lock bolt. Bend

the lock tab against the bolt head.

SHIFT FORK

23. Install the reverse gear with the collar and needte

bearing on the countershaft.

24. Align the spring pin of the control shaft with the

transmission housing groove by turning the control

shaft.

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins.

CONTROL

TRANSMISSION HOUSING

lnstall the transmission housing mounting bolts along

with the transmission hanger and the connector

bracket, then torque the bolts in two or more steps

in the sequence shown.

TOROUE: rt4 N'm (4.5 kgt.m, 33 lbt.lt)

TRANSMISSION

26.

LOCK WASHERReplace.

6 x 1.0 mm4 t{.m(1.4 kgf.m, 10

e

Large chamfered hole

/ -'K\,,

a

14-163

Page 580 of 1681

Transmission

SUB.SHAFT

MAINSHAFT

Reassembly {cont'd)

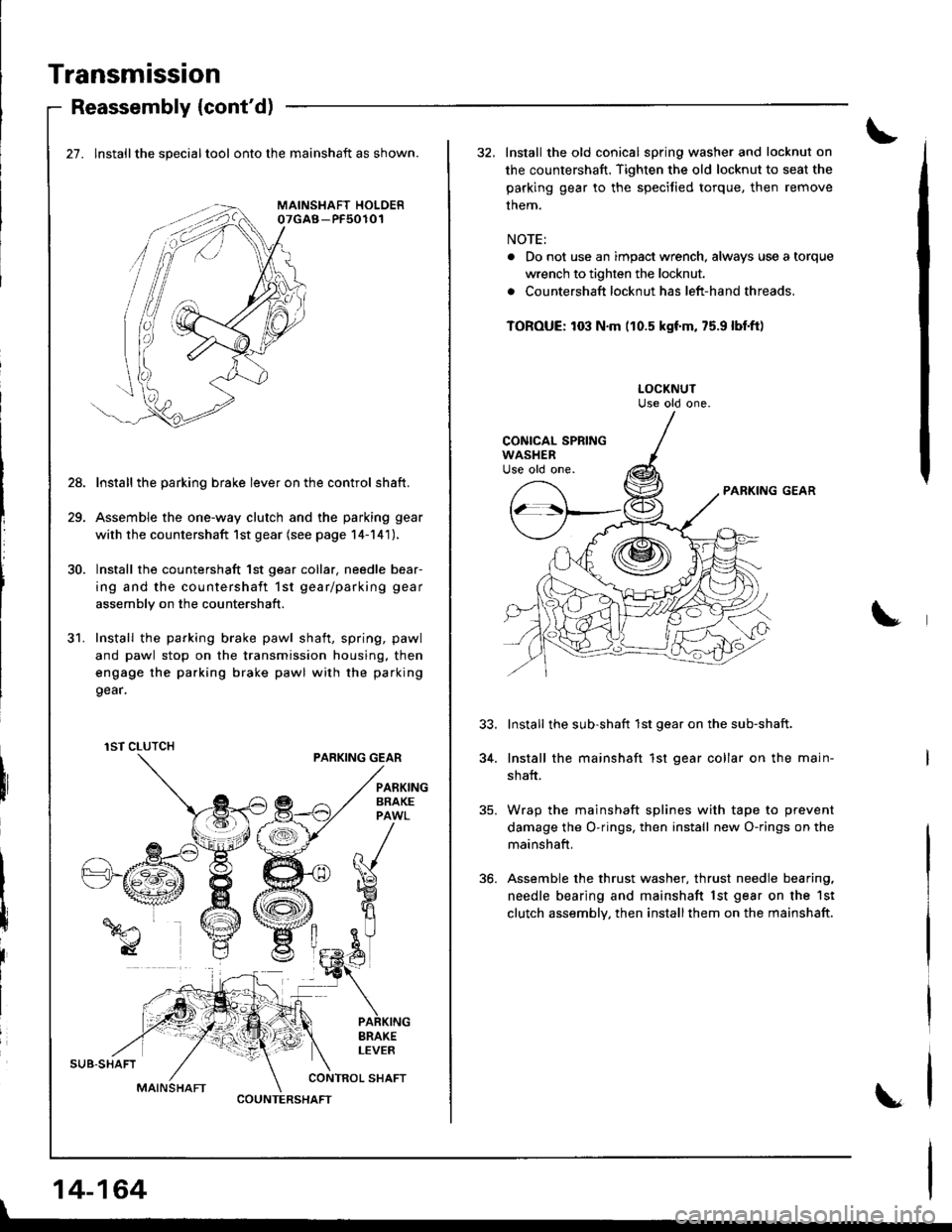

27. lnstallthe specialtool onto the mainshaft as shown.

Install the parking brake lever on the control shaft.

Assemble the one-way clutch and the parking gear

with the countershaft 1st gear (see page 14-141),

Install the countershaft 1st gear collar. needle bear-

ing and the countershaft 1st gear/parking gear

assembly on the countershaft.

Install the parking brake pawl shaft, spring, pawl

and pawl stop on the transmission housing. then

engage the parking brake pawl with the parking

9ear.

PARKING GEAR

28.

31.

I

I

iIBRAKELEVER

CONTROL SHAFT

1ST CLUTCH

COUNTERSHAFT

|

14-164

32, Install the old conical spring washer and locknut on

the countershaft. Tighten the old locknut to seat the

parking gear to the speciJied torque, then remove

them.

NOTE:

. Do not use an impact wrench, always use a torque

wrench to tighten the locknut.

. Countershaft locknut has left-hand threads,

TOROUE: to3 N.m (10.5 kgf'm, 75.9 lbl.ft)

PARKING GEAR

Install the sub-shaft 1st gear on the sub-shaft.

Install the mainshaft 1st gear collar on the main-

shaft.

Wrap the mainshaft splines with tape to prevent

damage the O-rings, then install new O-rings on the

mainshaft,

Assemble the thrust washer, thrust needle bearing,

needle bearing and mainshaft lst gear on the 1st

clutch assembly, then installthem on the mainshaft.

34.

Page 581 of 1681

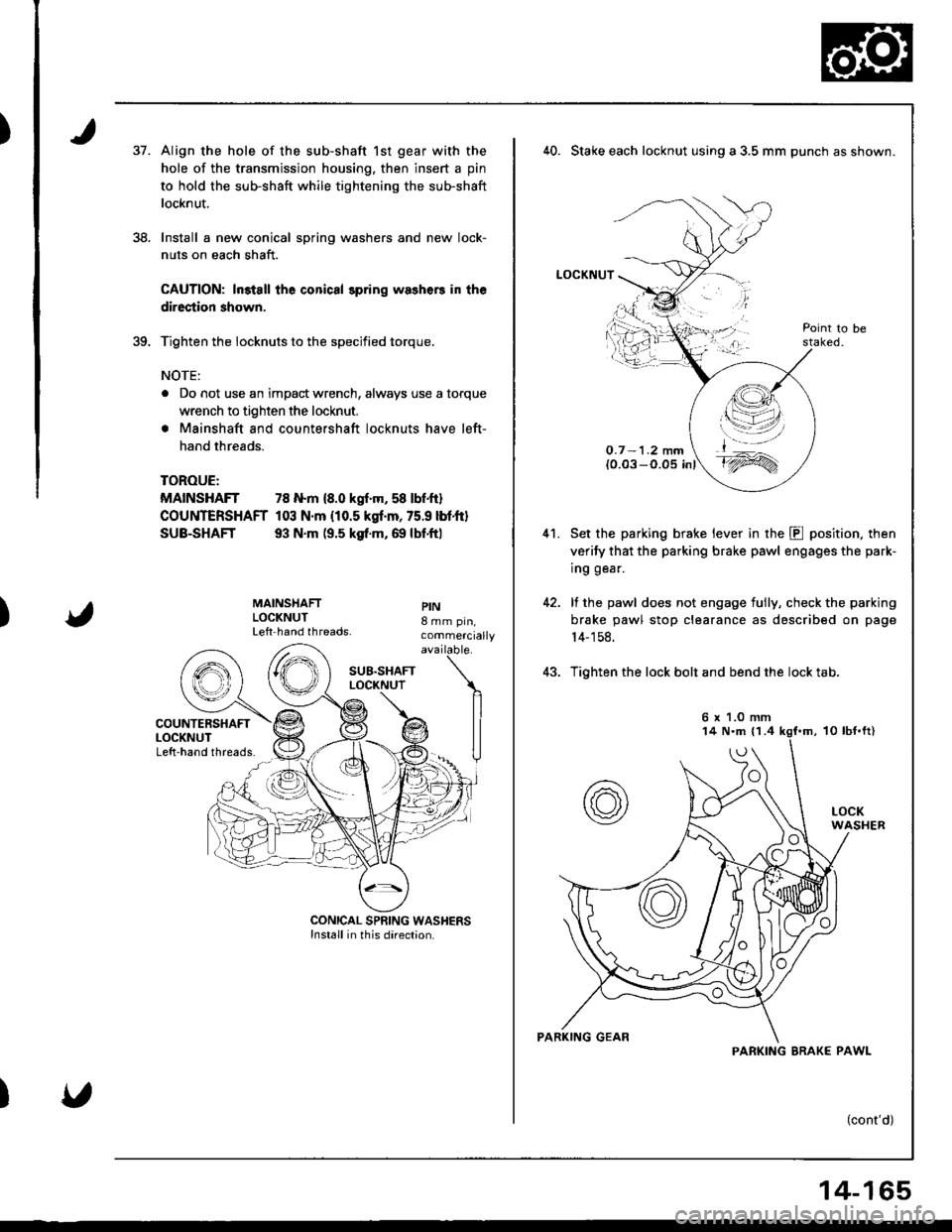

)37.

38.

Align the hole of the sub-shaft 1st gear with the

hole of the transmission housing. then insert a pin

to hold the sub-shaft while tightening the sub-shaft

locknut.

Install a new conical spring washers and new lock-

nuts on each shaft.

CAUTION: ln3tall the conical spring washers in the

direction shown.

Tighten the iocknuts to the specified torque.

NOTE:

a Do not use an impact wrench, always use a torque

wrench to tighten the locknut.

. Mainshaft and countershaft locknuts have left-

hand threads.

TOROUE:

MAINSHAFT 78 N.m {8.0 kgf.m, 58 lbf.ft}

COUNTERSHAFT 103 N.m {10.5 kgf.m, 75.9 lbtft}

SUB-SHAFT 93 N.m (9.5 ksf.m, 69 lbf.ftl

)

MAINSHAFTLOCKNUTLeft hand threads.

PIN8 mm pin,commercially

40. Stake each locknut using a 3,5 mm punch as shown.

LOCKNUT

O.7 -1.2 mm(0.03 -O.05 inl

Set the parking brake lever in the E position. then

verify that the parking brake pawl engages the park-

ing gear.

lf the pawl does not engage tully, check the parking

brake pawl stop clearance as described on page

14- 1 58.

Tighten the lock bolt and bend the lock tab.

(cont'd)

41.

t,\--l--'-,4 l';-.-='/

t_^

t'1ry

6 x 1.0 mm

PARKING BRAK€ PAWL

14-165

Page 583 of 1681

)

)

)

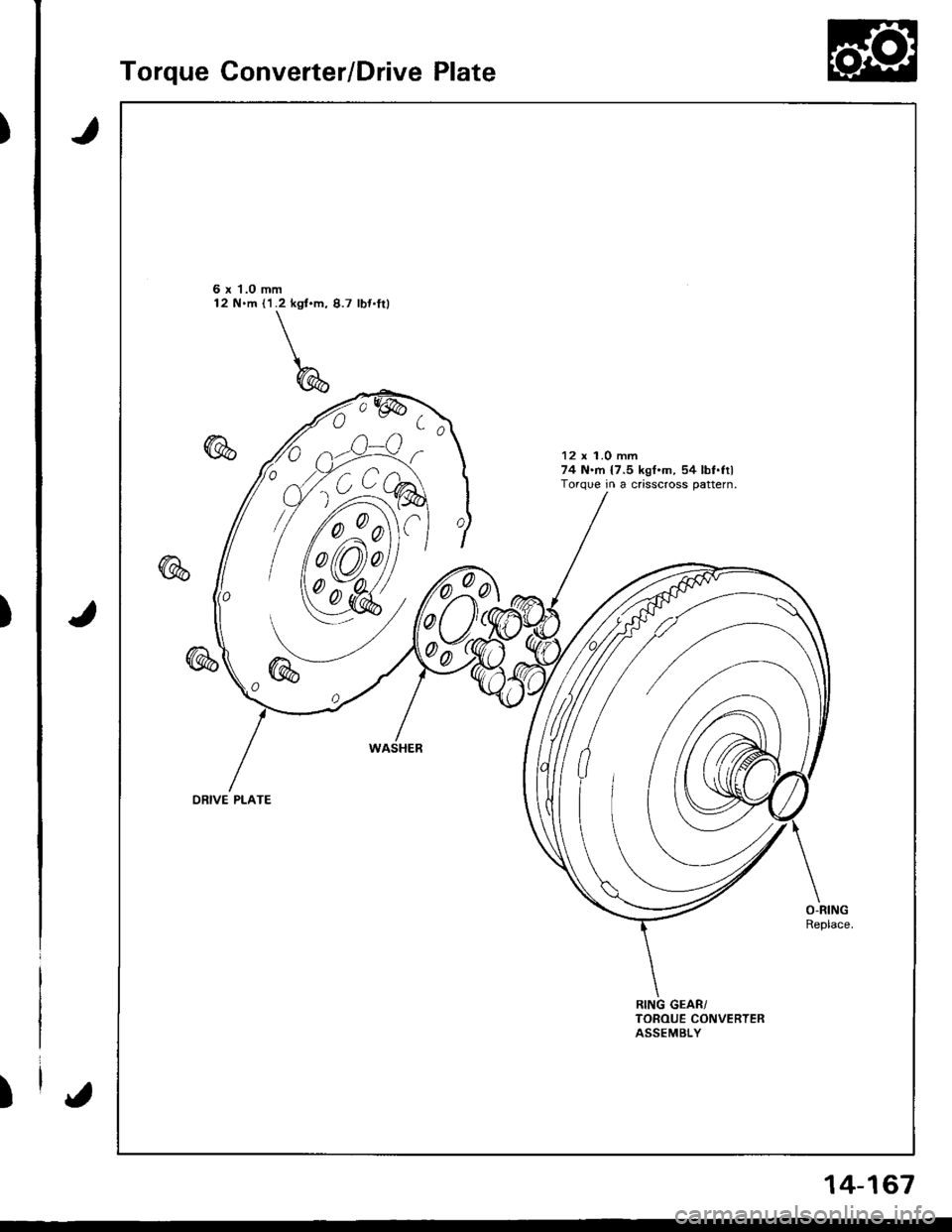

Torque Converter/Drive Plate

J

J

6 x 1.0 mm12 N.m ('l.2 kgt.m, 8.7 lbt.fil

12 x 1.0 mm74 N.rn {7.5 kgf.m, 54 lbf.filTorque in a crisscross pattern.

0

00

ORIVE PLATE

{

14-167

Page 584 of 1681

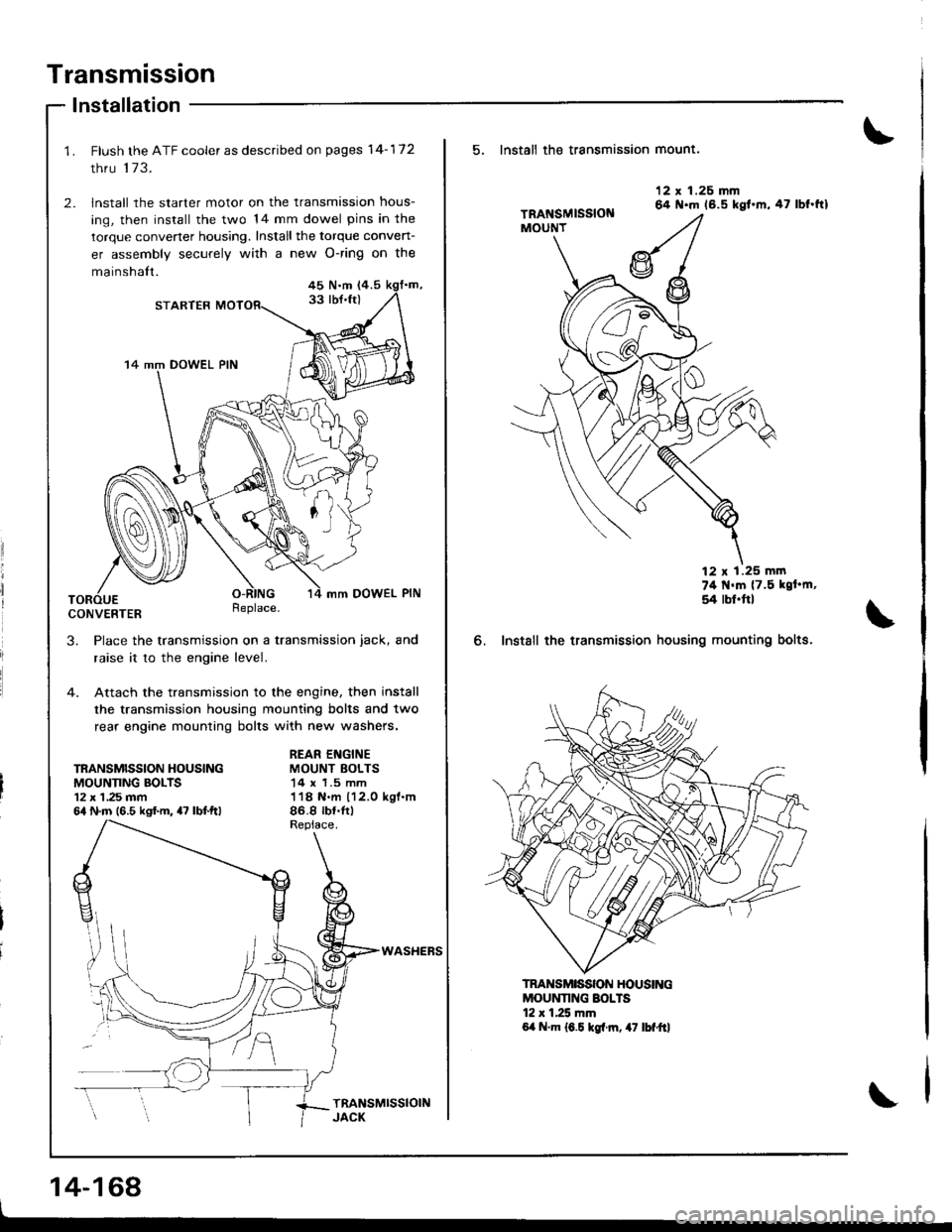

Transmission

lnstallation

Flush the ATF cooler as described on pages 14-172

thru 173.

lnstall the starter motor on the transmission hous-

ing, then install the two 14 mm dowel pins in the

torque convener housing. Install the torque conven-

er assembly securely with a new O-ring on the

mainshalt.45 N.m (4.5

33 lbJ.ft)STARTER

14 mm DOWEL PIN

mm DOWEL PIN

CONVERTERReplace.

3. Place the transmission on a transmission jack, and

raise it to the engine level.

4. Attach the transmission to the engine, then install

the transmission housing mounting bolts and two

rear engine mounting bolts with new washers.

TRANSMISSION HOUSINGMOUNNNG BOLTS12 x 1 ,25 mm64 N.m (6.5 kgf.m, 47 lbf.ftl

REAR ENGINEMOUNT BOLTS14 x 1.5 mm118 N.m 112.0 kgl.m86.8 rb{.tr)

WASHEFS

14-168

5. Install th€ transmission mount.

6. Instsll the transmission

12 x 1.26 mm64 N.m 16.5 kgt.m,47 lbf.ftl

74 t{'m {7.5 kgt'm,

54 rbl.ftl

housing mounting bolts.

MOUNNNG SOLTS12 r 1.25 mm6,t N.m 16.5 kgl.rn, 47 lbf"ftl

TRANSMISSON HOUSING

Page 585 of 1681

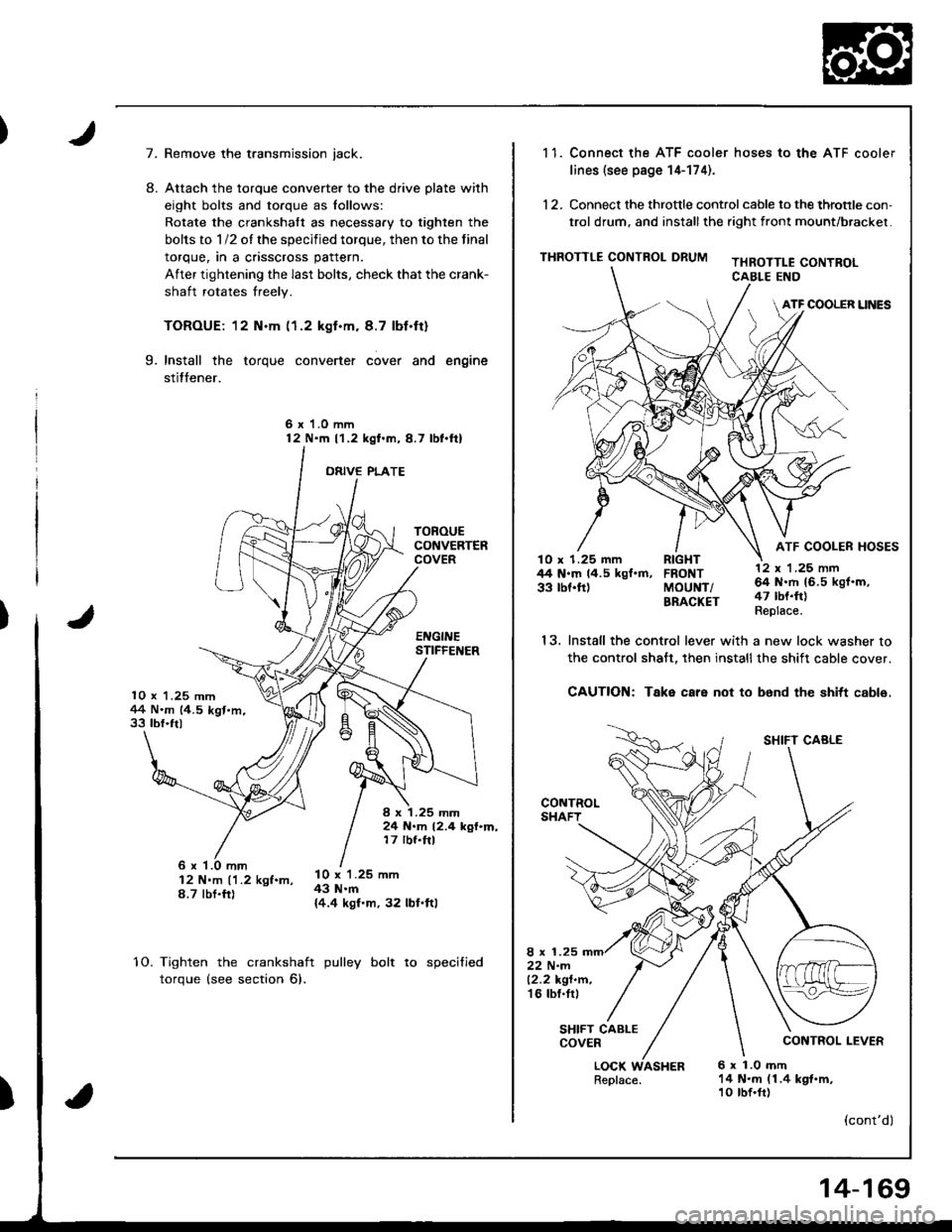

7.

10 x 1.25 mm1+4 N.m (4.5 kgt.m,33 tbf.ft)

TOROUECONVERTERCOVER

EI{GINESTIFFEI{ER

I x 1.25 mm24 N.m 12.4 kgf.m,17 rbf.ftl

8.

Remove the transmission jack.

Attach the torque converter to the drive plate with

eight bolts and torque as lollows:

Rotate the crankshatt as necessary to tighten the

bolts to 1/2 of the specified torque, then to the final

torque, in a crisscross pattern.

After tightening the last bolts, check that the crank-

shaft rotates freely.

TOROUE: 12 N.m (1.2 kgf.m. 8.7 lbf.ft)

Install the torque converter cover and engine

stitfener.

6 x 1.0 mm12 N'm l'1.2 kgl.m,8.7 lbl.ftl

ORIVE PLATE

9.

6 x '1.0 mm12 N'm ('1.2 kgf.m,8.7 tbt.fr)

l0 x 1.25 mm43 N.m{4.4 kgf.m, 32 lbl.ftl

10.Tighten the crankshaft

torque (see section 6).

pulley bolt to specified

)

1 1. Connect the ATF cooler hoses to the ATF cooler

lines (see page 14-174).

12. Connect the throttle control cable to the throtrle con,

trol drum, and installthe right front mount/brackel.

THROTTLE CONTROL DRUMTHROTTLE CONTROLCABLE END

ATF COOLER UNES

ATF COOLER HOSESlO x 1.25 mm RIGHT44 N.m 14.5 kgf.m, FRONT33 tbf.ft) MoUNT/BRACKET

13.

LOCK WASHERReplace.6 x 1.0 mft14 N.m (1.4 kgt.m,10 tbf.fr)

12 x 'l ,25 nn64 N.rh 16.5 kgf.m,47 tbt.ft)Replace.

SHIFT CABLE

CONTROL LEVER

(cont'dl

Install the control lever with a new lock washer to

the control shalt, then installthe shift cable cover.

CAUTION: Take care not to b6nd the shitt cable.

8 x 1.2522 N-m12.2 kgt.n.'t6 tbl.tr,

SHIFT CABLECOVER

14-169

Page 613 of 1681

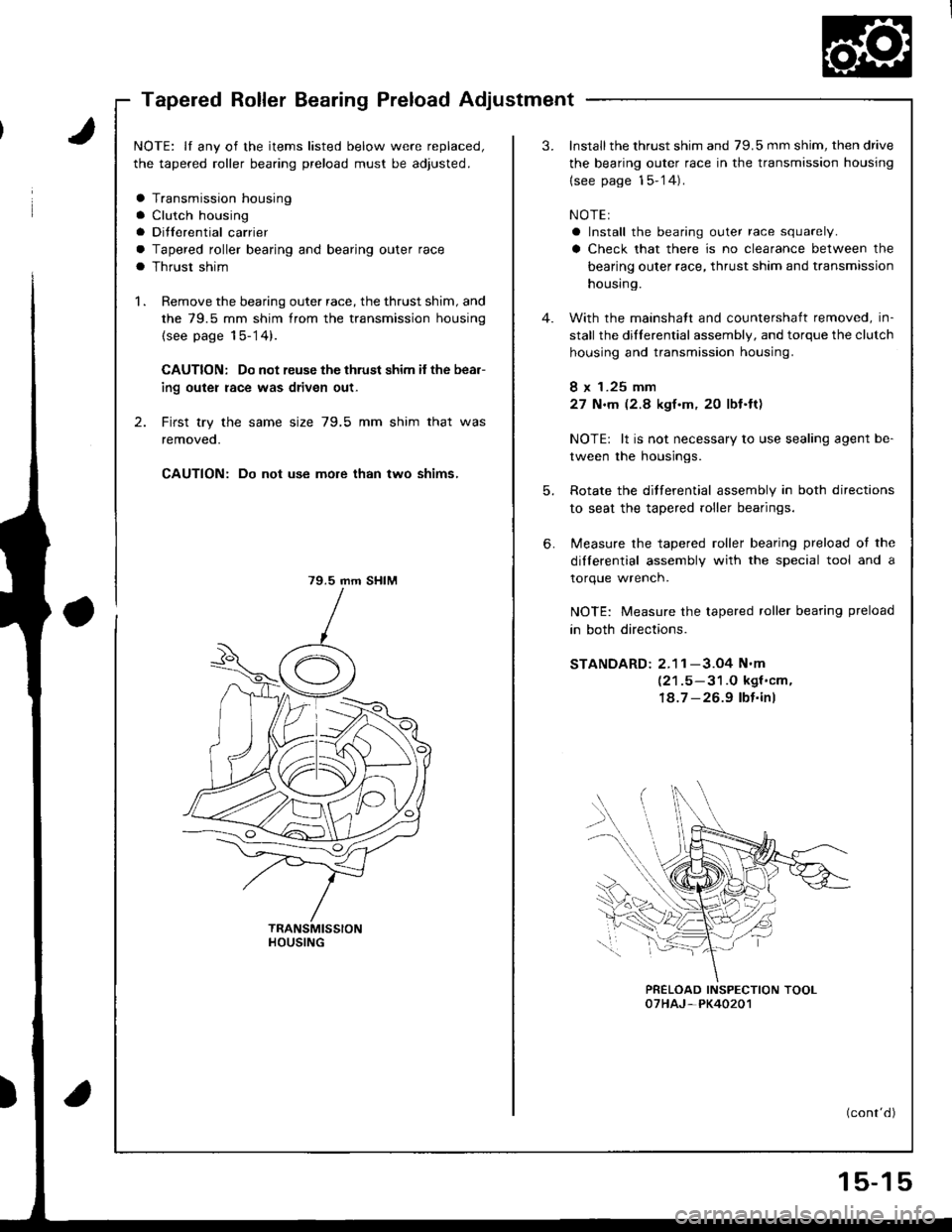

Tapered Roller Bearing Preload Adjustment

NOTE: lf any of the items listed below were replaced,

the tapered roller bearing preload must be adjusted.

a Transmission housing

a Clutch housing

a Ditferential carrier

a Tapered roller bearing and bearing outer race

a Thrust shim

1 . Remove the bearing outer race, the thrust shim, and

the 79.5 mm shim from the transmission housing

(see page 15-14).

CAUTION: Do not reuse the thrust shim if the bea.-

ing outer race was driven out-

2. First try the same size 79,5 mm shim that was

removeo.

CAUTION: Do not use more than two shims,

79.5 mm SHIM

HOUSING

3.Install the thrust shim and 79.5 mm shim, then drive

the bearing outer race in the transmission housing

{see page 15-'14).

NOTEI

a Install the bearing outer race squarely.

a Check that there is no clearance between the

bearing outer race, thrust shim and transmission

housing.

With the mainshatt and countershaft removed, in-

stall the dillerential assembly, and torque the clutch

housing and transmission housing.

8 x 1.25 mm

27 N.m (2.8 kgf.m. 2O lbf.ft)

NOTE: lt is not necessary to use sealing agent be-

tween the housings.

Rotate the ditferential assembly in both directions

to seat the tapered roller bearings.

Measure the tapered roller bearing preload ot the

dilferential assembly with the special tool and a

torque wrench.

NOTE: Measure the tapered roller bearing preload

in both directions.

STANDARD: 2.1 1 -3.O4 N'm

(21.5-31.O kgf'cm,

18.7 -26.9 lbt.inl

PRELOAD INSPECTION TOOL07HAJ-PK40201

(cont'd)

6.

5-1

Page 616 of 1681

Differential (818C5 engine)

SpecialTools .......... ........... 15-20

Limited Slip Differential

Description ..................... 15-21

OperationalGheck ......... 15-23

Rotating Torque Gheck .15-23

lffustrated Index .......... ..15-24

Tapered Roller Bearing Preload

Adjustment ................. 15-25

Page 619 of 1681

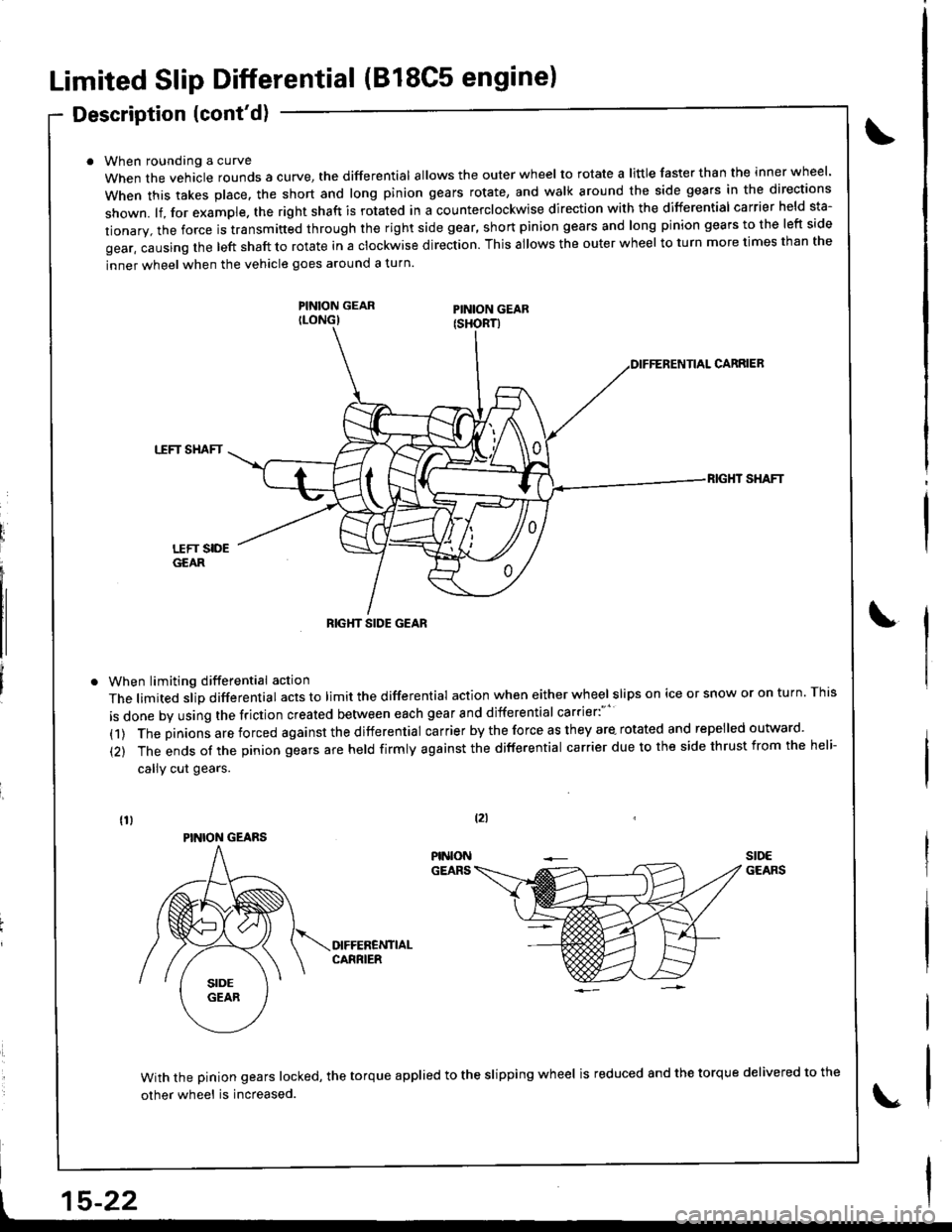

Limited Slip Differential (B18C5 engine)

Description (cont'd)

When roundang a curve

When the vehacle rounds a curye, tne differential allows the outer wheel to rotate a little faster than the inner wheel.

when this takes p|ace. the short and |ong pinion gears rotate, and wa|k around the side gears in the directions

shown. lf, for example. the right shaft is rotated in a counterclockwise direction with the differential carrier held sta-

tionary, the force is transmitted through the right side gear, short pinion gears and long pinion gears to the left side

gear, causing the left shaft to rotate in a clockwise direction. This allows the outer wheel to turn more times than the

inner wheel when the vehicle goes around a turn.

PINION GEARILONG)

When limiting differential action

The limited slip differential acts to limit the differential action when either wheel slips on ice or snow or on turn. This

is done by using the friction created between each gear and differential carrier:"''

(1) The pinions are forced against the differential carrier by the force as they are- rotated and repelled outward.

(2) The ends of the pinion gears are held firmly against the differential carrier due to the side thrust from the heli-

callY cut gears.

CARRIEB

TTFT SHAFT

RIG}IT SHAFT

With the pinion gears locked, the torque applied to the slipping wheel is reduced 8nd the torque delivered to the

other wheel is increased.

tzl

t15-22

RIGHT SIDE GEAR

PINION GEARS

Page 620 of 1681

Operational Check

Set the parking brake and block the rear wheels.

Raise the front of the vehicle, and support it with

safety stands in the proper locations (see section 1).

With the engine off, shift the transmission into lstgear,

Rotate either front wheel bv hand and check that

the other wheel rotates in the opposite direction.

lf the opposite tront wheel does not rotste, or if voucannot spin the front wheels at all, the limited slip

differential is faulty and should be roplaced.

Rotating Torque Check

Setting parking brake and block the rear wheels.

Raise the front of the vehicle, and support it with

safety stands in proper locations (see section 1).

With the engine off, shift the transmission into

Neutral.

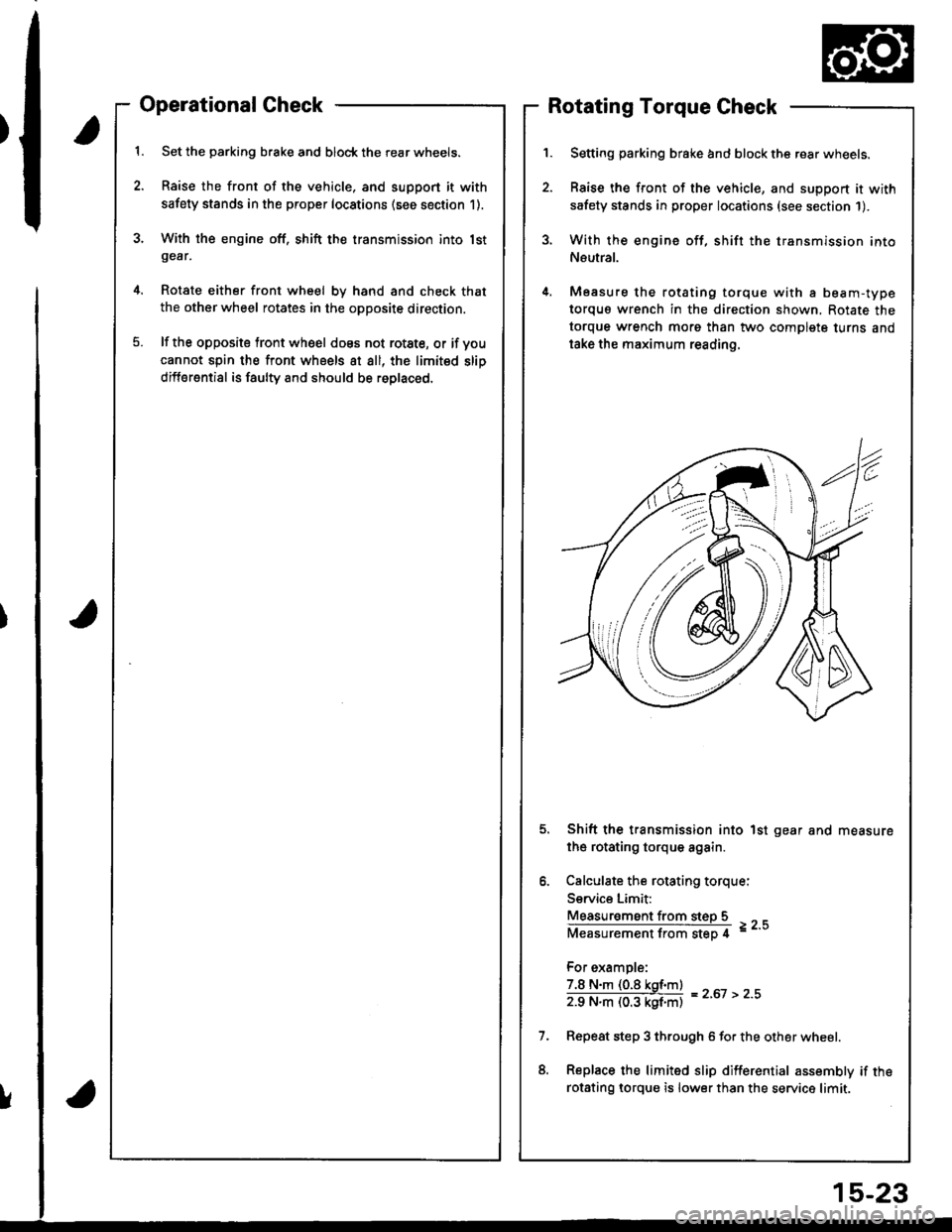

Measure the rotating torque with a beam-type

torquo wrench in the direction shown, Rotate the

torque wrench morg than two complete turns and

take the maximum reading.

Shift the transmission into 1st gear and measure

the rotating torque again.

Calculate the rotating torque:

Service Limit:

Measur€ment from steD 5

Measurementfrom step 4 =--

For example:

7.8 N.m (0.8 kgf.m)

zg N"ll (03 kgf'ntl = z'ot > z''

Repeat step 3 through 6 for the other wheel.

Replace the limited slip differential assembly if the

rotsting lorque is lower than the service limit.

!

15-23