ECO mode INFINITI FX35 2008 Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 932 of 3924

BL-198

< SERVICE INFORMATION >

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

“LOCK MODE” displayed on CONSULT-III screen

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “LOCK MO DE” is displayed on CONSULT-III screen.

Does CONSULT-III screen disp lay as shown in figure?

YES >> GO TO 2.

NO >> Refer to BL-195, "

Trouble Diagnosis Symptom Chart".

2.ESCAPE FROM LOCK MODE

1. Turn ignition switch OFF.

2. Turn ignition switch ON with registered key. (Do not start engine.) Wait 5 seconds.

3. Return the key to OFF position. Wait 5 seconds.

4. Repeat steps 2 and 3 twice (total of three cycles).

5. Start the engine.

Does engine start?

YES >> System is OK (Now system is escaped from “LOCK MODE”).

NO >> GO TO 3.

3.PERFORM INITIALIZATION WITH CONSULT-III

Perform initialization with CONSULT-III.

For initialization, refer to “CONSULT -III Operation Manual NATS-IVIS/NVIS”.

NOTE:

If the initialization is not completed or malf unction, CONSULT-III shows the message on the screen.

Can the system be initialized?

YES >> System is OK.

NO >> GO TO 4.

4.PERFORM INITIALIZATION WITH CONSULT-III AGAIN

1. Replace BCM.

2. Perform initialization with CONSULT-III. For initialization, refer to “CONSULT -III Operation Manual NATS-IVIS/NVIS”.

NOTE:

If the initialization is not completed or malf unctions, CONSULT-III shows the message on the screen.

Can the system be initialized?

YES >> System is OK. BCM is malfunctioning. Replace BCM.

Perform initialization with CONSULT-III.

For initialization, refer to “CONSULT -III Operation Manual NATS-IVIS/NVIS”.

NO >> ECM is malfunctioning. Replace ECM.

Perform initialization or re-communicating function.

- For initialization, refer to “CONSULT -III Operation Manual NATS-IVIS/NVIS”.

- For re-communicating function, refer to BL-187, "

ECM Re-Communicating Function".

Diagnosis Procedure 5INFOID:0000000001327938

Self-diagnostic results:

“CHAIN OF IMMU-KEY” is displayed on CONSULT-III screen

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm self-diagnostic results “CHAIN OF IM MU-KEY” is displayed on CONSULT-III screen.

Does CONSULT-III screen display as shown?

YES >> GO TO 2.

NO >> Refer to BL-195, "

Trouble Diagnosis Symptom Chart".

2.CHECK NATS ANTENNA AMP. INSTALLATION

Check NATS antenna amp. installation. Refer to BL-201, "

Removal and Installation NATS Antenna Amp".

OK or NG

OK >> GO TO 3.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1007 of 3924

FRONT DISC BRAKEBR-23

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

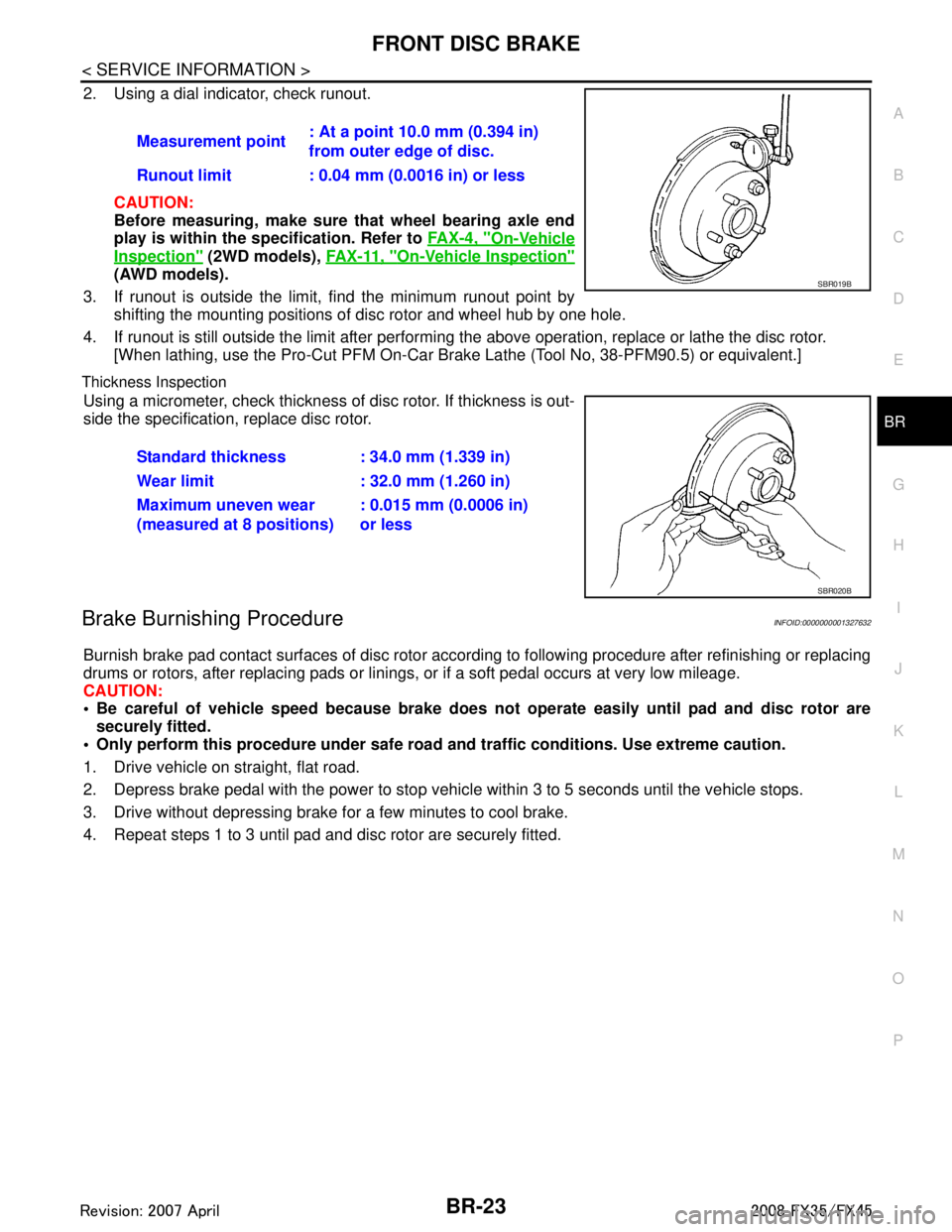

2. Using a dial indicator, check runout.

CAUTION:

Before measuring, make sure that wheel bearing axle end

play is within the sp ecification. Refer to FA X - 4 , "

On-Vehicle

Inspection" (2WD models), FA X - 11 , "On-Vehicle Inspection"

(AWD models).

3. If runout is outside the limit, find the minimum runout point by shifting the mounting positions of disc rotor and wheel hub by one hole.

4. If runout is still outside the limit after performing the above operation, replace or lathe the disc rotor.

[When lathing, use the Pro-Cut PFM On-Car Br ake Lathe (Tool No, 38-PFM90.5) or equivalent.]

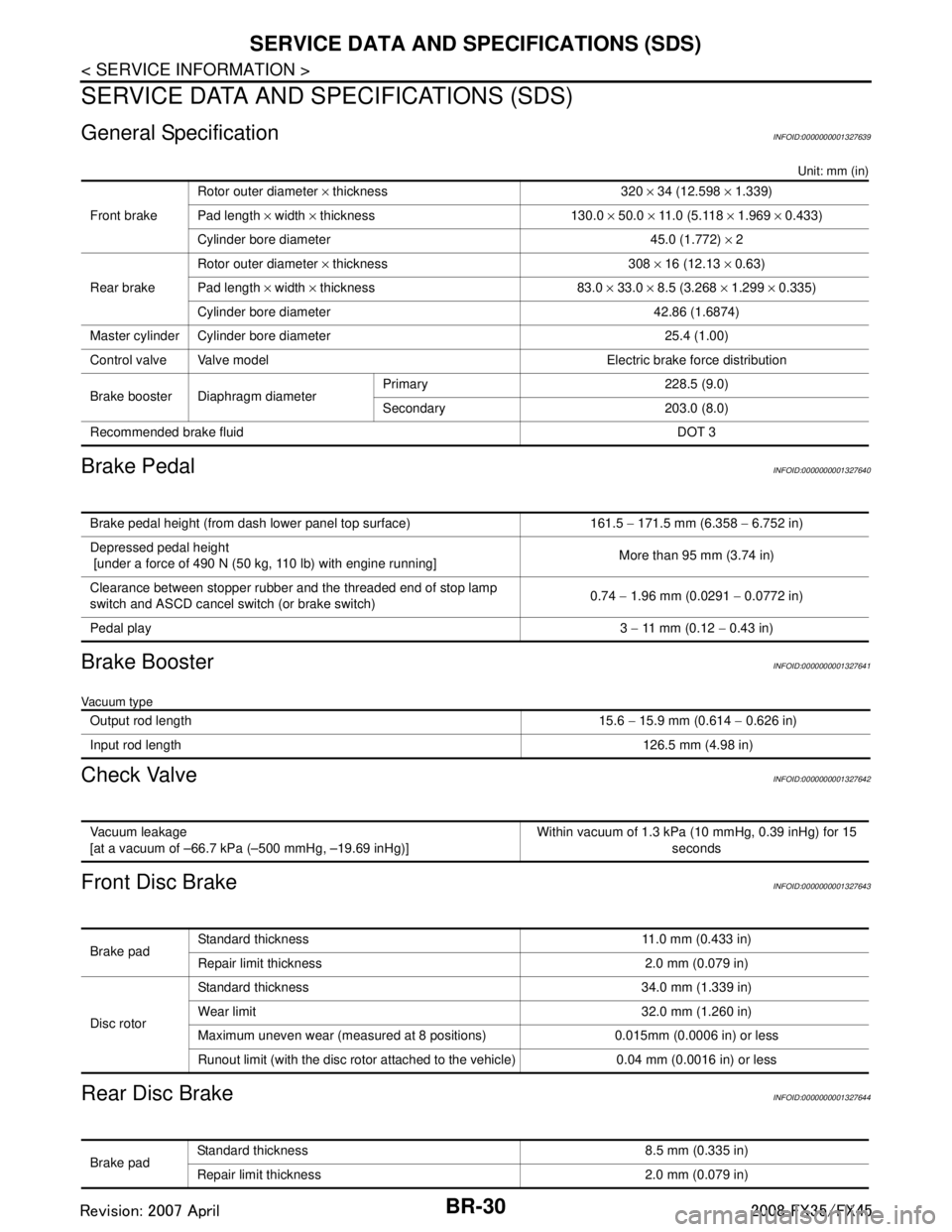

Thickness Inspection

Using a micrometer, check thickness of disc rotor. If thickness is out-

side the specification, replace disc rotor.

Brake Burnishing ProcedureINFOID:0000000001327632

Burnish brake pad contact surfaces of disc rotor according to following procedure after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal occurs at very low mileage.

CAUTION:

Be careful of vehicle speed because brake does no t operate easily until pad and disc rotor are

securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicl e within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted. Measurement point

: At a point 10.0 mm (0.394 in)

from outer edge of disc.

Runout limit : 0.04 mm (0.0016 in) or less

SBR019B

Standard thickness : 34.0 mm (1.339 in)

Wear limit : 32.0 mm (1.260 in)

Maximum uneven wear

(measured at 8 positions) : 0.015 mm (0.0006 in)

or less

SBR020B

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1014 of 3924

BR-30

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000001327639

Unit: mm (in)

Brake PedalINFOID:0000000001327640

Brake BoosterINFOID:0000000001327641

Vacuum type

Check ValveINFOID:0000000001327642

Front Disc BrakeINFOID:0000000001327643

Rear Disc BrakeINFOID:0000000001327644

Front brakeRotor outer diameter

× thickness 320 × 34 (12.598 × 1.339)

Pad length × width × thickness 130.0 × 50.0 × 11.0 (5.118 × 1.969 × 0.433)

Cylinder bore diameter 45.0 (1.772) × 2

Rear brake Rotor outer diameter

× thickness 308 × 16 (12.13 × 0.63)

Pad length × width × thickness 83.0 × 33.0 × 8.5 (3.268 × 1.299 × 0.335)

Cylinder bore diameter 42.86 (1.6874)

Master cylinder Cylinder bore diameter 25.4 (1.00)

Control valve Valve model Electric brake force distribution

Brake booster Diaphragm diameter Primary 228.5 (9.0)

Secondary 203.0 (8.0)

Recommended brake fluid DOT 3

Brake pedal height (from dash lower panel top surface) 161.5 − 171.5 mm (6.358 − 6.752 in)

Depressed pedal height

[under a force of 490 N (50 kg, 110 lb) with engine running] More than 95 mm (3.74 in)

Clearance between stopper rubber and the threaded end of stop lamp

switch and ASCD cancel switch (or brake switch) 0.74

− 1.96 mm (0.0291 − 0.0772 in)

Pedal play 3 − 11 mm (0.12 − 0.43 in)

Output rod length 15.6 − 15.9 mm (0.614 − 0.626 in)

Input rod length 126.5 mm (4.98 in)

Vacuum leakage

[at a vacuum of –66.7 kPa (–500 mmHg, –19.69 inHg)]Within vacuum of 1.3 kPa (10 mmHg, 0.39 inHg) for 15

seconds

Brake padStandard thickness 11.0 mm (0.433 in)

Repair limit thickness 2.0 mm (0.079 in)

Disc rotor Standard thickness 34.0 mm (1.339 in)

Wear limit 32.0 mm (1.260 in)

Maximum uneven wear (measured at 8 positions) 0.015mm (0.0006 in) or less

Runout limit (with the disc rotor attached to the vehicle) 0.04 mm (0.0016 in) or less

Brake pad

Standard thickness 8.5 mm (0.335 in)

Repair limit thickness 2.0 mm (0.079 in)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1023 of 3924

![INFINITI FX35 2008 Owners Manual

BRC-8

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angl

e Sensor Neutral PositionINFOID:0000000001327658

In case of doing work that applies to the INFINITI FX35 2008 Owners Manual

BRC-8

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angl

e Sensor Neutral PositionINFOID:0000000001327658

In case of doing work that applies to the](/img/42/57017/w960_57017-1022.png)

BRC-8

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angl

e Sensor Neutral PositionINFOID:0000000001327658

In case of doing work that applies to the list below, make sure to adjust neutral position of steering angle sen-

sor before running vehicle.

CAUTION:

To adjust neutral position of steering angl e sensor, make sure to use CONSULT-III.

(Adjustment can not be done without CONSULT-III.)

1. Stop vehicle with front wheels in straight-ahead position.

2. Touch “WORK SUPPORT” and “ST ANGLE SENSOR ADJUSTMENT” on CONSULT-III screen in this order.

3. Touch “START”. CAUTION:

Do not touch steering wheel whil e adjusting steering angle sensor.

4. After approximately 10 seconds, touch “END”. (After approximately 60 seconds, it ends automatically.)

5. Turn ignition switch OFF, then turn it ON again. CAUTION:

Be sure to perform above operation.

6. Run vehicle with front wheels in straight-ahead position, then stop.

7. Select “DATA MONITOR”, “SELECTION FROM ME NU”, and “STR ANGLE SIG” on CONSULT-III screen.

Then make sure “STR ANGLE SIG” is within 0 ± 3.5 deg. If value is more than specification, repeat steps

1 to 6.

8. Erase memory of ABS actuator and electric unit (control unit) and ECM.

9. Turn ignition switch OFF.

Calibration of Decel G Sensor (AWD Models)INFOID:0000000001327659

NOTE:

After removing/installing or replacing yaw rate/side/dec el G sensor, ABS actuator and electric unit (control

unit), suspension components, or after adjusting wheel ali gnment, make sure to calibration of decel G sensor

before running vehicle.

CAUTION:

To calibrate decel G sensor, make sure to use CONS ULT-III. (Adjustment can not be done without CON-

SULT-III.)

1. Stop vehicle with front wheels in straight-ahead position.

CAUTION:

The work should be done at a horizontal place when vehicle is in the unloaded vehicle condition.

Keep all tires inflated to correct pressures. Ad just the tire pressure to the specified pressure

value.

2. Touch “WORK SUPPORT” and “DECEL G-SEN CALI BRATION” on CONSULT-III screen in this order.

3. Touch “START”. CAUTION:

Set vehicle as shown in the display.

4. After approximately 10 seconds, touch “END”. (After approximately 60 seconds, it ends automatically.)

Situation Adjustment of Steering Angle Sensor Neutral Position

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit) ×

Removing/Installing steering angle sensor ×

Removing/Installing steering components ×

Removing/Installing suspension components ×

Change 4 tires to new ones —

Tire rotation —

Adjusting wheel alignment ×

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1041 of 3924

![INFINITI FX35 2008 Owners Manual

BRC-26

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: Approx. Within 2 seconds after ignition switch is INFINITI FX35 2008 Owners Manual

BRC-26

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: Approx. Within 2 seconds after ignition switch is](/img/42/57017/w960_57017-1040.png)

BRC-26

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: Approx. Within 2 seconds after ignition switch is turned ON, or when a malfunction is detected.

OFF: Approx. 2 seconds after ignition switch is turned ON (when sy

stem is in normal operation) and VDC/TCS function is not activated.

Note 3: ON/OFF timing of VDC OFF indicator lamp

ON: Approx. Within 2 seconds after ignition switch is turned ON, or when a malfunction is detected and VDC OFF switch is ON.

OFF: Approx. 2 seconds after ignition switch is turned ON (when system is in normal operation.) And when VDC OFF switch is OFF.

Note 4: ON/OFF timing of SLIP indicator lamp

ON: Approx. Within 2 seconds after ignition switch is turned ON, or when a malfunction is detected and VDC/TCS function is activa ted

while driving.

OFF: Approx. 2 seconds after ignition switch is turned ON (when sy stem is in normal operation) and VDC/TCS function is not activated.

Flashing: VDC/TCS function is active during driving

Note 5: Only AWD models.

Note 6: Serves as EBD warning lamp.

CONSULT-III Functions (ABS)INFOID:0000000001327671

CONSULT-III MAIN FUNCTION

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

Self-DiagnosisINFOID:0000000001327672

OPERATION PROCEDURE

Before performing the self-diagnosis, start engine and driv e vehicle at 30 km/h (19 MPH) or more for approxi-

mately 1 minute.

ERASE MEMORY

After erasing DTC memory, start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1

minute as the final inspection, and make sure that the ABS warning lamp, VDC OFF indicator lamp, SLIP indi-

cator lamp and brake warning lamp turn OFF.

CAUTION:

If memory cannot be erased, perform applicably diagnosis.

NOTE:

When the wheel sensor malfunctions, after inspecting the wheel sensor system, the ABS warning lamp,

VDC OFF indicator lamp, SLIP indicator lamp and br ake waning lamp will not turn OFF even when the sys-

tem is normal unless the vehicle is driving at approxim ately 30 km/h (19 MPH) or more for approximately 1

minute.

Brake warning lamp will turn ON in case of parki ng brake operation (when switch is ON) or of brake fluid

level switch should not stay “ON” position.

VDC OFF switch should not stay “ON” position.

2WD/4WD Drive axle 2WD model 2WD

AWD model AWD

Monitor item Display content

Data monitor

Condition Reference value in

normal operation

Diagnostic test mode Function

WORK SUPPORT This mode enables a technician to adjust some devices faster and more accurately by following the

indications on CONSULT-III.

SELF-DIAG RESULTS Self-diagnostic results can be read and erased quickly.

DATA MONITOR Input/Output data in the ABS actuator and electric unit (control unit) can be read.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of communication can be read.

ACTIVE TEST Diagnostic Test Mode in which CONSULT-III drives

some actuators apart from the ABS actuator and

electric unit (control unit) and also shifts some parameters in a specified range.

FUNCTION TEST Performed by CONSULT-III inst ead of a technician to determine whether each system is “OK” or “NG”.

ECU PART NUMBER ABS actuator and electric unit (control unit) part number can be read.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1043 of 3924

![INFINITI FX35 2008 Owners Manual

BRC-28

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note 1: After completing repairs of shorted sensor circuit, when turning ignition switch ON, ABS warning lamp turned on. Make t

hat ABS

w INFINITI FX35 2008 Owners Manual

BRC-28

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note 1: After completing repairs of shorted sensor circuit, when turning ignition switch ON, ABS warning lamp turned on. Make t

hat ABS

w](/img/42/57017/w960_57017-1042.png)

BRC-28

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note 1: After completing repairs of shorted sensor circuit, when turning ignition switch ON, ABS warning lamp turned on. Make t

hat ABS

warning lamp turned off while driving vehicle at approximately 30 km/h (19 MPH) or more for approximately 1 minute according to self-

diagnosis procedure. In addition, if whee l sensor 2 is displayed for wheels, check wheel sensor circuit and also check ABS actu ator and

electric unit (control unit) power voltage.

Note 2: If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for CAN communication line

first.

Note 3: “ACTUATOR RLY” on the CONSULT-III self-diagnostic results indicates the malfunction of actuator relay or circuit. Actua tor relay

is imbedded in ABS actuator and electric unit (control unit).

Note 4:Only AWD models.

Data MonitorINFOID:0000000001327673

DISPLAY ITEM LIST

ENGINE SIGNAL 2

[C1131] Based on the signal from ECM, ABS ac

tuator and electric unit (control

unit) judges that engine ETC system is malfunctioning. BRC-42, "DTC C1131 ENGINE

SIGNAL 2"

ENGINE SIGNAL 3

[C1132]Based on the signal from ECM, ABS ac

tuator and electric unit (control

unit) judges that engine CAN system is malfunctioning. BRC-42, "DTC C1132 ENGINE

SIGNAL 3"

ENGINE SIGNAL 4

[C1133]Based on the signal from ECM, ABS ac

tuator and electric unit (control

unit) judges that engine torque down system is malfunctioning. BRC-42, "DTC C1133 ENGINE

SIGNAL 4"

ENGINE SIGNAL 6

[C1136]

Based on the signal from ECM, ABS ac

tuator and electric unit (control

unit) judges that engine control system is malfunctioning. BRC-42, "DTC C1136 ENGINE

SIGNAL 6"

ACTUATOR RLY

[C1140] (Note 3) Actuator solenoid valve relay is ON, even if control unit sends off sig-

nal.

Actuator solenoid valve relay is OFF, even if control unit sends on sig- nal. BRC-43, "DTC C1140 ACTUA-

TOR RLY"

PRESS SEN CIRCUIT

[C1142]

Pressure sensor signal line is open or shorted, or sensor power voltage

is unusual, or pressure sensor is malfunctioning. BRC-43, "DTC C1142 PRESS

SEN CIRCUIT"

ST ANG SEN CIRCUIT

[C1143]Neutral position of steering angle sensor is dislocated, or steering angle

sensor is malfunctioning. BRC-44, "DTC C1143 ST ANG

SEN CIRCUIT"

ST ANG SEN SIGNAL

[C1144]

Neutral position correction of steering angle sensor is not finished. BRC-45, "DTC C1144 ST ANG

SEN SIGNAL"

YAW RATE SENSOR

[C1145]Yaw rate sensor has generated an error, or yaw rate sensor signal line

is open or shorted. BRC-46, "DTC C1145 YAW

RATE SENSOR"

SIDE G-SEN CIRCUIT

[C1146]Side G sensor is malfunctioning, or signal line of side G sensor is open

or shorted. BRC-46, "DTC C1146 SIDE G-

SEN CIRCUIT"

BR FLUID LEVEL LOW

[C1155]

Brake fluid level drops or

circuit between ABS actuat or and electric unit

(control unit) and brake fluid level switch is open or shorted. BRC-46, "DTC C1155 BR FLU-

ID LEVEL LOW"

ST ANG SEN COM CIR

[C1156]CAN communication line or steering angle sensor has generated an er-

ror. BRC-47, "DTC C1156 ST ANG

SEN COM CIR"

DECEL G SEN SET

[C1160] (Note 4)

Neutral position correction of decel G sensor is not finished.

BRC-47, "DTC C1160 DECEL G

SEN SET"

CV 1

[C1164]Primary side VDC switch-over solenoid valve 1 (cut valve 1) is open or

shorted, or control line is open or shorted to power supply or ground.

BRC-47, "DTC C1164 CV 1"

CV 2

[C1165]Secondary side VDC switch-over solenoid valve 2 (cut valve 2) is open

or shorted, or control line is open or shorted to power supply or ground.

BRC-47, "DTC C1165 CV 2"

SV 1

[C1166]Primary side VDC switch-over solenoid valve 1 (suction valve 1) is open

or shorted, or control line is open or shorted to power supply or ground.

BRC-47, "DTC C1166 SV 1"

SV 2

[C1167]Secondary side VDC switch-over solenoid valve 2 (suction valve 2) is

open or shorted, or control line is open or shorted to power supply or

ground.

BRC-47, "DTC C1167 SV 2"

VARIANT CODING

[C1170]

V coding is not functioning. BRC-48, "DTC C1170 VARIANT

CODING"

CAN COMM CIRCUIT

[U1000] (Note 2)When a ABS actuator and electric unit (control unit) is not transmitting

or receiving CAN communication signal for 2 seconds or more. BRC-48, "DTC U1000 CAN

COMM CIRCUIT"

Self-diagnostic item Malfunction detecting condition Check system

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1053 of 3924

![INFINITI FX35 2008 Owners Manual

BRC-38

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYSTEM

1. Disconnect ABS actuator and electric unit (contro

l unit) connector. Then reconnect it securely.

2. Perform self-diagnosis INFINITI FX35 2008 Owners Manual

BRC-38

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYSTEM

1. Disconnect ABS actuator and electric unit (contro

l unit) connector. Then reconnect it securely.

2. Perform self-diagnosis](/img/42/57017/w960_57017-1052.png)

BRC-38

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYSTEM

1. Disconnect ABS actuator and electric unit (contro

l unit) connector. Then reconnect it securely.

2. Perform self-diagnosis again.

Do any self-diagnosis item appear?

YES >> GO TO 3.

NO >> Poor connection. Repair or replace the applicable connector.

3.CHECK ABS MOTOR AND MOTOR RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF and disconnect ABS actuat or and electric unit (control unit) connector E56.

2. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

3. Check continuity between ABS ac tuator and electric unit (control

unit) harness connector and ground.

OK or NG

OK >> Perform self-diagnosis again. If the same result appears, replace ABS actuator and electric unit (control

unit). Refer to BRC-54

.

NG >> Repair harness or connectors.

DTC C1113 G-SENSORINFOID:0000000001327682

CAUTION:

Sudden turns (such as spin turns, acceleration turns), drifting, etc. may cause the G sensor circuit

indicate a malfunction. However, this is not a malf unction, if normal operation can be resumed after

restarting engine.

INSPECTION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Check the self-diagnostic results.

CAUTION:

When on a turntable, such as at a parking structure entrance, or wh en on a moving object with engine

running, VDC OFF indicator lamp might turn on and self-diagnosis using CONSULT-III the yaw rate

sensor system might be displayed, but in this case ther e is no malfunction in yaw rate sensor circuit.

As soon as vehicle leaves turntable or moving object , restart engine to return the system to normal.

Is the above displayed in the self-diagnosis display items?

YES >> GO TO 2.

NO >> INSPECTION END

2.CHECK CONNECTOR

ABS actuator and electric unit (control unit) Ground Voltage

1, 32 — Battery voltage

(Approx. 12 V)

SFIA1198E

ABS actuator and electric unit (control unit) Ground Continuity

16, 47 — Yes

SFIA1197E

Self-diagnostic resultsYAW RATE SENSOR

SIDE G-SEN CIRCUIT

G-SENSOR (AWD models)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1054 of 3924

![INFINITI FX35 2008 Owners Manual

TROUBLE DIAGNOSIS FOR SYSTEMBRC-39

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

1. Disconnect G sensor connector and ABS actuator and el ectric unit (control unit) connecto INFINITI FX35 2008 Owners Manual

TROUBLE DIAGNOSIS FOR SYSTEMBRC-39

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

1. Disconnect G sensor connector and ABS actuator and el ectric unit (control unit) connecto](/img/42/57017/w960_57017-1053.png)

TROUBLE DIAGNOSIS FOR SYSTEMBRC-39

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

1. Disconnect G sensor connector and ABS actuator and el ectric unit (control unit) connector and check ter-

minals for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace

terminal.

2. Reconnect connectors and perform a ABS actuator and electric unit (control unit) self-diagnosis again.

OK or NG

OK >> Connector terminal contact is loose, damaged, open or shorted.

NG >> GO TO 3.

3.CHECK G SENSOR HARNESS

1. Turn ignition switch OFF and disconnect G sensor connector M79 (2WD models) or M71 (A WD models) and ABS actuator

and electric unit (control unit) connector E56.

2. Check continuity between ABS ac tuator and electric unit (control

unit) harness connector and G sensor harness connector.

OK or NG

OK >> GO TO 4.

NG >> If the open or short in harness, repair or replace harness.

4.CHECK G SENSOR

1. Connect G sensor connector and ABS actuator and electric unit (control unit) connector.

2. Use CONSULT-III “DATA MONITOR” to check if G sensor are normal.

OK or NG

OK >> Perform ABS actuator and electric unit (control unit) self-diagnosis again.

NG >> Replace malfunctioning G sensor, and then perform self-diagnosis for ABS actuator and electric

unit (control unit) again.

DTC C1115 ABS SENSOR [ABNORMAL SIGNAL]INFOID:0000000001569698

Refer to BRC-34, "DTC C1101 RR RH SENSOR-1".

DTC C1116 STOP LAMP SWINFOID:0000000001327686

INSPECTION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Check the self-diagnostic results.

Is the above displayed in the self-diagnosis display item?

ABS actuator and electric unit (c ontrol unit) G sensor Continuity

63

Ye s

24 5

25 1

29 2

SFIA1192E

Vehicle status

Yaw rate sensor

(Data monitor standard) Side G sensor

(Data monitor standard) Decel G sensor (AWD models)

(Data monitor standard)

When stopped − 4 to + 4 deg/s

− 1.1 to + 1.1 m/s

2− 0 . 11 t o + 0 . 11 G

Right turn Negative value Negative value —

Left turn Positive value Positive value —

Speed up — — Negative value

Speed down — — Positive value

Self-diagnostic results STOP LAMP SW

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1133 of 3924

COMBINATION METERSDI-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Switch modes with following procedure.

When trip transfer switch is pressed, trip meter display changes.

If trip reset switch is pressed for 1 second or more while “trip A” is displayed, only “trip A” is reset.

NOTE:

The record of the odo meter is kept even if the battery cable is dis-

connected. The record of the trip meter is erased when the battery

cable is disconnected.

COMBINATION METER ILLUMINATION CONTROL

Daytime Mode

When ignition switch is turned ON, combination meter il lumination is turned ON by unified meter control unit.

Nighttime Mode

Unified meter control unit is transferred to nighttime mode, with ignitio\

n switch turned ON and position light

request signal from BCM with CAN communication.

When nighttime mode, illumination c ontrol switch illumination turns

ON by unified meter control unit. Each illumination is controlled by

unified meter control unit.

Each illumination can be adjusted to 16 step by illumination control switch in nighttime mode.

NOTE:

For further details of illumination circuit, refer to LT-169, "

System

Description".

FA I L - S A F E

Combination meter performs fail-safe operation when unified meter and A/C amp. communication is malfunc-

tioning.

SKIB8760E

SKIA4817E

SKIA4795E

Function Fail-safe operation

Speedometer

Return to zero.

Tachometer

Fuel gauge

Water temperature gauge

Illumination control Combination meter illumination Change to nighttime mode.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1141 of 3924

COMBINATION METERSDI-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

3. Turn ignition switch ON while pressing trip transfer switch and trip reset switch at the same time.

4. After ignition switch is turned ON, release trip transfer switch and trip reset switch (within 7 seconds after the ignition switch is

turned ON).

5. All the segments on the odo/trip meter, A/T indi cator and ICC system display illuminates, and simulta-

neously the low-fuel warning lamp indicator illuminates. At this time, the unified meter control unit is turned

to self-diagnosis mode.

NOTE:

Check odo/trip meter switch and combination meter power supply and ground circuit when self-diagno-

sis mode of combination meter does not start. Replace combination meter if the results of the check are

normal.

If any of the segments are not disp layed, replace combination meter.

6. Each meter/gauge activates during pressing trip reset switch. (Then low-fuel warning lamp turns OFF.)

NOTE:

If any of the meters/gauges are not activated, replace thecombination meter.

The figure is reference.

CONSULT-III Function (METER/M&A)INFOID:0000000001328441

Refer to DI-27, "CONSULT-III Function (METER/M&A)" in “UNIFIED METER AND A/C AMP”.

Trouble DiagnosisINFOID:0000000001328442

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer to "PRELIMINARY CHECK".

3. According to the symptom chart, repair or replace the cause of the symptom. Refer to DI-16, "

Symptom

Chart".

4. Does the meter operate normally? If so, GO TO 5. If not, GO TO 2.

5. INSPECTION END

PRELIMINARY CHECK

1.CHECK OPERATION OF SELF-DIAGNOSIS MODE (COMBINATION METER)

SKIA4817E

SKIA6170E

SKIA4831E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C