INFINITI M35 2006 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1531 of 5621

![INFINITI M35 2006 Factory Service Manual DI-98

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

DTC [U1000] CAN COMM CIRCUITNKS003VT

1. CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “LDW” with CONS INFINITI M35 2006 Factory Service Manual DI-98

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

DTC [U1000] CAN COMM CIRCUITNKS003VT

1. CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “LDW” with CONS](/img/42/57023/w960_57023-1530.png)

DI-98

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

DTC [U1000] CAN COMM CIRCUITNKS003VT

1. CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “LDW” with CONSULT-II.

2. Print out CONSULT-II screen.

>> Go to “LAN SYSTEM”. Refer to LAN-7, "

Precautions When Using CONSULT-II" .

DTC [U1010] CONTROL UNIT (CAN)NKS003VU

Replace LDW camera unit, when “[U1010] CONTROL UNIT (CAN)” is displayed on self-diagnosis display.

LDW Chime Circuit InspectionNKS003VV

1. CHECK OPERATION OF LDW CHIME

Check LDW chime operation “BUZZER DRIVE” in “ACTIVE TEST”

mode with CONSULT-II.

OK or NG

OK >> LDW chime is OK. Return to DI-96, "SYMPTOM

CHART" .

NG >> GO TO 2.

2. CHECK LDW CHIME POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW chime connector.

3. Turn ignition switch ON.

4. Check voltage between LDW chime harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between fuse and LDW chime.

3. CHECK LDW CHIME GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between LDW chime harness connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.“BUZZER DRIVE”

Touch “ON” : LDW chime is activated.

Touch “OFF” : LDW chime is not activated.

SKIB1787E

Terminals

Voltage (Approx.) (+)

(–)

LDW chime connector Terminal

M58 1 Ground Battery voltage

PKIC0248E

LDW chime connector Terminal

GroundContinuity

M58 3 Yes

PKIC0249E

Page 1532 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-99

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

4. CHECK LDW CHIME SIGNAL CIRCUIT

1. Disconnect LDW camera unit connector.

2. Check continuity between LDW camera unit harness connector

(A) and LDW chime harness connector (B).

3. Check continuity between LDW camera unit harness connector

(A) and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK LDW CHIME

1. Connect LDW chime connector.

2. Turn ignition switch ON.

3. Apply ground to LDW chime terminal.

4. Check condition of the LDW chime.

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace LDW chime.

LDW Switch Circuit InspectionNKS003VW

1. CHECK OPERATION OF LDW SYSTEM ON INDICATOR

1. Turn ignition switch ON.

2. Check LDW system ON indicator operation when LDW switch is ON/OFF.

OK or NG

OK >> LDW system ON indicator is OK. Return to DI-96, "SYMPTOM CHART" .

NG >> GO TO 2.

2. CHECK LDW SWITCH SIGNAL INPUT

Check voltage between LDW camera unit harness connector and

ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

AB

Continuity

Connector Terminal Connector Terminal

M182 3 M58 2 Yes

A

GroundContinuity

Connector Terminal

M182 3 No

PKIC0250E

LDW chime connector Terminal

GroundCondition

M58 2 LDW chime should operate.

PKIC0251E

Terminals

Condition

Voltage (Approx.) (+)

(–)

LDW camera

unit connectorTerminal LDW switch:

M182 9 GroundPush 0 V

Release 5 V

PKIC0252E

Page 1533 of 5621

DI-100

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

3. CHECK LDW SWITCH GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW switch connector.

3. Check continuity between LDW switch connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK LDW SWITCH SIGNAL INPUT CIRCUIT

1. Disconnect LDW camera unit connector.

2. Check continuity between LDW camera unit harness connector

(A) and LDW switch harness connector (B).

3. Check continuity between LDW camera unit harness connector

(A) and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK LDW SWITCH

Check LDW switch. Refer to DI-103, "

LDW SWITCH" .

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace LDW switch.

6. CHECK OPERATION OF LDW SYSTEM ON INDICATOR

Check LDW system ON indicator operation “SYSTEM ON LAMP

DRIVE” in “ACTIVE TEST” mode with CONSULT-II.

NOTE:

Perform “SYSTEM ON LAMP DRIVE” when LDW system ON indica-

tor turns OFF.

OK or NG

OK >> Replace LDW camera unit.

NG >> GO TO 7.

LDW switch connector Terminal

GroundContinuity

M49 6 Yes

PKIC0253E

AB

Continuity

Connector Terminal Connector Terminal

M1829 M497 Yes

A

GroundContinuity

Connector Terminal

M182 9 No

PKIC0254E

“SYSTEM ON LAMP DRIVE”

Touch “ON” : LDW system ON indicator illuminates.

Touch “OFF” : LDW system ON indicator turns OFF.

SKIB1788E

Page 1534 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-101

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

7. CHECK LDW SYSTEM ON INDICATOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW switch connector.

3. Turn ignition switch ON.

4. Check voltage between LDW switch harness connector and

ground.

OK or NG

OK >> GO TO 8.

NG >> Check harness between fuse and LDW switch.

8. CHECK LDW SYSTEM ON INDICATOR SIGNAL CIRCUIT

1. Disconnect LDW camera unit connector.

2. Check continuity between LDW camera unit harness connector

(A) and LDW switch harness connector (B).

3. Check continuity between LDW camera unit harness connector

(A) and ground.

OK or NG

OK >> GO TO 9.

NG >> Repair harness or connector.

9. CHECK LDW SYSTEM ON INDICATOR

1. Connect LDW switch connector.

2. Turn ignition switch ON.

3. Apply ground to LDW switch terminal.

4. Check condition of the LDW system ON indicator.

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace LDW switch.

Te r m i n a l s

Voltage (Approx.) (+)

(–)

LDW chime connector Terminal

M49 3 Ground Battery voltage

PKIC0255E

AB

Continuity

Connector Terminal Connector Terminal

M1824 M492 Yes

A

GroundContinuity

Connector Terminal

M182 4 No

PKIC0256E

LDW switch

connectorTerminal

GroundCondition

M49 2 LDW system ON indicator

should illuminate.

PKIC0257E

Page 1535 of 5621

DI-102

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

LDW Indicator Lamp Circuit InspectionNKS003VX

1. CHECK OPERATION OF LDW INDICATOR LAMP

Check LDW indicator operation “INDICATOR LAMP DRIVE” in

“ACTIVE TEST” mode with CONSULT-II.

OK or NG

OK >> LDW indicator is OK. Return to DI-96, "SYMPTOM

CHART" .

NG >> GO TO 2.

2. CHECK LDW INDICATOR LAMP SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW camera unit connector and combination meter

connector.

3. Check continuity between LDW camera unit harness connector

(A) and combination meter harness connector (B).

4. Check continuity between LDW camera unit harness connector

(A) and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK LDW INDICATOR LAMP

1. Connect combination meter connector.

2. Turn ignition switch ON.

3. Apply ground to combination meter terminal.

4. Check condition of the LDW indicator lamp.

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace combination meter.“INDICATOR LAMP DRIVE”

Touch “ON” : LDW indicator lamp illuminates.

Touch “OFF” : LDW indicator lamp OFF.

PKIB4692E

AB

Continuity

Connector Terminal Connector Terminal

M182 8 M52 8 Yes

A

GroundContinuity

Connector Terminal

M182 8 No

PKIB7671E

Combination meter

connectorTe r m i n a l

GroundCondition

M52 8LDW indicator lamp should

illuminate.

PKIB7672E

Page 1536 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-103

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

Turn Signal Input InspectionNKS003VY

1. CHECK TURN SIGNAL INPUT

Check turn signal input “TURN SIGNAL” in “DATA MONITOR” mode

with CONSULT-II.

OK or NG

OK >> Turn signal input is OK. Return to DI-96, "SYMPTOM

CHART" .

NG >> Check turn signal and hazard warning lamps system,

and repair or replace corresponding parts. Refer to LT- 2 2 0 , "

How to Perform Trouble Diagnoses" .

Electrical Component InspectionNKS003VZ

LDW SWITCH

Check continuity between terminals 6 and 7.

Removal and Installation for LDW Camera UnitNKS003W0

REMOVAL

1. Remove roof console. Refer to EI-52, "HEADLINING" .

2. Disconnect LDW camera unit connector (1).

3. Remove the bolts (A), and remove LDW camera unit (2).

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

Remove the camera lens cap for replacement.

Never give an impact to the LDW camera unit.

Adjust the camera aiming every time the LDW camera unit is removed or installed. Refer to DI-81,

"Camera Aiming Adjustment" . “TURN SIGNAL”

When lighting switch is in TURN RH position : RH

When lighting switch is in TURN LH position : LH

When hazard switch is turned ON : RH/LH

SKIB3125E

Terminal Condition Continuity

67When LDW switch is pushed. Yes

When LDW switch is released. No

PKIC0258E

PKIB7673E

Page 1537 of 5621

DI-104

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

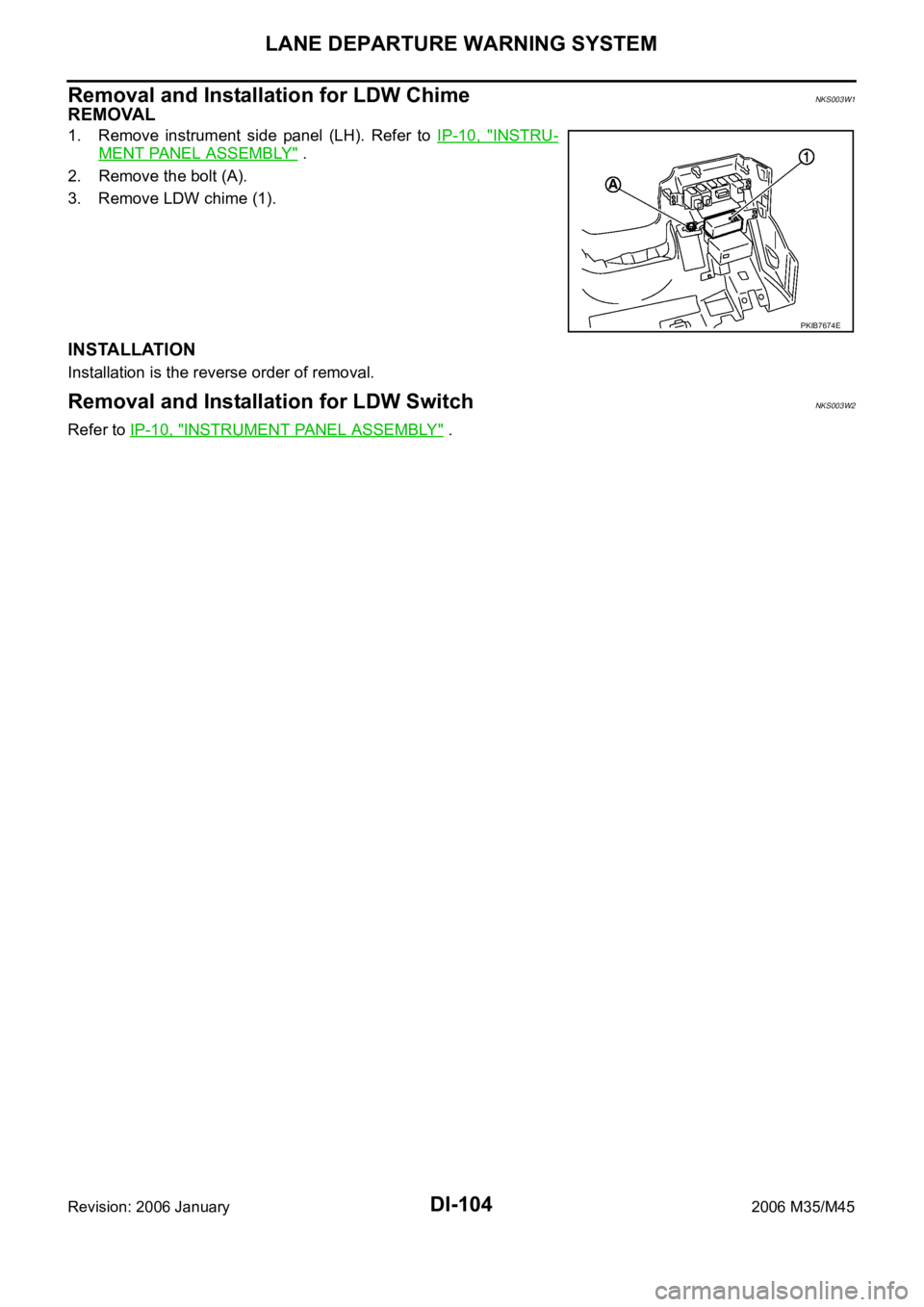

Removal and Installation for LDW ChimeNKS003W1

REMOVAL

1. Remove instrument side panel (LH). Refer to IP-10, "INSTRU-

MENT PANEL ASSEMBLY" .

2. Remove the bolt (A).

3. Remove LDW chime (1).

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation for LDW SwitchNKS003W2

Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

PKIB7674E

Page 1538 of 5621

COMPASS

DI-105

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

COMPASSPFP:24835

System DescriptionNKS003W3

This unit displays earth magnetism and heading direction of vehicle.

DIRECTION DISPLAY

Push “COMP” switch (1) when ignition switch is in “ON” or “START”

position. The direction will be displayed.

Pushing “COMP” switch (1) a second time will turn off the display (2).

NOTE:

Do not install the ski rack, antenna, etc. which are attached to

the vehicle by means of a magnet. They affect the operation of

the compass.

The compass may not indicate the correct compass point in tun-

nels or while driving up or down a steep hill. (The compass

returns to the correct compass point when the vehicle moves to

an area where the geomagnetism is stabilized.)

When cleaning the mirror, use a paper towel or similar material

dampened with glass cleaner. Do not spray glass cleaner directly on the mirror as that may cause the liq-

uid cleaner to enter the mirror housing.

Zone Variation Change ProcedureNKS003W4

The difference between magnetic north and geographical north is known as variance. In some areas, this dif-

ference can sometimes be great enough to cause false compass reading.

Follow these instructions to set the variance for the particular loca-

tion if this happens:

1. Push “COMP” switch for more than 3 seconds. The current zone

number will appear in the display.

2. Find the current location and variance one number on the zone

variation chart.

3. Push “COMP” switch until the new zone number appears in the

display. After stopping pushing the switch in, the display will

show a compass direction within a few seconds.

Correction Functions of the Compass DisplayNKS003W5

AUTOMATIC CORRECTION

The compass display is equipped with automatic correction function. If the direction is not shown correctly,

perform manual correction procedure set out below.

MANUAL CORRECTION PROCEDURE

When the display reads “C” or “CAL”, calibrate the compass by driving the vehicle in 3 complete circles at less

than 8 km/h (5 MPH).

The compass can be calibrated by driving the vehicle on everyday route. The compass will be calibrated once

it has tracked 3 complete circles.

In places where the terrestrial magnetism is extremely disturbed, the initial correction procedure may start

automatically.

PKIB7654E

SEL168Y

Page 1539 of 5621

DI-106

COMPASS

Revision: 2006 January2006 M35/M45

Wiring Diagram – COMPAS –NKS003W6

TKWT3425E

Page 1540 of 5621

COMPASS

DI-107

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

Removal and Installation of CompassNKS003W7

Refer to GW-71, "INSIDE MIRROR" .