Motor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3319 of 5621

![INFINITI M35 2006 Factory Service Manual EM-256

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

7. Install each main bearing cap bolt as follows:

a. Apply new engine oil to threads and seating surface of main

bearing cap INFINITI M35 2006 Factory Service Manual EM-256

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

7. Install each main bearing cap bolt as follows:

a. Apply new engine oil to threads and seating surface of main

bearing cap](/img/42/57023/w960_57023-3318.png)

EM-256

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

7. Install each main bearing cap bolt as follows:

a. Apply new engine oil to threads and seating surface of main

bearing cap bolts, and tighten all bolts temporarily.

b. Tighten main bearing cap bolt (M12) in order of 1 to 10.

c. Tighten main bearing cap sub bolt (M9) in order of 11 to 20.

d. Tighten main bearing cap bolt (M12) to 40 degrees clockwise in

order of 1 to 10. (Angle tightening)

CAUTION:

Use angle wrench (SST) to check tightening angle in step

“d” and “e”. Do not make judgment by visual inspection.

e. Tighten main bearing cap sub bolt (M9) to 30 degrees clockwise

in order of 11 to 20. (Angle tightening)

f. Tighten side bolt (M10) in order of 21 to 30.

After installing main bearing cap bolts, make sure that crankshaft can be rotated smoothly.

Check the crankshaft end play. Refer to EM-266, "CRANKSHAFT END PLAY" .

g. Install cover of cylinder block rear left side (next to the starter motor housing).

8. Install new rear oil seal on rear oil seal retainer.

Install new rear oil seal so that each seal lip is oriented as

shown in the figure.

Install rear oil seal to rear oil seal retainer with rear oil seal

drift (commercial service tool).

Tap until flattened with front edge of rear oil seal retainer. Do

not damage or scratch outer circumference of oil seal.

Make sure the garter spring is in position and seal lips not

inverted.

9. Install rear oil seal retainer.

Apply new engine oil to both oil seal lip and dust seal lip.: 39.2 Nꞏm (4.0 kg-m, 29 ft-lb)

: 29.4 Nꞏm (3.0 kg-m, 22 ft-lb)

PBIC0090E

PBIC0096E

: 49 Nꞏm (5.0 kg-m, 36 ft-lb)

SEM715A

Rear oil seal drift

Outer diameter : 102 mm (4.02 in)

Inner diameter : 86 mm (3.39 in)

PBIC0097E

Page 3520 of 5621

GW-1

GLASSES, WINDOW SYSTEM & MIRRORS

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION GW

A

B

GW

Revision: 2006 January2006 M35/M45

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Handling for Adhesive and Primer ........................... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation ......................................... 11

REMOVAL ........................................................

.... 11

INSTALLATION ................................................... 12

POWER WINDOW SYSTEM .................................... 13

Component Parts and Harness Connector Location ... 13

System Description ................................................ 13

MANUAL OPERATION ....................................... 14

AUTO OPERATION ............................................ 16

POWER WINDOW SERIAL LINK ....................... 16

POWER WINDOW LOCK ................................... 16

RETAINED POWER OPERATION ...................... 16ANTI-PINCH SYSTEM ........................................ 17

INITIALIZATION .................................................. 17

FAIL-SAFE CONTROL ........................................ 18

POWER WINDOW CONTROL BY THE KEY

CYLINDER SWITCH ........................................... 18

CAN Communication System Description .............. 19

CAN Communication Unit ....................................... 19

Schematic ............................................................... 20

Wiring Diagram — WINDOW — ............................. 21

Terminal and Reference Value for BCM ................. 27

Terminal and Reference Value for Power Window

Main Switch ............................................................ 28

Terminal and Reference Value for (Front and Rear)

Power Window Sub-Switch .................................... 29

CONSULT-II Function (BCM) ................................. 30

WORK SUPPORT ............................................... 31

DATE MONITOR ................................................. 31

Work Flow ............................................................... 32

Trouble Diagnosis Symptom Chart ......................... 32

BCM Power Supply and Ground Circuit Check ...... 34

Power Window Main Switch Power Supply Circuit

Check ..................................................................... 35

Power Window Sub-Switch (Front Passenger Side)

Power Supply and Ground Circuit Check ............... 36

Power Window Sub-Switch (Rear LH or RH) Power

Supply and Ground Circuit Check .......................... 37

Power Window Motor (Front Driver Side) Circuit

Check ..................................................................... 38

Power Window Motor (Front Passenger Side) Cir-

cuit Check ............................................................... 39

Power Window Motor (Rear LH or RH) Circuit Check ... 40

Encoder Circuit Check (Driver Side) ....................... 42

Encoder Circuit Check (Passenger Side) ............... 45

Encoder Circuit Check (Rear LH or RH) ................. 48

Door Switch Check ..............................................

... 52

Front Door Key Cylinder Switch Check .................. 54

Power Window Serial Link Check (Passenger Side) ... 56

Power Window Serial Link Check (Rear LH or RH) ... 58

Power Window Lock Switch Check ........................ 58

Page 3521 of 5621

GW-2Revision: 2006 January2006 M35/M45 SIDE WINDOW GLASS ............................................ 59

Removal and Installation ........................................ 59

REMOVAL ........................................................

... 59

INSTALLATION .................................................... 60

REAR WINDOW GLASS AND MOLDING ................ 61

Removal and Installation ........................................ 61

REMOVAL ........................................................

... 61

INSTALLATION .................................................... 62

FRONT DOOR GLASS AND REGULATOR ............. 63

Removal and Installation ........................................ 63

DOOR GLASS ..................................................... 63

REGULATOR ASSEMBLY .................................. 64

Disassembly and Assembly .................................... 65

REGULATOR ASSEMBLY .................................. 65

Inspection after Installation ..................................... 65

SYSTEM INITIALIZATION ................................... 65

INSPECT THE FUNCTION OF THE ANTI-

PINCH SYSTEM. ................................................. 65

FITTING INSPECTION ........................................ 66

REAR DOOR GLASS AND REGULATOR ............... 67

Removal and Installation ........................................ 67

DOOR GLASS ..................................................... 67

REGULATOR ASSEMBLY .................................. 68

Disassembly and Assembly .................................... 70

REGULATOR ASSEMBLY .................................. 70

Inspection after Installation ..................................... 70

SYSTEM INITIALIZATION ................................... 70

INSPECT THE FUNCTION OF THE ANTI-

PINCH SYSTEM .................................................. 70

FITTING INSPECTION ........................................ 70

INSIDE MIRROR ....................................................... 71

Wiring Diagram –I/MIRR– ....................................... 71

Removal and Installation ........................................ 72

REMOVAL ........................................................

... 72

INSTALLATION .................................................... 72

REAR WINDOW DEFOGGER .................................. 73

Component Parts and Harness Connector Location ... 73

System Description ................................................. 73

CAN Communication System Description .............. 75

CAN Communication Unit ....................................... 75

Schematic ............................................................... 76

Wiring Diagram — DEF — ..................................... 77

Terminal and Reference Value for BCM ................. 81

Terminal and Reference Value for IPDM E/R ......... 81

CONSULT-II Inspection Procedure ......................... 82

DATA MONITOR .................................................. 83

ACTIVE TEST ..................................................... 83

Work Flow ............................................................... 84Trouble Diagnoses Symptom Chart .....................

... 84

BCM Power Supply and Ground Circuit Check ...... 85

Rear Window Defogger Switch Circuit Check ......... 86

Rear Window Defogger Power Supply Circuit

Check ...................................................................... 86

Rear Window Defogger Circuit Check .................... 88

Door Mirror Defogger Power Supply Circuit Check ... 89

Driver Side Door Mirror Defogger Circuit Check ..... 91

Passenger Side Door Mirror Defogger Circuit Check

... 92

Filament Check ....................................................... 94

Filament Repair ....................................................... 94

REPAIR EQUIPMENT ......................................... 94

REPAIRING PROCEDURE ................................. 95

REVERSE INTERLOCK DOOR MIRROR SYSTEM ... 96

Component Parts and Harness Connector Location ... 96

System Description ................................................. 96

OPERATION CONDITIONS ................................ 96

MIRROR UNGLE MEMORY FUNCTION ............ 96

REVERSE INTERLOCK DOOR MIRROR SYS-

TEM OPERATION ............................................... 97

CAN Communication System Description .............. 97

CAN Communication Unit ....................................... 97

Schematic ............................................................... 98

Wiring Diagram —MIRROR— ................................ 99

Terminals and Reference Values for Automatic

Drive Positioner Control Unit .................................104

Terminals and Reference Values for Driver Seat

Control Unit ...........................................................105

CONSULT-II Function (AUTO DRIVE POS.) ........106

CONSULT-II INSPECTION PROCEDURE ........106

DATA MONITOR ................................................107

ACTIVE TEST ....................................................107

Work Flow .............................................................108

Symptom Chart .....................................................108

Check Changeover Switch Circuit ........................109

Check Mirror Switch Circuit Check ....................... 111

Check Mirror Motor Circuit Check .........................113

Check Mirror Sensor Circuit Check .......................116

Check A/T Control Device R Position Circuit ........119

DOOR MIRROR .......................................................120

Automatic Drive Positioner Interlocking Door Mirror .120

Removal and Installation .......................................120

REMOVAL ..........................................................120

INSTALLATION ..................................................120

Disassembly and Assembly ..................................121

DISASSEMBLY ..................................................121

ASSEMBLY ........................................................122

Page 3532 of 5621

POWER WINDOW SYSTEM

GW-13

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

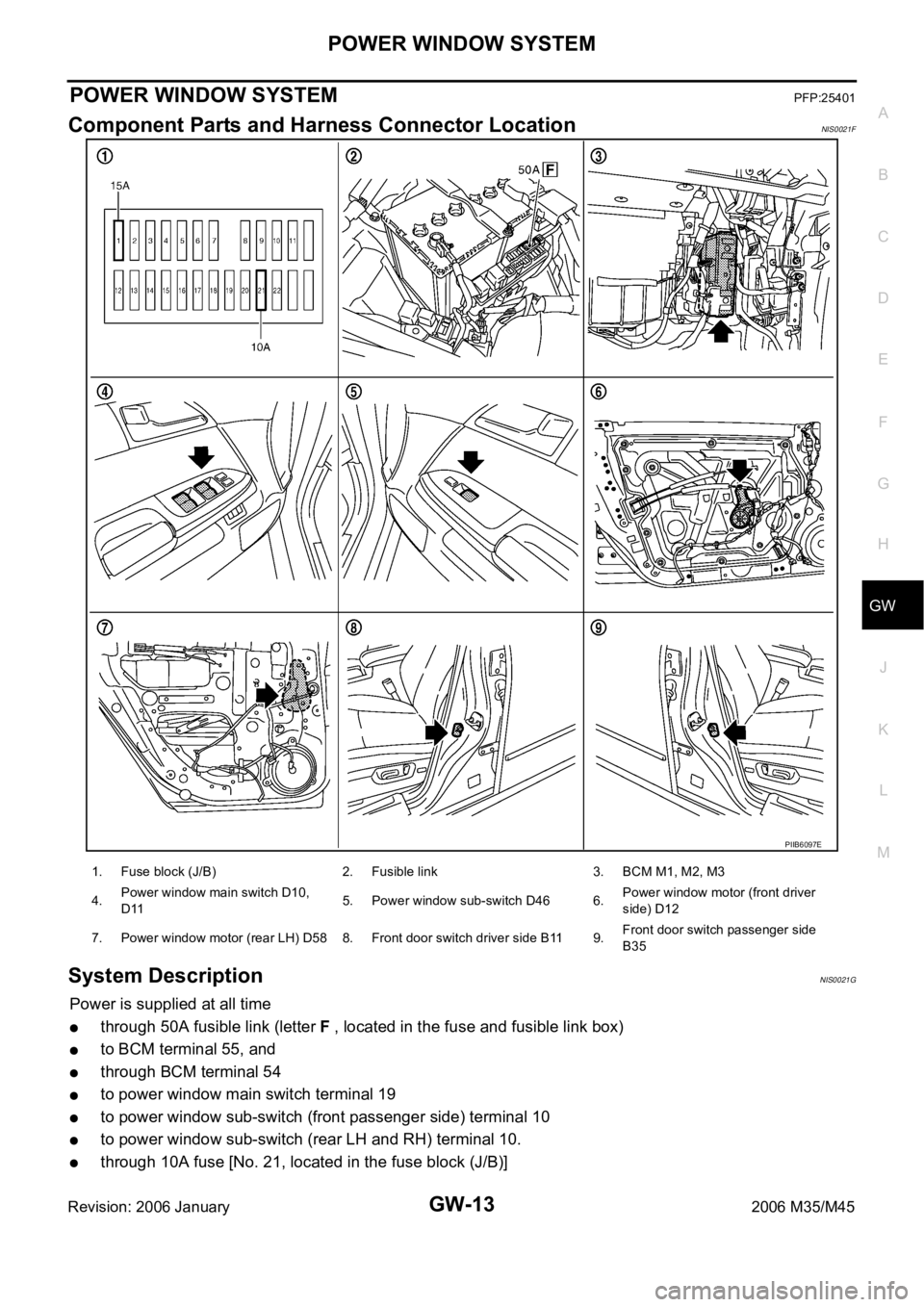

POWER WINDOW SYSTEMPFP:25401

Component Parts and Harness Connector LocationNIS0021F

System DescriptionNIS0021G

Power is supplied at all time

through 50A fusible link (letter F , located in the fuse and fusible link box)

to BCM terminal 55, and

through BCM terminal 54

to power window main switch terminal 19

to power window sub-switch (front passenger side) terminal 10

to power window sub-switch (rear LH and RH) terminal 10.

through 10A fuse [No. 21, located in the fuse block (J/B)]

PIIB6097E

1. Fuse block (J/B) 2. Fusible link 3. BCM M1, M2, M3

4.Power window main switch D10,

D115. Power window sub-switch D46 6.Power window motor (front driver

side) D12

7. Power window motor (rear LH) D58 8. Front door switch driver side B11 9.Front door switch passenger side

B35

Page 3533 of 5621

GW-14

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

to BCM terminal 42.

With ignition switch in ON or START position,

Power is supplied

through 15A fuse [No. 1, located in the fuse block (J/B)]

to BCM terminal 38, and

through BCM terminal 53

to power window main switch terminal 10

Ground supplied

to BCM terminal 52

through body grounds M16 and M70.

to power window main switch terminal 17

through body grounds M16 and M70.

to power window sub-switch (front passenger side) terminal 11

through body grounds M16 and M70.

to power window sub-switch (rear LH and RH) terminal 11

through body grounds B5, B40 and B131.

MANUAL OPERATION

Front Driver Side Door

WINDOW UP

When the front LH switch in the power window main switch is pressed in the up position,

Power is supplied

through power window main switch terminal 8

to power window motor (front driver side) terminal 2.

Ground is supplied

to power window motor (front driver side) terminal 1

through power window main switch terminal 11.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front LH switch in the power window main switch is pressed in the down position

Power is supplied

through power window main switch terminal 11

to power window motor (front driver side) terminal 1.

Ground is supplied

to power window motor (front driver side) terminal 2

through power window main switch terminal 8.

Then, the motor lowers the window until the switch is released.

Page 3534 of 5621

POWER WINDOW SYSTEM

GW-15

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

Front Passenger Side Door

POWER WINDOW SUB-SWITCH (FRONT PASSENGER SIDE) OPERATION

WINDOW UP

When the power window sub-switch (front passenger side) is pressed in the up position

Power is supplied

through power window sub-switch (front passenger side) terminal 8

to power window motor (front passenger side) terminal 2.

Ground is supplied

to power window motor (front passenger side) terminal 1

through power window sub-switch (front passenger side) terminal 9.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the power window sub-switch (front passenger side) is pressed in the down position

Power is supplied

through power window sub-switch (front passenger side) terminal 9

to power window motor (front passenger side) terminal 1.

Ground is supplied

to power window motor (front passenger side) terminal 2

through power window sub-switch (front passenger side) terminal 8.

Then, the motor lowers the window until the switch is released.

POWER WINDOW MAIN SWITCH OPERATION

Signal is sent

though power window main switch terminal 14.

to power window sub-switch (front passenger side) terminal 16

The operation of power window after receive the signal is as same as operate the power window with power

window sub-switch (front passenger side).

Rear Door (LH or RH)

POWER WINDOW SUB-SWITCH (REAR LH OR RH) OPERATION

WINDOW UP

When the power window sub-switch (rear LH or RH) is pressed in the up position

Power is supplied

through power window sub-switch (rear LH or RH) terminal 8

to power window motor (rear LH or RH) terminal 1.

Ground is supplied

to power window motor (rear LH or RH) terminal 2

through power window sub-switch (rear LH or RH) terminal 9.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the power window sub-switch (rear LH or RH) is pressed in the down position

Power is supplied

through power window sub-switch (rear LH or RH) terminal 9

to power window motor (rear LH or RH) terminal 2.

Ground is supplied

to power window motor (rear LH or RH) terminal 1

through power window sub-switch (rear LH or RH) terminal 8.

Then, the motor lowers the window until the switch is released.

POWER WINDOW MAIN SWITCH OPERATION

Signal is sent

though power window main switch terminal 14.

to power window sub-switch (rear LH or RH) terminal 16

The operation of power window after receive the signal is as same as operate the power window sub-switch

(rear LH or RH).

Page 3535 of 5621

GW-16

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

AUTO OPERATION

The power window AUTO feature enables the driver to open or close the window without holding the window

switch in the down or up position.

POWER WINDOW SERIAL LINK

Power window main switch, any power window sub-switches and BCM transmit and receive the signal by

power window serial link.

The under mentioned signal is transmitted from BCM to power window main switch and power window sub-

switches.

Keyless power window down signal.

The under mentioned signal is transmitted from power window main switch to power window sub-switch (front

passenger side)

Front passenger side door window operation signal.

Power window control by key cylinder switch signal.

Power window lock signal.

Retained power operation signal.

The under mentioned signal is transmitted from power window main switch to power window sub-switch (rear

LH or RH)

Rear LH or RH side door window operation signal.

Power window control by key cylinder switch signal.

Power window lock signal.

Retained power operation signal.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver side door window.

When the lock position, the power window lock signal is transmitted to any power window sub-switches by

power window serial link. This prevents the power window motors from operating.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position.

Power is supplied for 45 seconds

through BCM terminal 53

to power window main switch terminal 10.

When power and ground are supplied, the BCM continues to be energized, and the power window can be

operated.

The retained power operation is canceled when the driver or passenger side door is opened.

RAP signal period can be changed by CONSULT-II. Refer to GW-30, "

CONSULT-II Function (BCM)" .

Page 3536 of 5621

POWER WINDOW SYSTEM

GW-17

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

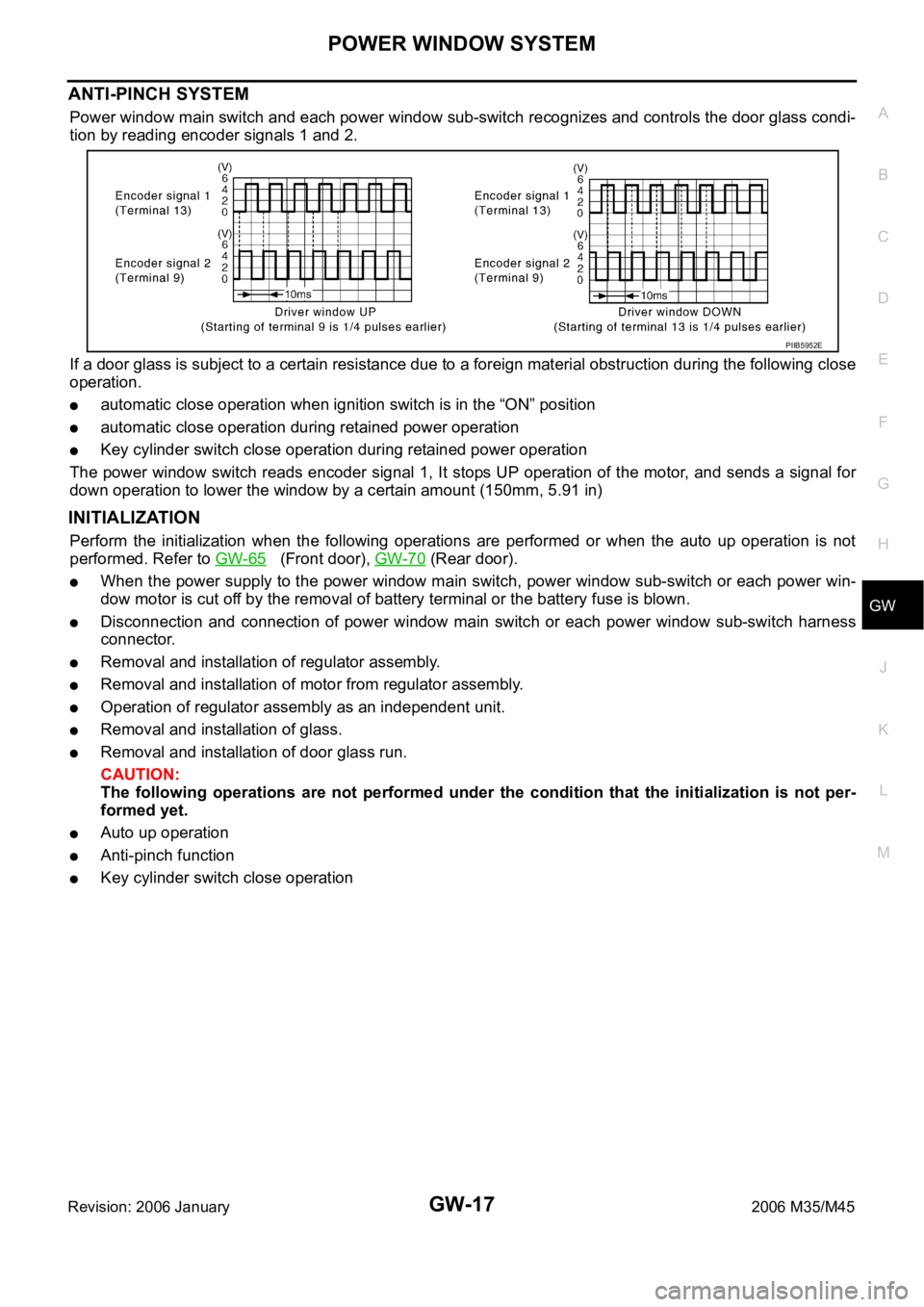

ANTI-PINCH SYSTEM

Power window main switch and each power window sub-switch recognizes and controls the door glass condi-

tion by reading encoder signals 1 and 2.

If a door glass is subject to a certain resistance due to a foreign material obstruction during the following close

operation.

automatic close operation when ignition switch is in the “ON” position

automatic close operation during retained power operation

Key cylinder switch close operation during retained power operation

The power window switch reads encoder signal 1, It stops UP operation of the motor, and sends a signal for

down operation to lower the window by a certain amount (150mm, 5.91 in)

INITIALIZATION

Perform the initialization when the following operations are performed or when the auto up operation is not

performed. Refer to GW-65

(Front door), GW-70 (Rear door).

When the power supply to the power window main switch, power window sub-switch or each power win-

dow motor is cut off by the removal of battery terminal or the battery fuse is blown.

Disconnection and connection of power window main switch or each power window sub-switch harness

connector.

Removal and installation of regulator assembly.

Removal and installation of motor from regulator assembly.

Operation of regulator assembly as an independent unit.

Removal and installation of glass.

Removal and installation of door glass run.

CAUTION:

The following operations are not performed under the condition that the initialization is not per-

formed yet.

Auto up operation

Anti-pinch function

Key cylinder switch close operation

PIIB5952E

Page 3537 of 5621

GW-18

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

FAIL-SAFE CONTROL

The encoder signal detects the up / down speed / detection of door glass. If the malfunction is detected to the

encoder signal or the difference between the glass fully closed position (memorized in power window main

switch or power window sub-switch) and the actual glass position is detected, it shifts into the fail-safe control

It is shifts into the fail-safe control, the initialization is not performed and the following function is not activated

Auto up operation

Anti-pinch function

It is shifts into the fail-safe control, performed the initialization to resume normal operation condition.

POWER WINDOW CONTROL BY THE KEY CYLINDER SWITCH

When ignition key switch is OFF, front power window can be opened or closed by turning the key cylinder

switch UNLOCK / LOCK position more than 1.5 second over condition.

Power window can be opened as the door key cylinder is kept fully turning to the UNLOCK position.

Power window can be closed as the door key cylinder is kept fully turning to the LOCK position.

The power window DOWN stops when the following operations are carried out.

While performing open / close the window, power window is stopped at the position as the door key cylin-

der is placed on NEUTRAL.

When the ignition switch is turned ON while the power window DOWN is operated.

DTC Condition

Pulse sensor detects malfunctionDuring the glass opening/closing operation, a pulse signal is continuously

detected for the specified terms or more

Both pulse sensors detect malfunctionDuring the glass opening/closing operation, both pulse signals are not

detected for the specified values or more

Pulse direction malfunctionThe following condition is detected for the specified values or more. The

pulse signal (detected during glass open/close operation) detects the

opposite direction to the driving direction of power window motor.

Glass recognized position malfunction 1During the glass opening/closing operation, the difference between the

glass fully closed position (memorized in power window main switch or

power window sub-switch) and the actual glass position is detected for

the specified values or more.

Glass recognized position malfunction 2During the glass opening/closing operation, a pulse count is detected that

is above the glass full stroke

Glass fully closed position not updated malfunctionContinuously perform the glass open/close operation (with the glass not

fully closed) at the specified value (approx. 10 time) or more

Page 3547 of 5621

![INFINITI M35 2006 Factory Service Manual GW-28

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

Terminal and Reference Value for Power Window Main SwitchNIS0021M

Terminal Wire color Item ConditionVoltage [V]

(Approx.)

2 W/B Encoder gro INFINITI M35 2006 Factory Service Manual GW-28

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

Terminal and Reference Value for Power Window Main SwitchNIS0021M

Terminal Wire color Item ConditionVoltage [V]

(Approx.)

2 W/B Encoder gro](/img/42/57023/w960_57023-3546.png)

GW-28

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

Terminal and Reference Value for Power Window Main SwitchNIS0021M

Terminal Wire color Item ConditionVoltage [V]

(Approx.)

2 W/B Encoder ground — 0

4BRDoor key cylinder switch

LOCK signalKey position

(Neutral

Locked)5 0

6V/RDoor key cylinder switch

UNLOCK signalKey position

(Neutral

Unlocked)5 0

8LFront driver side power window

motor UP signalWhen front LH switch in

power window main switch is

UP at operated. Battery voltage

9 G/W Encoder pulse signal 2When power window motor oper-

ates.

10 Y/B Rap signalIGN SW ON Battery voltage

Within 45 second after ignition

switch is turned to OFFBattery voltage

When driver side or passenger

side door is opened daring

retained power operation0

11 GFront driver side power window

motor DOWN signalWhen front LH switch in

power window main switch is

DOWN at operated. Battery voltage

13 G/Y Encoder pulse signal 1When power window motor oper-

ates.

14 Y Power window serial linkIGN SW ON or power window

timer operating.

15 G/R Encoder power supplyWhen ignition switch ON or power

window timer operates.10

17 B Ground — 0

19 W/B Battery power supply — Battery voltage

OCC3383D

OCC3383D

PIIA2344J