relay INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4525 of 5621

LT-98

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECTION DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item nameCONSULT-II

screen displayDisplay

or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Position lights request TAIL&CLR REQ ON/OFF

Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF

Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF

Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF

Signal status input from BCM

Daytime running light request DTRL REQ ON/OFF

–Signal status input from BCM

Test itemCONSULT-II

screen displayDescription

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON, LO

ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows fog lamp relay to operate by switching operation ON-OFF at your option.

Page 4527 of 5621

LT-100

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

4. CHECK DAYTIME LIGHT RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Remove daytime light relay.

3. Check voltage between daytime light relay harness connector

E34 terminals 2, 5 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK DAYTIME LIGHT RELAY

1. Apply battery voltage to daytime light relay terminals 1 and 2.

2. Check continuity between terminals 3 and 5.

OK or NG

OK >> GO TO 6.

NG >> Replace daytime light relay.

6. CHECK CIRCUIT BETWEEN DAYTIME LIGHT RELAY AND IPDM E/R

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector (A) E9

terminal 58 and daytime light relay harness connector (B) E34

terminal 1.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.2, 5 – Ground : Battery voltage

SKIB4746E

3 – 5 : Continuity should exist.

SKIB4671E

58 – 1 : Continuity should exist.

SKIB4748E

Page 4528 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-101

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

7. CHECK DAYTIME LIGHT RELAY SIGNAL

1. Connect IPDM E/R connector.

2. Install daytime light relay.

3. Turn ignition switch ON.

4. Applied parking brake.

5. Check voltage between IPDM E/R harness connector E9 termi-

nal 58 and ground.

6. Start engine and release parking break. Headlamp switch OFF.

7. Check voltage between IPDM E/R harness connector E9 termi-

nal 58 and ground.

OK or NG

OK >> Check connecting condition daytime relay harness con-

nector.

NG >> GO TO 8.

8. CHECK CAN COMMUNICATIONS

Select “BCM” by CONSULT-II, and perform self-diagnosis for “BCM”.

Displayed self-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-17, "Removal and Installa-

tion of BCM" .

CAN COMM CIRCUIT>>Check BCM CAN communication system.

Refer to BCS-15, "

CAN Communication Inspection

Using CONSULT-II (Self-Diagnosis)" . 58 – Ground : Battery voltage

58 – Ground : Approx. 0V

SKIB4747E

SKIA1039E

Page 4531 of 5621

LT-104

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

6. CHECK HEADLAMP (RH SIDE) GROUND

1. Remove daytime light relay.

2. Check continuity between front headlamp RH harness connec-

tor (A) E47 terminal 2 and daytime light relay harness connector

(B) E34 terminal 3.

3. Check continuity between daytime light relay harness connector

E34 terminal 4 and ground.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7. CHECK DAYTIME LIGHT RELAY

Check continuity between terminal 3 and 4.

OK >> Check headlamp bulb and connecting condition combi-

nation lamp terminal connector.

NG >> Replace daytime light relay.2 – 3 : Continuity should exist.

SKIB4751E

4 – Ground : Continuity should exist.

SKIB4674E

3 – 4 : Continuity should exist.

SKIB4660E

Page 4533 of 5621

LT-106

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

3. CHECK CONTINUITY BETWEEN IPDM E/R AND FRONT COMBINATION LAMP

1. Ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector (A) E7

terminal 27 and front combination lamp RH harness connector

(B) E47 terminal 6.

4. Check continuity between IPDM E/R harness connector (A) E7

terminal 27 and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

4. CHECK HEADLAMP GROUND (1)

1. Turn ignition switch OFF.

2. Remove daytime light relay.

3. Check continuity between front combination lamp RH harness

connector (A) E47 terminal 2 and daytime light relay harness

connector (B) E34 terminal 3.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK HEADLAMP GROUND (2)

Check continuity between daytime light relay harness connector E34

terminal 4 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.27 – 6 : Continuity should exist.

27 – Ground : Continuity should not exist.

SKIB4755E

2 – 3 : Continuity should exist.

SKIB4751E

4 – Ground : Continuity should exist.

SKIB4674E

Page 4534 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-107

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

6. CHECK DAYTIME RELAY

Check continuity between terminal 3 and 4.

OK >> Check connecting condition front combination lamp RH

harness connector.

NG >> Replace daytime light relay.

LH High Beam Does Not Illuminate But RH High Beam IlluminatesNKS003PN

1. CHECK BULB

Check bulb of lamp.

OK or NG

OK >> GO TO 2.

NG >> Replace bulb of lamp.

2. CHECK HEADLAMP INPUT SIGNAL

With CONSULT-II

1. Disconnect front combination lamp LH connector.

2. Select “IPDM E/R” on CONSULT-II and select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch “HI” screen.

4. When headlamp high beam is operating, check voltage between

front combination lamp LH harness connector E54 terminal 6

and ground. (Headlamp high beam repeats ON–OFF every 1

second.)

Without CONSULT-II

1. Disconnect front combination lamp LH connector.

2. Start auto active test. Refer to PG-24, "

Auto Active Test" .

3. When headlamp high beam is operating, check voltage between

front combination lamp LH harness connector E54 terminal 6

and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.3 – 4 : Continuity should exist.

SKIB4660E

6 – Ground : Battery voltage

6 – Ground : Battery voltage

SKIB4749E

Page 4557 of 5621

LT-130

AUTO LIGHT SYSTEM

Revision: 2006 January2006 M35/M45

ACTIVE TEST

Operation Procedure

1. Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch item to be tested and check operation of the selected item.

4. During the operation check, touching “BACK” deactivates the operation.

Display Item List

NOTE:

This item is tested only for CANADA models.

Symptom ChartNKS003QA

Test item Description

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows front fog lamp relay to operate by switching ON-OFF.

DAYTIME RUNNING LIGHT

NOTEAllows daytime light relay to operate by switching ON-OFF.

HEAD LAMP (HI, LO) Allows headlamp relay to operate by switching ON-OFF.

Phenomenon Malfunction system and reference

Parking lamps and headlamps will not illuminate when outside

of the vehicle becomes dark. (Lighting switch 1ST position and

2ND position operate normally.)

Parking lamps and headlamp will not go out when outside of the

vehicle becomes light. (Lighting switch 1ST position and 2ND

position operate normally.)

Headlamps go out when outside of the vehicle becomes light,

but parking lamps stay on.

Refer to LT-128, "WORK SUPPORT" .

Refer to LT-131, "Lighting Switch Inspection" .

Refer to LT-131, "Optical Sensor System Inspection" .

If above systems are normal, replace BCM.

Parking lamps illuminate when outside of the vehicle becomes

dark, but headlamps stay off. (Lighting switch 1ST position and

2ND position operate normally.)

Refer to LT-128, "WORK SUPPORT" .

Refer to LT-131, "Optical Sensor System Inspection" .

If above systems are normal, replace BCM.

With the ignition key in ACC position, headlamps, clearance

lamps, tail lamps, etc. will not go out when the driver's door is

opened.

Refer toBL-96, "Check Door Switch" .

If above system is normal, replace BCM.

Auto light adjustment system will not operate. (Lighting switch

AUTO, 1ST position and 2ND position operate normally.)

Refer to LT-131, "Optical Sensor System Inspection" .

If above system is normal, replace BCM.

Auto light adjustment system of combination meter will not oper-

ate.

CAN communication line inspection between BCM and combi-

nation meter: Refer to BCS-15, "

CAN Communication Inspec-

tion Using CONSULT-II (Self-Diagnosis)" .

Page 4620 of 5621

FRONT FOG LAMP

LT-193

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

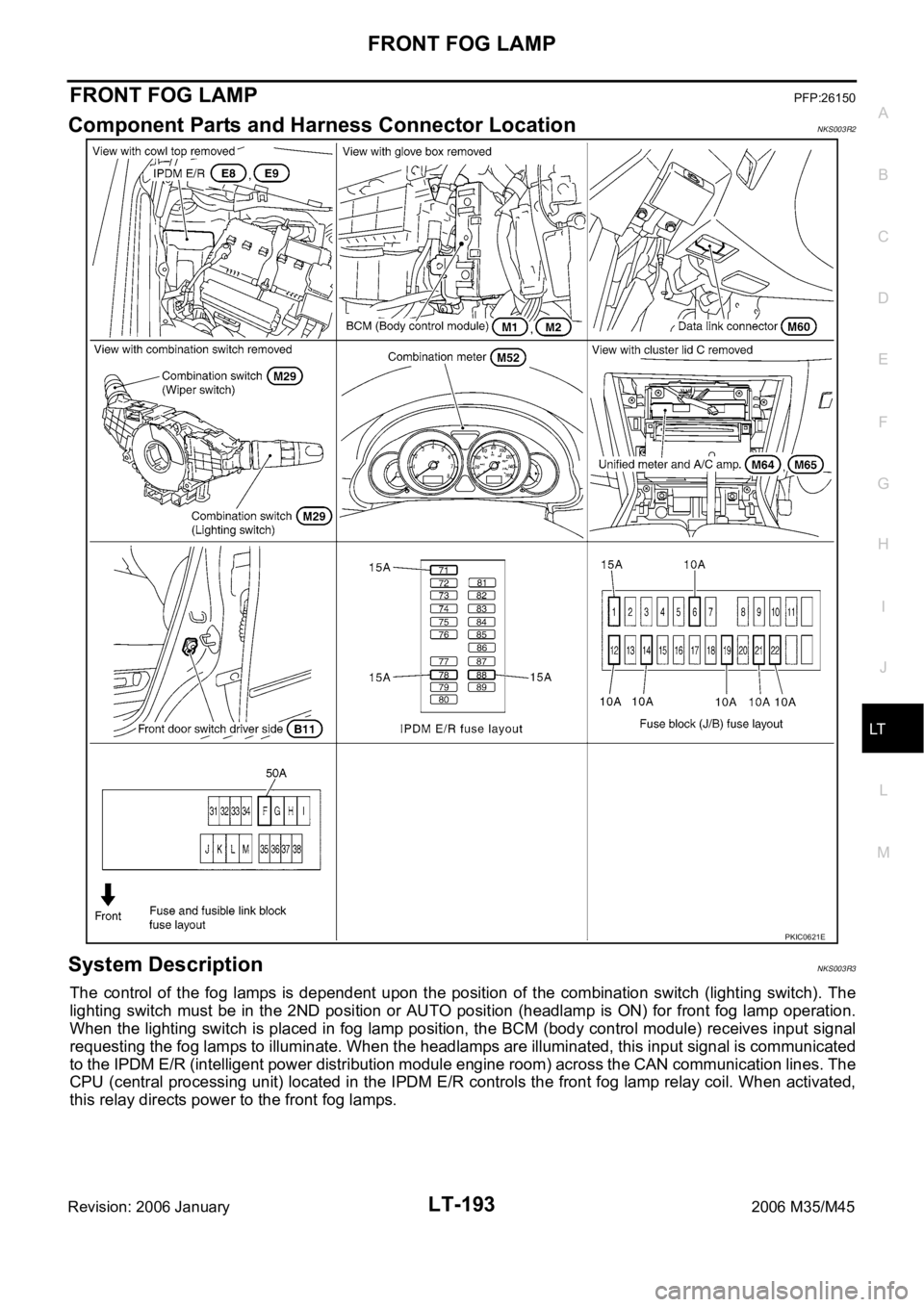

FRONT FOG LAMPPFP:26150

Component Parts and Harness Connector LocationNKS003R2

System DescriptionNKS003R3

The control of the fog lamps is dependent upon the position of the combination switch (lighting switch). The

lighting switch must be in the 2ND position or AUTO position (headlamp is ON) for front fog lamp operation.

When the lighting switch is placed in fog lamp position, the BCM (body control module) receives input signal

requesting the fog lamps to illuminate. When the headlamps are illuminated, this input signal is communicated

to the IPDM E/R (intelligent power distribution module engine room) across the CAN communication lines. The

CPU (central processing unit) located in the IPDM E/R controls the front fog lamp relay coil. When activated,

this relay directs power to the front fog lamps.

PKIC0621E

Page 4621 of 5621

LT-194

FRONT FOG LAMP

Revision: 2006 January2006 M35/M45

OUTLINE

Power is supplied at all times

through 15A fuse (No. 88, located in IPDM E/R)

to front fog lamp relay, located in IPDM E/R,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU, located in IPDM E/R,

through 15A fuse (No. 71, located in IPDM E/R)

to CPU, located in IPDM E/R,

through 50A fusible link (letter F, located in fuse fusible link and relay block)

to BCM terminal 55,

through 10A fuse [No. 21, located in fuse block (J/B)]

to BCM terminal 42, and

to combination meter terminal 23,

through 10A fuse [No. 19, located in fuse block (J/B)]

to unified meter and A/C amp. terminal 54,

through 10A fuse [No. 22, located in fuse block (J/B)]

to key slot terminal 1.

With the ignition switch in the ON or START position, power is supplied

to CPU, located in IPDM E/R,

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 14, located in fuse block (J/B)]

to combination meter terminal 12,

through 10A fuse [No. 12, located in fuse block (J/B)]

to unified meter and A/C amp. terminal 53.

With the ignition switch in the ACC or ON position, power is supplied

through 10A fuse [No. 6, located in fuse block (J/B)]

to BCM terminal 11.

Ground is supplied

to BCM terminal 52

to combination meter terminals 9, 10 and 11

to unified meter and A/C amp. terminals 55 and 71

to engine switch (push switch) terminal 1

to key slot terminal 8

through grounds M16 and M70,

to IPDM E/R terminals 38 and 51

through grounds E22 and E43.

Page 4622 of 5621

FRONT FOG LAMP

LT-195

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

FOG LAMP OPERATION

The fog lamp switch is built in combination switch. The lighting switch must be in 2ND position or AUTO posi-

tion (headlamp is ON) and fog lamp switch must be ON for fog lamp operation.

With the fog lamp switch in the ON position, the CPU located in IPDM E/R grounds coil side of the fog lamp

relay. Fog lamp relay then directs power

through IPDM E/R terminal 37

to front fog lamp RH terminal 1,

through IPDM E/R terminal 36

to front fog lamp LH terminal 1.

Ground is supplied

to front fog lamp RH terminal 2

through grounds E22 and E43,

to front fog lamp LH terminal 2

through grounds E22 and E43.

With power and grounds supplied, the front fog lamps illuminate.

The unified meter and A/C amp. that received the front fog lamp request signal by BCM across the CAN com-

munication makes a front fog lamp indicator lamp turn on in combination meter.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "COMBINATION SWITCH READING FUNCTION" .

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 2ND position (ON), and the ignition switch is turned

from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the headlamps remain illuminated for 5 minutes, then the headlamps are turned off.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionNKS003R4

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitNKS003R5

Refer to LAN-34, "CAN Communication Unit" .