INFINITI M35 2006 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5531 of 5621

WT-6

ROAD WHEEL

Revision: 2006 January2006 M35/M45

ROAD WHEELPFP:40300

InspectionNES000JO

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from aluminum wheel and mount on a tire balance machine.

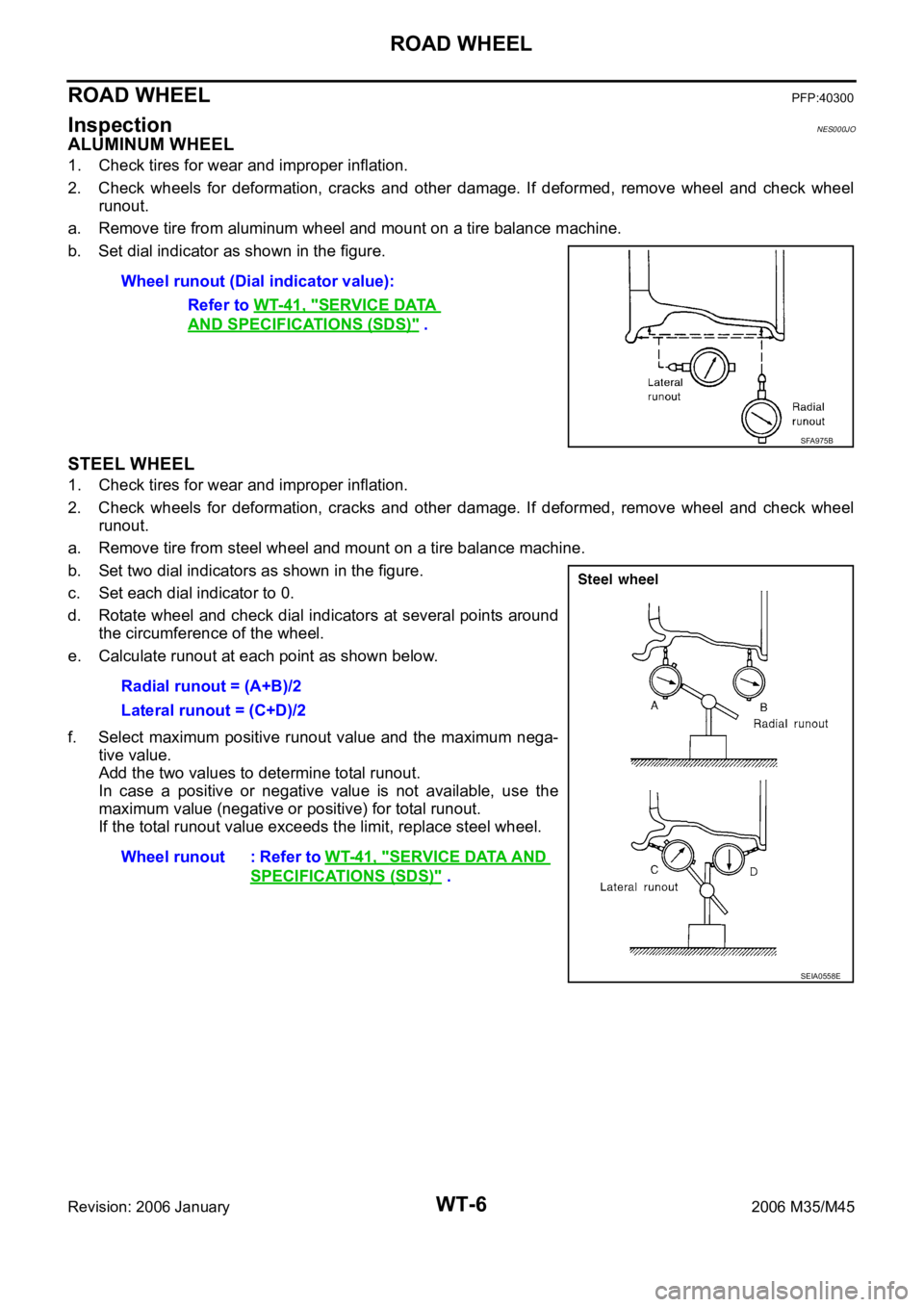

b. Set dial indicator as shown in the figure.

STEEL WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from steel wheel and mount on a tire balance machine.

b. Set two dial indicators as shown in the figure.

c. Set each dial indicator to 0.

d. Rotate wheel and check dial indicators at several points around

the circumference of the wheel.

e. Calculate runout at each point as shown below.

f. Select maximum positive runout value and the maximum nega-

tive value.

Add the two values to determine total runout.

In case a positive or negative value is not available, use the

maximum value (negative or positive) for total runout.

If the total runout value exceeds the limit, replace steel wheel. Wheel runout (Dial indicator value):

Refer to WT-41, "

SERVICE DATA

AND SPECIFICATIONS (SDS)" .

SFA975B

Radial runout = (A+B)/2

Lateral runout = (C+D)/2

Wheel runout : Refer to WT-41, "

SERVICE DATA AND

SPECIFICATIONS (SDS)" .

SEIA0558E

Page 5532 of 5621

ROAD WHEEL TIRE ASSEMBLY

WT-7

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

ROAD WHEEL TIRE ASSEMBLYPFP:40300

Balancing Wheels (Bonding Weight Type)NES000JP

REMOVAL

1. Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal.

After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

WHEEL BALANCE ADJUSTMENT

If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting, select

and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on wheel balancer using the center hole as a guide. Start the tire balance machine.

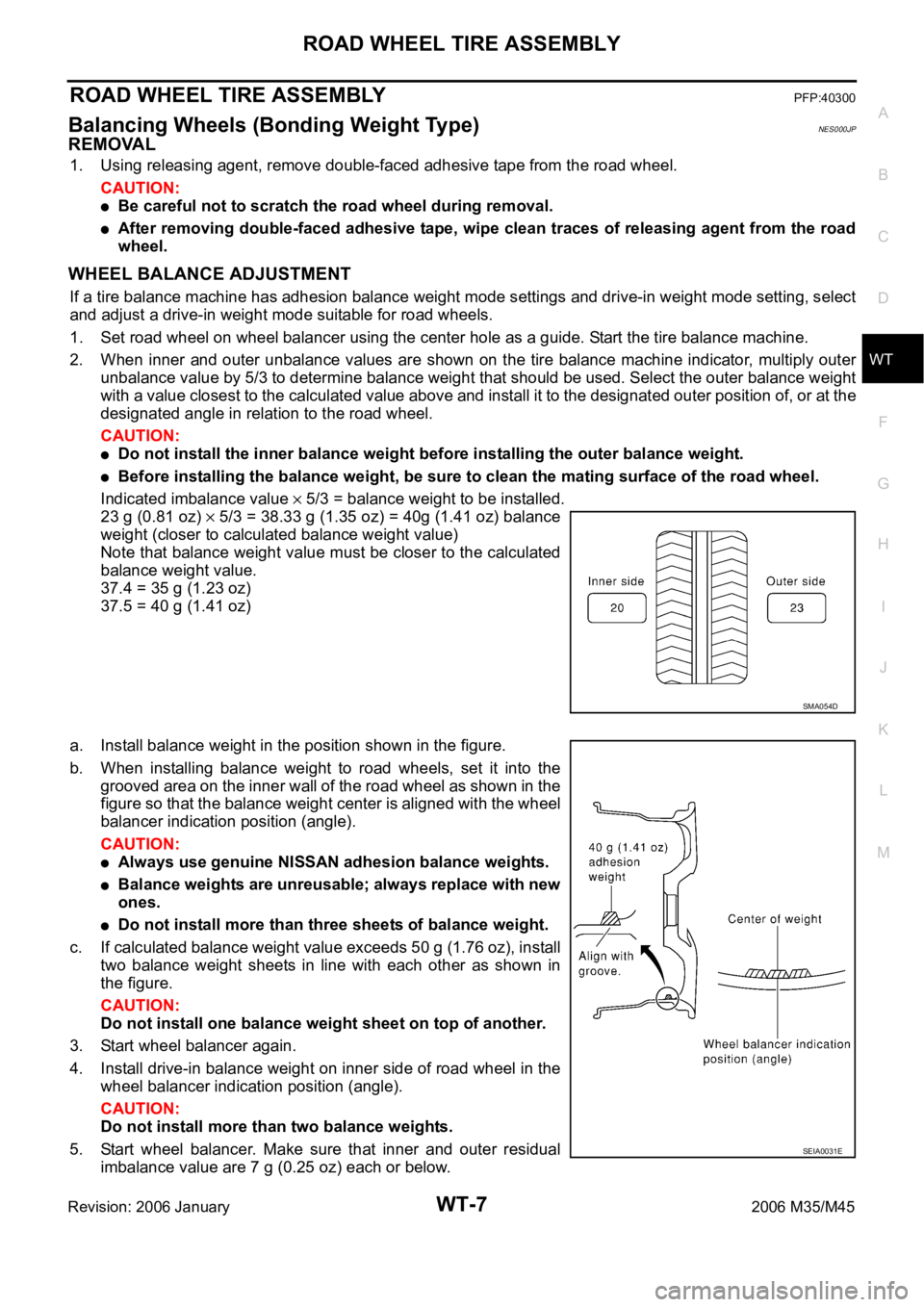

2. When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer

unbalance value by 5/3 to determine balance weight that should be used. Select the outer balance weight

with a value closest to the calculated value above and install it to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

Do not install the inner balance weight before installing the outer balance weight.

Before installing the balance weight, be sure to clean the mating surface of the road wheel.

Indicated imbalance value

5/3 = balance weight to be installed.

23 g (0.81 oz)

5/3 = 38.33 g (1.35 oz) = 40g (1.41 oz) balance

weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated

balance weight value.

37.4 = 35 g (1.23 oz)

37.5 = 40 g (1.41 oz)

a. Install balance weight in the position shown in the figure.

b. When installing balance weight to road wheels, set it into the

grooved area on the inner wall of the road wheel as shown in the

figure so that the balance weight center is aligned with the wheel

balancer indication position (angle).

CAUTION:

Always use genuine NISSAN adhesion balance weights.

Balance weights are unreusable; always replace with new

ones.

Do not install more than three sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

imbalance value are 7 g (0.25 oz) each or below.

SMA054D

SEIA0031E

Page 5533 of 5621

WT-8

ROAD WHEEL TIRE ASSEMBLY

Revision: 2006 January2006 M35/M45

If either residual imbalance value exceeds 7 g (0.25 oz), repeat installation procedures.

RotationNES000JQ

Follow the maintenance schedule for tire rotation service intervals. Refer to MA-7, "PERIODIC MAINTE-

NANCE" .

Do not include the T-type spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding

the criteria for preventing strain of disc rotor.

Maximum allowable unbalanceDynamic (At rim flange) Less than 7 g (0.25 oz) (one side)

Static (At flange) Less than 14 g (0.49 oz)

Tightening torque

of wheel nut: 108 Nꞏm (11 kg-m, 80 ft-lb)

SMA829C

Page 5534 of 5621

LOW TIRE PRESSURE WARNING SYSTEM

WT-9

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

LOW TIRE PRESSURE WARNING SYSTEMPFP:40300

System ComponentsNES000JR

System DescriptionNES000JS

TRANSMITTER

A sensor-transmitter integrated with a valve is installed on a wheel,

and transmits a detected air pressure signal in the form of a radio

wave.

1. Tire pressure transmitter front LH 2. Tire pressure transmitter front RH 3. Tire pressure receiver front LH

4. Tire pressure receiver front RH 5. Low tire pressure warning control

unit6. Low tire pressure warning lamp

7. Display unit 8. Tire pressure transmitter rear LH 9. Tire pressure transmitter rear RH

10. Tire pressure receiver rear LH 11. Tire pressure receiver rear RH

SEIA0648E

SEIA0521E

Page 5535 of 5621

WT-10

LOW TIRE PRESSURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

RECEIVER

The receiver receives the air pressure signal transmitted by the transmitter in each wheel.

LOW TIRE PRESSURE WARNING CONTROL UNIT

The low tire pressure warning control unit (1) reads the air pressure

signal received by the receiver, and controls the low tire pressure

warning lamp and the buzzer operations. It also has a judgement

function to detect a system malfunction.

LOW TIRE PRESSURE WARNING LAMP

The combination meter receives tire pressure status from the low tire

pressure warning control unit using CAN communication. When a

low tire pressure condition is sensed by the low tire pressure control

unit, the combination meter low tire pressure warning lamp and

buzzer are activated.

Low Tire Pressure Warning Lamp Indication

*: Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicle. 1. Tire pressure receiver front 2. Tire pressure receiver rear A. Front wheel house

B. Rear wheel house

Refer to GI-11, "

Components" , for the symbols in the figure.

SEIA0649E

SEIA0650E

SEIA0434E

ConditionLow tire pressure warning

lampBuzzer

Less than 186 kPa

(1.86 kg/cm

2 , 27 psi) [Flat tire]*ON Sounds for 10 sec.

Low tire pressure warning system malfunction [Other diagnostic item]Warning lamp flashes 1 min,

then turns ONOFF

Page 5536 of 5621

LOW TIRE PRESSURE WARNING SYSTEM

WT-11

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

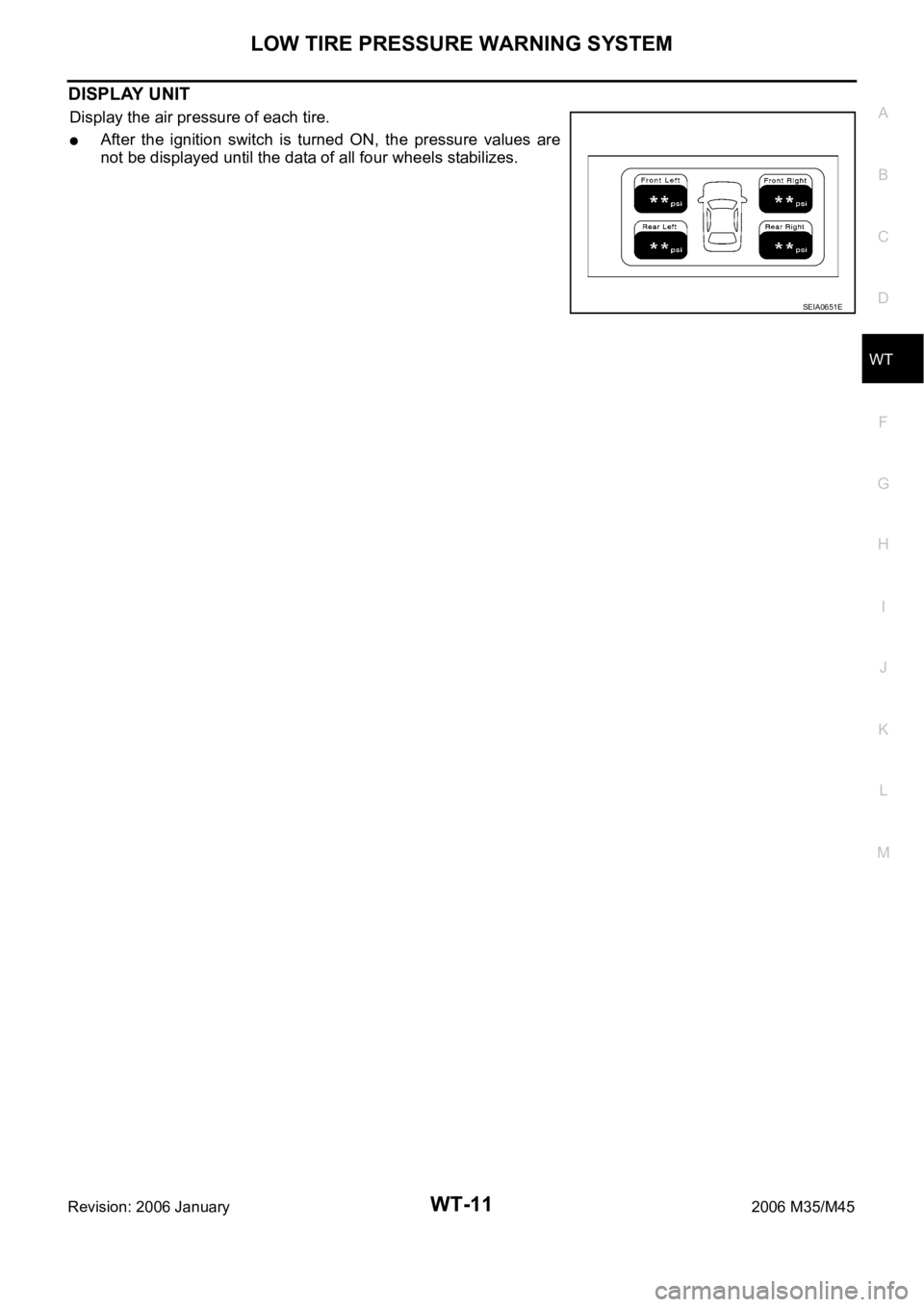

DISPLAY UNIT

Display the air pressure of each tire.

After the ignition switch is turned ON, the pressure values are

not be displayed until the data of all four wheels stabilizes.

SEIA0651E

Page 5537 of 5621

WT-12

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

CAN COMMUNICATIONPFP:23710

System DescriptionNES000JT

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Refer to LAN-34, "

CAN COMMUNICATION" .

Page 5538 of 5621

TROUBLE DIAGNOSES

WT-13

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSESPFP:00004

How to Perform Trouble DiagnosesNES000JU

BASIC CONCEPT

The most important point to perform trouble diagnosis is to understand systems (control and mechanism)

in vehicle thoroughly.

It is also important to clarify customer complaints before inspec-

tion.

First of all, reproduce symptom, and understand it fully.

Ask customer about his/her complaints carefully. In some cases,

they will be necessary to check symptom by driving vehicle with

customer.

CAUTION:

Customers are not professionals. Do not assume “maybe

customer means...” or “maybe the customer mentioned this

symptom”.

It is essential to check symptoms right from beginning in order to

repair a malfunction completely.

For an intermittent malfunction, it is important to reproduce

symptom based on interview with customer and past examples.

Do not perform inspection on ad hoc basis. Most intermittent

malfunctions are caused by poor contacts. In this case, it will be

effective to shake suspected harness or connector by hand.

When repairs are performed without any symptom check, no

one can judge if malfunction has actually been eliminated.

Always diagnosis, make sure to perform “ERASE MEMORY”.

Always read “GI General information” to confirm general precau-

tions. Refer to GI-4, "

General Precautions" .

EFJ0028D

SEF233G

Page 5539 of 5621

WT-14

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

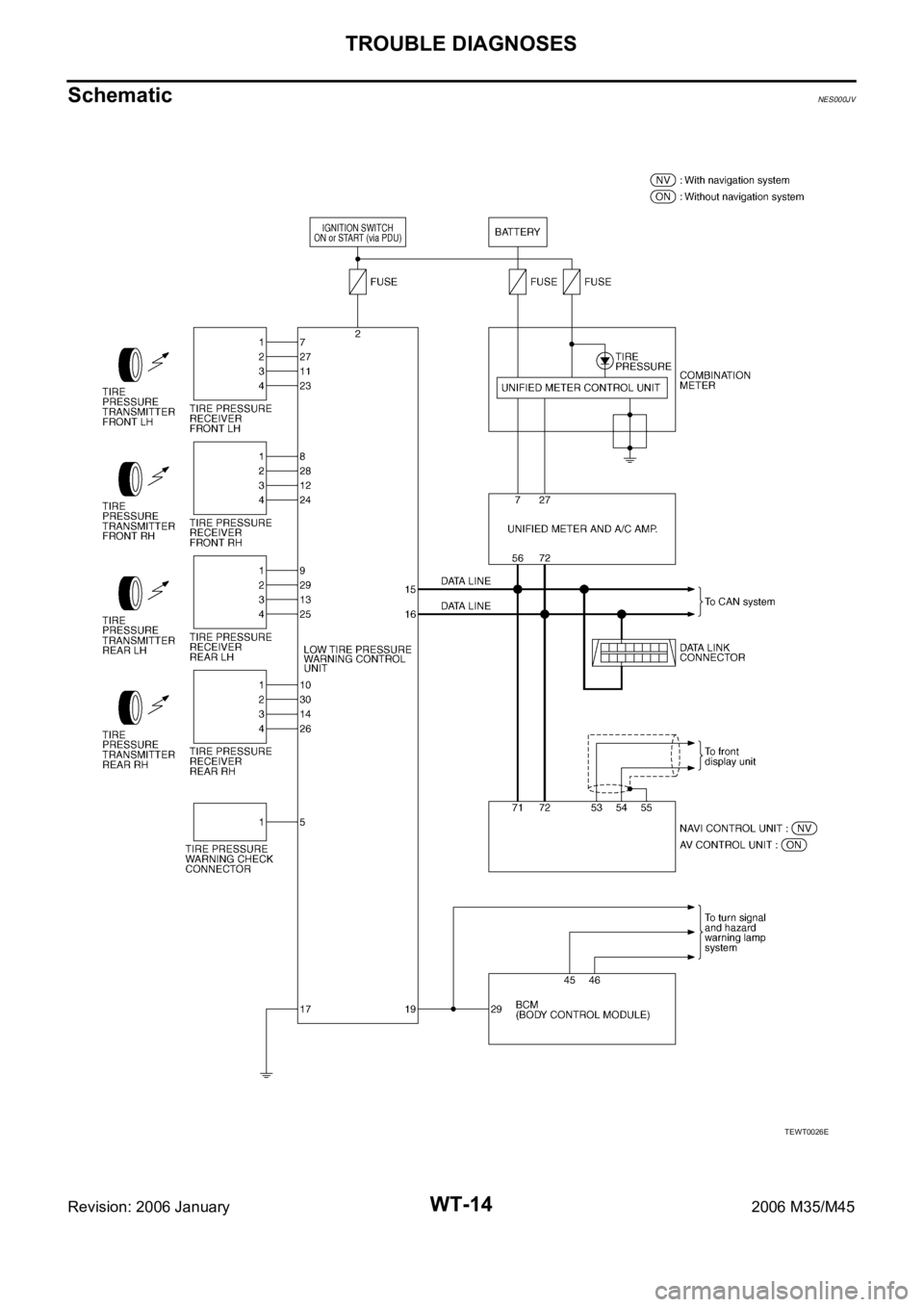

SchematicNES000JV

TEWT0026E

Page 5540 of 5621

TROUBLE DIAGNOSES

WT-15

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Wiring Diagram — T/WARN —NES000JW

TEWT0027E