service INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1649 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

KV10117100

(J3647-A)

Heated oxygen sensor

wrench

NT379

Loosening or tightening heated oxygen sensor

For 22 mm (0.87 in) hexagon nut

KV10114400

(J38365)

Heated oxygen sensor

wrench

NT636

Loosening or tightening rear heated oxygen sensor

a: 22 mm (0.87 in)

KV10117700

(J44716)

Ring gear stopper

NT822

Removing and installing crankshaft pulley

Commercial Service ToolsNBEM0004

Tool number

(Kent-Moore No.)

Tool nameDescription

Spark plug wrench

NT047

Removing and installing spark plug

Valve seat cutter set

NT048

Finishing valve seat dimensions

Piston ring expander

NT030

Removing and installing piston ring

Valve guide drift

NT015

Removing and installing valve guide

Intake & Exhaust:

a = 9.5 mm (0.374 in) dia.

b = 5.5 mm (0.217 in) dia.

PREPARATION

Special Service Tools (Cont'd)

EM-6

Page 1650 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

Valve guide reamer

NT016

Reaming valve guide 1 or hole for oversize valve

guide 2

Intake & Exhaust:

d

1= 6.0 mm (0.236 in) dia.

d

2= 10.2 mm (0.402 in) dia.

(J-43897-18)

(J-43897-12)

Oxygen sensor thread

cleaner

AEM488

Reconditioning the exhaust system threads before

installing a new oxygen sensor (Use with anti-seize

lubricant shown below.)

a = J-43897-18 (18 mm dia.) for zirconia oxygen

sensor

b = J-43897-12 (12 mm dia.) for titania oxygen

sensor

Anti-seize lubricant

(Permatex 133AR or

equivalent meeting MIL

specification MIL-A-

907)

AEM489

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Commercial Service Tools (Cont'd)

EM-7

Page 1687 of 2395

SEM938C

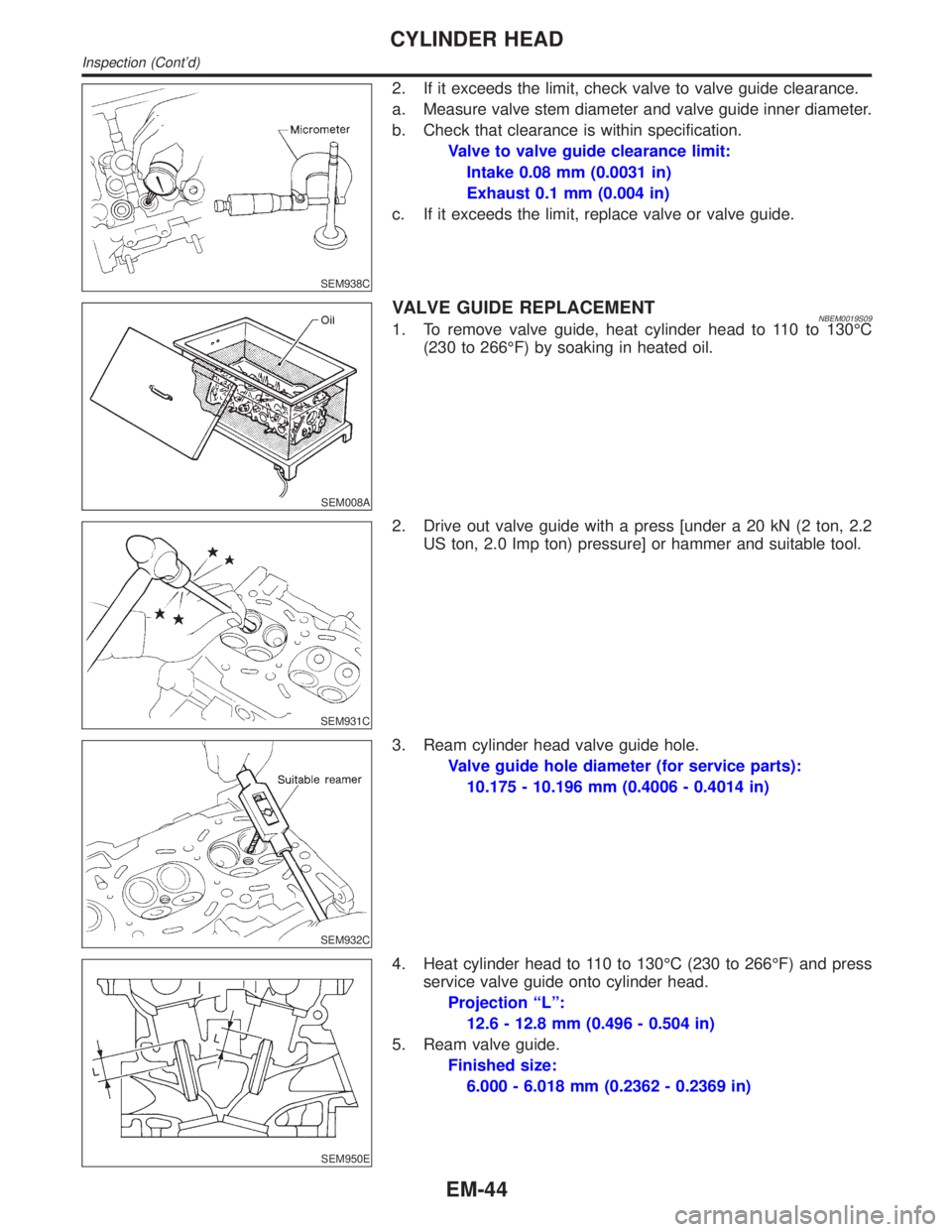

2. If it exceeds the limit, check valve to valve guide clearance.

a. Measure valve stem diameter and valve guide inner diameter.

b. Check that clearance is within specification.

Valve to valve guide clearance limit:

Intake 0.08 mm (0.0031 in)

Exhaust 0.1 mm (0.004 in)

c. If it exceeds the limit, replace valve or valve guide.

SEM008A

VALVE GUIDE REPLACEMENTNBEM0019S091. To remove valve guide, heat cylinder head to 110 to 130ÉC

(230 to 266ÉF) by soaking in heated oil.

SEM931C

2. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer and suitable tool.

SEM932C

3. Ream cylinder head valve guide hole.

Valve guide hole diameter (for service parts):

10.175 - 10.196 mm (0.4006 - 0.4014 in)

SEM950E

4. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF) and press

service valve guide onto cylinder head.

Projection ªLº:

12.6 - 12.8 mm (0.496 - 0.504 in)

5. Ream valve guide.

Finished size:

6.000 - 6.018 mm (0.2362 - 0.2369 in)

CYLINDER HEAD

Inspection (Cont'd)

EM-44

Page 1688 of 2395

SEM934C

VALVE SEATSNBEM0019S10Check valve seats for any evidence of pitting at valve contact

surface, and reseat or replace if it has worn out excessively.

IBefore repairing valve seats, check valve and valve guide

for wear. If they have worn, replace them. Then correct

valve seat.

IUse both hands to cut uniformly.

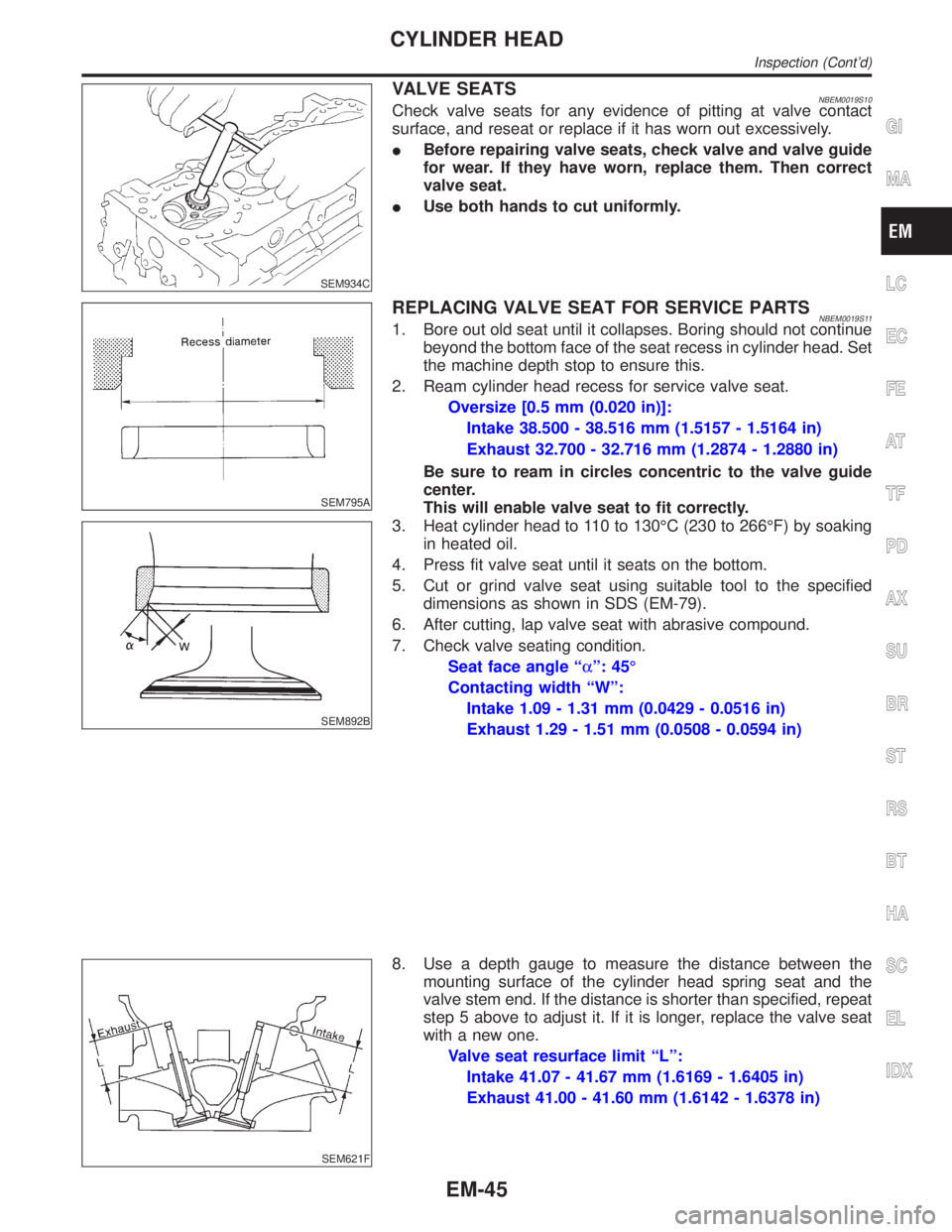

SEM795A

REPLACING VALVE SEAT FOR SERVICE PARTSNBEM0019S111. Bore out old seat until it collapses. Boring should not continue

beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Oversize [0.5 mm (0.020 in)]:

Intake 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust 32.700 - 32.716 mm (1.2874 - 1.2880 in)

Be sure to ream in circles concentric to the valve guide

center.

This will enable valve seat to fit correctly.

SEM892B

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF) by soaking

in heated oil.

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool to the specified

dimensions as shown in SDS (EM-79).

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ªaº: 45É

Contacting width ªWº:

Intake 1.09 - 1.31 mm (0.0429 - 0.0516 in)

Exhaust 1.29 - 1.51 mm (0.0508 - 0.0594 in)

SEM621F

8. Use a depth gauge to measure the distance between the

mounting surface of the cylinder head spring seat and the

valve stem end. If the distance is shorter than specified, repeat

step 5 above to adjust it. If it is longer, replace the valve seat

with a new one.

Valve seat resurface limit ªLº:

Intake 41.07 - 41.67 mm (1.6169 - 1.6405 in)

Exhaust 41.00 - 41.60 mm (1.6142 - 1.6378 in)

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEAD

Inspection (Cont'd)

EM-45

Page 1709 of 2395

SEM843E

SEM321AA

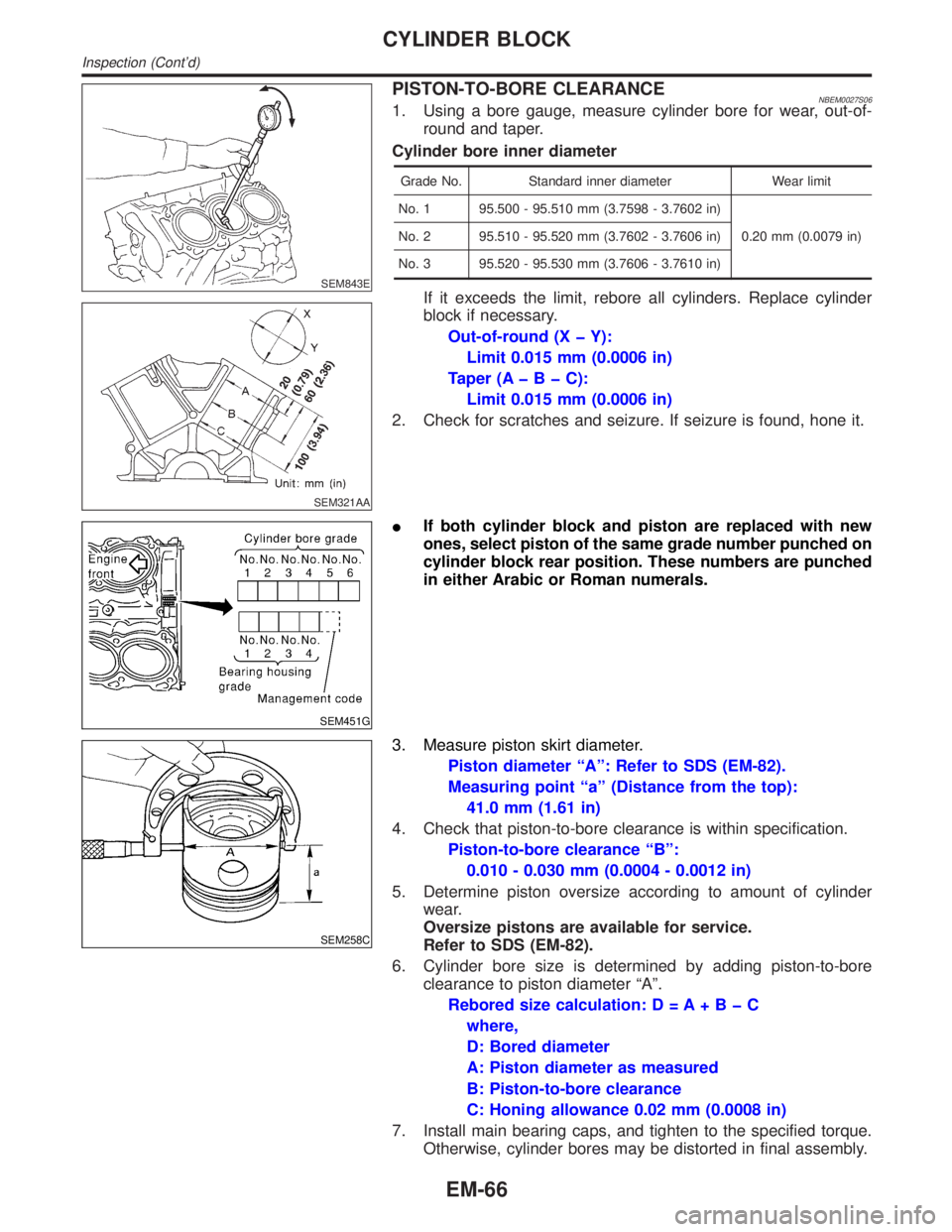

PISTON-TO-BORE CLEARANCENBEM0027S061. Using a bore gauge, measure cylinder bore for wear, out-of-

round and taper.

Cylinder bore inner diameter

Grade No. Standard inner diameter Wear limit

No. 1 95.500 - 95.510 mm (3.7598 - 3.7602 in)

0.20 mm (0.0079 in) No. 2 95.510 - 95.520 mm (3.7602 - 3.7606 in)

No. 3 95.520 - 95.530 mm (3.7606 - 3.7610 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder

block if necessary.

Out-of-round (X þ Y):

Limit 0.015 mm (0.0006 in)

Taper (AþBþC):

Limit 0.015 mm (0.0006 in)

2. Check for scratches and seizure. If seizure is found, hone it.

SEM451G

IIf both cylinder block and piston are replaced with new

ones, select piston of the same grade number punched on

cylinder block rear position. These numbers are punched

in either Arabic or Roman numerals.

SEM258C

3. Measure piston skirt diameter.

Piston diameter ªAº: Refer to SDS (EM-82).

Measuring point ªaº (Distance from the top):

41.0 mm (1.61 in)

4. Check that piston-to-bore clearance is within specification.

Piston-to-bore clearance ªBº:

0.010 - 0.030 mm (0.0004 - 0.0012 in)

5. Determine piston oversize according to amount of cylinder

wear.

Oversize pistons are available for service.

Refer to SDS (EM-82).

6. Cylinder bore size is determined by adding piston-to-bore

clearance to piston diameter ªAº.

Rebored size calculation: D = A+BþC

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston-to-bore clearance

C: Honing allowance 0.02 mm (0.0008 in)

7. Install main bearing caps, and tighten to the specified torque.

Otherwise, cylinder bores may be distorted in final assembly.

CYLINDER BLOCK

Inspection (Cont'd)

EM-66

Page 1711 of 2395

SEM845E

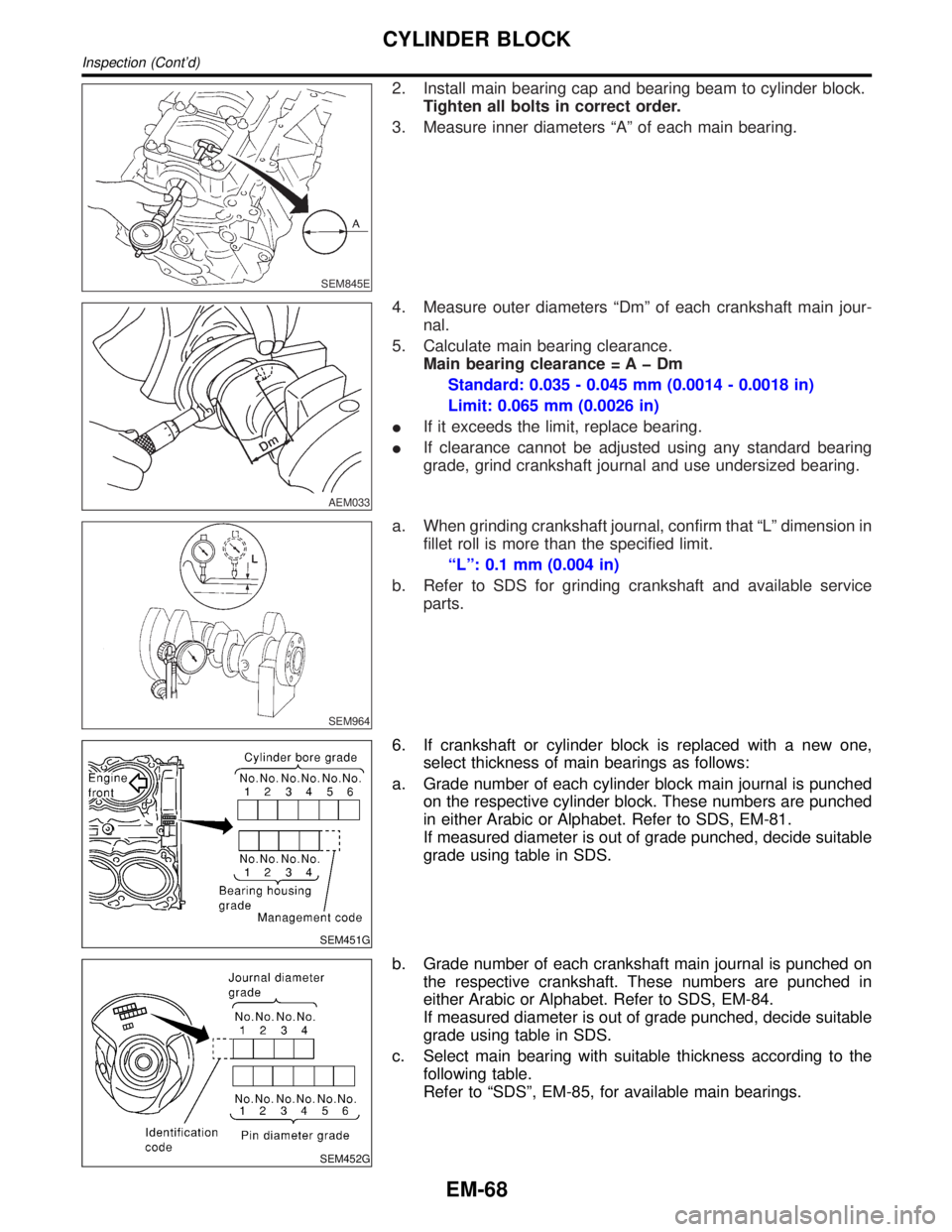

2. Install main bearing cap and bearing beam to cylinder block.

Tighten all bolts in correct order.

3. Measure inner diameters ªAº of each main bearing.

AEM033

4. Measure outer diameters ªDmº of each crankshaft main jour-

nal.

5. Calculate main bearing clearance.

Main bearing clearance = A þ Dm

Standard: 0.035 - 0.045 mm (0.0014 - 0.0018 in)

Limit: 0.065 mm (0.0026 in)

IIf it exceeds the limit, replace bearing.

IIf clearance cannot be adjusted using any standard bearing

grade, grind crankshaft journal and use undersized bearing.

SEM964

a. When grinding crankshaft journal, confirm that ªLº dimension in

fillet roll is more than the specified limit.

ªLº: 0.1 mm (0.004 in)

b. Refer to SDS for grinding crankshaft and available service

parts.

SEM451G

6. If crankshaft or cylinder block is replaced with a new one,

select thickness of main bearings as follows:

a. Grade number of each cylinder block main journal is punched

on the respective cylinder block. These numbers are punched

in either Arabic or Alphabet. Refer to SDS, EM-81.

If measured diameter is out of grade punched, decide suitable

grade using table in SDS.

SEM452G

b. Grade number of each crankshaft main journal is punched on

the respective crankshaft. These numbers are punched in

either Arabic or Alphabet. Refer to SDS, EM-84.

If measured diameter is out of grade punched, decide suitable

grade using table in SDS.

c. Select main bearing with suitable thickness according to the

following table.

Refer to ªSDSº, EM-85, for available main bearings.

CYLINDER BLOCK

Inspection (Cont'd)

EM-68

Page 1718 of 2395

General SpecificationsNBEM0029

Cylinder arrangementV- 6

Displacement cm

3(cu in)3,498 (213.45)

Bore and stroke mm (in)95.5 x 81.4 (3.760 x 3.205)

Valve arrangementDOHC

Firing order1-2-3-4-5-6

Number of piston ringsCompression 2

Oil 1

Number of main bearings4

Compression ratio10.0

Compression PressureNBEM0030Unit: kPa (kg/cm2, psi)/300 rpm

Compression pressureStandard 1,275 (13.0, 185)

Minimum 981 (10.0, 142)

Differential limit between cylinders 98 (1.0, 14)

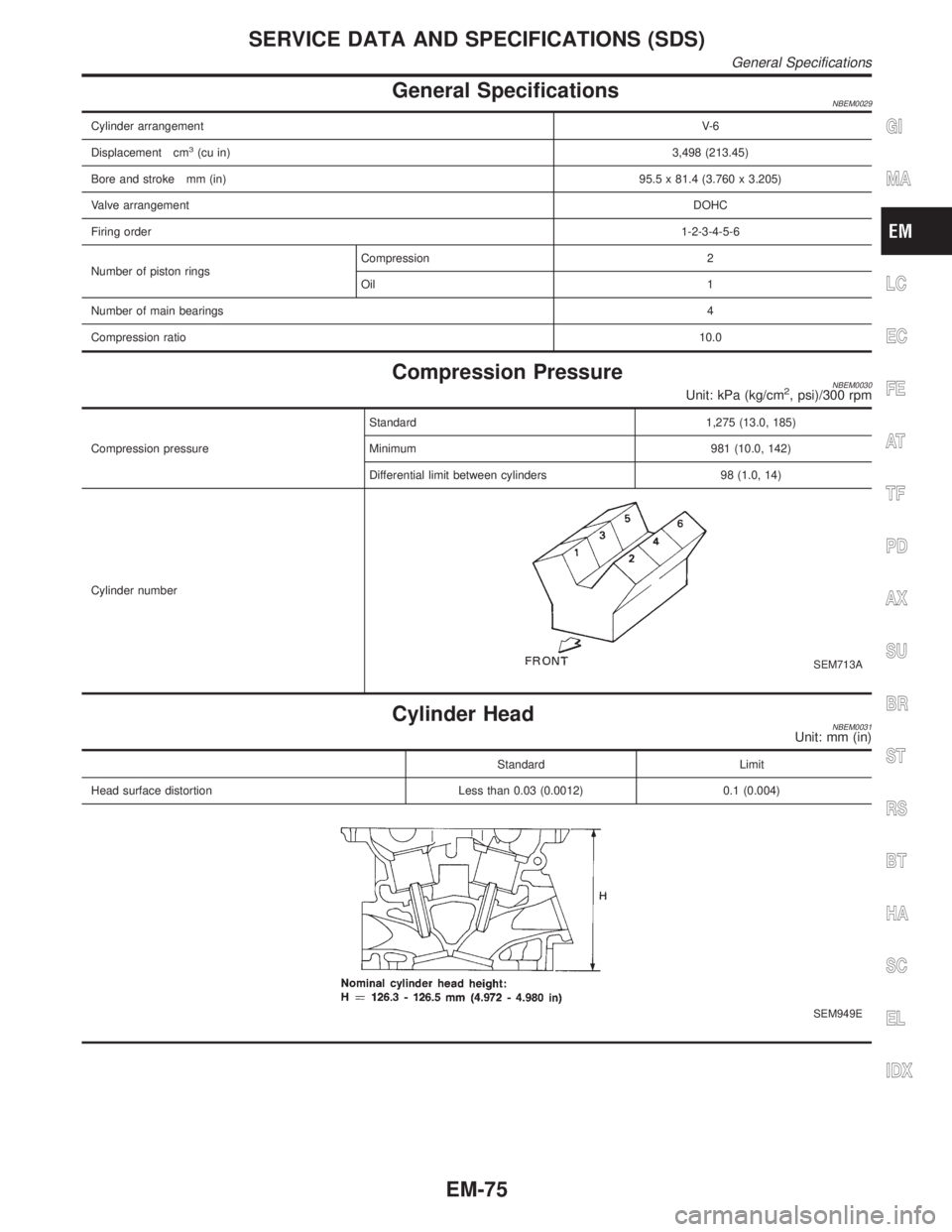

Cylinder number

SEM713A

Cylinder HeadNBEM0031Unit: mm (in)

Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.1 (0.004)

SEM949E

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

EM-75

Page 1719 of 2395

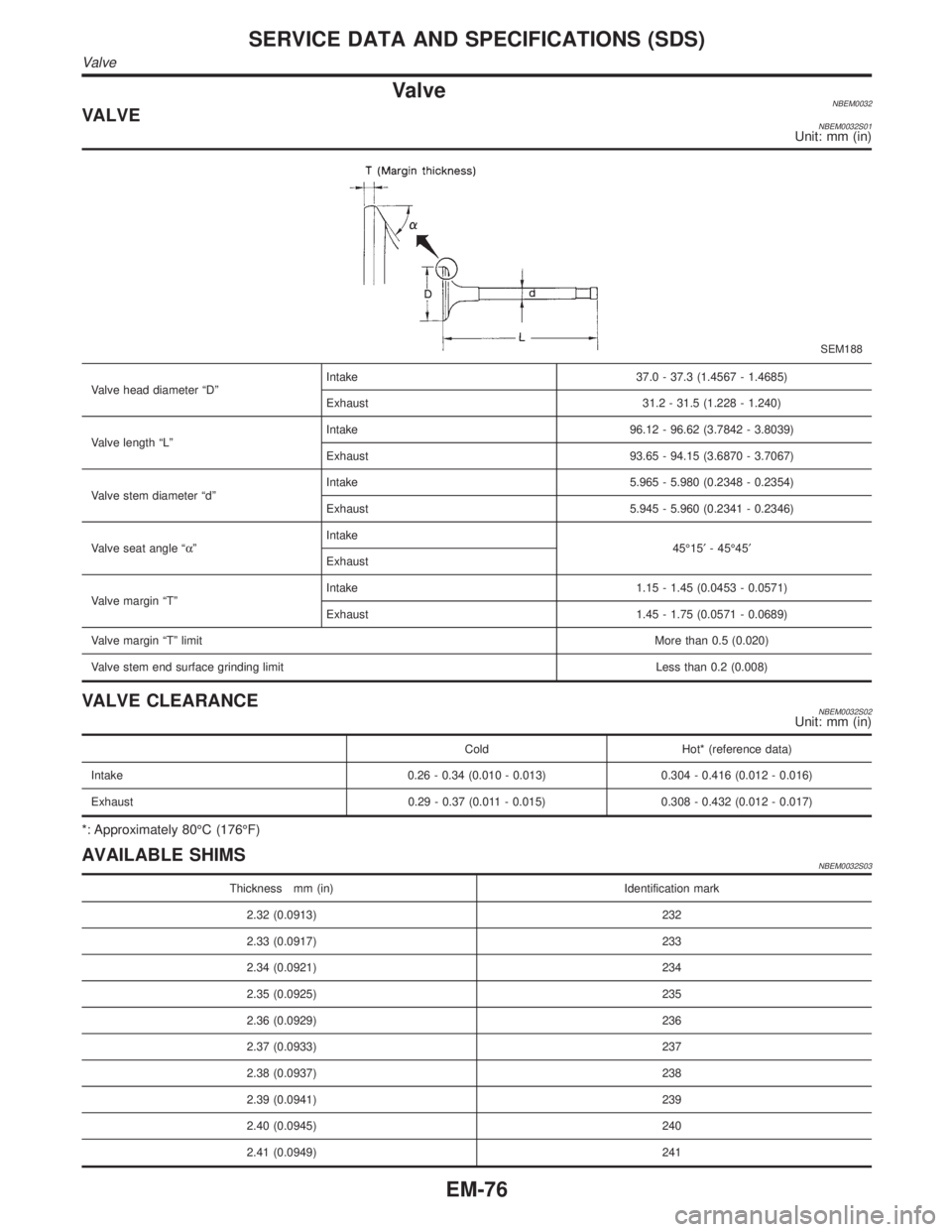

ValveNBEM0032VALVENBEM0032S01Unit: mm (in)

SEM188

Valve head diameter ªDºIntake 37.0 - 37.3 (1.4567 - 1.4685)

Exhaust 31.2 - 31.5 (1.228 - 1.240)

Valve length ªLºIntake 96.12 - 96.62 (3.7842 - 3.8039)

Exhaust 93.65 - 94.15 (3.6870 - 3.7067)

Valve stem diameter ªdºIntake 5.965 - 5.980 (0.2348 - 0.2354)

Exhaust 5.945 - 5.960 (0.2341 - 0.2346)

Valve seat angle ªaºIntake

45É15¢- 45É45¢

Exhaust

Valve margin ªTºIntake 1.15 - 1.45 (0.0453 - 0.0571)

Exhaust 1.45 - 1.75 (0.0571 - 0.0689)

Valve margin ªTº limitMore than 0.5 (0.020)

Valve stem end surface grinding limit Less than 0.2 (0.008)

VALVE CLEARANCENBEM0032S02Unit: mm (in)

Cold Hot* (reference data)

Intake 0.26 - 0.34 (0.010 - 0.013) 0.304 - 0.416 (0.012 - 0.016)

Exhaust 0.29 - 0.37 (0.011 - 0.015) 0.308 - 0.432 (0.012 - 0.017)

*: Approximately 80ÉC (176ÉF)

AVAILABLE SHIMSNBEM0032S03

Thickness mm (in) Identification mark

2.32 (0.0913) 232

2.33 (0.0917) 233

2.34 (0.0921) 234

2.35 (0.0925) 235

2.36 (0.0929) 236

2.37 (0.0933) 237

2.38 (0.0937) 238

2.39 (0.0941) 239

2.40 (0.0945) 240

2.41 (0.0949) 241

SERVICE DATA AND SPECIFICATIONS (SDS)

Valve

EM-76

Page 1720 of 2395

Thickness mm (in) Identification mark

2.42 (0.0953) 242

2.43 (0.0957) 243

2.44 (0.0961) 244

2.45 (0.0965) 245

2.46 (0.0969) 246

2.47 (0.0972) 247

2.48 (0.0976) 248

2.49 (0.0980) 249

2.50 (0.0984) 250

2.51 (0.0988) 251

2.52 (0.0992) 252

2.53 (0.0996) 253

2.54 (0.1000) 254

2.55 (0.1004) 255

2.56 (0.1008) 256

2.57 (0.1012) 257

2.58 (0.1016) 258

2.59 (0.1020) 259

2.60 (0.1024) 260

2.61 (0.1028) 261

2.62 (0.1031) 262

2.63 (0.1035) 263

2.64 (0.1039) 264

2.65 (0.1043) 265

2.66 (0.1047) 266

2.67 (0.1051) 267

2.68 (0.1055) 268

2.69 (0.1059) 269

2.70 (0.1063) 270

2.71 (0.1067) 271

2.72 (0.1071) 272

2.73 (0.1075) 273

2.74 (0.1079) 274

2.75 (0.1083) 275

2.76 (0.1087) 276

2.77 (0.1091) 277

2.78 (0.1094) 278

2.79 (0.1098) 279

2.80 (0.1102) 280

2.81 (0.1106) 281

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Valve (Cont'd)

EM-77

Page 1721 of 2395

Thickness mm (in) Identification mark

2.82 (0.1110) 282

2.83 (0.1114) 283

2.84 (0.1118) 284

2.85 (0.1122) 285

2.86 (0.1126) 286

2.87 (0.1130) 287

2.88 (0.1134) 288

2.89 (0.1138) 289

2.90 (0.1142) 290

2.91 (0.1146) 291

2.92 (0.1150) 292

2.93 (0.1154) 293

2.94 (0.1157) 294

2.95 (0.1161) 295

SEM966E

VALVE SPRINGNBEM0032S04

Free height mm (in)47.10 (1.8543)

Pressure N (kg, lb) at height mm (in)Standard 202 (20.6, 45.4) at 37.0 (1.457)

Limit 436 (44.5, 98.1) at 28.2 (1.110)

Out-of-square mm (in)Less than 2.0 (0.079)

VALVE LIFTERNBEM0032S05Unit: mm (in)

Valve lifter outer diameter 34.960 - 34.975 (1.3764 - 1.3770)

Lifter guide inner diameter 35.000 - 35.021 (1.3780 - 1.3788)

Clearance between lifter and lifter guide 0.025 - 0.061 (0.0010 - 0.0024)

SERVICE DATA AND SPECIFICATIONS (SDS)

Valve (Cont'd)

EM-78