INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2171 of 2395

Wiring Diagram Ð CHARGE ÐNBSC0010

MEL653L

CHARGING SYSTEM

Wiring Diagram Ð CHARGE Ð

SC-20

Page 2172 of 2395

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NBSC0020NOTE:

To ensure a complete and thorough diagnosis, the battery, starter

and alternator test segments must be done as a set from start to

finish.

SEL417X

1. Turn off all loads on the vehicle electrical system.

2. Perform battery and starting system test with Battery/Starting/

Charging system tester.

3. Press ªENTERº to begin the charging system test.

4. Start engine.

SEL418X

5. Press ªENTERº until ªLOADS OFF REV ENGINE 5 SECº is

displayed.

6. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return to the engine to idle.

Once the increase in engine rpm is detected, press ªENTERº

to continue.

NOTE:

IIf after 30 seconds an increase in engine idle speed is not

detected, ªRPM NOT DETECTEDº will display.

ISome engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect this

without any other action being taken. If this occurs, continue on

with the testing process. The final results will not be affected.

SEL419X

7. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

8. When complete, the tester will prompt you to turn on the fol-

lowing electrical loads.

IHeater fun set to highest. Do not run the A/C or windshield

defroster.

IHeadlamp high beam

IRear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester

SC-21

Page 2173 of 2395

SEL420X

9. Press ªENTERº to continue.

SEL421X

10. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return the engine to idle. Once the

increase in engine rpm is detected, press ªENTERº to con-

tinue.

NOTE:

If after 30 seconds an increase in engine idle speed is not detected,

ªRPM NOT DETECTEDº will be displayed. Press ªENTERº to

restart the test.

SEL422X

11. Diagnostic result is displayed on the tester. Refer to ªDIAG-

NOSTIC RESULT ITEM CHARTº, SC-23.

SEL577X

12. Press ªENTERº then test output code is displayed. Record the

test output code on the repair order.

13. Toggle back to the ªDIAGNOSTIC SCREENº for test results.

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-22

Page 2174 of 2395

DIAGNOSTIC RESULT ITEM CHARTNBSC0020S01

Diagnostic item Service procedure

CHARGING SYSTEM NORMAL Charging system is normal and will also show DIODE RIPPLE test result.

NO CHARGING VOLTAGE Go to ªWORK FLOWº, SC-24.

LOW CHARGING VOLTAGE Go to ªWORK FLOWº, SC-24.

HIGH CHARGING VOLTAGE Go to ªWORK FLOWº, SC-24.

DIODE RIPPLE NORMAL Diode ripple is OK and will also show CHARGING VOLTAGE test result.

EXCESS RIPPLE DETECTEDReplace the alternator. Perform ªDIODE RIPPLEº test again using Battery/Starting/

Charging system tester to confirm repair.

DIODE RIPPLE NOT DETECTED Go to ªWORK FLOWº, SC-24.GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-23

Page 2175 of 2395

WORK FLOWNBSC0020S02

SEL423X

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-24

Page 2176 of 2395

DIAGNOSTIC PROCEDURE 1NBSC0020S03Check ªLº Terminal CircuitNBSC0020S0301

1 CHECK ªLº TERMINAL CONNECTION

Check to see if ªLº terminal is clean and tight.

OK or NG

OK©GO TO 2.

NG©Repair ªLº terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK ªLº TERMINAL CIRCUIT

1. Disconnect E106 connector from alternator.

2. Apply ground to E106 connector terminal 1 with the ignition switch in the ON position.

SEL424X

OK or NG

OK©Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG©Check the following.

I10A fuse [No. 8, located in fuse block (J/B)]

ICHARGE lamp

IHarness for open or short between combination meter and fuse

IHarness for open or short between combination meter and alternator

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-25

Page 2177 of 2395

DIAGNOSTIC PROCEDURE 2=NBSC0020S04Check ªBº Terminal CircuitNBSC0020S0401

1 CHECK ªBº TERMINAL CONNECTION

Check to see if ªBº terminal is clean and tight.

OK or NG

OK©GO TO 2. Confirm repair by performing complete Battery/Starting/Charging system test.

NG©Repair ªBº terminal connection.

2 CHECK ALTERNATOR ªBº TERMINAL CIRCUIT

Check voltage between alternator terminal B and ground using a digital circuit tester.

SEL425X

OK or NG

OK©GO TO 3.

NG©Check the following.

I120A fusible link (lettera, located in fuse and fusible link box)

IHarness for open or short between alternator and fusible link

3 CHECK ªBº TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between alternator terminal B and battery positive terminal using a digital tester.

SEL426X

OK or NG

OK©Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG©Check harness between the battery and the alternator for poor continuity.

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-26

Page 2178 of 2395

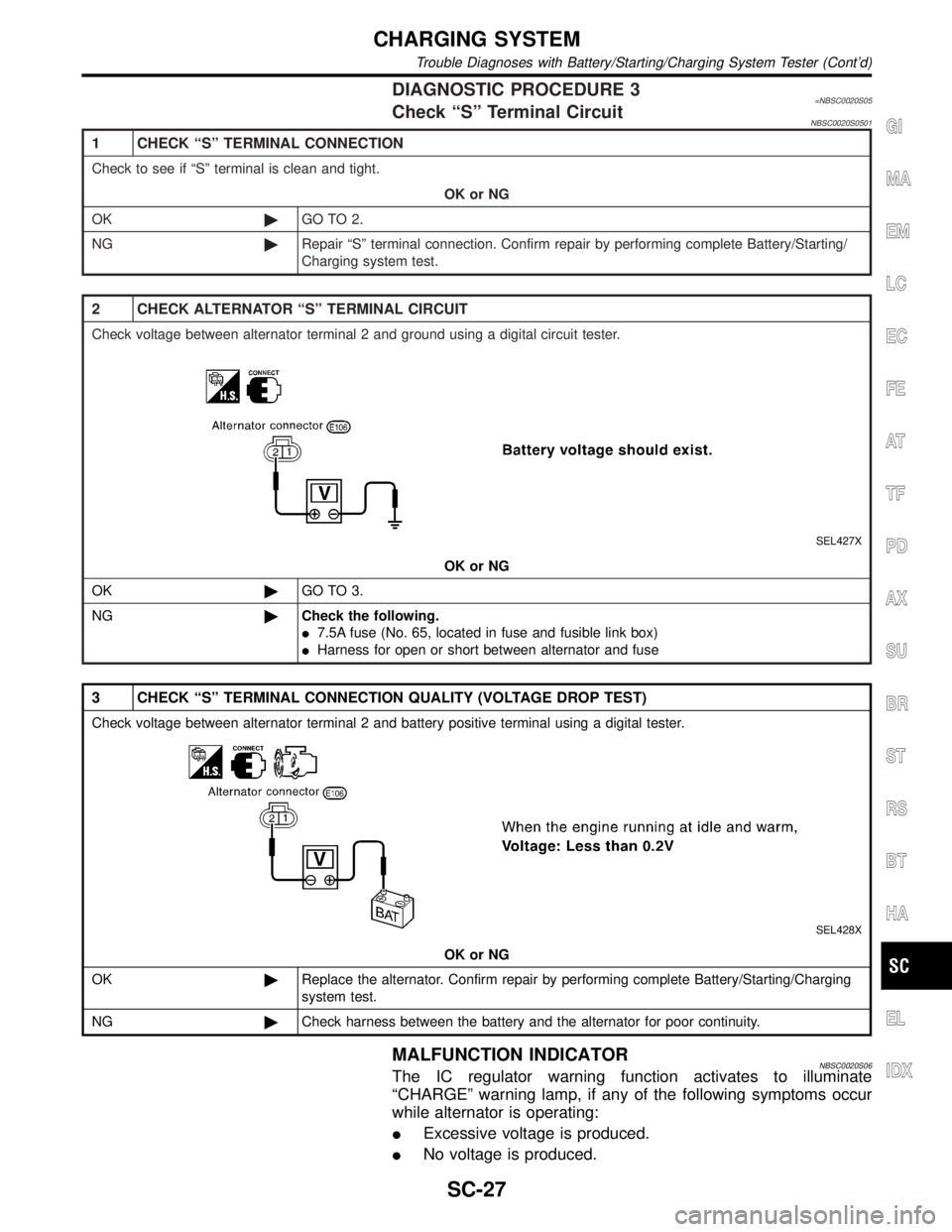

DIAGNOSTIC PROCEDURE 3=NBSC0020S05Check ªSº Terminal CircuitNBSC0020S0501

1 CHECK ªSº TERMINAL CONNECTION

Check to see if ªSº terminal is clean and tight.

OK or NG

OK©GO TO 2.

NG©Repair ªSº terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK ALTERNATOR ªSº TERMINAL CIRCUIT

Check voltage between alternator terminal 2 and ground using a digital circuit tester.

SEL427X

OK or NG

OK©GO TO 3.

NG©Check the following.

I7.5A fuse (No. 65, located in fuse and fusible link box)

IHarness for open or short between alternator and fuse

3 CHECK ªSº TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between alternator terminal 2 and battery positive terminal using a digital tester.

SEL428X

OK or NG

OK©Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG©Check harness between the battery and the alternator for poor continuity.

MALFUNCTION INDICATORNBSC0020S06The IC regulator warning function activates to illuminate

ªCHARGEº warning lamp, if any of the following symptoms occur

while alternator is operating:

IExcessive voltage is produced.

INo voltage is produced.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-27

Page 2179 of 2395

ConstructionNBSC0012

MEL951LA

MEL952LA

Removal and InstallationNBSC0013

CHARGING SYSTEM

Construction

SC-28

Page 2180 of 2395

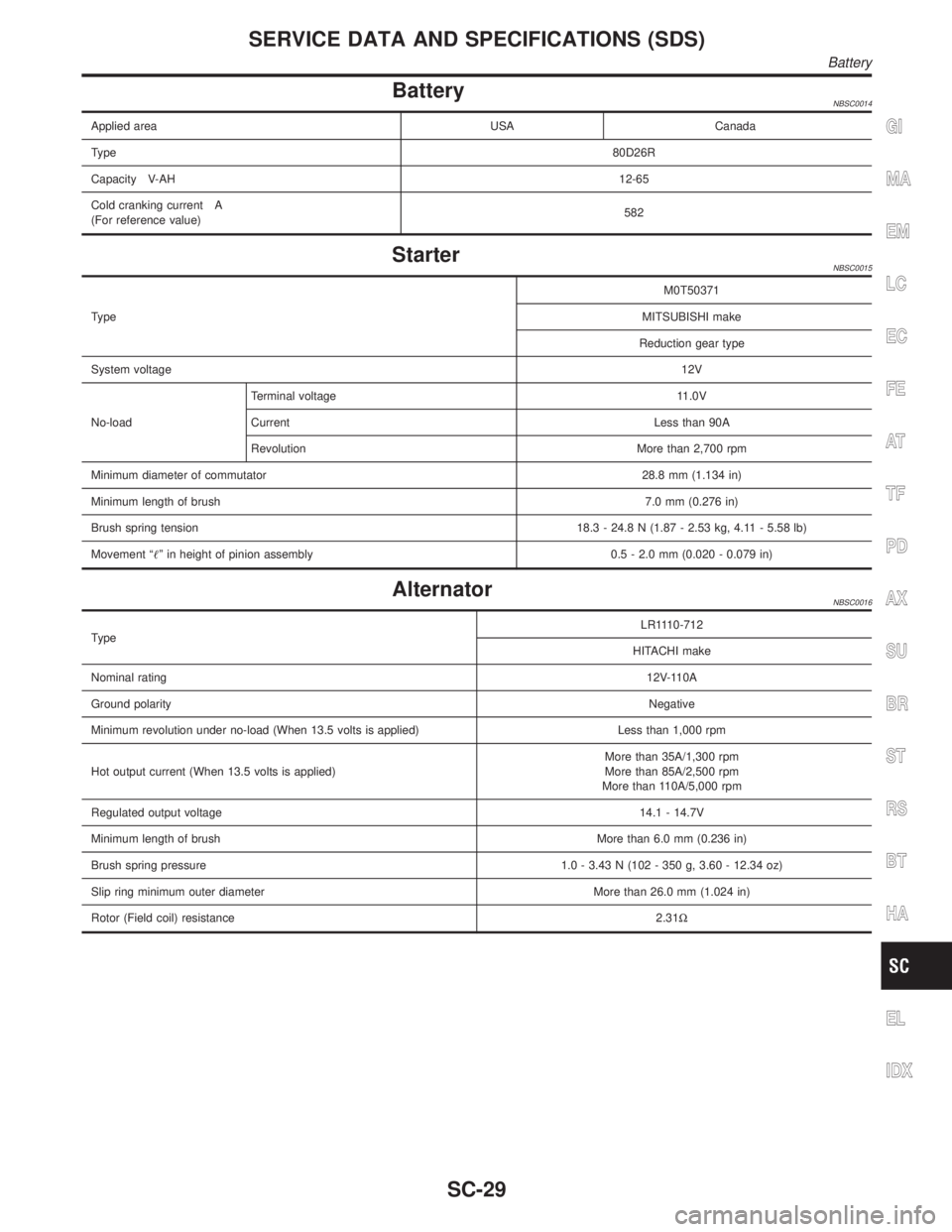

BatteryNBSC0014

Applied area USA Canada

Type80D26R

Capacity V-AH12-65

Cold cranking current A

(For reference value)582

StarterNBSC0015

TypeM0T50371

MITSUBISHI make

Reduction gear type

System voltage12V

No-loadTerminal voltage 11.0V

Current Less than 90A

Revolution More than 2,700 rpm

Minimum diameter of commutator28.8 mm (1.134 in)

Minimum length of brush7.0 mm (0.276 in)

Brush spring tension18.3 - 24.8 N (1.87 - 2.53 kg, 4.11 - 5.58 lb)

Movement ªº in height of pinion assembly 0.5 - 2.0 mm (0.020 - 0.079 in)

AlternatorNBSC0016

TypeLR1110-712

HITACHI make

Nominal rating12V-110A

Ground polarityNegative

Minimum revolution under no-load (When 13.5 volts is applied) Less than 1,000 rpm

Hot output current (When 13.5 volts is applied)More than 35A/1,300 rpm

More than 85A/2,500 rpm

More than 110A/5,000 rpm

Regulated output voltage14.1 - 14.7V

Minimum length of brushMore than 6.0 mm (0.236 in)

Brush spring pressure 1.0 - 3.43 N (102 - 350 g, 3.60 - 12.34 oz)

Slip ring minimum outer diameter More than 26.0 mm (1.024 in)

Rotor (Field coil) resistance2.31W

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Battery

SC-29