elec INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2129 of 2395

![INFINITI QX4 2001 Factory Service Manual SRS701

If no malfunction is detected on ªSELF-DIAG [CURRENT]º even

though malfunction is detected in ªSRS Operation Checkº, check

the battery voltage.

If the battery voltage is less than 9V, charg INFINITI QX4 2001 Factory Service Manual SRS701

If no malfunction is detected on ªSELF-DIAG [CURRENT]º even

though malfunction is detected in ªSRS Operation Checkº, check

the battery voltage.

If the battery voltage is less than 9V, charg](/img/42/57027/w960_57027-2128.png)

SRS701

If no malfunction is detected on ªSELF-DIAG [CURRENT]º even

though malfunction is detected in ªSRS Operation Checkº, check

the battery voltage.

If the battery voltage is less than 9V, charge the battery. Then go

to DIAGNOSTIC PROCEDURE 3, page RS-42.

If the battery voltage is OK, go to DIAGNOSTIC PROCEDURE 4,

page RS-44, to diagnose the following cases:

ISelf-diagnostic result ªSELF-DIAG [PAST]º (previously stored

in the memory) might not be erased after repair.

IThe SRS system malfunctions intermittently.

8. Touch ªPRINTº.

9. Compare diagnostic codes to ªCONSULT-II Diagnostic Code

Chartº, page RS-40.

10. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears in order to return to User mode from Diagnosis mode.

11. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

12. Repair the system as outlined by the ªRepair orderº in ªCON-

SULT-II Diagnostic Code Chartº, that corresponds to the self-

diagnostic result. For replacement procedure of component

parts, refer to RS-15.

13. After repairing the system, go to DIAGNOSTIC PROCEDURE

3, page RS-42 for final checking.

CONSULT-II Diagnostic Code Chart (ªSELF-DIAG

[CURRENT]º)

NBRS0045S0101

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replace-

ment.º

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User modeILow battery voltage (Less than 9V)IGo to DIAGNOSTIC PROCEDURE 3

(RS-42) after charging battery.

ISelf-diagnostic result ªSELF-DIAG

[PAST]º (previously stored in the

memory) might not be erased after

repair.

IIntermittent malfunction has been

detected in the past.IGo to DIAGNOSTIC PROCEDURE 4

(RS-44).

INo malfunction is detected.IGo to DIAGNOSTIC PROCEDURE 3

(RS-42).

AIRBAG MODULE

[OPEN]IDriver's air bag module circuit is open. (including the spiral

cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver's air bag module.

(Before disposal of it, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the diagnosis sensor unit.

6. Replace the related harness.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-40

Page 2132 of 2395

![INFINITI QX4 2001 Factory Service Manual SRS771

5. Touch ªAIR BAGº.

SRS697

6. Touch ªSELF-DIAG [CURRENT]º.

SRS701

7. If no malfunction is detected on ªSELF-DIAG [CURRENT]º,

repair of SRS is completed. Go to step 8.

If any malfunction i INFINITI QX4 2001 Factory Service Manual SRS771

5. Touch ªAIR BAGº.

SRS697

6. Touch ªSELF-DIAG [CURRENT]º.

SRS701

7. If no malfunction is detected on ªSELF-DIAG [CURRENT]º,

repair of SRS is completed. Go to step 8.

If any malfunction i](/img/42/57027/w960_57027-2131.png)

SRS771

5. Touch ªAIR BAGº.

SRS697

6. Touch ªSELF-DIAG [CURRENT]º.

SRS701

7. If no malfunction is detected on ªSELF-DIAG [CURRENT]º,

repair of SRS is completed. Go to step 8.

If any malfunction is displayed on ªSELF-DIAG [CURRENT]º,

the malfunctioning part is not repaired completely or another

malfunctioning part is detected. Go to DIAGNOSTIC PROCE-

DURE 2, page RS-39, and repair malfunctioning part com-

pletely.

SRS773

8. Touch ªERASEº.

NOTE:

Touch ªERASEº to clear the memory of the malfunction

(ªSELF-DIAG [PAST]º).

If the memory of the malfunction in ªSELF-DIAG [PAST]º is not

erased, the User mode shows the system malfunction by the

operation of the warning lamp even if the malfunction is repaired

completely.

SRS697

9. Touch ªBACKº key of CONSULT-II to ªSELECT SYSTEMº

screen. Touch ªSELF-DIAG [PAST]º.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-43

Page 2133 of 2395

![INFINITI QX4 2001 Factory Service Manual SRS702

10. Check that no malfunction is detected on ªSELF-DIAG

[PAST]º.

11. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears in order to return to User mode from Diagnosis mode.

12. INFINITI QX4 2001 Factory Service Manual SRS702

10. Check that no malfunction is detected on ªSELF-DIAG

[PAST]º.

11. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears in order to return to User mode from Diagnosis mode.

12.](/img/42/57027/w960_57027-2132.png)

SRS702

10. Check that no malfunction is detected on ªSELF-DIAG

[PAST]º.

11. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears in order to return to User mode from Diagnosis mode.

12. Turn ignition switch ªOFFº, then turn off and disconnect CON-

SULT-II.

13. Go to ªSRS Operation Checkº, page RS-38 to check SRS

operation by using ªAIR BAGº warning lamp with User mode.

DIAGNOSTIC PROCEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)

NBRS0045S03Inspecting SRS malfunctioning record

1 CONSIDER POSSIBILITY OF NOT ERASING SELF-DIAGNOSTIC RESULT AFTER REPAIRING

Is it the first time for maintenance of SRS?

YesorNo

Ye s©Go to DIAGNOSTIC PROCEDURE 5 (RS-44).

No©Self-diagnostic result ªSELF-DIAG [PAST]º (previously stored in the memory) might not

be erased after repair. Go to DIAGNOSTIC PROCEDURE 3, step 8 (RS-42).

SRS844

DIAGNOSTIC PROCEDURE 5NBRS0045S04Inspecting SRS intermittent malfunction by using CONSULT-II

Ð Diagnosis mode

1. Turn ignition switch ªOFFº.

2. Connect CONSULT-II to Data link connector.

SRS695

3. Turn ignition switch ªONº.

4. Touch ªSTARTº.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-44

Page 2134 of 2395

![INFINITI QX4 2001 Factory Service Manual SRS771

5. Touch ªAIR BAGº.

SRS697

6. Touch ªSELF-DIAG [PAST]º.

SRS700

7. If diagnostic codes are displayed on ªSELF-DIAG [PAST]º, go

to step 10.

SRS702

If no malfunction is detected on ªSELF-DI INFINITI QX4 2001 Factory Service Manual SRS771

5. Touch ªAIR BAGº.

SRS697

6. Touch ªSELF-DIAG [PAST]º.

SRS700

7. If diagnostic codes are displayed on ªSELF-DIAG [PAST]º, go

to step 10.

SRS702

If no malfunction is detected on ªSELF-DI](/img/42/57027/w960_57027-2133.png)

SRS771

5. Touch ªAIR BAGº.

SRS697

6. Touch ªSELF-DIAG [PAST]º.

SRS700

7. If diagnostic codes are displayed on ªSELF-DIAG [PAST]º, go

to step 10.

SRS702

If no malfunction is detected on ªSELF-DIAG [PAST]º, touch

ªBACKº and go back to ªSELECT DIAG MODEº.

SRS697

8. Touch ªTROUBLE DIAG RECORDº.

NOTE:

With ªTROUBLE DIAG RECORDº, diagnosis results previ-

ously erased by a reset operation can be displayed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-45

Page 2135 of 2395

SRS704

9. Diagnostic code is displayed on ªTROUBLE DIAG RECORDº.

10. Touch ªPRINTº.

11. Compare diagnostic codes to ªIntermittent Malfunction Diag-

nostic Code Chartº, page RS-46.

12. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears.

13. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

14. Repair the system as outlined by the ªRepair orderº in ªInter-

mittent Malfunction Diagnostic Code Chartº, that corresponds

to the self-diagnostic result. For replacement procedure of

component parts, refer to RS-15.

15. Go to DIAGNOSTIC PROCEDURE 3, page RS-42, for final

checking.

Intermittent Malfunction Diagnostic Code Chart (ªSELF-

DIAG [PAST]º or ªTROUBLE DIAG RECORDº)

NBRS0045S0401

Diagnostic item Explanation Repair order

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User modeILow battery voltage (Less than 9V)IGo to DIAGNOSTIC PROCEDURE

3 (RS-42) after charging battery.

INo malfunction is detected.IGo to DIAGNOSTIC PROCEDURE

3 (RS-42).

AIRBAG MODULE

[OPEN]IDriver's air bag module circuit is open. (including the spiral

cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. If the harness check result is OK,

replace driver's air bag module

(Before disposal of it, it must be

deployed.), diagnosis sensor unit

and spiral cable. AIRBAG MODULE

[VB-SHORT]IDriver's air bag module circuit is shorted to some power sup-

ply circuit. (including the spiral cable)

AIRBAG MODULE

[GND-SHORT]IDriver's air bag module circuit is shorted to ground. (including

the spiral cable)

AIRBAG MODULE

[SHORT]IDriver's air bag module circuits are shorted to each other.

ASSIST A/B MODULE

[VB-SHORT]IFront passenger air bag module circuit is shorted to some

power supply circuit.1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. If the harness check result is OK,

replace front air bag module

(Before disposal of it, it must be

deployed.), and diagnosis sensor

unit. ASSIST A/B MODULE

[OPEN]IFront passenger air bag module circuit is open.

ASSIST A/B MODULE

[GND-SHORT]IFront passenger air bag module circuit is shorted to ground.

ASSIST A/B MODULE

[SHORT]IFront passenger air bag module circuits are shorted to each

other.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-46

Page 2152 of 2395

STARTING & CHARGING SYSTEM

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnosis .....................2

PREPARATION...............................................................3

Special Service Tool ....................................................3

BATTERY.........................................................................4

How to Handle Battery ................................................4

METHODS OF PREVENTING OVER-DISCHARGE......4

CHECKING ELECTROLYTE LEVEL............................4

SPECIFIC GRAVITY CHECK......................................5

CHARGING THE BATTERY........................................6

Trouble Diagnoses with Battery/Starting/Charging

System Tester ..............................................................7

DIAGNOSTIC RESULT ITEM CHART..........................9

STARTING SYSTEM.....................................................10

System Description ....................................................10

Wiring Diagram - START -......................................... 11

Trouble Diagnoses with Battery/Starting/Charging

System Tester ............................................................12

DIAGNOSTIC RESULT ITEM CHART........................13

WORK FLOW..........................................................14

DIAGNOSTIC PROCEDURE 1..................................15

DIAGNOSTIC PROCEDURE 2..................................17

MINIMUM SPECIFICATION OF CRANKING

VOLTAGE REFERENCING COOLANT

TEMPERATURE

......................................................17

Construction ...............................................................18

Removal and Installation ...........................................18

Pinion/Clutch Check ..................................................18

CHARGING SYSTEM....................................................19

System Description ....................................................19

Wiring Diagram - CHARGE -.....................................20

Trouble Diagnoses with Battery/Starting/Charging

System Tester ............................................................21

DIAGNOSTIC RESULT ITEM CHART........................23

WORK FLOW..........................................................24

DIAGNOSTIC PROCEDURE 1..................................25

DIAGNOSTIC PROCEDURE 2..................................26

DIAGNOSTIC PROCEDURE 3..................................27

MALFUNCTION INDICATOR....................................27

Construction ...............................................................28

Removal and Installation ...........................................28

SERVICE DATA AND SPECIFICATIONS (SDS).........29

Battery........................................................................29

Starter ........................................................................29

Alternator ...................................................................29

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

Page 2153 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBSC0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Wiring Diagrams and Trouble DiagnosisNBSC0002When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSISº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

SC-2

Page 2155 of 2395

How to Handle BatteryNBSC0003CAUTION:

IIf it becomes necessary to start the engine with a booster

battery and jumper cables, use a 12-volt booster battery.

IAfter connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

INever add distilled water through the hole used to check

specific gravity.

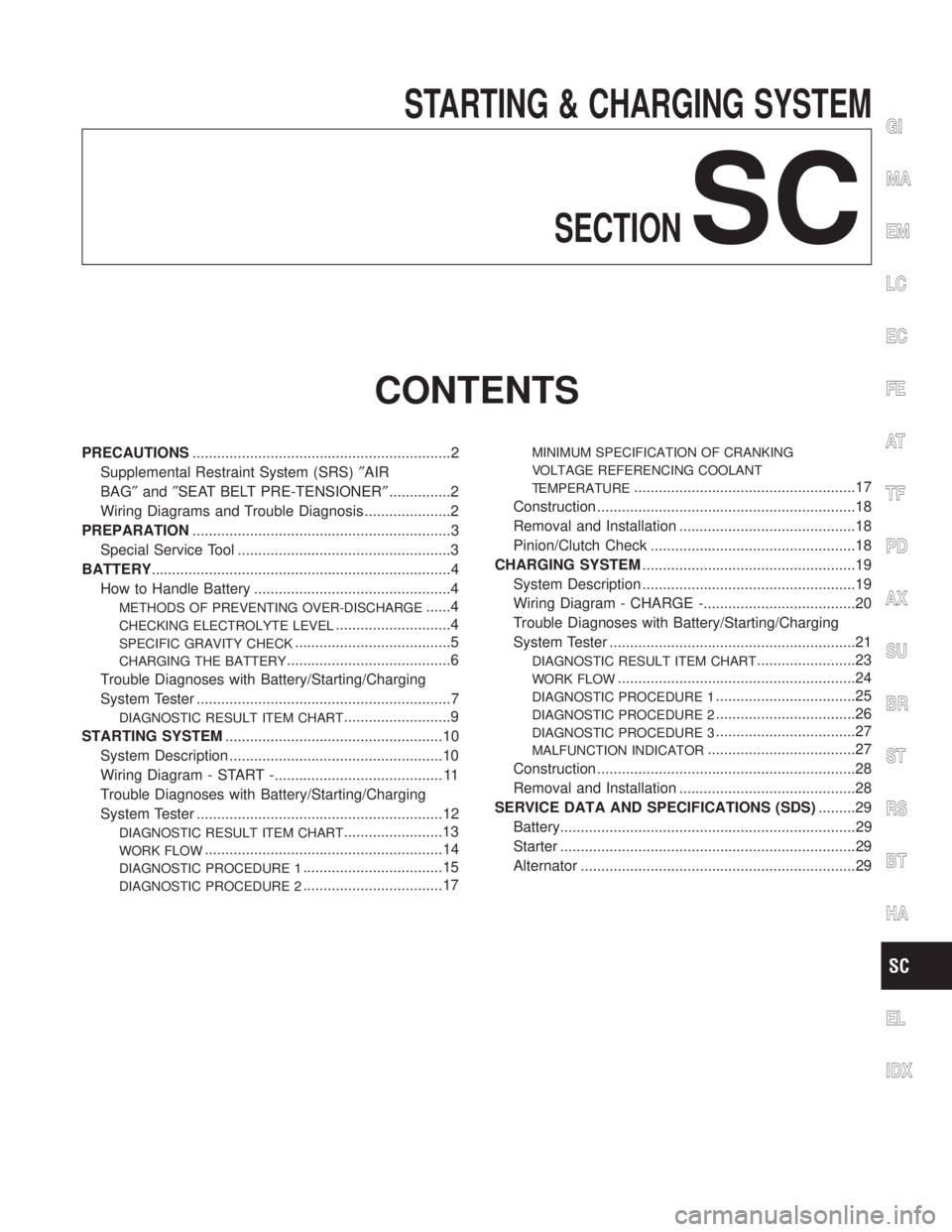

MEL040F

METHODS OF PREVENTING OVER-DISCHARGENBSC0003S01The following precautions must be taken to prevent over-discharg-

ing a battery.

IThe battery surface (particularly its top) should always be kept

clean and dry.

IThe terminal connections should be clean and tight.

IAt every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

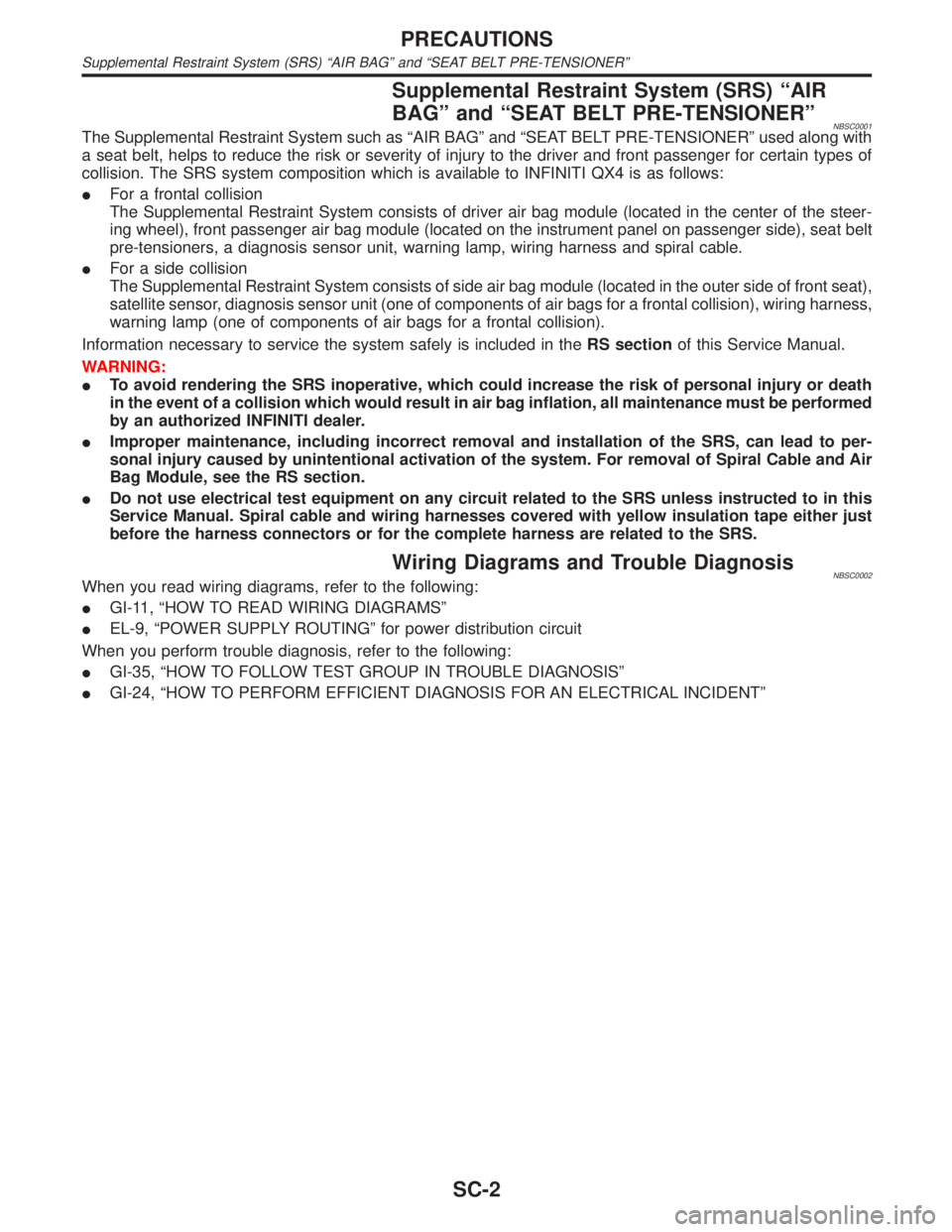

MEL041F

IWhen the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle

has an extended storage switch, turn it off.)

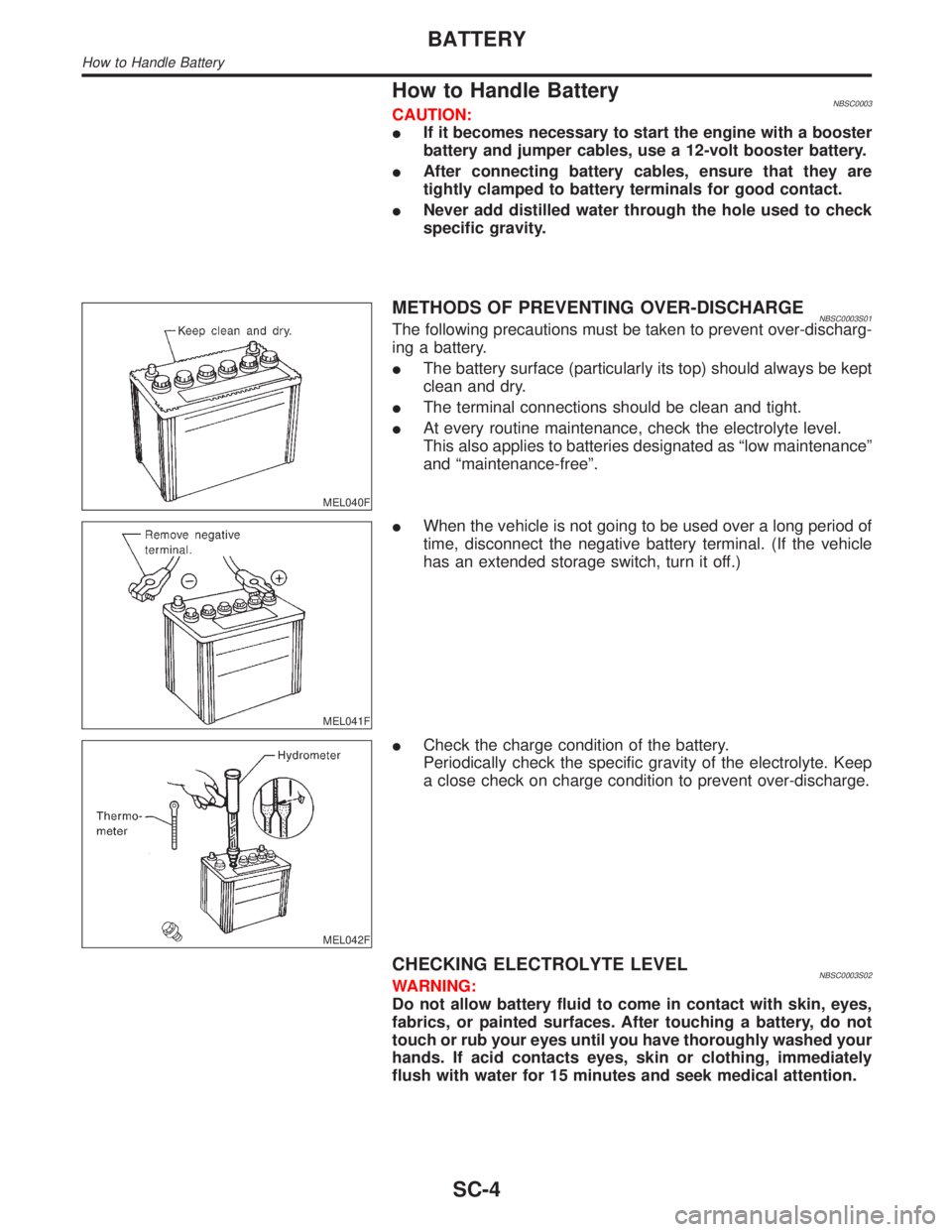

MEL042F

ICheck the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVELNBSC0003S02WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

BATTERY

How to Handle Battery

SC-4

Page 2156 of 2395

MEL043F

IRemove the cell plug using a suitable tool.

IAdd distilled water up to the MAX level.

SEL709E

SulphationNBSC0003S0201A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been ªsulphatedº, note its volt-

age and current when charging it. As shown in the figure, less

current and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

MEL042FA

SPECIFIC GRAVITY CHECKNBSC0003S031. Read hydrometer and thermometer indications at eye level.

2. Use the chart below to correct your hydrometer reading

according to electrolyte temperature.

Hydrometer Temperature CorrectionNBSC0003S0301

Battery electrolyte temperature ÉC (ÉF) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) þ0.004

16 (60) þ0.008

10 (50) þ0.012

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

BATTERY

How to Handle Battery (Cont'd)

SC-5

Page 2157 of 2395

Battery electrolyte temperature ÉC (ÉF) Add to specific gravity reading

4 (40) þ0.016

þ1 (30) þ0.020

þ7 (20) þ0.024

þ12 (10) þ0.028

þ18 (0) þ0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

CHARGING THE BATTERYNBSC0003S04CAUTION:

IDo not ªquick chargeº a fully discharged battery.

IKeep the battery away from open flame while it is being

charged.

IWhen connecting the charger, connect the leads first, then

turn on the charger. Do not turn on the charger first, as

this may cause a spark.

IIf battery electrolyte temperature rises above 60ÉC (140ÉF),

stop charging. Always charge battery at a temperature

below 60ÉC (140ÉF).

Charging RatesNBSC0003S0401

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically

decrease as the battery charges. This indicates that the voltage of

the battery is increasing normally as the state of charge improves.

The charging amps indicated above refer to initial charge rate.

IIf, after charging, the specific gravity of any two cells varies

more than .050, the battery should be replaced.

BATTERY

How to Handle Battery (Cont'd)

SC-6