oil INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 294 of 2395

SAT999A

13. Remove converter housing from transmission case.

IBe careful not to scratch converter housing.

SAT995A

14. Remove O-ring from input shaft.

SAT027B

15. Remove oil pump assembly.

a. Attach Tool to oil pump assembly and extract it evenly from

transmission case.

SAT028B

b. Remove O-ring from oil pump assembly.

c. Remove traces of sealant from oil pump housing.

IBe careful not to scratch pump housing.

SAT108B

d. Remove needle bearing and thrust washer from oil pump

assembly.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-289

Page 295 of 2395

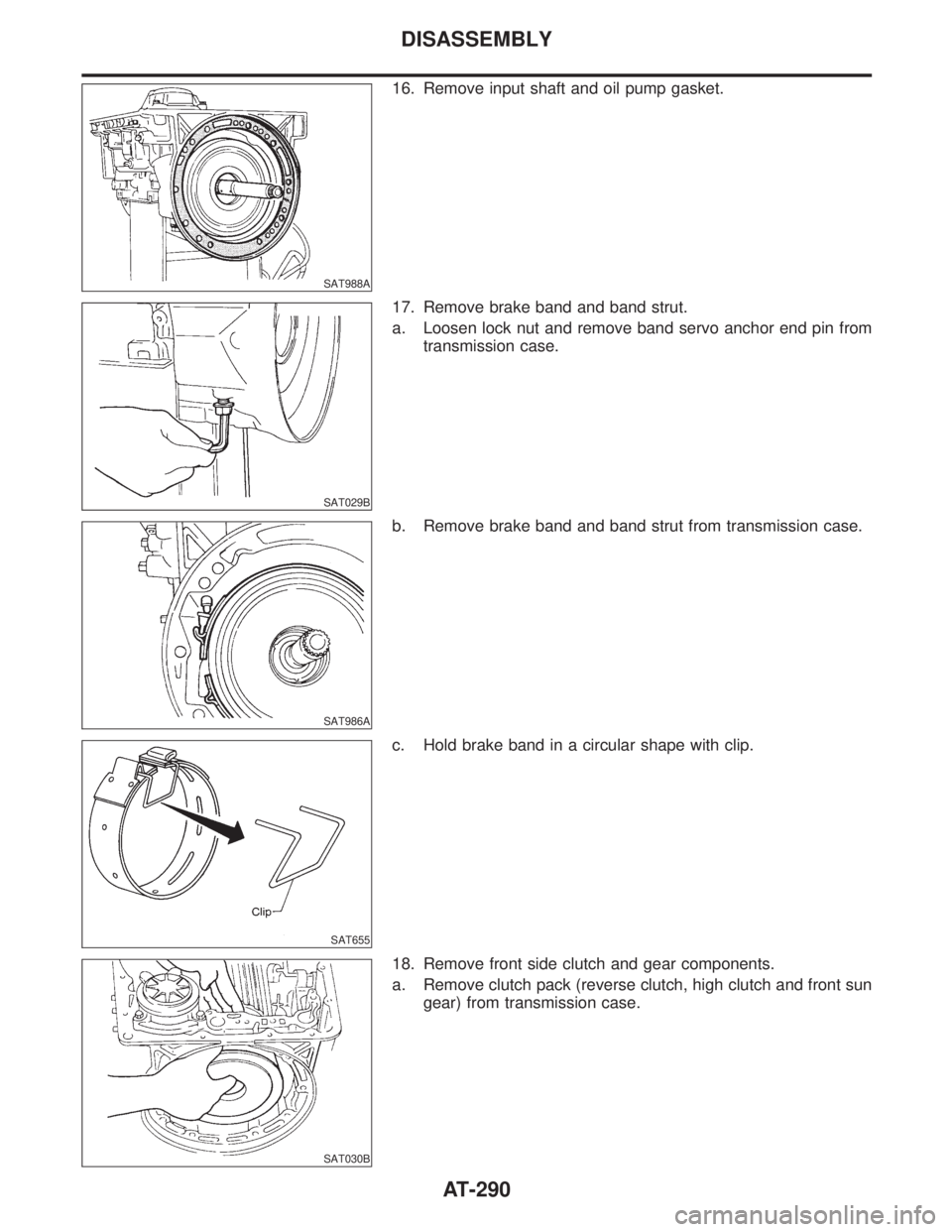

SAT988A

16. Remove input shaft and oil pump gasket.

SAT029B

17. Remove brake band and band strut.

a. Loosen lock nut and remove band servo anchor end pin from

transmission case.

SAT986A

b. Remove brake band and band strut from transmission case.

SAT655

c. Hold brake band in a circular shape with clip.

SAT030B

18. Remove front side clutch and gear components.

a. Remove clutch pack (reverse clutch, high clutch and front sun

gear) from transmission case.

DISASSEMBLY

AT-290

Page 297 of 2395

SAT755I

20. Remove adapter case (4WD model only).

a. Remove adapter case from transmission case.

b. Remove adapter case gasket from transmission case.

SAT756I

c. Remove oil seal from adapter case.

IBe careful not to scratch adapter case.

IDo not remove oil seal unless it is to be replaced.

SAT556J

21. Remove revolution sensor from rear extension or adapter

case.

a. Remove O-ring from revolution sensor.

SAT960A

22. Remove output shaft and parking gear (4WD model only).

a. Remove rear snap ring from output shaft.

SAT957A

b. Slowly push output shaft all the way forward.

IDo not use excessive force.

c. Remove snap ring from output shaft.

DISASSEMBLY

AT-292

Page 300 of 2395

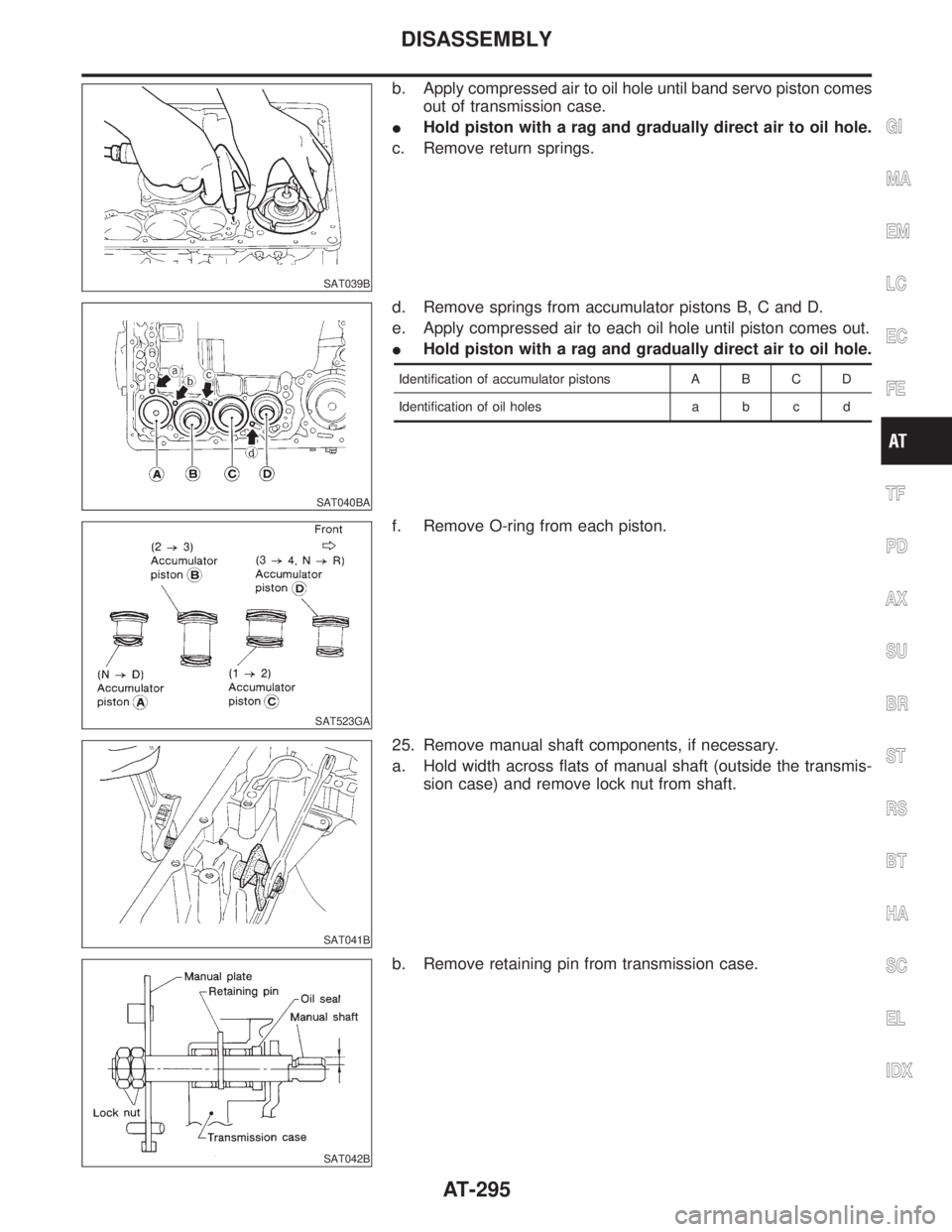

SAT039B

b. Apply compressed air to oil hole until band servo piston comes

out of transmission case.

IHold piston with a rag and gradually direct air to oil hole.

c. Remove return springs.

SAT040BA

d. Remove springs from accumulator pistons B, C and D.

e. Apply compressed air to each oil hole until piston comes out.

IHold piston with a rag and gradually direct air to oil hole.

Identification of accumulator pistons A B C D

Identification of oil holes a b c d

SAT523GA

f. Remove O-ring from each piston.

SAT041B

25. Remove manual shaft components, if necessary.

a. Hold width across flats of manual shaft (outside the transmis-

sion case) and remove lock nut from shaft.

SAT042B

b. Remove retaining pin from transmission case.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-295

Page 301 of 2395

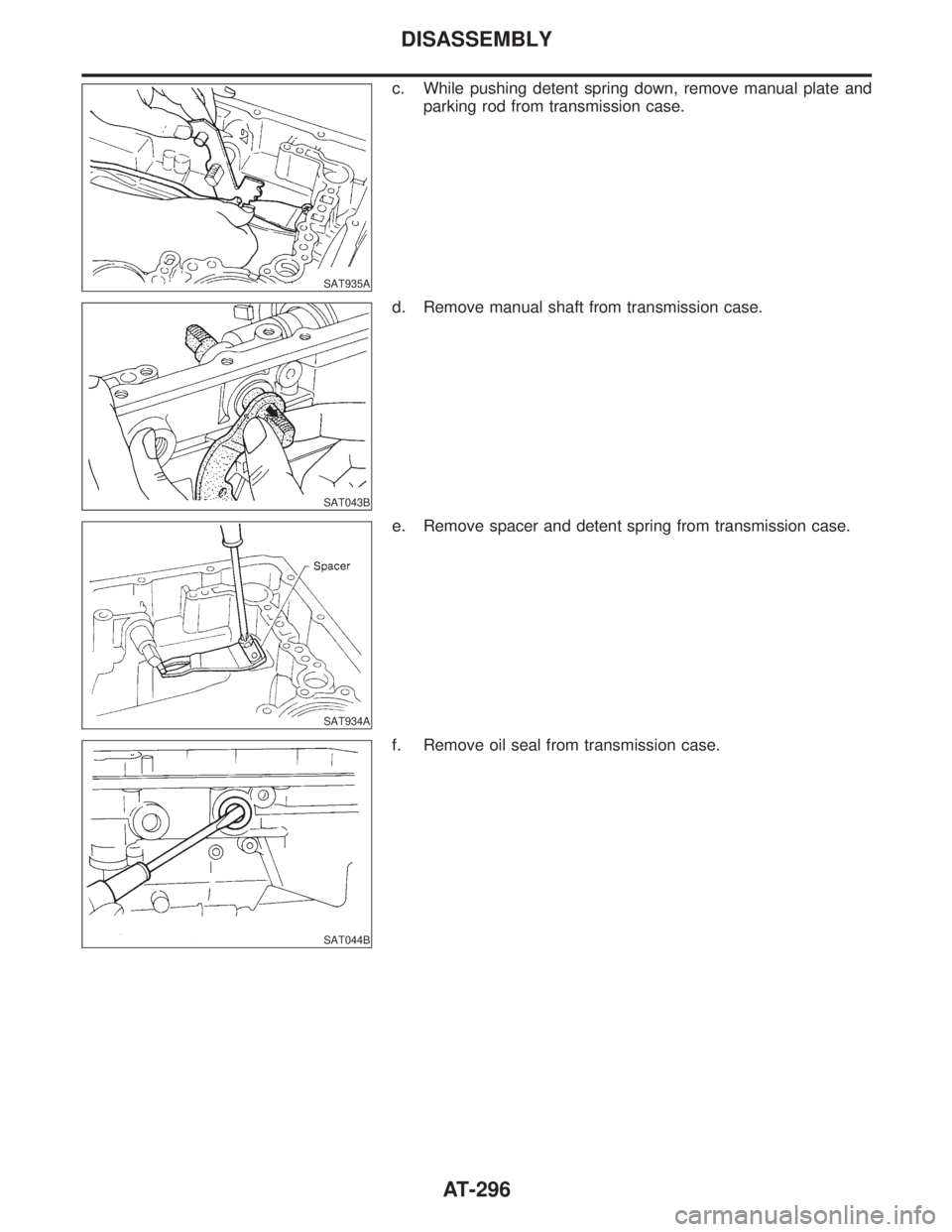

SAT935A

c. While pushing detent spring down, remove manual plate and

parking rod from transmission case.

SAT043B

d. Remove manual shaft from transmission case.

SAT934A

e. Remove spacer and detent spring from transmission case.

SAT044B

f. Remove oil seal from transmission case.

DISASSEMBLY

AT-296

Page 302 of 2395

Oil Pump

COMPONENTSNBAT0112

SAT648AB

SAT649A

DISASSEMBLYNBAT01131. Loosen bolts in numerical order and remove oil pump cover.

SAT650A

2. Remove rotor, vane rings and vanes.

IInscribe a mark on back of rotor for identification of fore-

aft direction when reassembling rotor. Then remove rotor.

SAT651A

3. While pushing on cam ring remove pivot pin.

IBe careful not to scratch oil pump housing.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Oil Pump

AT-297

Page 303 of 2395

SAT652A

4. While holding cam ring and spring lift out cam ring spring.

IBe careful not to damage oil pump housing.

IHold cam ring spring to prevent it from jumping.

SAT653A

5. Remove cam ring and cam ring spring from oil pump housing.

SAT654A

6. Remove pivot pin from control piston and remove control pis-

ton assembly.

SAT655A

7. Remove oil seal from oil pump housing.

IBe careful not to scratch oil pump housing.

SAT656A

INSPECTIONNBAT0114Oil Pump Cover, Rotor, Vanes, Control Piston, Side

Seals, Cam Ring and Friction Ring

NBAT0114S01ICheck for wear or damage.

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-298

Page 304 of 2395

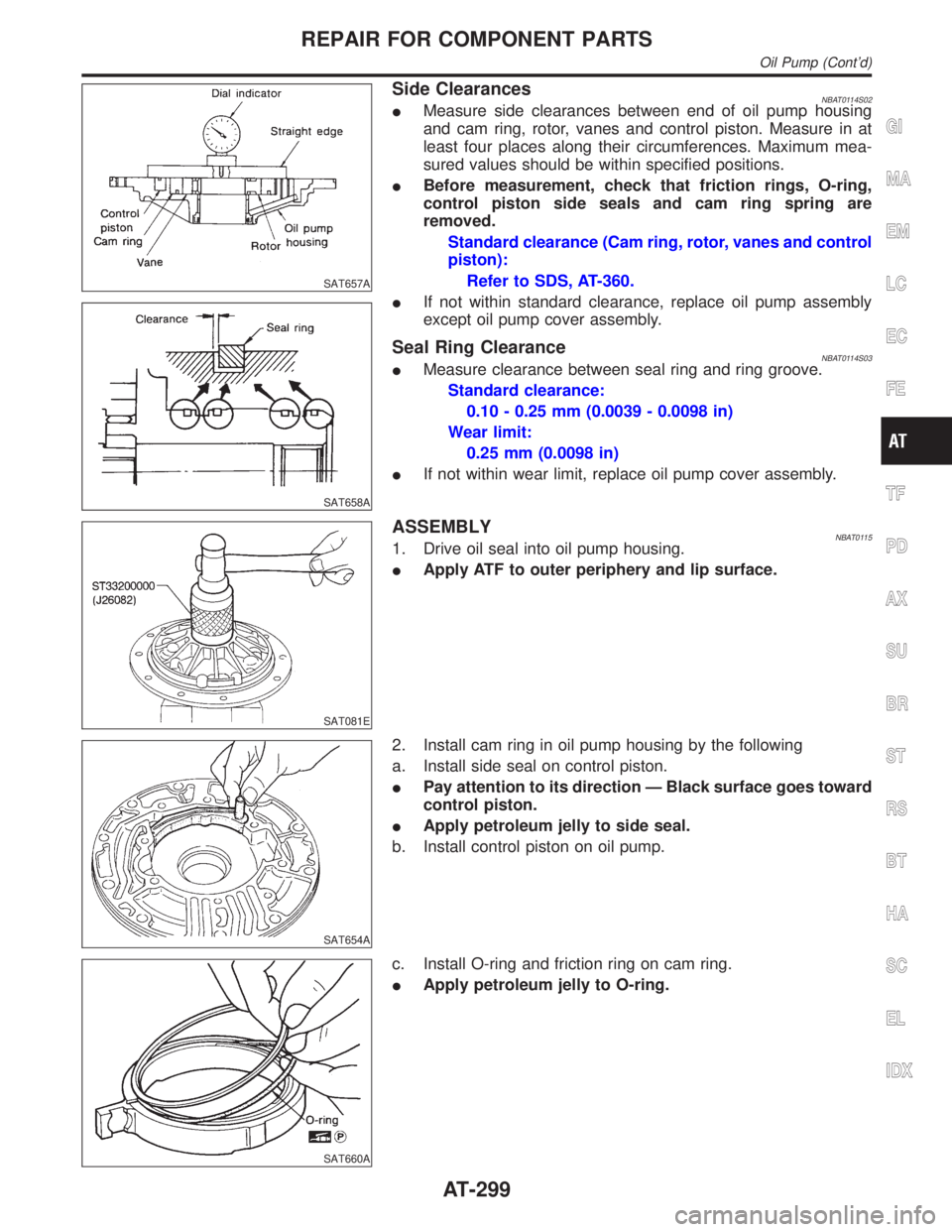

SAT657A

SAT658A

Side ClearancesNBAT0114S02IMeasure side clearances between end of oil pump housing

and cam ring, rotor, vanes and control piston. Measure in at

least four places along their circumferences. Maximum mea-

sured values should be within specified positions.

IBefore measurement, check that friction rings, O-ring,

control piston side seals and cam ring spring are

removed.

Standard clearance (Cam ring, rotor, vanes and control

piston):

Refer to SDS, AT-360.

IIf not within standard clearance, replace oil pump assembly

except oil pump cover assembly.

Seal Ring ClearanceNBAT0114S03IMeasure clearance between seal ring and ring groove.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Wear limit:

0.25 mm (0.0098 in)

IIf not within wear limit, replace oil pump cover assembly.

SAT081E

ASSEMBLYNBAT01151. Drive oil seal into oil pump housing.

IApply ATF to outer periphery and lip surface.

SAT654A

2. Install cam ring in oil pump housing by the following

a. Install side seal on control piston.

IPay attention to its direction Ð Black surface goes toward

control piston.

IApply petroleum jelly to side seal.

b. Install control piston on oil pump.

SAT660A

c. Install O-ring and friction ring on cam ring.

IApply petroleum jelly to O-ring.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-299

Page 305 of 2395

SAT661A

d. Assemble cam ring, cam ring spring and spring seat. Install

spring by pushing it against pump housing.

SAT651A

e. While pushing on cam ring install pivot pin.

SAT662A

3. Install rotor, vanes and vane rings.

IPay attention to direction of rotor.

SAT649A

4. Install oil pump housing and oil pump cover.

a. Wrap masking tape around splines of oil pump cover assem-

bly to protect seal. Position oil pump cover assembly in oil

pump housing assembly, then remove masking tape.

b. Tighten bolts in a criss-cross pattern.

SAT663A

5. Install new seal rings carefully after packing ring grooves with

petroleum jelly. Press rings down into jelly to a close fit.

ISeal rings come in two different diameters. Check fit care-

fully in each groove.

Small dia. seal ring:

No mark

Large dia. seal ring:

Yellow mark in area shown by arrow

IDo not spread gap of seal ring excessively while install-

ing. It may deform ring.

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-300

Page 308 of 2395

SAT671A

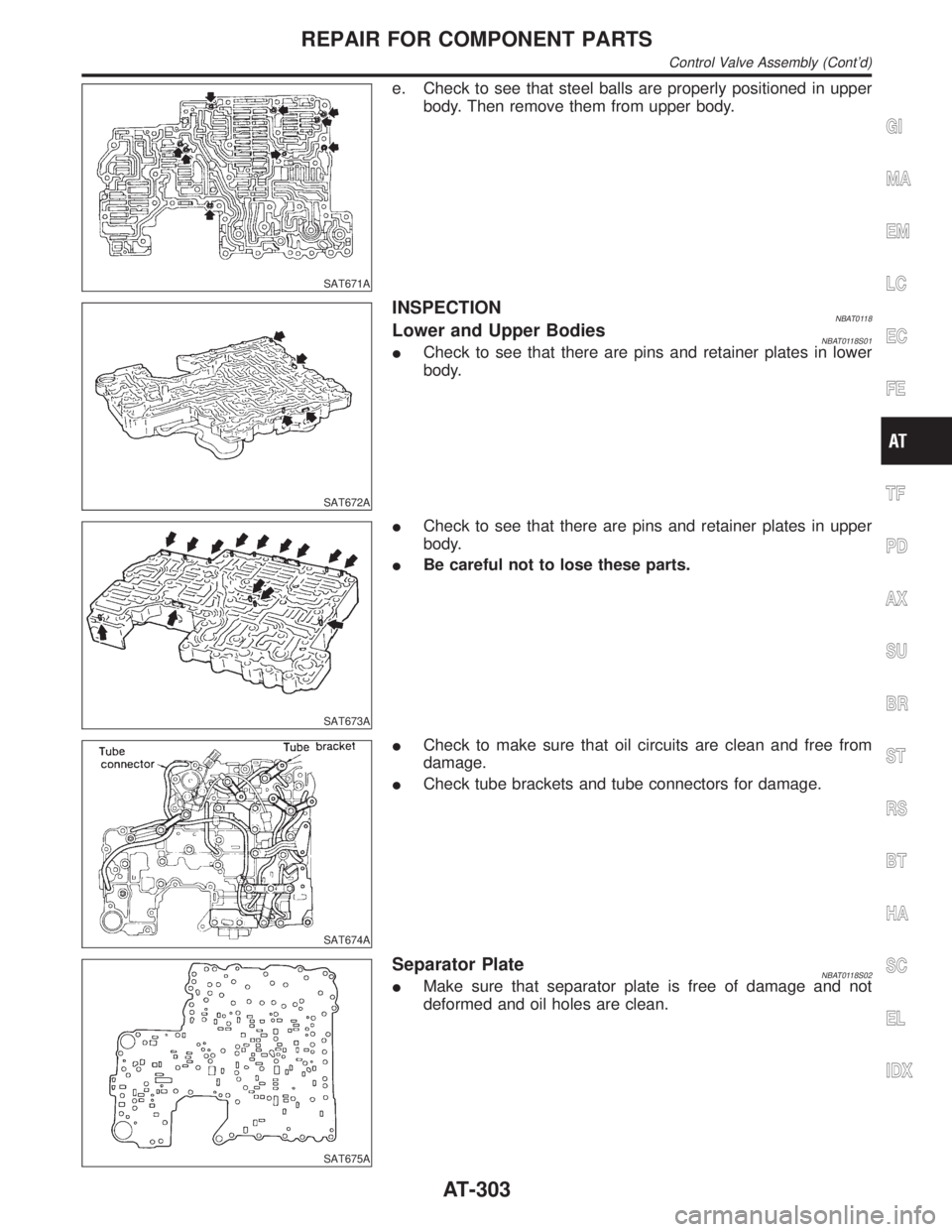

e. Check to see that steel balls are properly positioned in upper

body. Then remove them from upper body.

SAT672A

INSPECTIONNBAT0118Lower and Upper BodiesNBAT0118S01ICheck to see that there are pins and retainer plates in lower

body.

SAT673A

ICheck to see that there are pins and retainer plates in upper

body.

IBe careful not to lose these parts.

SAT674A

ICheck to make sure that oil circuits are clean and free from

damage.

ICheck tube brackets and tube connectors for damage.

SAT675A

Separator PlateNBAT0118S02IMake sure that separator plate is free of damage and not

deformed and oil holes are clean.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-303