02 sensor INFINITI QX4 2001 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 181 of 2395

SAT142K

DescriptionNBAT0066IThrottle position sensor

The throttle position sensor detects the throttle valve position

and sends a signal to the TCM.

IThrottle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch. The wide open position switch sends

a signal to the TCM when the throttle valve is open at least 1/2

of the full throttle position. The closed throttle position switch

sends a signal to the TCM when the throttle valve is fully

closed.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0066S02Remarks: Specification data are reference values.

Monitor item Condition Specification

Throttle position sensorFully-closed throttle Approximately 0.5V

Fully-open throttle Approximately 4V

TCM TERMINALS AND REFERENCE VALUENBAT0066S03Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

16 OR/WClosed throttle

position switch

(in throttle

position switch)

When releasing accelerator pedal after warm-

ing up engine.

[Refer to ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-46.]Battery volt-

age

When depressing accelerator pedal after

warming up engine.

[Refer to ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-46.]0V

17 OR/BWide open

throttle position

switch

(in throttle

position switch)When depressing accelerator pedal more than

half-way after warming up engine.Battery volt-

age

When releasing accelerator pedal after warm-

ing up engine.0V

32 P/BThrottle position

sensor

(Power source)Ignition switch ªONº. 4.5 - 5.5V

Ignition switch ªOFFº. 0V

41 PThrottle position

sensorWhen depressing accelerator pedal slowly

after warming up engine.

(Voltage rises gradually in response to throttle

position.)Fully-closed

throttle:

0.5 - 0.7V

Fully-open

throttle:

4V

42 BThrottle position

sensor

(Ground)ÐÐ

DTC P1705 THROTTLE POSITION SENSOR

Description

AT-176

Page 182 of 2395

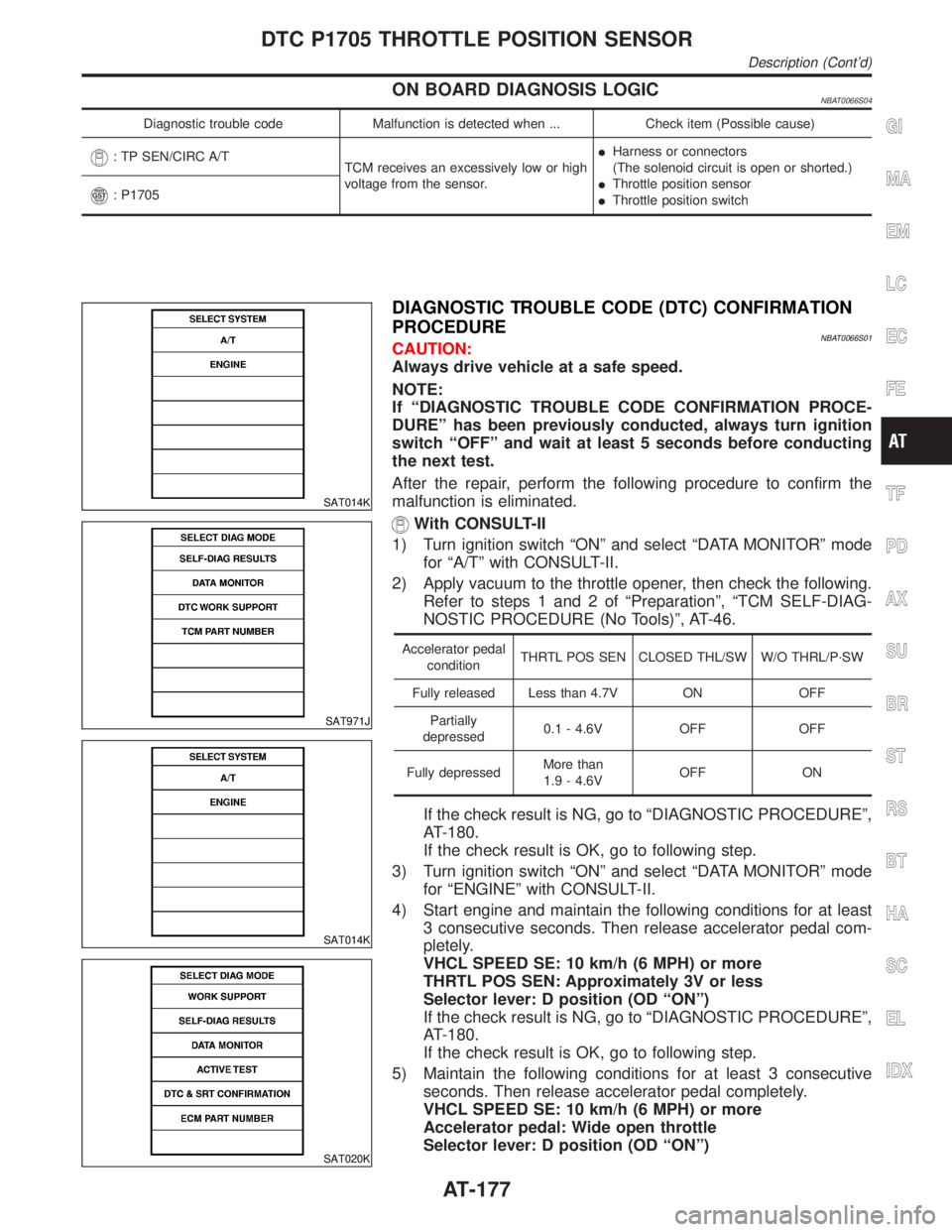

ON BOARD DIAGNOSIS LOGICNBAT0066S04

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: TP SEN/CIRC A/T

TCM receives an excessively low or high

voltage from the sensor.IHarness or connectors

(The solenoid circuit is open or shorted.)

IThrottle position sensor

IThrottle position switch

: P1705

SAT014K

SAT971J

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0066S01CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªA/Tº with CONSULT-II.

2) Apply vacuum to the throttle opener, then check the following.

Refer to steps 1 and 2 of ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-46.

Accelerator pedal

conditionTHRTL POS SEN CLOSED THL/SW W/O THRL/P´SW

Fully released Less than 4.7V ON OFF

Partially

depressed0.1 - 4.6V OFF OFF

Fully depressedMore than

1.9 - 4.6VOFF ON

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-180.

If the check result is OK, go to following step.

3) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

4) Start engine and maintain the following conditions for at least

3 consecutive seconds. Then release accelerator pedal com-

pletely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: Approximately 3V or less

Selector lever: D position (OD ªONº)

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-180.

If the check result is OK, go to following step.

5) Maintain the following conditions for at least 3 consecutive

seconds. Then release accelerator pedal completely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

Accelerator pedal: Wide open throttle

Selector lever: D position (OD ªONº)

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1705 THROTTLE POSITION SENSOR

Description (Cont'd)

AT-177

Page 183 of 2395

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P1705 THROTTLE POSITION SENSOR

Description (Cont'd)

AT-178

Page 184 of 2395

Wiring Diagram Ð AT Ð TPSNBAT0199

MAT915A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1705 THROTTLE POSITION SENSOR

Wiring Diagram Ð AT Ð TPS

AT-179

Page 185 of 2395

Diagnostic ProcedureNBAT0067

1 CHECK DTC WITH ECM

ICheck P code CONSULT-II ªENGINEº.

Turn ignition switch ªONº and select ªSELF-DIAG RESULTSº mode for ªENGINEº with CONSULT-II.

Refer to EC-74, ªDESCRIPTIONº.

OK or NG

OK©GO TO 2.

NG©Check throttle position sensor circuit for engine control. Refer to EC-174, ªDescriptionº.

DTC P1705 THROTTLE POSITION SENSOR

Diagnostic Procedure

AT-180

Page 186 of 2395

2 CHECK INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªTHRTL POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5 - 0.7V

Fully-open throttle:

Approximately 4V

SAT614J

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 41 and 42 while accelerator pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5 - 0.7V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in response to throttle position.)

SAT513J

OK or NG

OK (With CONSULT-II)©GO TO 3.

OK (Without CONSULT-

II)©GO TO 4.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1705 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

AT-181

Page 187 of 2395

3 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 and 2 of ªPreparationº, ªTCM SELF-

DIAGNOSTIC PROCEDURE (No Tools)º, AT-46.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT646J

OK or NG

OK©GO TO 6.

NG©GO TO 4.

4 DETECT MALFUNCTIONING ITEM

Check the following items:

IThrottle position switch

Refer to ªComponent Inspectionº, AT-184.

IHarness for short or open between ignition switch and throttle position switch (Main harness)

IHarness for short or open between throttle position switch and TCM (Main harness)

OK or NG

OK©GO TO 6.

NG©Repair or replace damaged parts.

DTC P1705 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

AT-182

Page 188 of 2395

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(after warming up engine)

[Refer to ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, AT-46.]

MTBL0519

SAT526J

OK or NG

OK©GO TO 6.

NG©GO TO 4.

6 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-177.

OK or NG

OK©INSPECTION END

NG©GO TO 7.

7 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1705 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

AT-183

Page 189 of 2395

SAT132K

Component InspectionNBAT0205THROTTLE POSITION SWITCHNBAT0205S01Closed Throttle Position Switch (Idle position)NBAT0205S0101ICheck continuity between terminals 5 and 6.

[Refer to ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCE-

DURE (No Tools)º, AT-46.]

Accelerator pedal condition Continuity

Released Yes

Depressed No

ITo adjust closed throttle position switch, refer to EC-154, ªSystem

Descriptionº.

SAT137K

Wide Open Throttle Position SwitchNBAT0205S0102ICheck continuity between terminals 4 and 5.

Accelerator pedal condition Continuity

Released No

Depressed Yes

DTC P1705 THROTTLE POSITION SENSOR

Component Inspection

AT-184

Page 190 of 2395

SAT341H

DescriptionNBAT0068The overrun clutch solenoid valve is activated by the TCM in

response to signals sent from the inhibitor switch, overdrive con-

trol switch, vehicle speed and throttle position sensors. The over-

run clutch operation will then be controlled.

TCM TERMINALS AND REFERENCE VALUENBAT0068S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

20 L/BOverrun clutch

solenoid valve

When overrun clutch solenoid valve operates.Battery volt-

age

When overrun clutch solenoid valve does not

operate.0V

ON BOARD DIAGNOSIS LOGICNBAT0068S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: O/R CLTCH SOL/CIRCTCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

IOverrun clutch solenoid valve

: P1760

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0068S01CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve accuracy of

test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Accelerate vehicle to a speed of more than 10 km/h (6MPH)

in ªDº position (OD ªONº).

4) Release accelerator pedal completely in ªDº position (OD

ªOFFº).

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE

Description

AT-185