02 sensor INFINITI QX4 2001 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 242 of 2395

4 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-174, ªDescriptionº.

SAT142K

OK or NG

OK©GO TO 5.

NG©Repair or replace throttle position sensor.

5 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 6.

NG©GO TO 8.

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-273.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

9. A/T Does Not Shift: D1®D2Or Does Not Kickdown: D4®D2(Cont'd)

AT-237

Page 244 of 2395

10. A/T Does Not Shift: D2®D3=NBAT0082SYMPTOM:

A/T does not shift from D

2to D3at the specified speed.

1 CHECK SYMPTOM

Are ª7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Positionº and ª8. Vehicle Cannot Be Started From D1º OK?

YesorNo

Ye s©GO TO 2.

No©Go to ª7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Positionº and ª8. Vehicle

Cannot Be Started From D

1º, AT-230, 233.

2 CHECK PNP SWITCH CIRCUIT

With CONSULT-II

Does ªTCM INPUT SIGNALSº in Data Monitor show damage to PNP switch circuit?

Without CONSULT-II

Does self-diagnosis show damage to PNP switch circuit?

SAT367J

YesorNo

Ye s©Check PNP switch circuit. Refer to ªDTC P0705º, AT-99.

No©GO TO 3.

3 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-174, ªDescriptionº.

SAT142K

OK or NG

OK©GO TO 4.

NG©Repair or replace throttle position sensor.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

10. A/T Does Not Shift: D2®D3

AT-239

Page 247 of 2395

11. A/T Does Not Shift: D3®D4=NBAT0083SYMPTOM:

IA/T does not shift from D

3to D4at the specified speed.

IA/T must be warm before D

3to D4shift will occur.

1 CHECK SYMPTOM

Are ª7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Positionº and ª8. Vehicle Cannot Be Started From D1º OK?

YesorNo

Ye s©GO TO 2.

No©Go to ª7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Positionº and ª8. Vehicle

Cannot Be Started From D

1º, AT-230, 233.

2 CHECK SELF-DIAGNOSTIC RESULTS

With CONSULT-II

Does self-diagnosis, after cruise test, show damage to any of the following circuits?

IInhibitor switch

IOverdrive control switch

IA/T fluid temperature sensor

IRevolution sensor

IShift solenoid valve A or B

IVehicle speed sensor

SAT580I

YesorNo

Ye s©Check damaged circuit. Refer to ªDTC P0705, P0710, P0720, P0750, P0755 or VHCL

SPEED SEN´MTRº, AT-99, 105, 111, 168, 172 or 197.

No©GO TO 3.

TROUBLE DIAGNOSES FOR SYMPTOMS

11. A/T Does Not Shift: D3®D4

AT-242

Page 248 of 2395

3 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-174, ªDescriptionº.

SAT142K

OK or NG

OK©GO TO 4.

NG©Repair or replace throttle position sensor.

4 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 5.

NG©GO TO 7.

5 DETECT MALFUNCTIONING ITEM

1. Remove control valve Assembly. Refer to AT-273.

2. Check the following items:

IShift valve B

IOverrun clutch control valve

IShift solenoid valve B

IPilot valve

IPilot filter

OK or NG

OK©GO TO 6.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

11. A/T Does Not Shift: D3®D4(Cont'd)

AT-243

Page 250 of 2395

12. A/T Does Not Perform Lock-up=NBAT0084SYMPTOM:

A/T does not perform lock-up at the specified speed.

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to torque converter clutch solenoid valve circuit after cruise test?

SAT581I

YesorNo

Ye s©Check torque converter clutch solenoid valve circuit. Refer to ªDTC P0740º, AT-148.

No©GO TO 2.

2 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-174, ªDescriptionº.

SAT142K

OK or NG

OK©GO TO 3.

NG©Repair or replace throttle position sensor.

3 DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-273.

2. Check following items:

ITorque converter clutch control valve

ITorque converter relief valve

ITorque converter clutch solenoid valve

IPilot valve

IPilot filter

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

12. A/T Does Not Perform Lock-up

AT-245

Page 255 of 2395

15. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)=NBAT0087SYMPTOM:

IEngine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

IVehicle does not decelerate by engine brake when turning

overdrive control switch OFF.

IVehicle does not decelerate by engine brake when shifting

A/T from ªDº to ª2º position.

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to overrun clutch solenoid valve circuit after cruise test?

SAT583I

YesorNo

Ye s©Check overrun clutch solenoid valve circuit. Refer to ªDTC P1760º, AT-185.

No©GO TO 2.

2 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-174, ªDescriptionº.

SAT142K

OK or NG

OK©GO TO 3.

NG©Repair or replace throttle position sensor.

TROUBLE DIAGNOSES FOR SYMPTOMS

15. Engine Speed Does Not Return To Idle (Light Braking D4®D3)

AT-250

Page 257 of 2395

16. Vehicle Does Not Start From D1NBAT0088SYMPTOM:

Vehicle does not start from D

1on Cruise test Ð Part 2.

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to vehicle speed sensor´A/T (revolution sensor), shift solenoid valve A, B or vehicle

speed sensor´MTR after cruise test?

SAT686I

YesorNo

Ye s©Check damaged circuit. Refer to ªDTC P0720, P0750, P0755 or VHCL SPEED

SEN´MTRº, AT-111, 176, 172 or 197.

No©GO TO 2.

2 CHECK SYMPTOM

Check again.

OK or NG

OK©Go to ª8. Vehicle Cannot Be Started From D

1º, AT-233.

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

16. Vehicle Does Not Start From D1

AT-252

Page 278 of 2395

SAT359I

Control Valve Assembly and AccumulatorsNBAT0100REMOVALNBAT0100S011. Remove exhaust front tube.

2. Remove oil pan and gasket and drain ATF.

SAT073BA

3. Remove A/T fluid temperature sensor if necessary.

4. Remove oil strainer.

SAT353B

5. Remove control valve assembly by removing fixing bolts and

disconnecting harness connector.

Bolt length and location

Bolt symbolmm (in)

A 33 (1.30)

B 45 (1.77)

6. Remove solenoids and valves from valve body if necessary.

7. Remove terminal cord assembly if necessary.

SAT074BA

8. Remove accumulatorA, B, CandDby applying compressed

air if necessary.

IHold each piston with rag.

9. Reinstall any part removed.

IAlways use new sealing parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators

AT-273

Page 279 of 2395

SAT360IA

Revolution Sensor ReplacementNBAT0210Ð 4WD MODEL ÐNBAT0210S011. Remove rear engine mounting member from side member

while supporting A/T with transfer case with jack. Tighten rear

engine mounting member to the specified torque. Refer to

EM-59, ªRear Engine Mountingº.

2. Lower A/T with transfer case as much as possible.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

IAlways use new sealing parts.

SAT661I

Ð 2WD MODEL ÐNBAT0210S02IRemove revolution sensor from A/T.

IAlways use new sealing parts.

SAT136K

Turbine Revolution Sensor ReplacementNBAT02311. Remove A/T assembly, Refer to ªRemovalº, AT-277.

2. Remove turbine revolution sensor from A/T assembly upper

side.

3. Reinstall any part removed.

IAlways use new sealing parts.

SAT035E

Rear Oil Seal ReplacementNBAT0211Ð 4WD MODEL ÐNBAT0211S011. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

2. Remove rear oil seal.

IDo not remove oil seal unless it is to be replaced.

3. Install rear oil seal.

IApply ATF before installing.

4. Reinstall any part removed.

ON-VEHICLE SERVICE

Revolution Sensor Replacement

AT-274

Page 280 of 2395

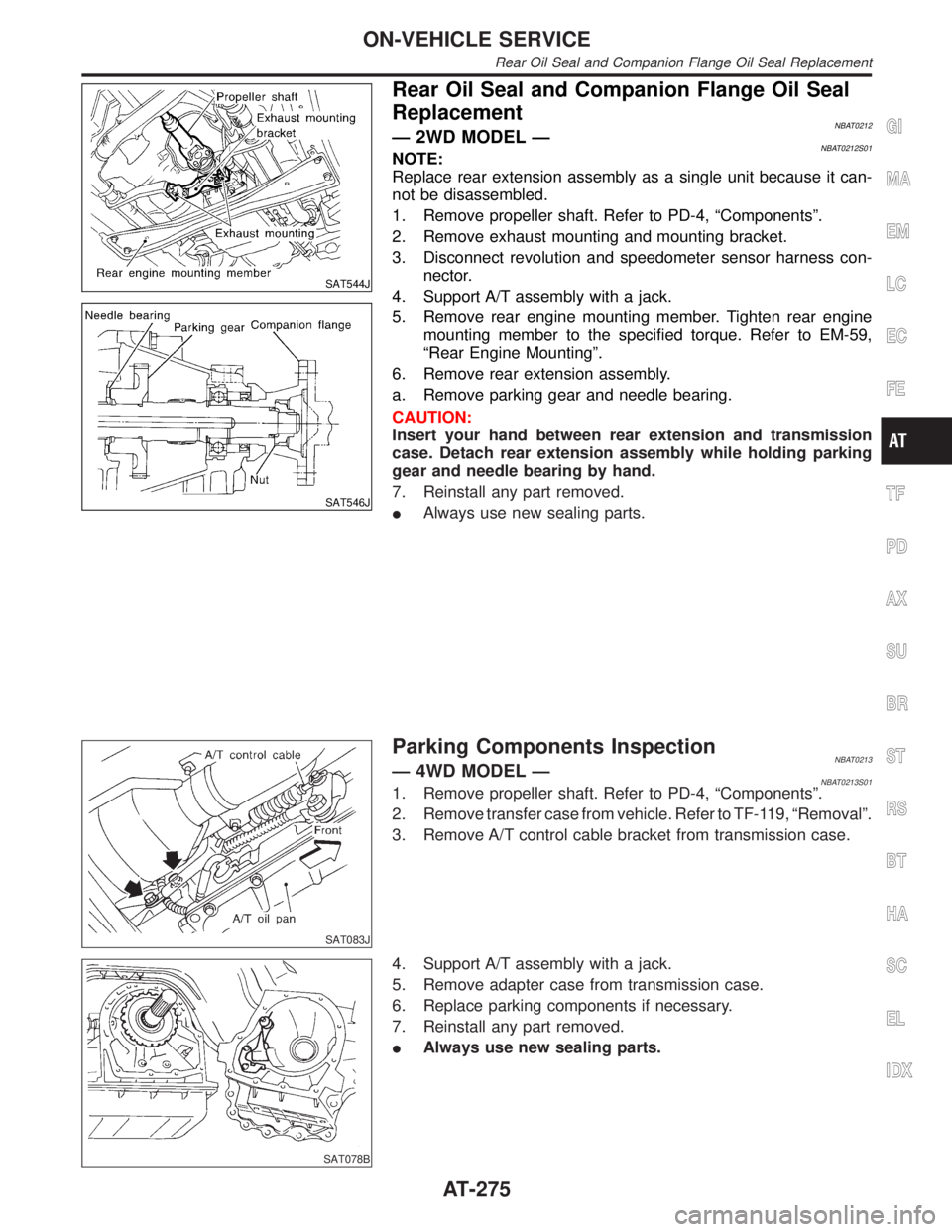

SAT544J

SAT546J

Rear Oil Seal and Companion Flange Oil Seal

Replacement

NBAT0212Ð 2WD MODEL ÐNBAT0212S01NOTE:

Replace rear extension assembly as a single unit because it can-

not be disassembled.

1. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove exhaust mounting and mounting bracket.

3. Disconnect revolution and speedometer sensor harness con-

nector.

4. Support A/T assembly with a jack.

5. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

6. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

7. Reinstall any part removed.

IAlways use new sealing parts.

SAT083J

Parking Components InspectionNBAT0213Ð 4WD MODEL ÐNBAT0213S011. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

3. Remove A/T control cable bracket from transmission case.

SAT078B

4. Support A/T assembly with a jack.

5. Remove adapter case from transmission case.

6. Replace parking components if necessary.

7. Reinstall any part removed.

IAlways use new sealing parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Rear Oil Seal and Companion Flange Oil Seal Replacement

AT-275