key INFINITI QX56 2007 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1130 of 3061

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-47

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

DescriptionINFOID:0000000003531603

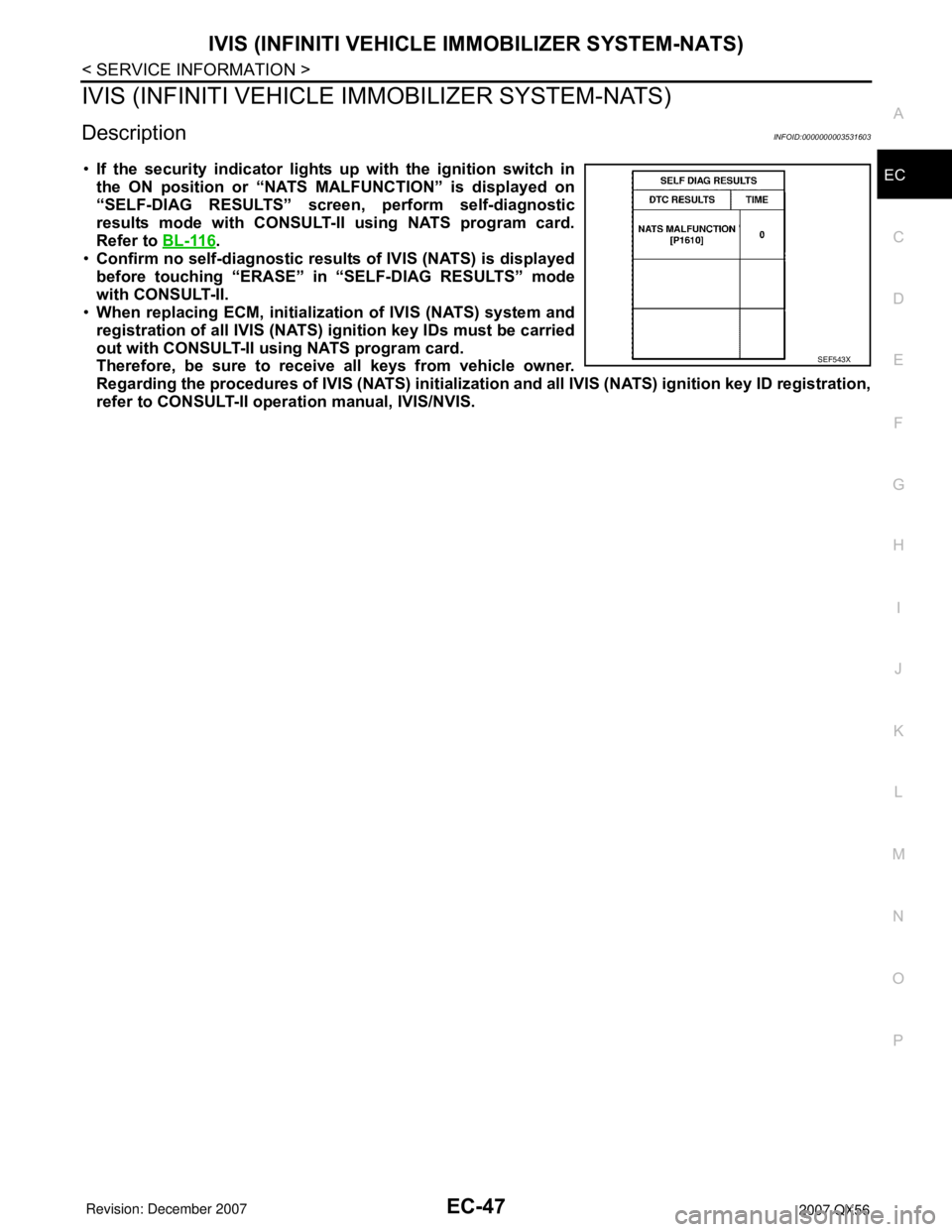

•If the security indicator lights up with the ignition switch in

the ON position or “NATS MALFUNCTION” is displayed on

“SELF-DIAG RESULTS” screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to BL-116

.

•Confirm no self-diagnostic results of IVIS (NATS) is displayed

before touching “ERASE” in “SELF-DIAG RESULTS” mode

with CONSULT-II.

•When replacing ECM, initialization of IVIS (NATS) system and

registration of all IVIS (NATS) ignition key IDs must be carried

out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of IVIS (NATS) initialization and all IVIS (NATS) ignition key ID registration,

refer to CONSULT-II operation manual, IVIS/NVIS.

SEF543X

Page 1146 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-63

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)INFOID:0000000003531607

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-26

or see EC-643.

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

SEF217U

Diagnostic Test

ModeKEY and ENG.

Sta tusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

• Misfire (Possible three way catalyst damage)

• One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Page 1156 of 3061

BASIC SERVICE PROCEDURE

EC-73

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-75, "

Idle Speed and Ignition Timing Check" .

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-75, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-342

.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-336

.

OK or NG

OK >> GO TO 9.

NG >> 1. Repair or replace.

2. GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-75, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 19.

NG >> GO TO 11.

11 .PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

>> GO TO 12.

12.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-77, "

Throttle Valve Closed Position Learning" .

>> GO TO 13. 650 ± 50 rpm (in P or N position)

650 ± 50 rpm (in P or N position)

15 ± 5° BTDC (in P or N position)

BBIA0379E

Page 1158 of 3061

BASIC SERVICE PROCEDURE

EC-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

>> GO TO 4.

19.INSPECTION END

Did you replace ECM, referring this Basic Inspection procedure?

Ye s o r N o

Ye s > > 1 . P e r f o r m EC-77, "VIN Registration" .

2.INSPECTION END

No >>INSPECTION END

Idle Speed and Ignition Timing CheckINFOID:0000000003531610

IDLE SPEED

With CONSULT-II

Check idle speed in “DATA MONITOR” mode with CONSULT-II.

With GST

Check idle speed with GST.

IGNITION TIMING

Any of following two methods may be used.

Method A

1. Attach timing light to loop wire as shown.

SEF058Y

BBIA0377E

Page 1160 of 3061

BASIC SERVICE PROCEDURE

EC-77

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Procedure After Replacing ECMINFOID:0000000003531611

When replacing ECM, the following procedure must be performed.

1. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs.

Refer to BL-117, "

ECM Re-communicating Function".

2. Perform EC-77, "

VIN Registration".

3. Perform EC-77, "

Accelerator Pedal Released Position Learning".

4. Perform EC-77, "

Throttle Valve Closed Position Learning".

5. Perform EC-78, "

Idle Air Volume Learning".

VIN RegistrationINFOID:0000000003531612

DESCRIPTION

VIN Registration is an operation to registering VIN in ECM. It must be performed each time ECM is replaced.

NOTE:

Accurate VIN which is registered in ECM may be required for Inspection & Maintenance (I/M).

OPERATION PROCEDURE

With CONSULT-II

1. Check the VIN of the vehicle and note it. Refer to GI-46.

2. Turn ignition switch ON and engine stopped.

3. Select “VIN REGISTRATION” in “WORK SUPPORT” mode.

4. Follow the instruction of CONSULT-II display.

Accelerator Pedal Released Position LearningINFOID:0000000003531613

DESCRIPTION

Accelerator Pedal Released Position Learning is an operation to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal position sensor output signal. It must be performed each time

harness connector of accelerator pedal position sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Closed Position LearningINFOID:0000000003531614

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to learn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal. It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

PBIB2242E

Page 1218 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-135

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

>> GO TO 22.

22.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> 1. Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to EC-194 .

2. GO TO 29.

NG >> GO TO 23.

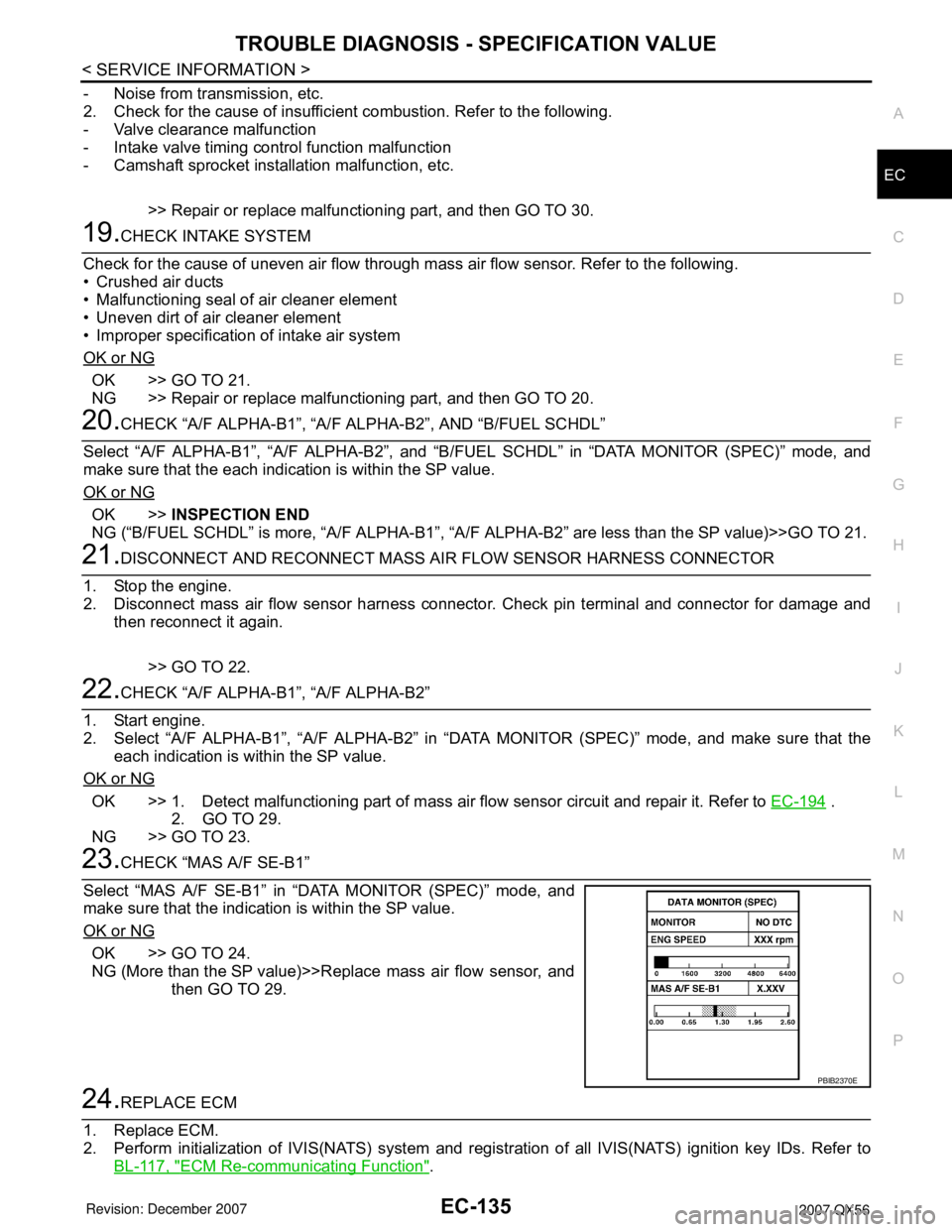

23.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >> GO TO 24.

NG (More than the SP value)>>Replace mass air flow sensor, and

then GO TO 29.

24.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

PBIB2370E

Page 1231 of 3061

EC-148

< SERVICE INFORMATION >

DTC U1010 CAN COMMUNICATION

2.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

3. Perform EC-77, "

VIN Registration" .

4. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

5. Perform EC-77, "

Throttle Valve Closed Position Learning" .

6. Perform EC-78, "

Idle Air Volume Learning" .

>>INSPECTION END

Page 1515 of 3061

EC-432

< SERVICE INFORMATION >

DTC P0506 ISC SYSTEM

NG >> Discover air leak location and repair.

2.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

4. Perform EC-77, "

VIN Registration" .

5. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

6. Perform EC-77, "

Throttle Valve Closed Position Learning" .

7. Perform EC-78, "

Idle Air Volume Learning" .

>>INSPECTION END

Page 1517 of 3061

EC-434

< SERVICE INFORMATION >

DTC P0507 ISC SYSTEM

NG >> Repair or replace.

2.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 3.

NG >> Discover air leak location and repair.

3.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

4. Perform EC-77, "

VIN Registration" .

5. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

6. Perform EC-77, "

Throttle Valve Closed Position Learning" .

7. Perform EC-78, "

Idle Air Volume Learning" .

>>INSPECTION END

Page 1526 of 3061

DTC P0603 ECM POWER SUPPLY

EC-443

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

3. Perform EC-77, "

VIN Registration".

4. Perform EC-77, "

Accelerator Pedal Released Position Learning".

5. Perform EC-77, "

Throttle Valve Closed Position Learning".

6. Perform EC-78, "

Idle Air Volume Learning".

>>INSPECTION END