service indicator INFINITI QX56 2007 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1494 of 3061

DTC P0455 EVAP CONTROL SYSTEM

EC-411

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

8.INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely.

NOTE:

Improper installation of the EVAP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-II>>GO TO 9.

Without CONSULT-II>>GO TO 10.

9.CHECK FOR EVAP LEAK

With CONSULT-II

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode

with CONSULT-II.

3. Touch “START” and apply pressure into the EVAP line until the

pressure indicator reaches the middle of the bar graph.

CAUTION:

• Do not use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure

in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the instruction manual for more details.

Refer to EC-33, "

Description".

OK or NG

OK >> GO TO 11.

NG >> Repair or replace.

10.CHECK FOR EVAP LEAK

Without CONSULT-II

BBIA0366E

SEF916U

PEF917U

SEF200U

Page 1501 of 3061

EC-418

< SERVICE INFORMATION >

DTC P0456 EVAP CONTROL SYSTEM

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-35, "

Component Inspection" .

OK or NG

OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one.

5.INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely.

NOTE:

Improper installation of the EVAP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-II>>GO TO 6.

Without CONSULT-II>>GO TO 7.

6.CHECK FOR EVAP LEAK

With CONSULT-II

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-II.

3. Touch “START” and apply pressure into the EVAP line until the

pressure indicator reaches the middle of the bar graph.

CAUTION:

• Do not use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2 , 0.6 psi) of pres-

sure in the system.

BBIA0366E

SEF916U

PEF917U

Page 1612 of 3061

DTC P1572 ASCD BRAKE SWITCH

EC-529

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

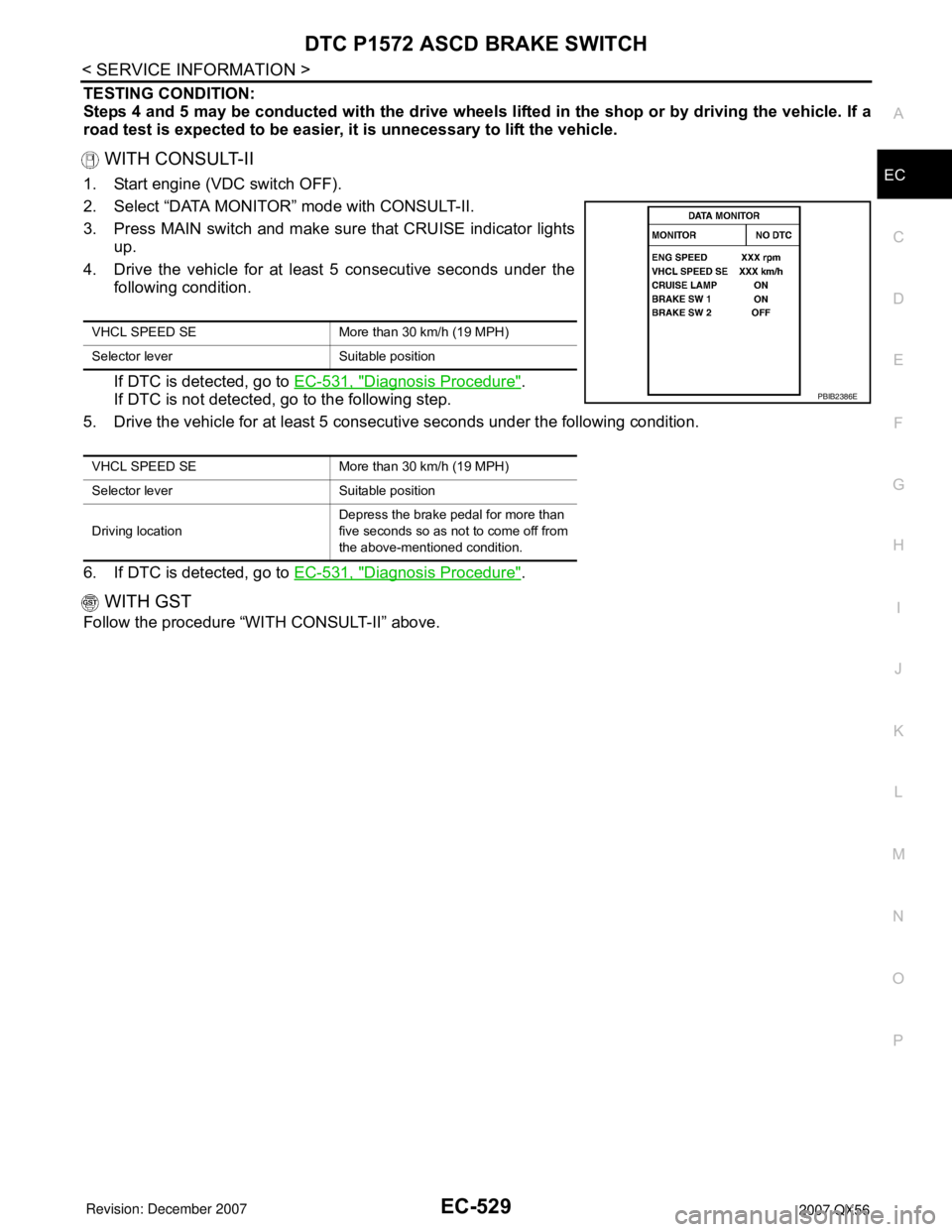

TESTING CONDITION:

Steps 4 and 5 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Start engine (VDC switch OFF).

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Press MAIN switch and make sure that CRUISE indicator lights

up.

4. Drive the vehicle for at least 5 consecutive seconds under the

following condition.

If DTC is detected, go to EC-531, "

Diagnosis Procedure".

If DTC is not detected, go to the following step.

5. Drive the vehicle for at least 5 consecutive seconds under the following condition.

6. If DTC is detected, go to EC-531, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

VHCL SPEED SE More than 30 km/h (19 MPH)

Selector lever Suitable position

VHCL SPEED SE More than 30 km/h (19 MPH)

Selector lever Suitable position

Driving locationDepress the brake pedal for more than

five seconds so as not to come off from

the above-mentioned condition.

PBIB2386E

Page 1686 of 3061

ASCD INDICATOR

EC-603

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ASCD INDICATOR

Component DescriptionINFOID:0000000003532153

ASCD indicator lamp illuminates to indicate ASCD operation status. Lamp has two indicators, CRUISE and

SET, and is integrated in combination meter.

CRUISE indicator illuminates when MAIN switch on ASCD steering switch is turned ON to indicate that ASCD

system is ready for operation.

SET indicator illuminates when following conditions are met.

• CRUISE indicator is illuminated.

• SET/COAST switch on ASCD steering switch is turned ON while vehicle speed is within the range of ASCD

setting.

SET indicator remains lit during ASCD control.

Refer to EC-30

for the ASCD function.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532154

Specification data are reference value.

MONITOR ITEM CONDITION SPECIFICATION

CRUISE LAMP • Ignition switch: ON• MAIN switch: Pressed at the 1st

time → at the 2nd timeON → OFF

SET LAMP• MAIN switch: ON

• When vehicle speed is be-

tween 40 km/h (25 MPH) and

144 km/h (89 MPH)• ASCD: Operating ON

• ASCD: Not operating OFF

Page 1687 of 3061

EC-604

< SERVICE INFORMATION >

ASCD INDICATOR

Wiring Diagram

INFOID:0000000003532155

Diagnosis ProcedureINFOID:0000000003532156

1.CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

BBWA2109E

Page 1688 of 3061

ASCD INDICATOR

EC-605

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC U1000 or U1001 is not displayed.

OK or NG

OK >> GO TO 3.

NG >> Perform trouble diagnosis for DTC U1000, U1001. Refer to EC-145

.

3.CHECK COMBINATION METER FUNCTION

Refer to DI-5

.

OK or NG

OK >> GO TO 4.

NG >> Go to DI-5

.

4.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

ASCD INDICATOR CONDITION SPECIFICATION

CRUISE LAMP • Ignition switch: ON• MAIN switch: Pressed at the 1st

time → at the 2nd timeON → OFF

SET LAMP• MAIN switch: ON

• When vehicle speed is between

40 km/h (25 MPH) and 144 km/h

(89 MPH)•ASCD: Operating ON

• ASCD: Not operating OFF

Page 1783 of 3061

DRIVE BELTSEM-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

DRIVE BELTS

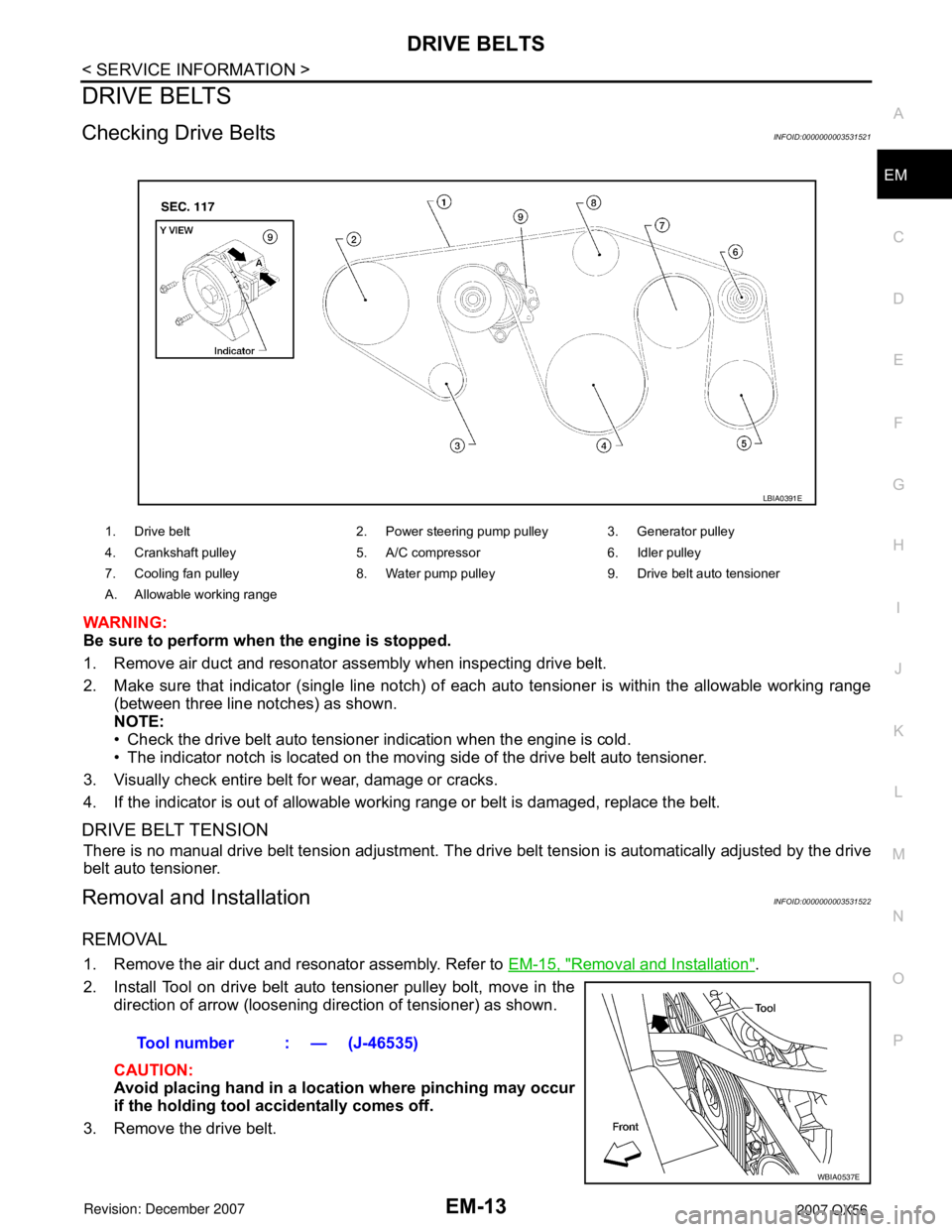

Checking Drive BeltsINFOID:0000000003531521

WARNING:

Be sure to perform when the engine is stopped.

1. Remove air duct and resonator assembly when inspecting drive belt.

2. Make sure that indicator (single line notch) of eac

h auto tensioner is within the allowable working range

(between three line notches) as shown.

NOTE:

• Check the drive belt auto tensioner indication when the engine is cold.

• The indicator notch is located on the moving side of the drive belt auto tensioner.

3. Visually check entire belt for wear, damage or cracks.

4. If the indicator is out of allowable work ing range or belt is damaged, replace the belt.

DRIVE BELT TENSION

There is no manual drive belt tension adjustment. The driv e belt tension is automatically adjusted by the drive

belt auto tensioner.

Removal and InstallationINFOID:0000000003531522

REMOVAL

1. Remove the air duct and resonator assembly. Refer to EM-15, "Removal and Installation".

2. Install Tool on drive belt auto tensioner pulley bolt, move in the direction of arrow (loosening direction of tensioner) as shown.

CAUTION:

Avoid placing hand in a locat ion where pinching may occur

if the holding tool accidentally comes off.

3. Remove the drive belt.

1. Drive belt 2. Power steering pump pulley 3. Generator pulley

4. Crankshaft pulley 5. A/C compressor 6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley 9. Drive belt auto tensioner

A. Allowable working range

LBIA0391E

Tool number : — (J-46535)

WBIA0537E

Page 1784 of 3061

EM-14

< SERVICE INFORMATION >

DRIVE BELTS

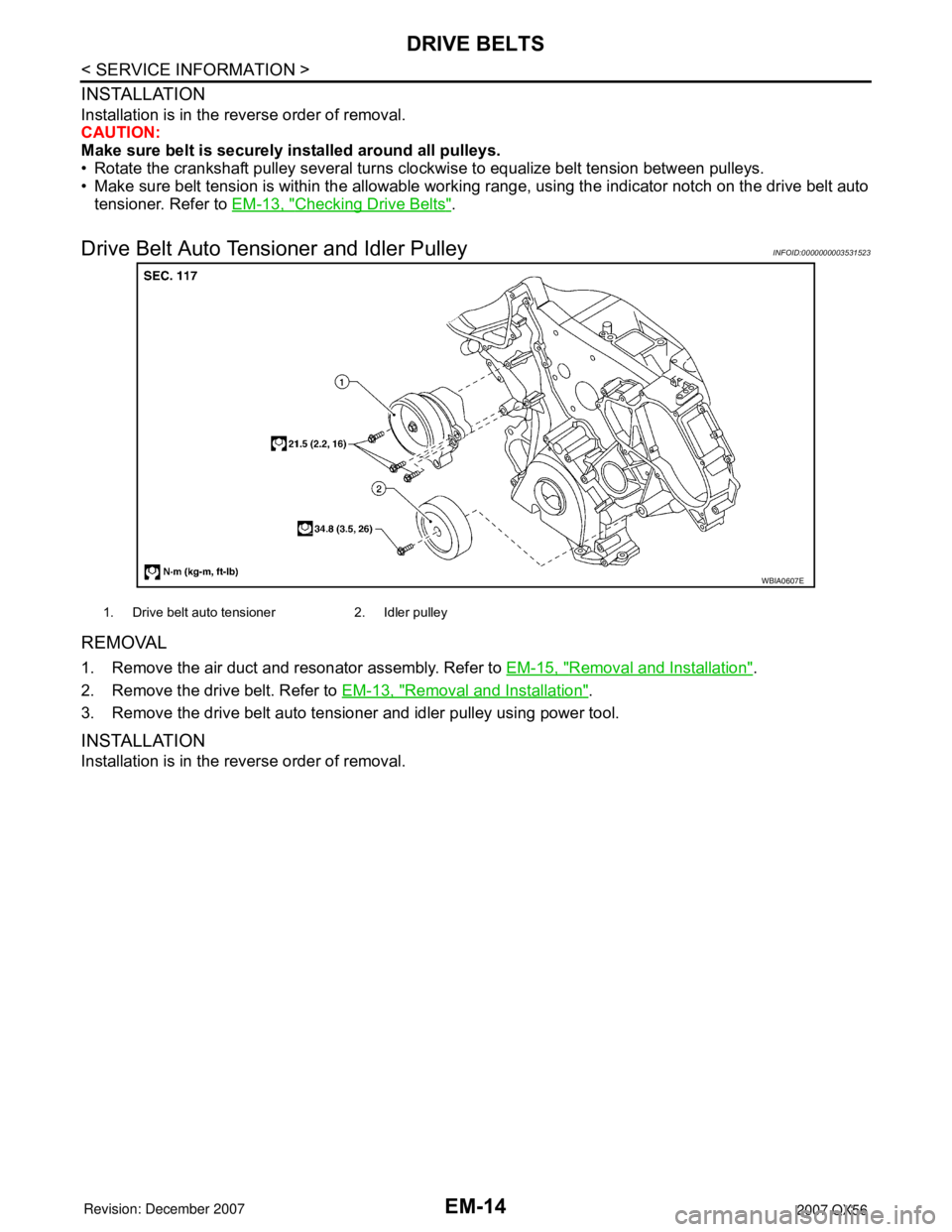

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Make sure belt is securely installed around all pulleys.

• Rotate the crankshaft pulley several turns clockwise to equalize belt tension between pulleys.

• Make sure belt tension is within the allowable working range, using the indicator notch on the drive belt auto

tensioner. Refer to EM-13, "

Checking Drive Belts".

Drive Belt Auto Tensioner and Idler PulleyINFOID:0000000003531523

REMOVAL

1. Remove the air duct and resonator assembly. Refer to EM-15, "Removal and Installation".

2. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

3. Remove the drive belt auto tensioner and idler pulley using power tool.

INSTALLATION

Installation is in the reverse order of removal.

WBIA0607E

1. Drive belt auto tensioner 2. Idler pulley

Page 1809 of 3061

TIMING CHAINEM-39

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

4. Obtain compression TDC of No. 1 cylinder as follows:

a. Turn the crankshaft pulley clockwise to align the TDC identifica-

tion notch (without paint mark) with the timing indicator on the

front cover.

b. At this time, make sure both intake and exhaust cam lobes of No. 1 cylinder (top front on LH bank) point outside.

• If they do not point outside, turn crankshaft pulley once more.

5. Remove the crankshaft pulley.

a. Loosen the crankshaft pulley bolts using a hammer handle to secure the crankshaft.

b. Remove the crankshaft pulley from the crankshaft using tool. • Remove the crankshaft pulley using suitable tool. Set the boltsin the two bolt holes [M6 x 1.0 mm (0.04 in)] on the front sur-

face.

NOTE:

The dimension between the centers of the two bolt holes is 61

mm (2.40 in).

6. Remove the front cover.

a. Loosen and remove the bolts in the reverse of order shown.

b. Cut the liquid gasket and remove the covers using Tool. CAUTION:

Do not damage mating surfaces.

7. Remove the front oil seal using suitable tool. CAUTION:

Do not damage front cover.

KBIA2476E

KBIA0400J

PBIC0053E

KBIA2477E

Tool number : KV10111100 (J-37228)

KBIA2478E

Page 1816 of 3061

EM-46

< SERVICE INFORMATION >

CAMSHAFT

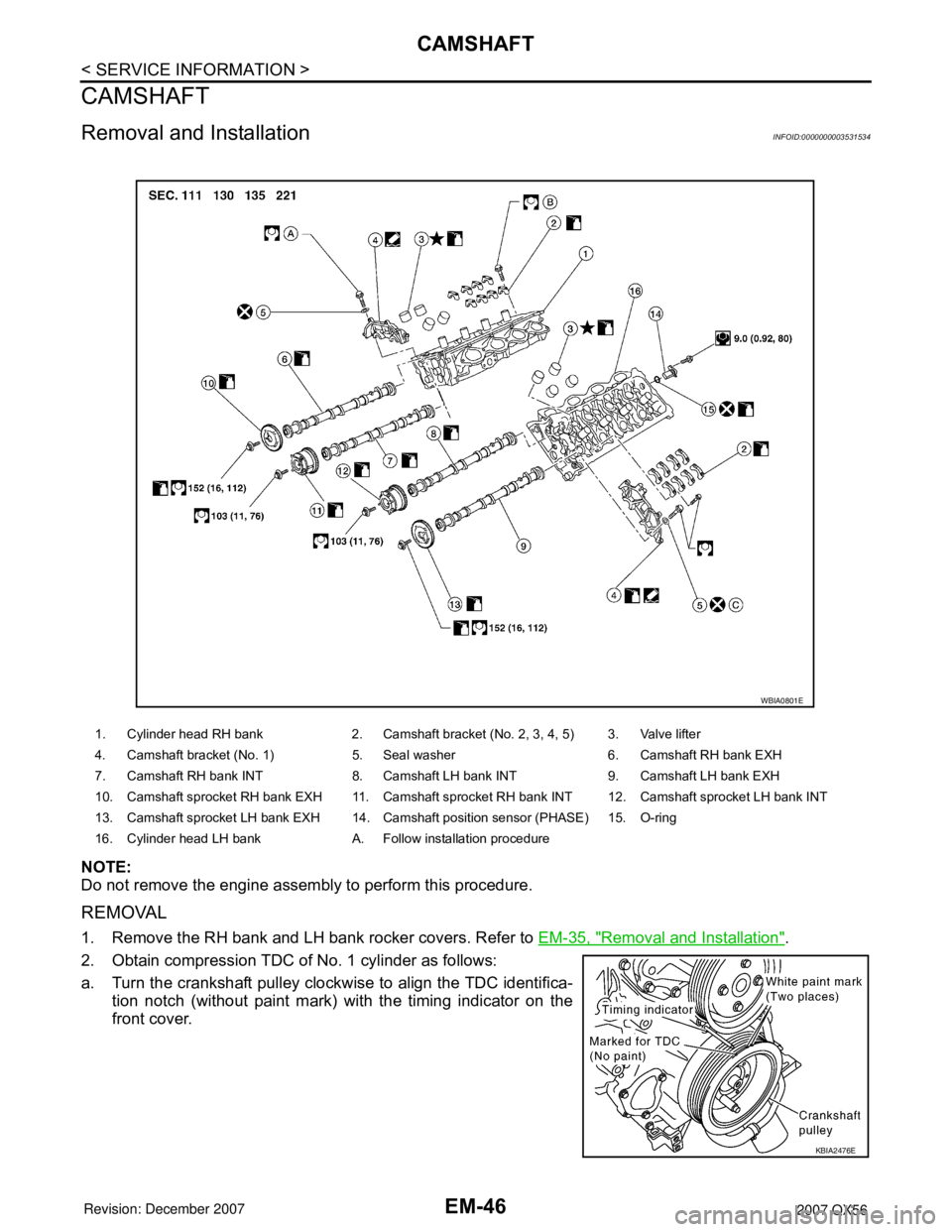

CAMSHAFT

Removal and InstallationINFOID:0000000003531534

NOTE:

Do not remove the engine assembly to perform this procedure.

REMOVAL

1. Remove the RH bank and LH bank rocker covers. Refer to EM-35, "Removal and Installation".

2. Obtain compression TDC of No. 1 cylinder as follows:

a. Turn the crankshaft pulley clockwise to align the TDC identifica- tion notch (without paint mark) with the timing indicator on the

front cover.

1. Cylinder head RH bank 2. Camshaft bracket (No. 2, 3, 4, 5) 3. Valve lifter

4. Camshaft bracket (No. 1) 5. Seal washer 6. Camshaft RH bank EXH

7. Camshaft RH bank INT 8. Camshaft LH bank INT 9. Camshaft LH bank EXH

10. Camshaft sprocket RH bank EXH 11. Camshaft sprocket RH bank INT 12. Camshaft sprocket LH bank INT

13. Camshaft sprocket LH bank EXH 14. Camshaft position sensor (PHASE) 15. O-ring

16. Cylinder head LH bank A. Follow installation procedure

WBIA0801E

KBIA2476E