torque INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 295 of 3061

TRANSMISSION ASSEMBLY

AT-225

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

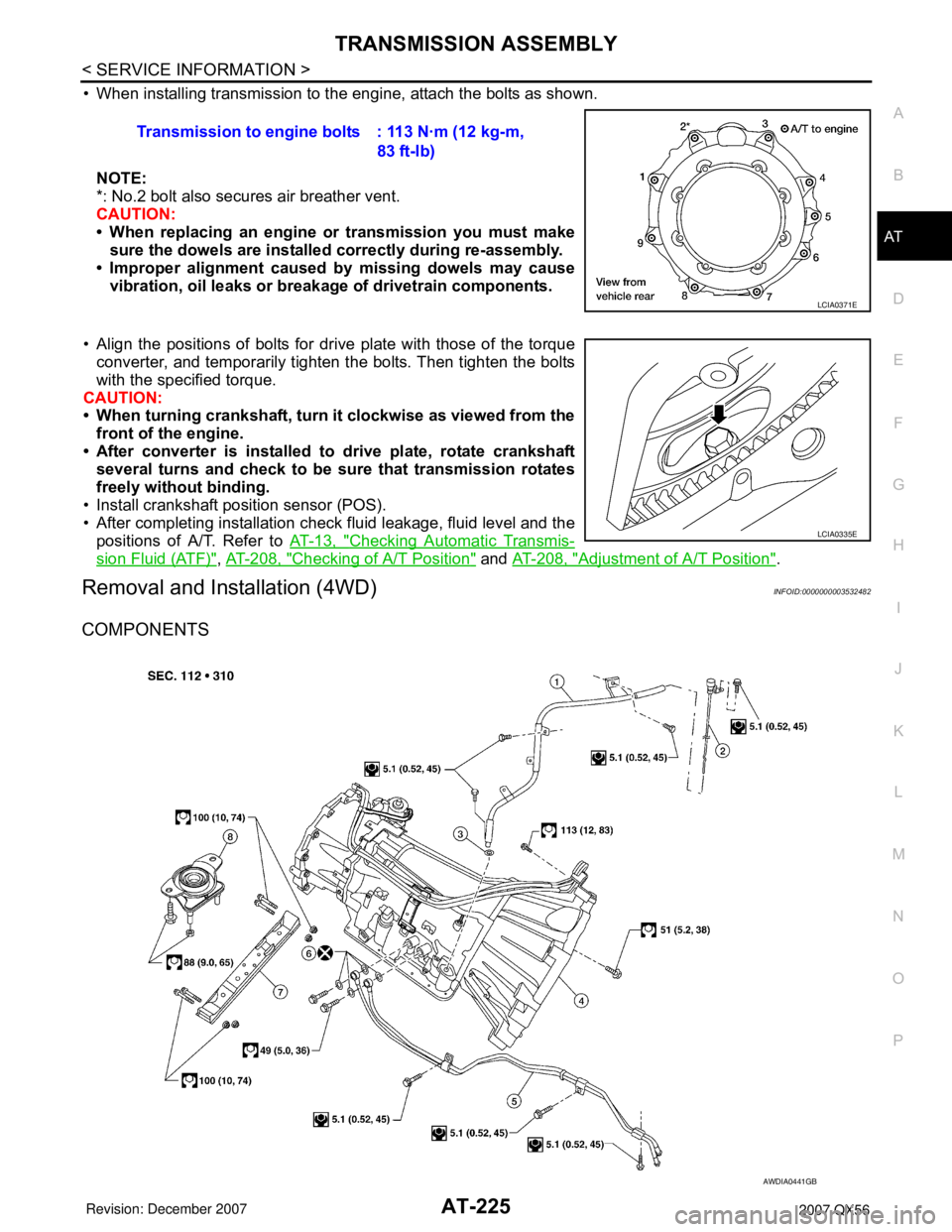

• When installing transmission to the engine, attach the bolts as shown.

NOTE:

*: No.2 bolt also secures air breather vent.

CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

• Align the positions of bolts for drive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft position sensor (POS).

• After completing installation check fluid leakage, fluid level and the

positions of A/T. Refer to AT-13, "

Checking Automatic Transmis-

sion Fluid (ATF)", AT-208, "Checking of A/T Position" and AT-208, "Adjustment of A/T Position".

Removal and Installation (4WD)INFOID:0000000003532482

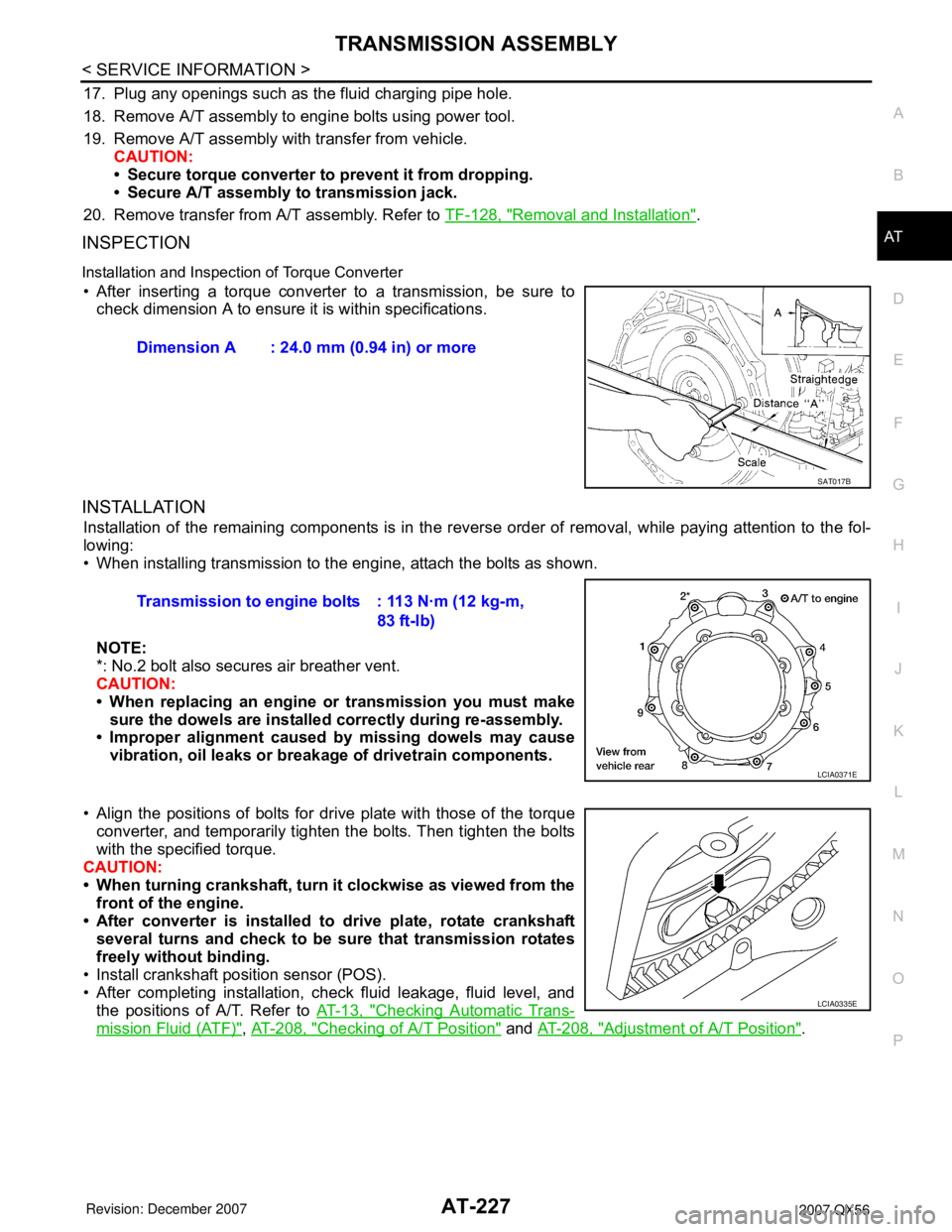

COMPONENTS

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

AWDIA0441GB

Page 296 of 3061

AT-226

< SERVICE INFORMATION >

TRANSMISSION ASSEMBLY

REMOVAL

CAUTION:

When removing the A/T assembly from engine, first remove the crankshaft position sensor (POS) from

the A/T assembly.

Be careful not to damage sensor edge.

1. Disconnect the negative battery terminal.

2. Remove engine cover using power tool.

3. Remove A/T fluid indicator.

4. Remove undercovers using power tool.

5. Remove exhaust front tube and center muffler using power tool. Refer to EX-3, "

Removal and Installa-

tion".

6. Remove propeller shafts. Refer to PR-4, "

Removal and Installation" and PR-8, "Removal and Installation".

7. Remove A/T control cable. Refer to AT-207, "

Control Device Removal and Installation".

8. Remove crankshaft position sensor (POS) from A/T assembly.

CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Do not disassemble.

• Do not allow metal filings or foreign material to get on the

sensor's front edge magnetic area.

• Do not place in an area affected by magnetism.

9. Disconnect A/T fluid cooler tube from A/T assembly.

10. Remove dust cover from converter housing.

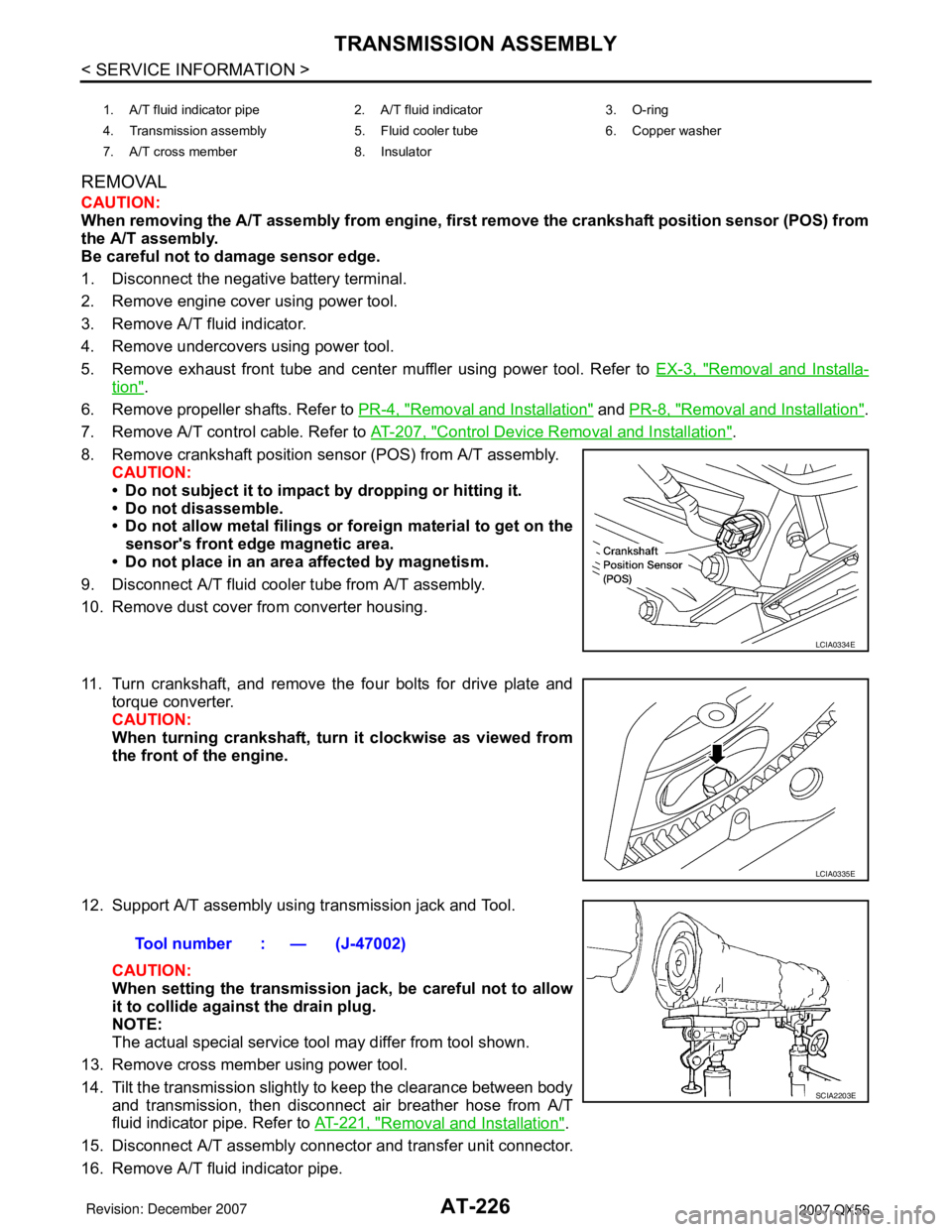

11. Turn crankshaft, and remove the four bolts for drive plate and

torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly using transmission jack and Tool.

CAUTION:

When setting the transmission jack, be careful not to allow

it to collide against the drain plug.

NOTE:

The actual special service tool may differ from tool shown.

13. Remove cross member using power tool.

14. Tilt the transmission slightly to keep the clearance between body

and transmission, then disconnect air breather hose from A/T

fluid indicator pipe. Refer to AT-221, "

Removal and Installation".

15. Disconnect A/T assembly connector and transfer unit connector.

16. Remove A/T fluid indicator pipe.

1. A/T fluid indicator pipe 2. A/T fluid indicator 3. O-ring

4. Transmission assembly 5. Fluid cooler tube 6. Copper washer

7. A/T cross member 8. Insulator

LCIA0334E

LCIA0335E

Tool number : — (J-47002)

SCIA2203E

Page 297 of 3061

TRANSMISSION ASSEMBLY

AT-227

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

17. Plug any openings such as the fluid charging pipe hole.

18. Remove A/T assembly to engine bolts using power tool.

19. Remove A/T assembly with transfer from vehicle.

CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to transmission jack.

20. Remove transfer from A/T assembly. Refer to TF-128, "

Removal and Installation".

INSPECTION

Installation and Inspection of Torque Converter

• After inserting a torque converter to a transmission, be sure to

check dimension A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the reverse order of removal, while paying attention to the fol-

lowing:

• When installing transmission to the engine, attach the bolts as shown.

NOTE:

*: No.2 bolt also secures air breather vent.

CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

• Align the positions of bolts for drive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft position sensor (POS).

• After completing installation, check fluid leakage, fluid level, and

the positions of A/T. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)", AT-208, "Checking of A/T Position" and AT-208, "Adjustment of A/T Position". Dimension A : 24.0 mm (0.94 in) or more

SAT017B

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Page 298 of 3061

AT-228

< SERVICE INFORMATION >

OVERHAUL

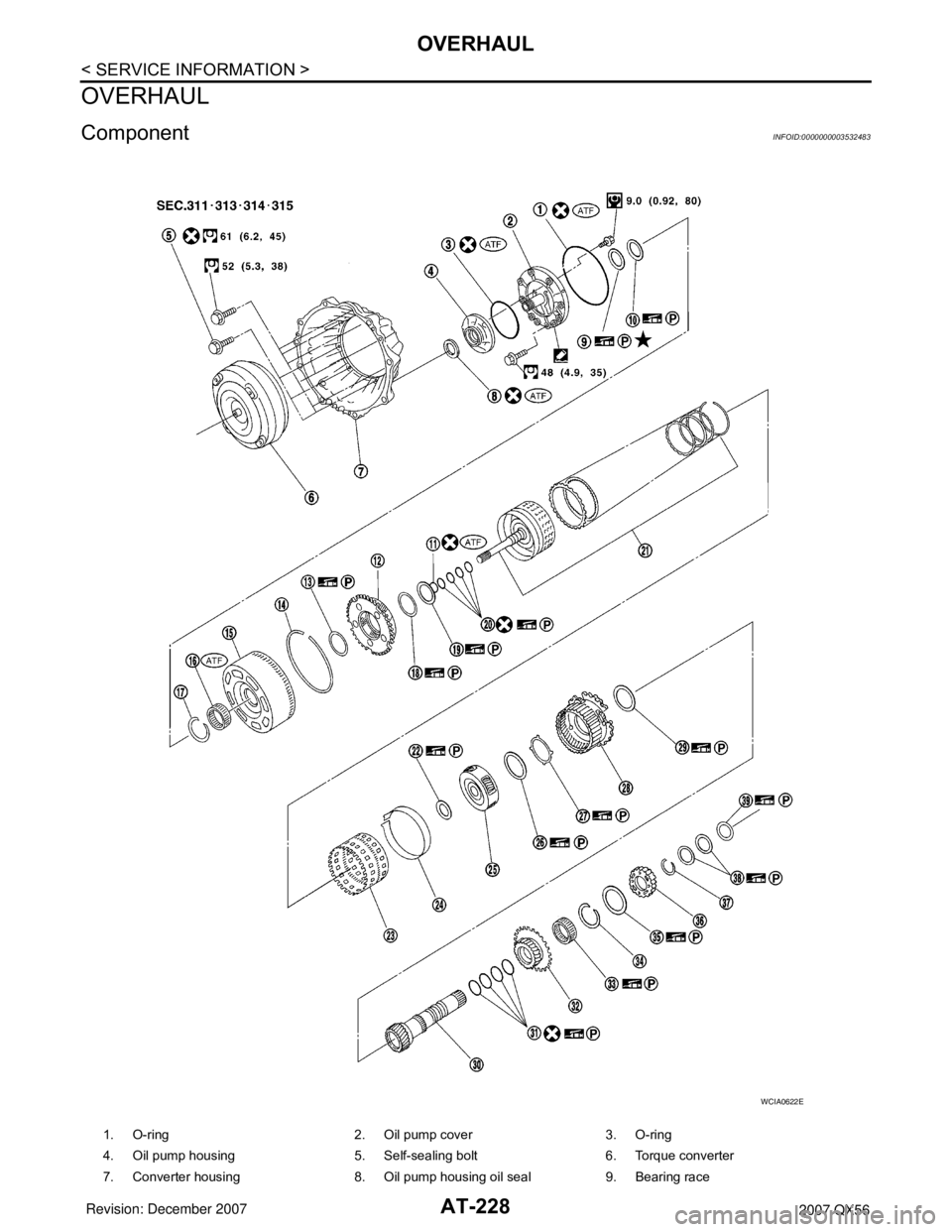

OVERHAUL

ComponentINFOID:0000000003532483

1. O-ring 2. Oil pump cover 3. O-ring

4. Oil pump housing 5. Self-sealing bolt 6. Torque converter

7. Converter housing 8. Oil pump housing oil seal 9. Bearing race

WCIA0622E

Page 310 of 3061

AT-240

< SERVICE INFORMATION >

DISASSEMBLY

DISASSEMBLY

DisassemblyINFOID:0000000003532486

CAUTION:

Do not disassemble parts behind drum support. Refer to AT-19, "

Cross-Sectional View (2WD models)"

or AT-20, "Cross-Sectional View (4WD models)".

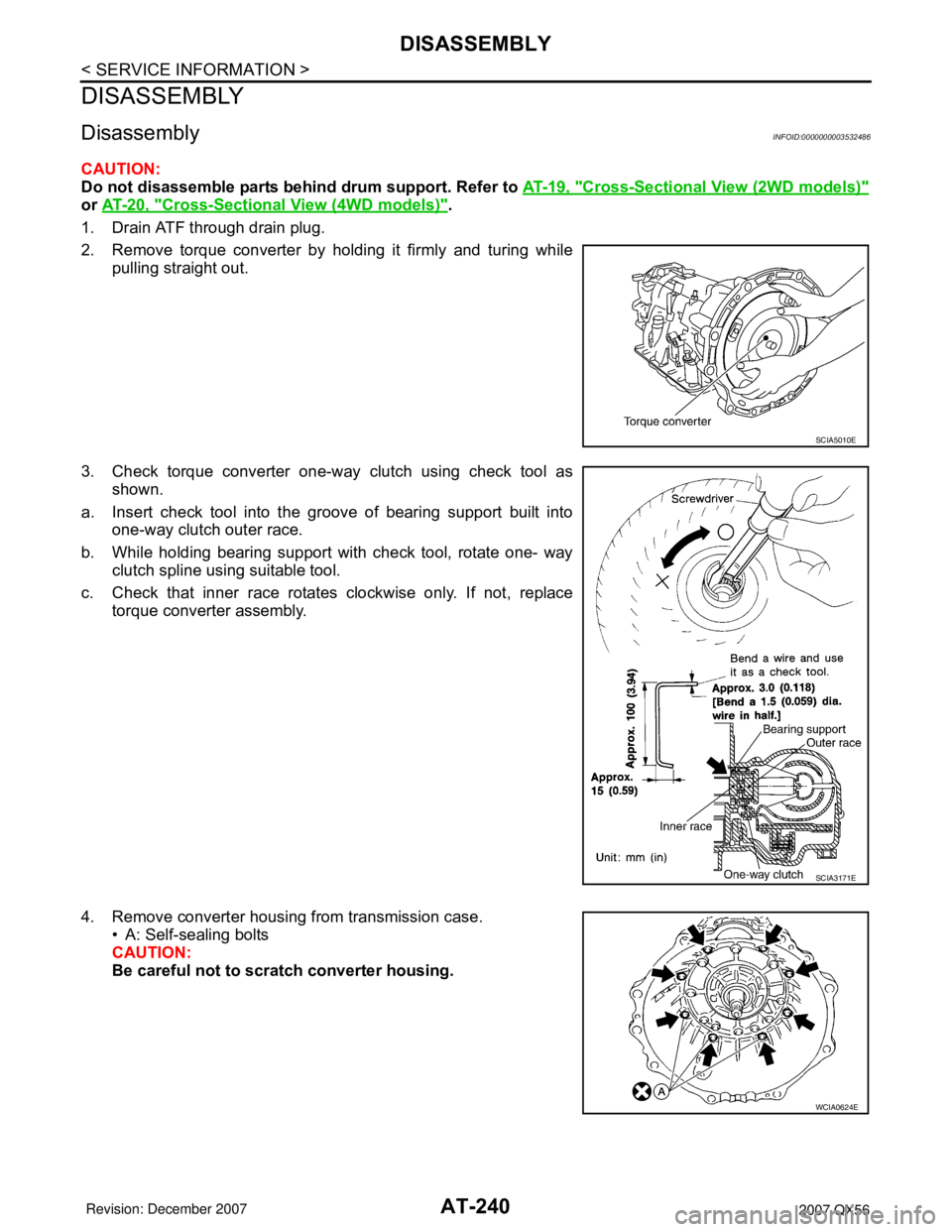

1. Drain ATF through drain plug.

2. Remove torque converter by holding it firmly and turing while

pulling straight out.

3. Check torque converter one-way clutch using check tool as

shown.

a. Insert check tool into the groove of bearing support built into

one-way clutch outer race.

b. While holding bearing support with check tool, rotate one- way

clutch spline using suitable tool.

c. Check that inner race rotates clockwise only. If not, replace

torque converter assembly.

4. Remove converter housing from transmission case.

• A: Self-sealing bolts

CAUTION:

Be careful not to scratch converter housing.

SCIA5010E

SCIA3171E

WCIA0624E

Page 330 of 3061

AT-260

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

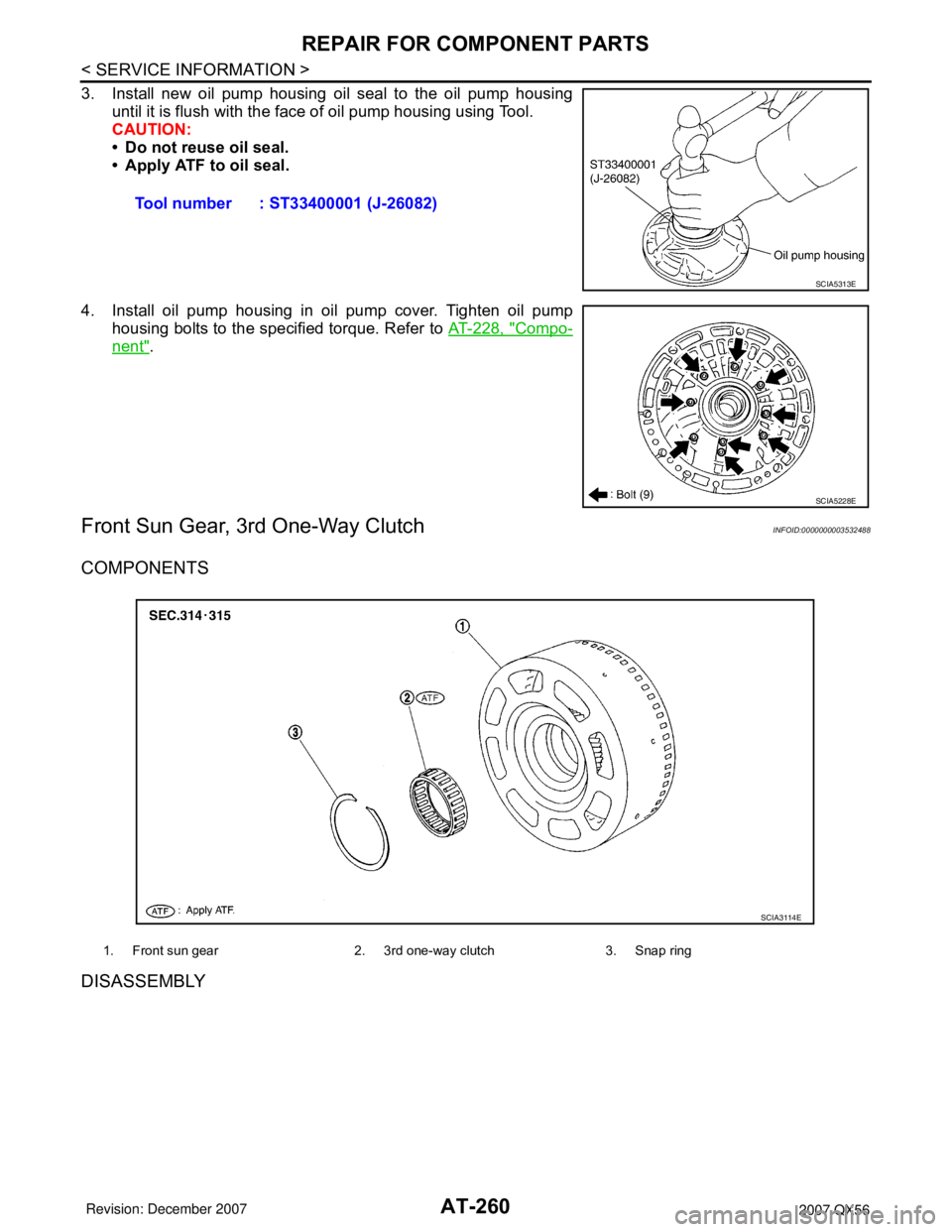

3. Install new oil pump housing oil seal to the oil pump housing

until it is flush with the face of oil pump housing using Tool.

CAUTION:

• Do not reuse oil seal.

• Apply ATF to oil seal.

4. Install oil pump housing in oil pump cover. Tighten oil pump

housing bolts to the specified torque. Refer to AT-228, "

Compo-

nent".

Front Sun Gear, 3rd One-Way ClutchINFOID:0000000003532488

COMPONENTS

DISASSEMBLY

Tool number : ST33400001 (J-26082)

SCIA5313E

SCIA5228E

1. Front sun gear 2. 3rd one-way clutch 3. Snap ring

SCIA3114E

Page 347 of 3061

ASSEMBLY

AT-277

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

ASSEMBLY

Assembly (1)INFOID:0000000003532493

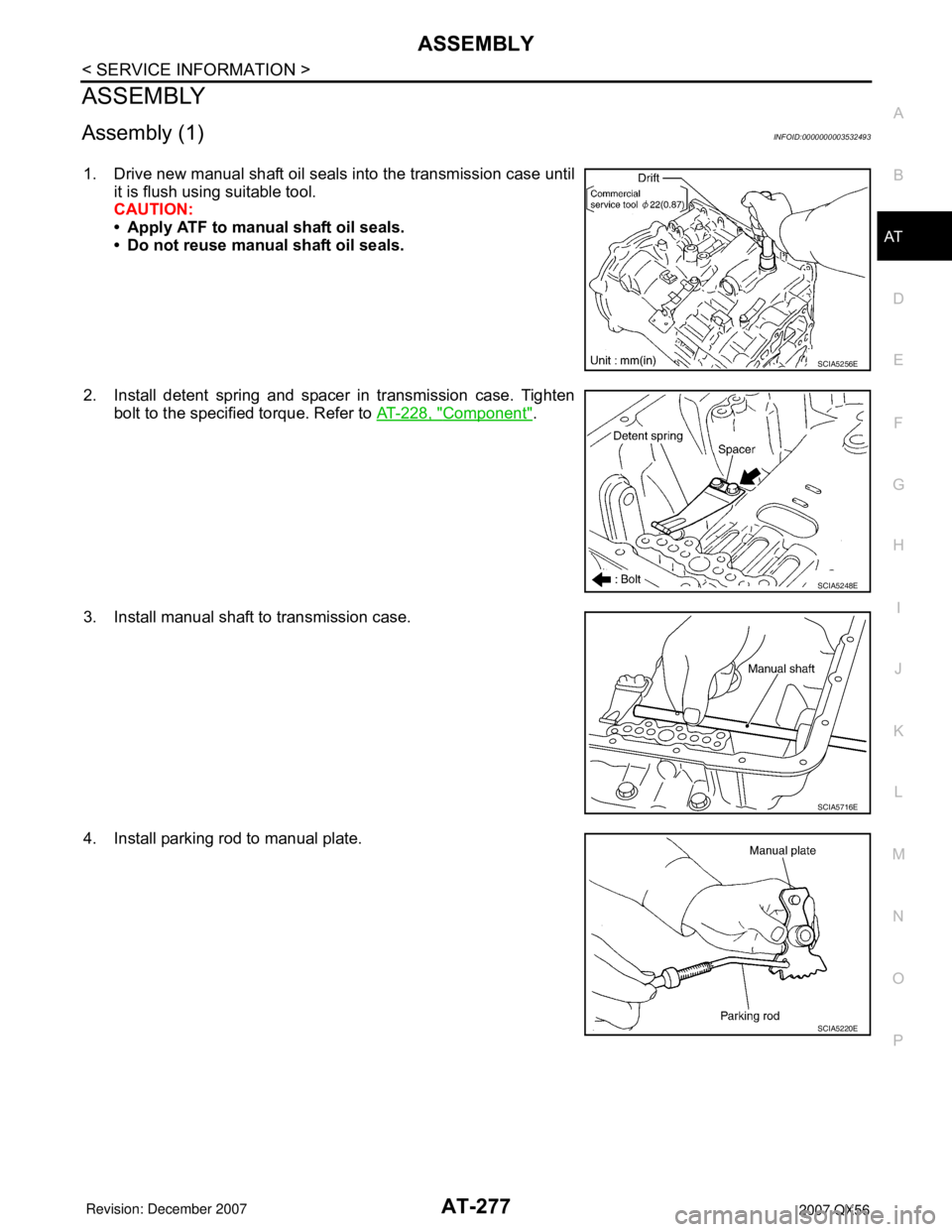

1. Drive new manual shaft oil seals into the transmission case until

it is flush using suitable tool.

CAUTION:

• Apply ATF to manual shaft oil seals.

• Do not reuse manual shaft oil seals.

2. Install detent spring and spacer in transmission case. Tighten

bolt to the specified torque. Refer to AT-228, "

Component".

3. Install manual shaft to transmission case.

4. Install parking rod to manual plate.

SCIA5256E

SCIA5248E

SCIA5716E

SCIA5220E

Page 352 of 3061

AT-282

< SERVICE INFORMATION >

ASSEMBLY

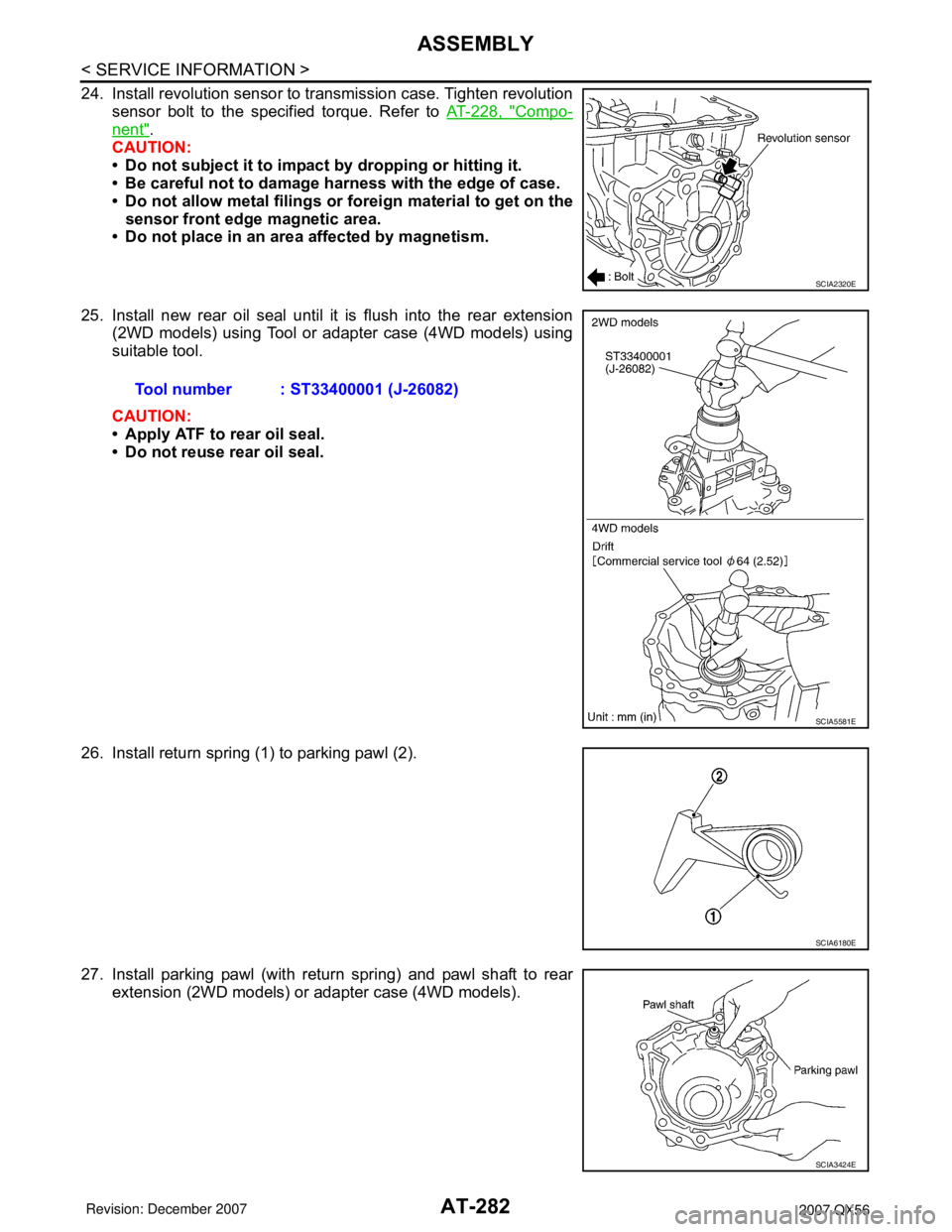

24. Install revolution sensor to transmission case. Tighten revolution

sensor bolt to the specified torque. Refer to AT-228, "

Compo-

nent".

CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Be careful not to damage harness with the edge of case.

• Do not allow metal filings or foreign material to get on the

sensor front edge magnetic area.

• Do not place in an area affected by magnetism.

25. Install new rear oil seal until it is flush into the rear extension

(2WD models) using Tool or adapter case (4WD models) using

suitable tool.

CAUTION:

• Apply ATF to rear oil seal.

• Do not reuse rear oil seal.

26. Install return spring (1) to parking pawl (2).

27. Install parking pawl (with return spring) and pawl shaft to rear

extension (2WD models) or adapter case (4WD models).

SCIA2320E

Tool number : ST33400001 (J-26082)

SCIA5581E

SCIA6180E

SCIA3424E

Page 354 of 3061

AT-284

< SERVICE INFORMATION >

ASSEMBLY

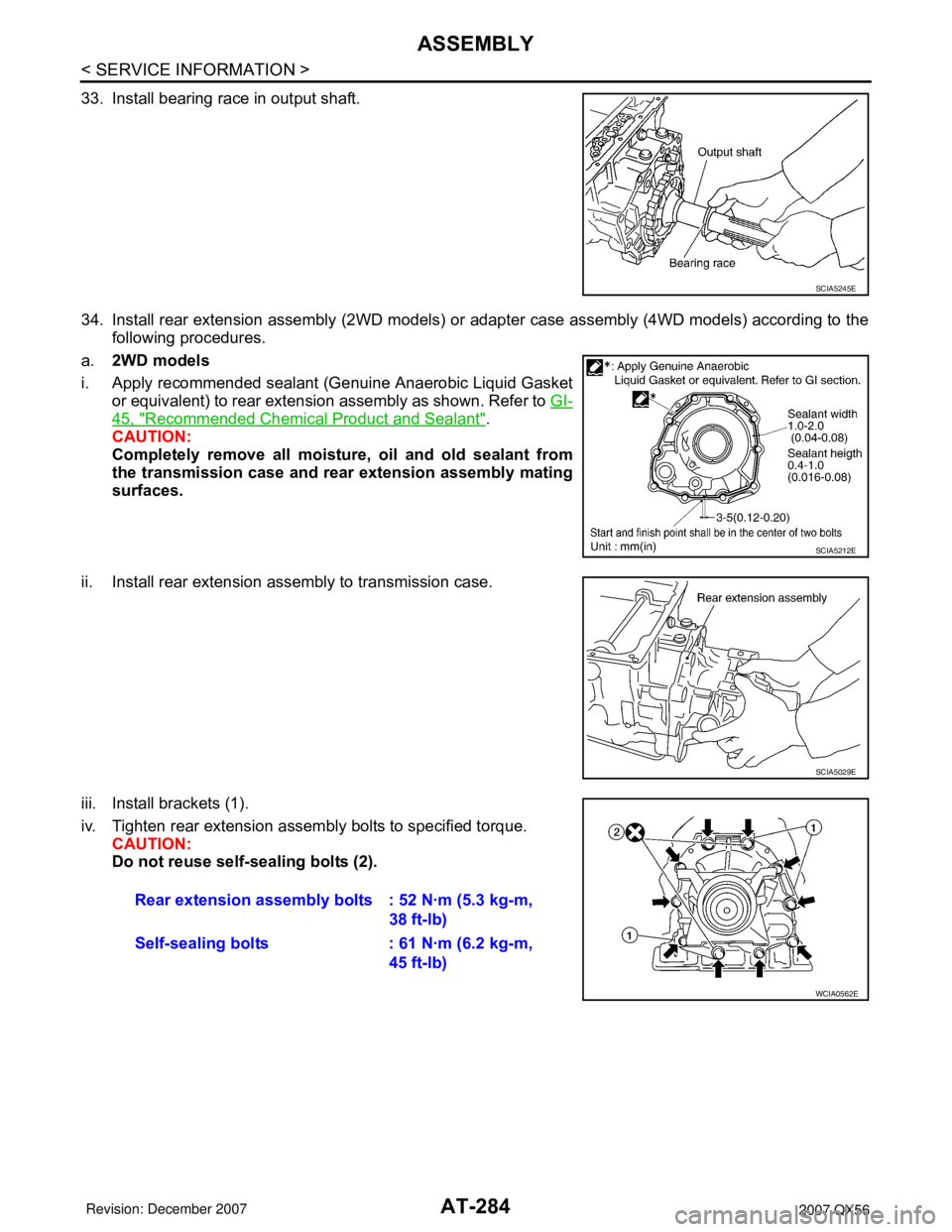

33. Install bearing race in output shaft.

34. Install rear extension assembly (2WD models) or adapter case assembly (4WD models) according to the

following procedures.

a.2WD models

i. Apply recommended sealant (Genuine Anaerobic Liquid Gasket

or equivalent) to rear extension assembly as shown. Refer to GI-

45, "Recommended Chemical Product and Sealant".

CAUTION:

Completely remove all moisture, oil and old sealant from

the transmission case and rear extension assembly mating

surfaces.

ii. Install rear extension assembly to transmission case.

iii. Install brackets (1).

iv. Tighten rear extension assembly bolts to specified torque.

CAUTION:

Do not reuse self-sealing bolts (2).

SCIA5245E

SCIA5212E

SCIA5029E

Rear extension assembly bolts : 52 N·m (5.3 kg-m,

38 ft-lb)

Self-sealing bolts : 61 N·m (6.2 kg-m,

45 ft-lb)

WCIA0562E

Page 355 of 3061

ASSEMBLY

AT-285

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

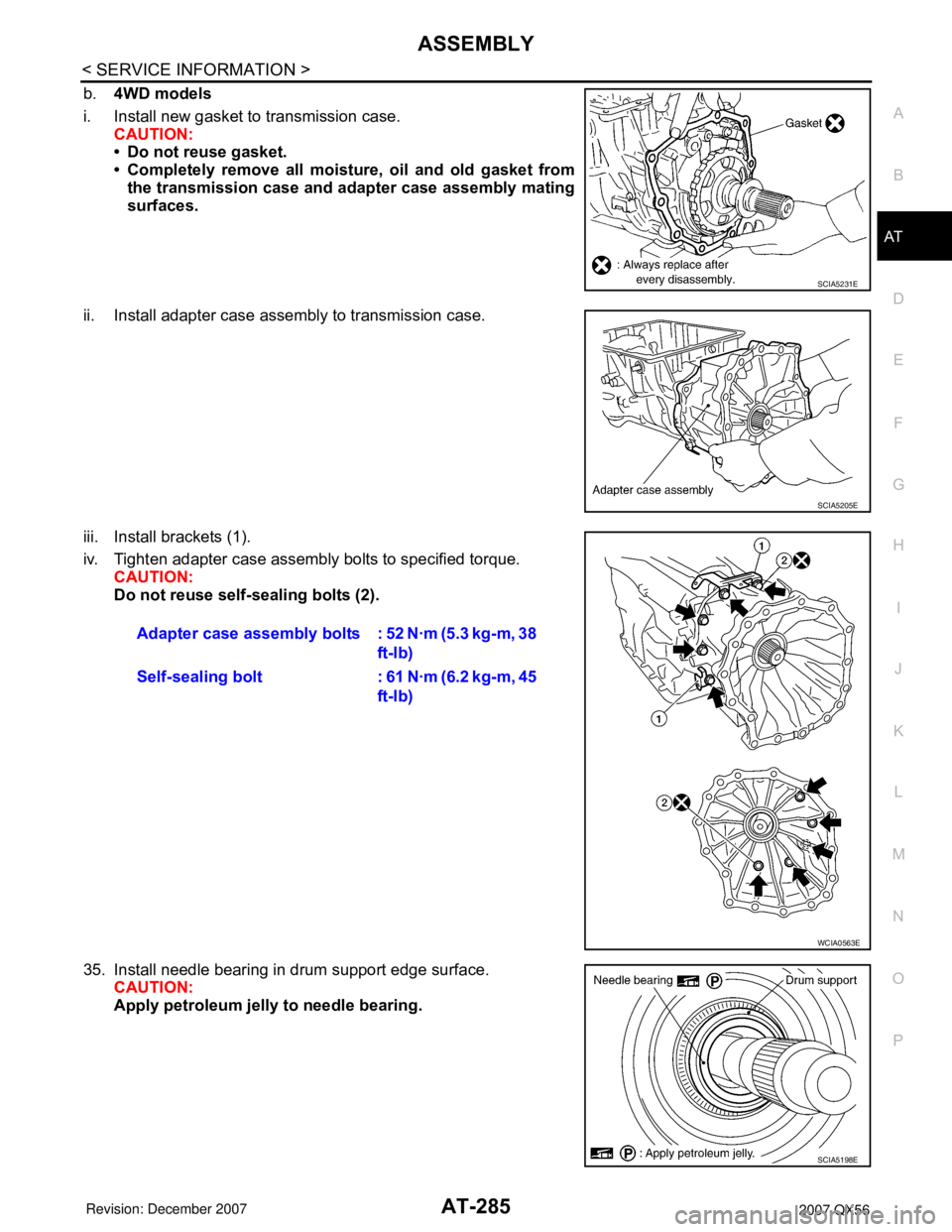

b.4WD models

i. Install new gasket to transmission case.

CAUTION:

• Do not reuse gasket.

• Completely remove all moisture, oil and old gasket from

the transmission case and adapter case assembly mating

surfaces.

ii. Install adapter case assembly to transmission case.

iii. Install brackets (1).

iv. Tighten adapter case assembly bolts to specified torque.

CAUTION:

Do not reuse self-sealing bolts (2).

35. Install needle bearing in drum support edge surface.

CAUTION:

Apply petroleum jelly to needle bearing.

SCIA5231E

SCIA5205E

Adapter case assembly bolts : 52 N·m (5.3 kg-m, 38

ft-lb)

Self-sealing bolt : 61 N·m (6.2 kg-m, 45

ft-lb)

WCIA0563E

SCIA5198E