torque INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 108 of 3061

AT-38

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

FUNCTION OF PRESSURE SWITCH

Pilot valve AAdjusts the line pressure and produces the constant pressure (pilot pressure) required

for line pressure control, shift change control, and lock-up control.

Pilot valve BAdjusts the line pressure and produces the constant pressure (pilot pressure) required

for shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valveWhen the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4th gear and switches the direct clutch coupling capacity.

High and low reverse clutch control valveWhen the high and low reverse clutch is coupled, adjusts the line pressure to the opti-

mum pressure (high and low reverse clutch pressure) and supplies it to the high and low

reverse clutch. (In 1st, 3rd, 4th and 5th gears, adjusts the clutch pressure.)

Input clutch control valveWhen the input clutch is coupled, adjusts the line pressure to the optimum pressure (in-

put clutch pressure) and supplies it to the input clutch. (In 4th and 5th gears, adjusts the

clutch pressure.)

Direct clutch control valveWhen the direct clutch is coupled, adjusts the line pressure to the optimum pressure (di-

rect clutch pressure) and supplies it to the direct clutch. (In 2nd, 3rd, and 4th gears, ad-

justs the clutch pressure.)

TCC control valve

TCC control plug

TCC control sleeveSwitches the lock-up to operating or released. Also, by performing the lock-up operation

transiently, lock-up smoothly.

Torque converter lubrication valveOperates during lock-up to switch the torque converter, cooling, and lubrication system

oil path.

Cool bypass valve Allows excess oil to bypass cooler circuit without being fed into it.

Line pressure relief valve Discharges excess oil from line pressure circuit.

N-D accumulator Produces the stabilizing pressure for when N-D is selected.

Manual valveSends line pressure to each circuit according to the select position. The circuits to which

the line pressure is not sent drain. Name Function

Name Function

Pressure switch 1 (FR/B)Detects any malfunction in the front brake hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

Pressure switch 2 (LC/B)Detects any malfunction in the low coast brake hydraulic pressure. When it detects any

malfunction, it puts the system into fail-safe mode.

Pressure switch 3 (I/C)Detects any malfunction in the input clutch hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

Pressure switch 5 (D/C)Detects any malfunction in the direct clutch hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

Pressure switch 6 (HLR/C)Detects any malfunction in the high and low reverse clutch hydraulic pressure. When it

detects any malfunction, it puts the system into fail-safe mode.

Page 114 of 3061

AT-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

l: NG X: OK

A/T 1st Engine Braking

• When there is an A/T first gear engine brake judgment malfunction, the low coast brake solenoid is switched

“OFF” to avoid the engine brake operation.

Line Pressure Solenoid

• The solenoid is switched “OFF” and the line pressure is set to the maximum hydraulic pressure to make driv-

ing possible.

Torque Converter Clutch Solenoid

• The solenoid is switched “OFF” to release the lock-up.

Low Coast Brake Solenoid

• When a (electrical or functional) malfunction occurs, in order to make driving possible, the engine brake is

not applied in 1st and 2nd gear.

Input Clutch Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid either “ON” or “OFF”, the transmission is

held in 4th gear to make driving possible.

Direct Clutch Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid either “ON” or “OFF”, the transmission is

held in 4th gear to make driving possible.

Front Brake Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid “ON”, in order to make driving possible, the

A/T is held in 5th gear; if the solenoid is OFF, 4th gear.

High and Low Reverse Clutch Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid either “ON” or “OFF”, the transmission is

held in 4th gear to make driving possible.

Turbine Revolution Sensor 1 or 2

• The control is the same as if there were no turbine revolution sensors, 5th gear is prohibited.

How To Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000003532245

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelerator pedal position sensor (throttle position

sensor) or PNP switch and provides shift control or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

Gear positionATF pressure switch output

Fail-safe

functionClutch pressure output pattern after fail-safe func-

tion

SW3

(I/C)SW6

(HLR/

C)SW5

(D/C)SW1

(FR/B)SW2

(LC/B)I/C HLR/C D/C FR/B LC/B L/U

A/T interlock

coupling pat-

tern3rd – X X – lHeld in

2nd gearOFF OFF ON OFF OFF OFF

4th – X X –lHeld in

2nd gearOFF OFF ON OFF OFF OFF

5th X X – XlHeld in

2nd gearOFF OFF ON OFF OFF OFF

SAT631IB

Page 117 of 3061

TROUBLE DIAGNOSIS

AT-47

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P Diagnostic Worksheet Chart

Customer name MR/MS Model & Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequencyo Continuouso Intermittent ( times a day)

Symptomso Vehicle does not move. (o Any positiono Particular position)

o No up-shift (o 1st → 2ndo 2nd → 3rdo 3rd → 4th o 4th → 5th)

o No down-shift (o 5th → 4th o 4th → 3rdo 3rd → 2ndo 2nd → 1st)

o Lock-up malfunction

o Shift point too high or too low.

o Shift shock or slip (o N → Do Lock-upo Any drive position)

o Noise or vibration

o No kick down

o No pattern select

o Others

()

Malfunction indicator lamp (MIL)o Continuously lito Not lit

1o Read the item on cautions concerning fail-safe and understand the customer's complaint.AT- 4 3

2o ATF inspection

AT- 5 1o Leak (Repair leak location.)

o Sta te

o Amount

3o Stall test and line pressure test

AT- 5 1

, AT-

51

o Stall test

o Torque converter one-way clutch

o Front brake

o High and low reverse clutch

o Low coast brake

o Forward brake

o Reverse brake

o Forward one-way clutcho 1st one-way clutch

o 3rd one-way clutch

o Engine

o Line pressure low

o Except for input clutch and direct

clutch, clutches and brakes OK

o Line pressure inspection - Suspected part:

Page 123 of 3061

TROUBLE DIAGNOSIS

AT-53

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P Judgement of Stall Test

O: Stall speed within standard value position

H: Stall speed higher than standard value

L: Stall speed lower than standard value

Stall test standard value position

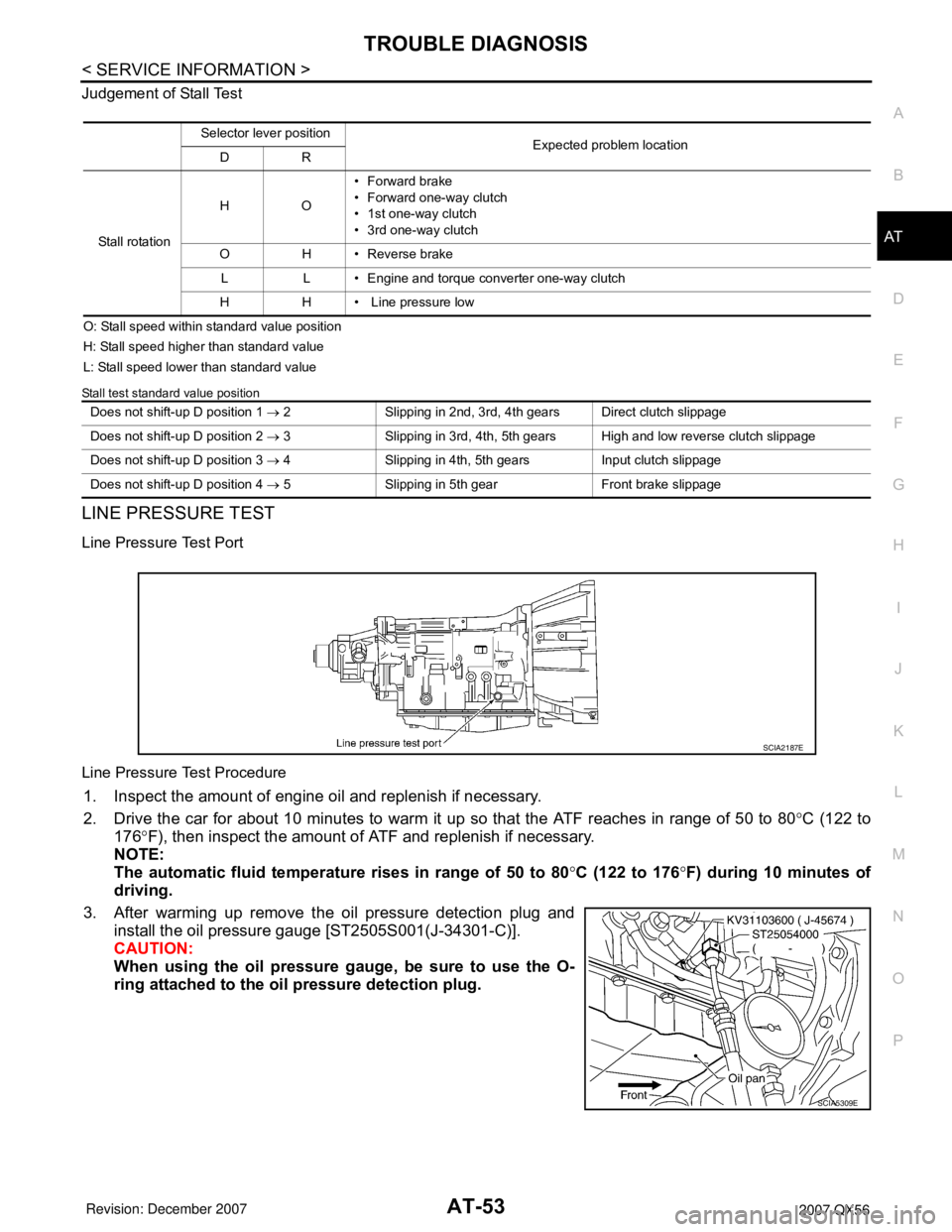

LINE PRESSURE TEST

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the ATF reaches in range of 50 to 80°C (122 to

176°F), then inspect the amount of ATF and replenish if necessary.

NOTE:

The automatic fluid temperature rises in range of 50 to 80°C (122 to 176°F) during 10 minutes of

driving.

3. After warming up remove the oil pressure detection plug and

install the oil pressure gauge [ST2505S001(J-34301-C)].

CAUTION:

When using the oil pressure gauge, be sure to use the O-

ring attached to the oil pressure detection plug.

Selector lever position

Expected problem location

DR

Stall rotation HO• Forward brake

• Forward one-way clutch

• 1st one-way clutch

• 3rd one-way clutch

O H • Reverse brake

L L • Engine and torque converter one-way clutch

H H • Line pressure low

Does not shift-up D position 1 → 2 Slipping in 2nd, 3rd, 4th gears Direct clutch slippage

Does not shift-up D position 2 → 3 Slipping in 3rd, 4th, 5th gears High and low reverse clutch slippage

Does not shift-up D position 3 → 4 Slipping in 4th, 5th gears Input clutch slippage

Does not shift-up D position 4 → 5 Slipping in 5th gear Front brake slippage

SCIA2187E

SCIA5309E

Page 124 of 3061

AT-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

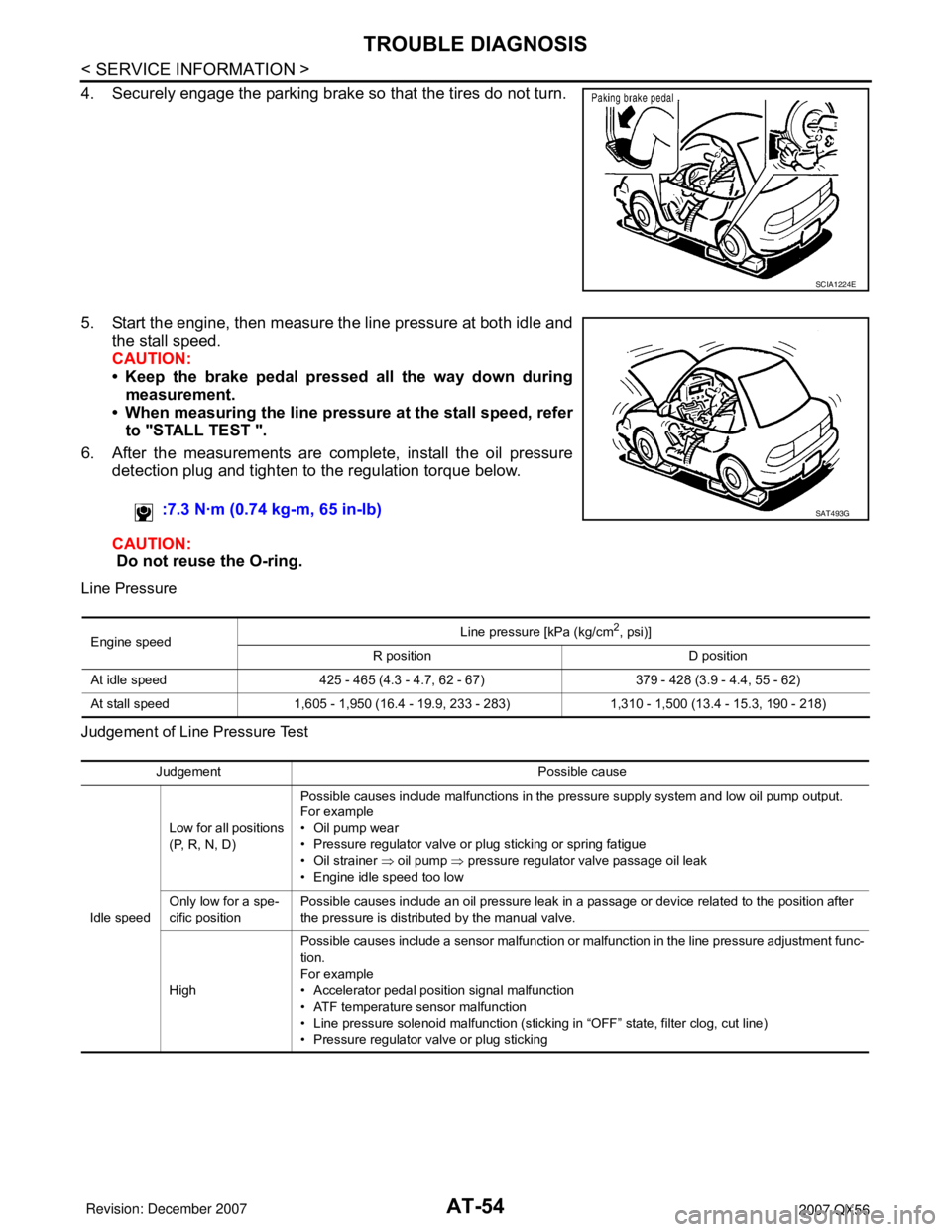

4. Securely engage the parking brake so that the tires do not turn.

5. Start the engine, then measure the line pressure at both idle and

the stall speed.

CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer

to "STALL TEST ".

6. After the measurements are complete, install the oil pressure

detection plug and tighten to the regulation torque below.

CAUTION:

Do not reuse the O-ring.

Line Pressure

Judgement of Line Pressure Test

SCIA1224E

:7.3 N·m (0.74 kg-m, 65 in-lb)SAT493G

Engine speedLine pressure [kPa (kg/cm

2, psi)]

R position D position

At idle speed 425 - 465 (4.3 - 4.7, 62 - 67) 379 - 428 (3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.4 - 15.3, 190 - 218)

Judgement Possible cause

Idle speedLow for all positions

(P, R, N, D)Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

•Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer ⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a spe-

cific positionPossible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

HighPossible causes include a sensor malfunction or malfunction in the line pressure adjustment func-

tion.

For example

• Accelerator pedal position signal malfunction

• ATF temperature sensor malfunction

• Line pressure solenoid malfunction (sticking in “OFF” state, filter clog, cut line)

• Pressure regulator valve or plug sticking

Page 133 of 3061

TROUBLE DIAGNOSIS

AT-63

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

7

Shift

ShockShock is too large for

upshift when accelera-

tor pedal is released.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. Engine speed signalAT-109

4. CAN communication lineAT- 9 1

5. Turbine revolution sensorAT-103

6. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

7. Fluid level and stateAT- 5 1

8. Control valve with TCMAT-210

OFF vehicle9. Front brake (brake band)AT-22810. Input clutchAT-262

11. High and low reverse clutchAT-272

12. Direct clutchAT-274

8Shock is too large for

lock-up.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. Engine speed signalAT-109

4. CAN communication lineAT- 9 1

5. Turbine revolution sensorAT-103

6. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

7. Torque converter clutch solenoid valveAT- 111

8. Fluid level and stateAT- 5 1

9. Control valve with TCMAT-210

OFF vehicle 10. Torque converterAT-240

9Shock is too large dur-

ing engine brake.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. CAN communication lineAT- 9 1

4. Fluid level and stateAT- 5 1

5. Control valve with TCMAT-210

OFF vehicle6. Front brake (brake band)AT-2287. Input clutchAT-262

8. High and low reverse clutchAT-272

9. Direct clutchAT-274

No. Items Symptom Condition Diagnostic ItemReference

page

Page 138 of 3061

AT-68

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

22

Slips/Will

Not En-

gageWhen “D” position, re-

mains in 5th gear.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0

,

AT- 1 3 4

4. Line pressure testAT- 5 1

5. CAN communication lineAT- 9 1

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. Front brake (brake band)AT- 2 4 08. Input clutchAT- 2 6 2

9. Gear systemAT- 2 2 8

10. High and low reverse clutchAT- 2 7 2

23Vehicle cannot be

started from D

1.

Refer to AT-177, "

Ve -

hicle Cannot Be Start-

ed from D1".ON vehicle1. Fluid level and stateAT- 5 1

2. Accelerator pedal position sensorAT- 11 7

3. Line pressure testAT- 5 1

4. CAN communication lineAT- 9 1

5. Control valve with TCMAT- 2 1 0

OFF vehicle6. Torque converterAT- 2 4 0

7. Oil pump assemblyAT- 2 5 8

8. 3rd one-way clutchAT- 2 6 0

9. 1st one-way clutchAT- 2 6 7

10. Gear systemAT- 2 2 8

11. Reverse brakeAT- 2 4 0

12. Forward one-way clutch (Parts behind drum support is im-

possible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT- 2 4 0

13. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

24Does not lock-up.

Refer to AT-187, "A/T

Does Not Perform

Lock-up".ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Engine speed signalAT- 1 0 9

4. Turbine revolution sensorAT- 1 0 3

5. Torque converter clutch solenoid valveAT- 111

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT- 2 1 0

OFF vehicle8. Torque converterAT- 2 4 09. Oil pump assemblyAT- 2 5 8

No. Items Symptom Condition Diagnostic ItemReference

page

Page 139 of 3061

TROUBLE DIAGNOSIS

AT-69

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P25

Slips/Will

Not en-

gageDoes not hold lock-up

condition.

Refer to AT- 1 8 9 , "A/T

Does Not Hold Lock-

up Condition".ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Engine speed signalAT-109

4. Turbine revolution sensorAT-103

5. Torque converter clutch solenoid valveAT- 111

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT-210

OFF vehicle8. Torque converterAT-2409. Oil pump assemblyAT-258

26Lock-up is not re-

leased.

Refer to AT- 1 9 0 ,

"Lock-up Is Not Re-

leased".ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Engine speed signalAT-109

4. Turbine revolution sensorAT-103

5. Torque converter clutch solenoid valveAT- 111

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT-210

OFF vehicle8. Torque converterAT-2409. Oil pump assemblyAT-258

27No shock at all or the

clutch slips when vehi-

cle changes speed D1

→ D

2. ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT-138

4. CAN communication lineAT- 9 1

5. Line pressure testAT- 5 1

6. Control valve with TCMAT-210

OFF vehicle7. Torque converterAT-240

8. Oil pump assemblyAT-258

9. 3rd one-way clutchAT-260

10. Gear systemAT-228

11. Direct clutchAT-274

12. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT-240

No. Items Symptom Condition Diagnostic ItemReference

page

Page 140 of 3061

AT-70

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

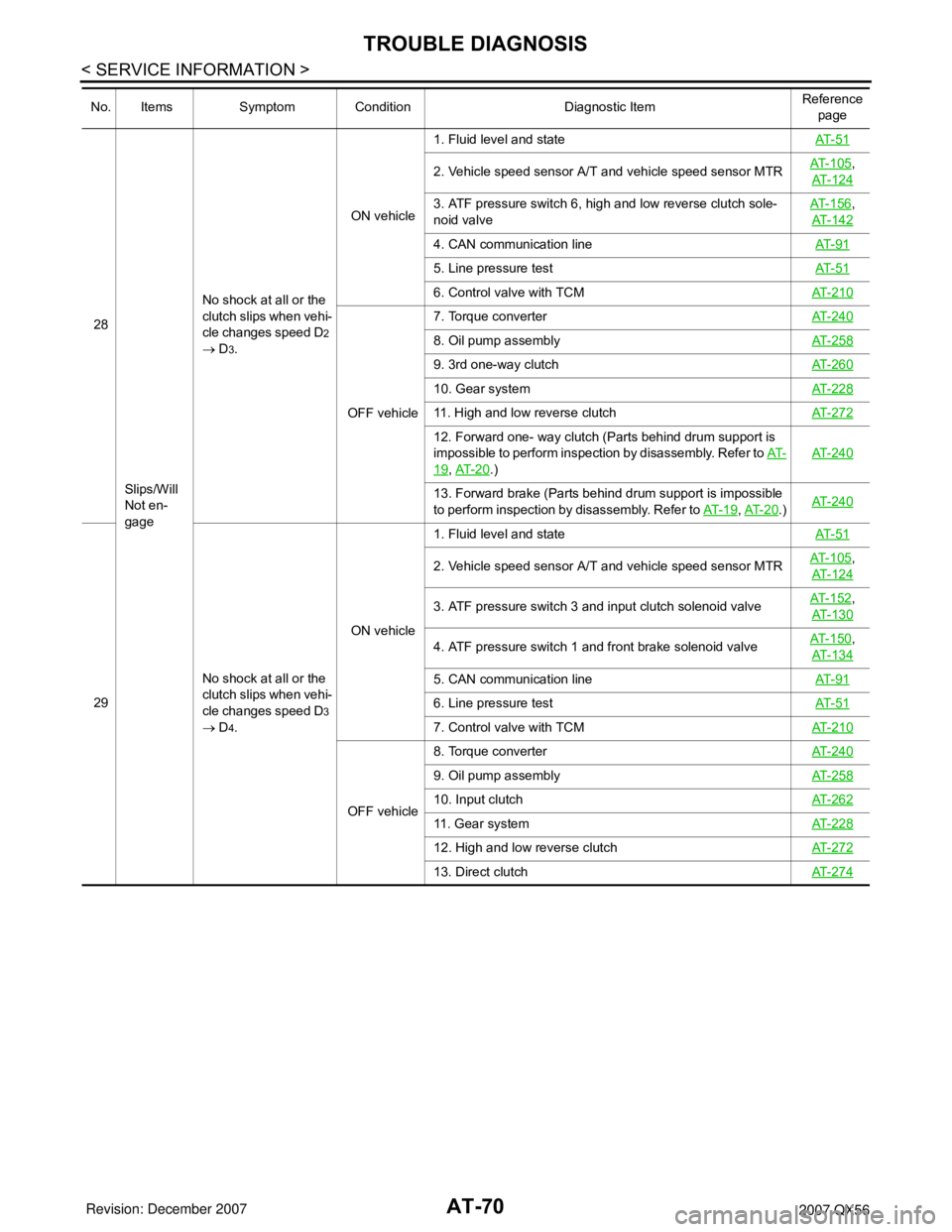

28

Slips/Will

Not en-

gageNo shock at all or the

clutch slips when vehi-

cle changes speed D2

→ D

3.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 6, high and low reverse clutch sole-

noid valveAT- 1 5 6,

AT- 1 4 2

4. CAN communication lineAT- 9 1

5. Line pressure testAT- 5 1

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. Torque converterAT- 2 4 0

8. Oil pump assemblyAT- 2 5 8

9. 3rd one-way clutchAT- 2 6 0

10. Gear systemAT- 2 2 8

11. High and low reverse clutchAT- 2 7 2

12. Forward one- way clutch (Parts behind drum support is

impossible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT- 2 4 0

13. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

29No shock at all or the

clutch slips when vehi-

cle changes speed D3

→ D

4.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 3 and input clutch solenoid valveAT- 1 5 2,

AT- 1 3 0

4. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0

,

AT- 1 3 4

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 5 1

7. Control valve with TCMAT- 2 1 0

OFF vehicle8. Torque converterAT- 2 4 0

9. Oil pump assemblyAT- 2 5 8

10. Input clutchAT- 2 6 2

11. Gear systemAT- 2 2 8

12. High and low reverse clutchAT- 2 7 2

13. Direct clutchAT- 2 7 4

No. Items Symptom Condition Diagnostic ItemReference

page

Page 141 of 3061

TROUBLE DIAGNOSIS

AT-71

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

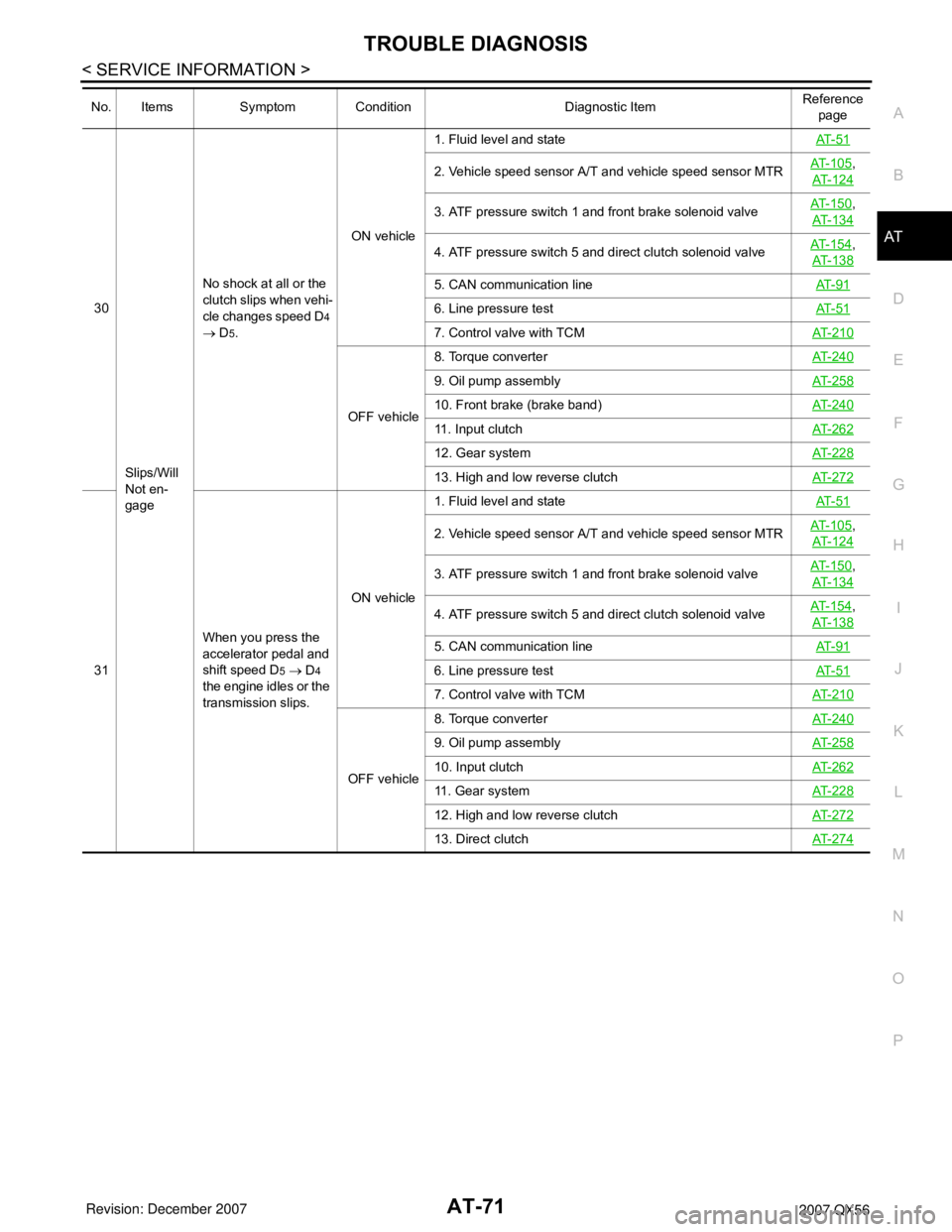

30

Slips/Will

Not en-

gageNo shock at all or the

clutch slips when vehi-

cle changes speed D4

→ D

5.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT-134

4. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT-138

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 5 1

7. Control valve with TCMAT-210

OFF vehicle8. Torque converterAT-240

9. Oil pump assemblyAT-258

10. Front brake (brake band)AT-240

11. Input clutchAT-262

12. Gear systemAT-228

13. High and low reverse clutchAT-272

31When you press the

accelerator pedal and

shift speed D5 → D4

the engine idles or the

transmission slips.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT-134

4. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT-138

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 5 1

7. Control valve with TCMAT-210

OFF vehicle8. Torque converterAT-240

9. Oil pump assemblyAT-258

10. Input clutchAT-262

11. Gear systemAT-228

12. High and low reverse clutchAT-272

13. Direct clutchAT-274

No. Items Symptom Condition Diagnostic ItemReference

page