warning INFINITI QX56 2010 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 445 of 4210

![INFINITI QX56 2010 Factory Owners Manual BCS

BCM (BODY CONTROL MODULE)BCS-59

< ON-VEHICLE REPAIR > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:0000000005146436

REMOVAL

NOTE:

INFINITI QX56 2010 Factory Owners Manual BCS

BCM (BODY CONTROL MODULE)BCS-59

< ON-VEHICLE REPAIR > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:0000000005146436

REMOVAL

NOTE:](/img/42/57032/w960_57032-444.png)

BCS

BCM (BODY CONTROL MODULE)BCS-59

< ON-VEHICLE REPAIR > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Removal and InstallationINFOID:0000000005146436

REMOVAL

NOTE:

If possible, before removing BCM, retrieve current BCM configuration to use for reference when configuring

brand-new BCM after installation. Refer to

WT-6, "

ID Registration Procedure".

1. Disconnect the battery negative terminal.

2. Remove the lower knee protector. Refer to IP-11, "

Exploded View".

3. Remove the screw and release the BCM.

4. Disconnect the connectors and then remove the BCM.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

• When replacing BCM, it must be configured. Refer to BCS-4, "

CONFIGURATION : Special Repair Require-

ment".

• When replacing BCM, perform initialization of NATS sy stem and registration of all NATS ignition key IDs.

Refer to the CONSULT-III operation manual for the initialization procedure.

• When replacing BCM, perform ID regi stration procedure of low tire pressure warning system. Refer to WT-6,

"ID Registration Procedure".

LEIA0068E

Revision: April 20092010 QX56

Page 448 of 4210

PRECAUTIONSBR-3

< PRECAUTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005403123

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005403124

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 449 of 4210

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

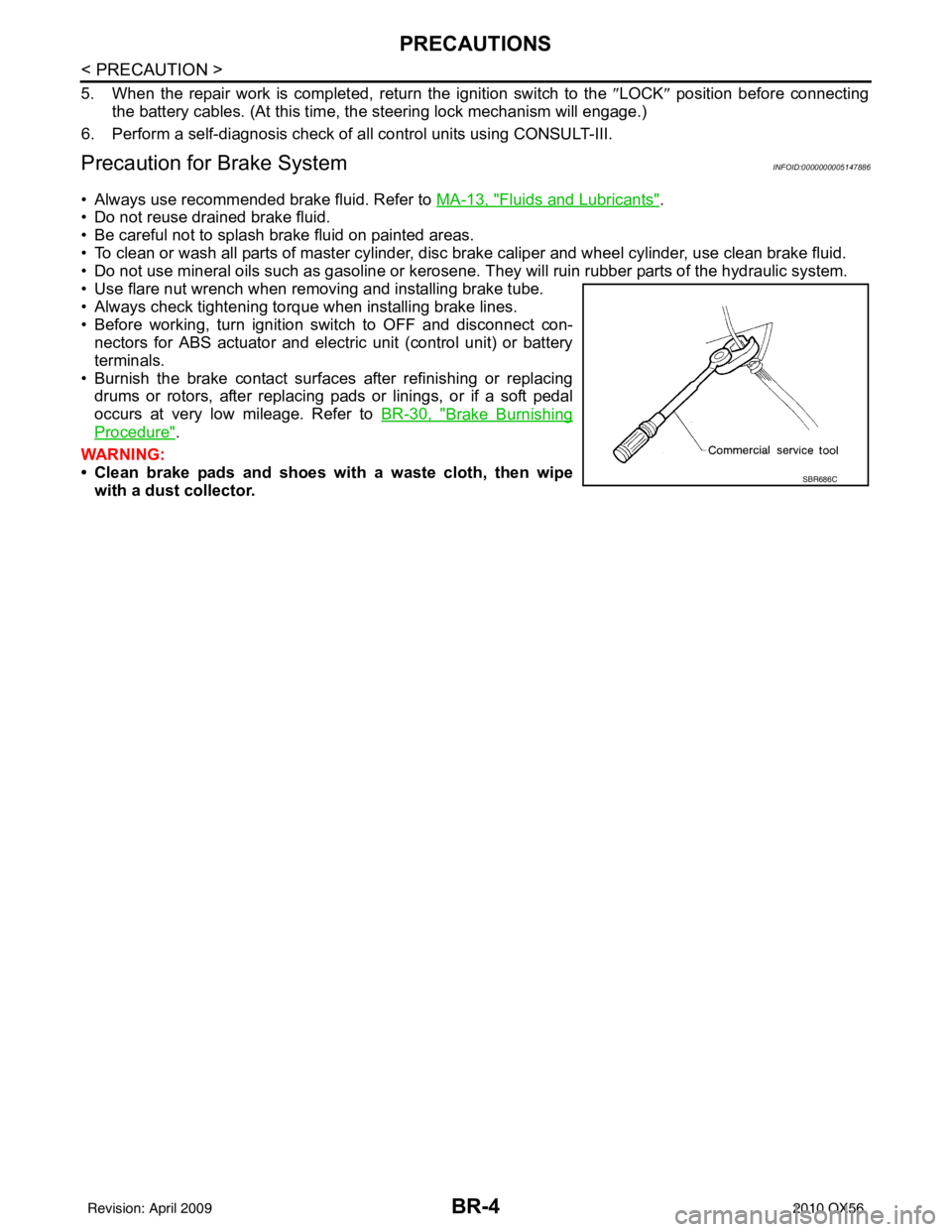

Precaution for Brake SystemINFOID:0000000005147886

• Always use recommended brake fluid. Refer to MA-13, "Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas.

• To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

• Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

• Use flare nut wrench when removing and installing brake tube.

• Always check tightening torque when installing brake lines.

• Before working, turn ignition switch to OFF and disconnect con- nectors for ABS actuator and electric unit (control unit) or battery

terminals.

• Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer to BR-30, "

Brake Burnishing

Procedure".

WARNING:

• Clean brake pads and shoes wi th a waste cloth, then wipe

with a dust collector.

SBR686C

Revision: April 20092010 QX56

Page 462 of 4210

BRAKE FLUIDBR-17

< ON-VEHICLE MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE FLUID

On Board InspectionINFOID:0000000005147901

LEVEL CHECK

• Make sure the fluid level in reservoir tank is between MAX and MIN lines as shown.

• Visually check around reservoir tank for fluid leaks.

• If fluid level is excessively low, check brake system for leaks.

• If brake warning lamp remains illuminated after parking brake pedal is released, check brake system for fluid leaks.

Drain and RefillINFOID:0000000005147902

CAUTION:

• Refill with new brake fluid. Refer to MA-13, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Do not let brake fluid splash on the painted surfaces of the body. This might damage the paint, so if

splashing it, immediately wipe off the area and wash away with water.

• Before servicing, disconnect ABS actuator and electri c unit (control unit) connector or battery nega-

tive terminal.

1. Connect a vinyl tube to each bleed valve.

2. Depress brake pedal, loosen each bleed valve, and gradually remove brake fluid.

3. Make sure there is no foreign material in reservoir tank, and refill with new brake fluid.

4. Rest foot on brake pedal. Loosen bleed valve. Slowly depress pedal until it stops. Tighten bleed valve. Release brake pedal.

Repeat this process a few times, then pause to add new brake

fluid to master cylinder. Continue until new brake fluid flows out

of the bleed valve.

Bleed the air out of the brake hydraulic system. Refer to BR-17,

"Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000005147903

CAUTION:

While bleeding, pay attention to master cylinder fluid level.

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector or battery

negative terminal.

2. Connect a vinyl tube to the rear right bleed valve.

LFIA0225E

SBR419C

SBR995

Revision: April 20092010 QX56

Page 465 of 4210

BR-20

< ON-VEHICLE REPAIR >

BRAKE PEDAL

3. Disconnect the adjustable brake pedal cable from the adjustablepedal electric motor.

• Unlock (1) then pull (2) the adjustable brake pedal cable to dis-connect it from the adjustable pedal electric motor as shown.

4. Remove snap pin and clevis pin from the clevis of brake booster.

5. Remove brake pedal assembly nuts and remove the brake pedal assembly. • Temporarily install the brake pedal assembly nuts by hand to support the brake booster.

WARNING:

Do not bend the brake tubing.

CAUTION:

• Before removal and installation, the accelerator and brake pedals must be in the forward mostposition (closest to the floor). This is to align the base position of the accelerator and brake ped-

als.

• Do not disassemble the brake pedal adjusting mechanism.

• Avoid damage from dropping th e brake pedal assembly during handling.

• Keep the brake pedal assembly away from water.

INSPECTION AFTER REMOVAL

Check the brake pedal assembly for the following items:

• Crack or deformation of clevis pin stopper

• Clevis pin deformation

• Crack of any welded portion of the brake pedal assembly

• Brake pedal bend or deformation

INSTALLATION

Installation is in the reverse order of removal.

• Check the brake pedal for smooth operation. Ther e should be no binding or sticking when applying or

releasing the brake pedal.

• Check the brake pedal adjustable feature for smooth operation. There should be no binding or sticking when adjusting the brake pedal forward or backward.

• After installing the brake pedal assembly, be sure to adjust it. Refer to BR-15, "

Inspection and Adjustment".

LBIA0374E

SBR997

Revision: April 20092010 QX56

Page 474 of 4210

FRONT DISC BRAKEBR-29

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

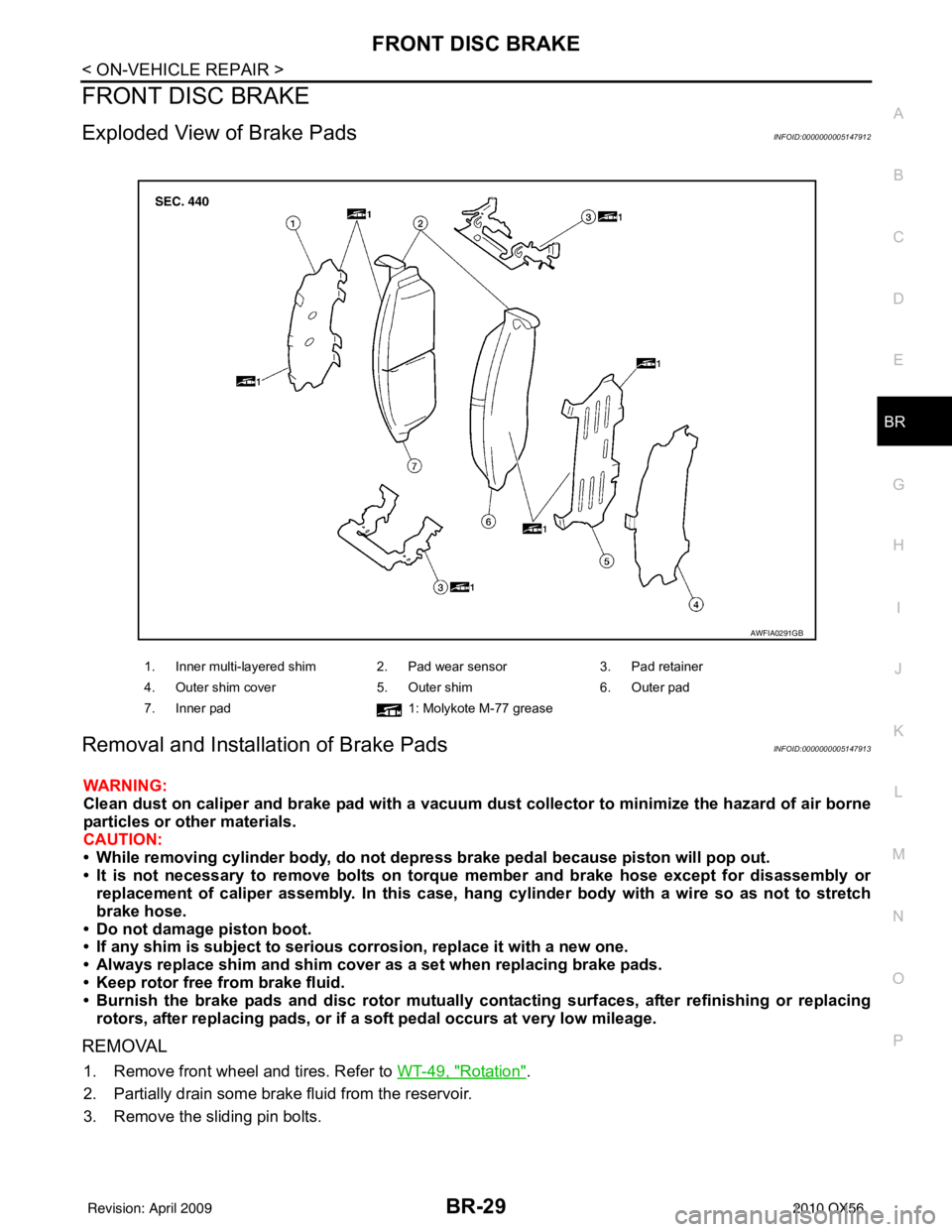

Exploded View of Brake PadsINFOID:0000000005147912

Removal and Installation of Brake PadsINFOID:0000000005147913

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing rotors, after replacing pads, or if a so ft pedal occurs at very low mileage.

REMOVAL

1. Remove front wheel and tires. Refer to WT-49, "Rotation".

2. Partially drain some brake fluid from the reservoir.

3. Remove the sliding pin bolts.

1. Inner multi-layered shim 2. Pad wear sensor 3. Pad retainer

4. Outer shim cover 5. Outer shim6. Outer pad

7. Inner pad 1: Molykote M-77 grease

AWFIA0291GB

Revision: April 20092010 QX56

Page 476 of 4210

FRONT DISC BRAKEBR-31

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

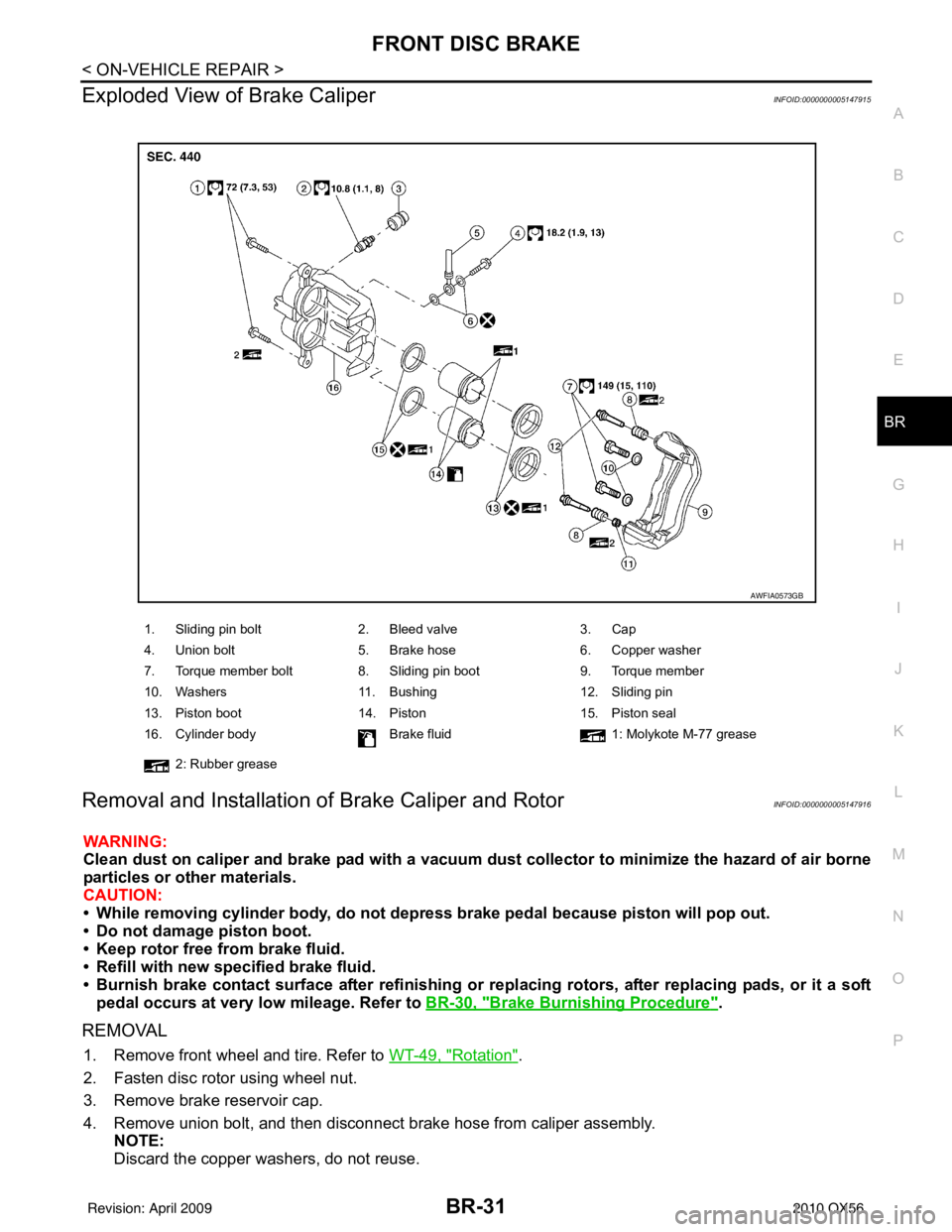

Exploded View of Brake CaliperINFOID:0000000005147915

Removal and Installation of Brake Caliper and RotorINFOID:0000000005147916

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or replacing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-30, "

Brake Burnishing Procedure".

REMOVAL

1. Remove front wheel and tire. Refer to WT-49, "Rotation".

2. Fasten disc rotor using wheel nut.

3. Remove brake reservoir cap.

4. Remove union bolt, and then disconnect brake hose from caliper assembly. NOTE:

Discard the copper washers, do not reuse.

1. Sliding pin bolt 2. Bleed valve 3. Cap

4. Union bolt 5. Brake hose 6. Copper washer

7. Torque member bolt 8. Sliding pin boot 9. Torque member

10. Washers 11. Bushing 12. Sliding pin

13. Piston boot 14. Piston 15. Piston seal

16. Cylinder body Brake fluid1: Molykote M-77 grease

2: Rubber grease

AWFIA0573GB

Revision: April 20092010 QX56

Page 479 of 4210

BR-34

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

REAR DISC BRAKE

Exploded View of Brake PadsINFOID:0000000005147917

Removal and Installation of Brake PadINFOID:0000000005147918

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to disconnect brake hose connection except for disassembly or replacement of

caliper assembly. In this case, ha ng cylinder body with a wire so as not to stretch brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

REMOVAL

1. Remove rear wheel and tires using power tools.

2. Partially drain some brake fluid from the reservoir.

3. Remove the sliding sleeves and sliding pin bolts from the cylinder body.

4. Support the cylinder body with wire, remove pads, shims, cover and retainers.

INSTALLATION

1. Push piston in using suitable tool.

CAUTION:

By pushing in piston, brake fluid returns to mast er cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the piston.

1. Inner shim cover 2. Outer pad3. Outer multi-layered shim

4. Pad wear sensor 5. Inner pad (RH)6. Pad retainer

7. Inner pad 8. Inner shim

1: Molykote M-77 grease

AWFIA0293GB

Revision: April 20092010 QX56

Page 481 of 4210

BR-36

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Removal and Installation of Brake Caliper and Disc Rotor

INFOID:0000000005147921

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or re placing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-35, "

Brake Burnishing Procedure".

REMOVAL

1. Remove rear wheel and tire using power tool.

2. Fasten disc rotor using wheel nut.

3. Remove brake reservoir cap.

4. Remove union bolt and cylinder body bolts, then remove cylin-

der body.

NOTE:

Discard the copper washers, do not reuse.

5. Apply matching marks to disc rotor and wheel hub assembly if the disc rotor is to be reused, then remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

INSTALLATION

1. If reusing the disc rotor, use the matching marks to align disc rotor on the wheel hub assembly, then install

disc rotor using a wheel nut to hold it in place.

CAUTION:

Use matching marks on wheel hub assembly and di sc rotor if the disc rotor is to be reused.

2. Install cylinder body and tighten cylinder body bolts to specification. CAUTION:

Before installing cylinder body to the vehic le, wipe off mating surface of cylinder body.

3. Install brake hose to cylinder body with new copper washers and tighten union bolt to specification.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed. Refer to BR-17, "

Bleeding

Brake System".

5. Check rear disc brake for drag and correct as necessary.

6. Install rear wheel and tire. Refer to WT-49, "

Rotation".

13. Sliding sleeveB. Brake fluid R. Rubber grease

M. Molykote M-77 Front

LFIA0211E

SFIA1137E

Revision: April 20092010 QX56

Page 495 of 4210

BRC-3

C

DE

G H

I

J

K L

M A

B

BRC

N

O P

C1185 ICC UNIT .................................................77

Description .......................................................... ....77

DTC Logic ...............................................................77

Diagnosis Procedure ...............................................77

Special Repair Requirement ...................................78

U1000 CAN COMM CIRCUIT .............................79

Description .......................................................... ....79

DTC Logic ...............................................................79

Diagnosis Procedure ...............................................79

VDC OFF SWITCH .............................................80

Description .......................................................... ....80

Component Function Check ....................................80

Diagnosis Procedure ...............................................80

Component Inspection ............................................81

Special Repair Requirement ...................................81

ABS WARNING LAMP ................................... ....82

Description .......................................................... ....82

Component Function Check ....................................82

Diagnosis Procedure ...............................................82

Special Repair Requirement ...................................82

BRAKE WARNING LAMP ............................. ....83

Description .......................................................... ....83

Component Function Check ....................................83

Diagnosis Procedure ...............................................83

Special Repair Requirement ...................................83

VDC OFF INDICATOR LAMP ........................ ....84

Description .......................................................... ....84

Component Function Check ....................................84

Diagnosis Procedure ...............................................84

Special Repair Requirement ...................................85

SLIP INDICATOR LAMP ................................ ....86

Description .......................................................... ....86

Component Function Check ....................................86

Diagnosis Procedure ...............................................86

Special Repair Requirement ...................................86

ECU DIAGNOSIS ........... ..............................87

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .......................................... ....

87

Reference Value ................................................. ....87

Wiring Diagram - BRAKE CONTROL SYSTEM - ....92

Fail-Safe ..................................................................99

DTC No. Index ......................................................100

SYMPTOM DIAGNOSIS ............................102

VDC/TCS/ABS ................................................ ..102

Symptom Table ................................................... ..102

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY ...................................................

103

Diagnosis Procedure ........................................... ..103

UNEXPECTED PEDAL REACTION ...............104

Diagnosis Procedure .............................................104

THE BRAKING DISTANCE IS LONG .............105

Diagnosis Procedure .............................................105

ABS FUNCTION DOES NOT OPERATE .......106

Diagnosis Procedure .............................................106

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS ...........................................

107

Diagnosis Procedure ........................................... ..107

VEHICLE JERKS DURING VDC/TCS/ABS

CONTROL .......................................................

108

Diagnosis Procedure .............................................108

NORMAL OPERATING CONDITION .............109

Description .............................................................109

PRECAUTION ............................................110

PRECAUTIONS ...............................................110

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

110

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

110

Precaution for Brake System .................................111

Precaution for Brake Control .................................111

Precaution for CAN System ...................................112

PREPARATION .........................................113

PREPARATION ...............................................113

Special Service Tool ............................................ ..113

Commercial Service Tool ......................................113

REMOVAL AND INSTALLATION .............114

WHEEL SENSORS .........................................114

Removal and Installation ..................................... ..114

SENSOR ROTOR ............................................115

Removal and Installation .......................................115

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ................................................................

116

Removal and Installation .......................................116

STEERING ANGLE SENSOR .........................118

Removal and Installation .......................................118

G SENSOR ......................................................119

Removal and Installation .......................................119

Revision: April 20092010 QX56