brake sensor INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1820 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-18

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

SYSTEM

SYSTEM

4WD SYSTEM

4WD SYSTEM : System DescriptionINFOID:0000000006222224

In AUTO mode, distribution of traction force is cont

rolled from 2WD INFINITI QX56 2011 Factory Service Manual

DLN-18

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

SYSTEM

SYSTEM

4WD SYSTEM

4WD SYSTEM : System DescriptionINFOID:0000000006222224

In AUTO mode, distribution of traction force is cont

rolled from 2WD](/img/42/57033/w960_57033-1819.png)

DLN-18

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

SYSTEM

SYSTEM

4WD SYSTEM

4WD SYSTEM : System DescriptionINFOID:0000000006222224

In AUTO mode, distribution of traction force is cont

rolled from 2WD status (0:100) to 4WD status (50:50)

according to signal from each sensor and switch.

In accordance with fail-safe function, when system is malfunctioning, 4WD warning lamp on combination meter turns ON and 4WD control stops. For fail-safe function, refer to DLN-20, "

4WD SYSTEM : Fail-Safe".

When a high load status continues for transfer assembly (transfer control actuator or transfer fluid), 4WD

control temporarily becomes 4H or 2WD status, according to protection function.

NOTE:

4WD system is not malfunctioning.

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL

It transmits/receives each signal from the followi ng transfer control unit via CAN communication line.

JPDIE0272GB

Component parts Control signal

ABS actuator and electric unit (control unit) Transmits the following signals via CAN communication line to transfer control unit.

Vehicle spee

d signal (ABS)

Stop lamp switch signal (brake signal)

ABS operation signal

VDC operation signal

TCS operation signal

ECM Transmits the following signals via CAN communication line to transfer control unit.

Accelerator pedal position signal

Engine speed signal

Engine torque signal

Revision: 2010 May2011 QX56

Page 1821 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMDLN-19

< SYSTEM DESCRIPTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD SHIFT SWITCH AND 4WD SHIFT INDICATOR LAMP

*1: Blinking 2 times/1 second

*2: “4HI” and “4LO” blink a INFINITI QX56 2011 Factory Service Manual

SYSTEMDLN-19

< SYSTEM DESCRIPTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD SHIFT SWITCH AND 4WD SHIFT INDICATOR LAMP

*1: Blinking 2 times/1 second

*2: “4HI” and “4LO” blink a](/img/42/57033/w960_57033-1820.png)

SYSTEMDLN-19

< SYSTEM DESCRIPTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD SHIFT SWITCH AND 4WD SHIFT INDICATOR LAMP

*1: Blinking 2 times/1 second

*2: “4HI” and “4LO” blink alternately.

CONDITION FOR TURN ON THE WARNING LAMP

TCM Transmits the following signals via CAN communication line to transfer control unit.

Shift position signal

Gear position signal

Output shaft revolution signal

Steering angle sensor Transmits the following signals via CAN communication line to transfer control unit.

Steering angle sensor signal

Combination meter Receives the following signals via CAN communication line from transfer control unit.

4WD warning lamp signal

ATP warning lamp signal

4WD mode indicator signal

Component parts Control signal

4WD shift switch 4WD shift indicator lamp (in Information display) 4WD shift procedure

AUTO

1. Start the engine.

2. Turn the 4WD shift switch.

NOTE:

Mode can be switched between AU-

TO⇔4H while driving straight.

4H

↓↑

4WD status: 4H ⇔4L (Blinking)

*1*2

1. Start the engine.

2. Never drive the vehicle.

3. Shift A/T shift selector to N position.

4. Press and rotate 4WD shift switch

while depressing brake pedal.

CAUTION:

4WD mode does not switch when 4WD

shift switch is operated while the vehi-

cle is running or A/T shift selector is

shifted to any position other than neu-

tral.

4L

JPDIE0230ZZJPDIE0234ZZ

JPDIE0231ZZJPDIE0235ZZ

JPDIE0231ZZ

JPDIE0233ZZ

JPDIE0236ZZ

JPDIE0233ZZJPDIE0237ZZ

Revision: 2010 May2011 QX56

Page 2025 of 5598

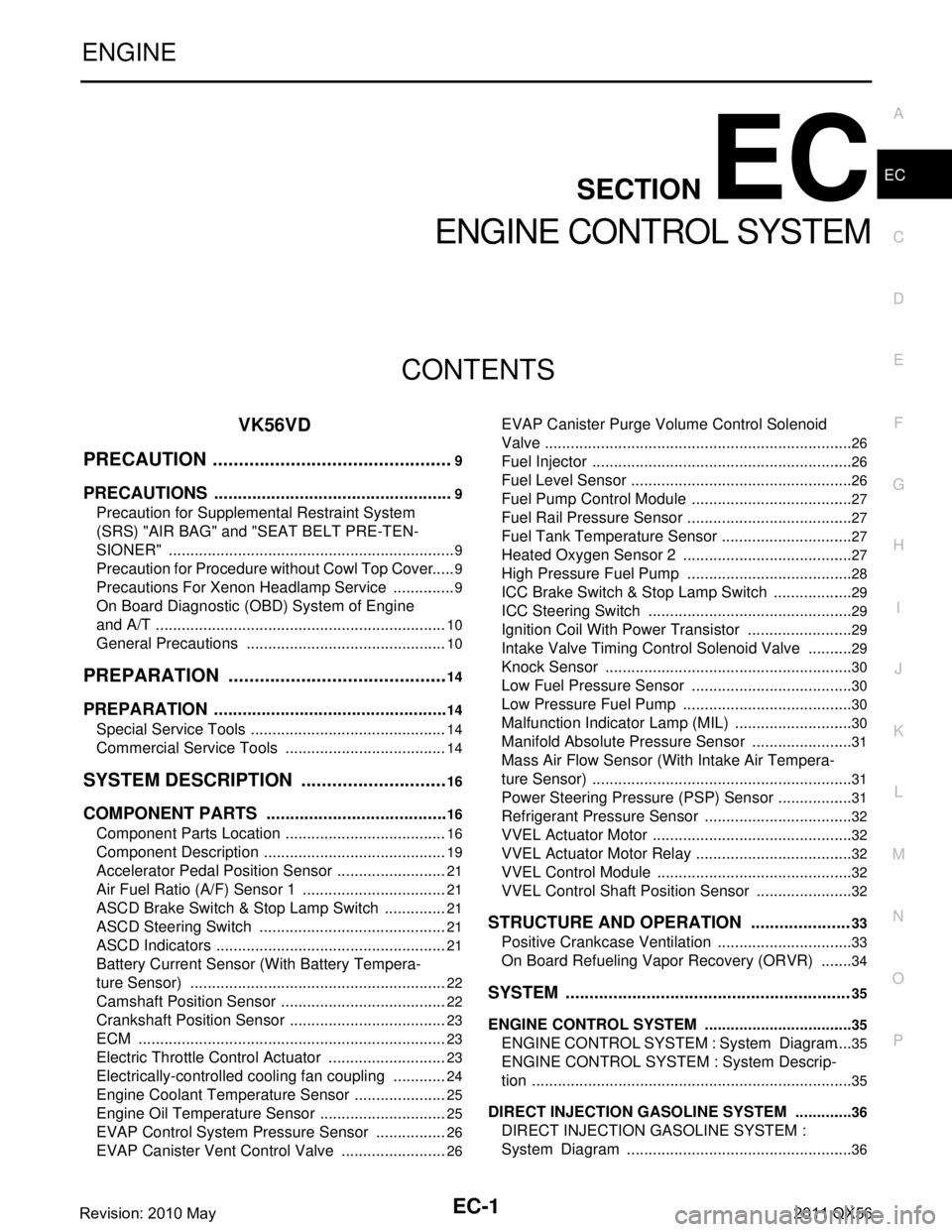

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VK56VD

PRECAUTION ................ ...............................

9

PRECAUTIONS .............................................. .....9

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

9

Precaution for Procedure without Cowl Top Cover ......9

Precautions For Xenon Headlamp Service ...............9

On Board Diagnostic (OBD) System of Engine

and A/T ....................................................................

10

General Precautions ...............................................10

PREPARATION ...........................................14

PREPARATION .............................................. ....14

Special Service Tools .......................................... ....14

Commercial Service Tools ......................................14

SYSTEM DESCRIPTION .............................16

COMPONENT PARTS ................................... ....16

Component Parts Location .................................. ....16

Component Description ...........................................19

Accelerator Pedal Position Sensor ..........................21

Air Fuel Ratio (A/F) Sensor 1 ..................................21

ASCD Brake Switch & Stop Lamp Switch ...............21

ASCD Steering Switch ............................................21

ASCD Indicators ......................................................21

Battery Current Sensor (With Battery Tempera-

ture Sensor) ............................................................

22

Camshaft Position Sensor .......................................22

Crankshaft Position Sensor .....................................23

ECM ........................................................................23

Electric Throttle Control Actuator ............................23

Electrically-controlled cooling fan coupling .............24

Engine Coolant Temperature Sensor ......................25

Engine Oil Temperature Sensor ..............................25

EVAP Control System Pressure Sensor .................26

EVAP Canister Vent Control Valve .........................26

EVAP Canister Purge Volume Control Solenoid

Valve .................................................................... ....

26

Fuel Injector .............................................................26

Fuel Level Sensor ....................................................26

Fuel Pump Control Module ......................................27

Fuel Rail Pressure Sensor .......................................27

Fuel Tank Temperature Sensor ...............................27

Heated Oxygen Sensor 2 ........................................27

High Pressure Fuel Pump .......................................28

ICC Brake Switch & Stop Lamp Switch ...................29

ICC Steering Switch ................................................29

Ignition Coil With Power Transistor .........................29

Intake Valve Timing Control Solenoid Valve ...........29

Knock Sensor ...................................................... ....30

Low Fuel Pressure Sensor ......................................30

Low Pressure Fuel Pump ........................................30

Malfunction Indicator Lamp (MIL) ............................30

Manifold Absolute Pressure Sensor ........................31

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) .............................................................

31

Power Steering Pressure (PSP) Sensor ..................31

Refrigerant Pressure Sensor ............................... ....32

VVEL Actuator Motor ...............................................32

VVEL Actuator Motor Relay .....................................32

VVEL Control Module ..............................................32

VVEL Control Shaft Position Sensor .......................32

STRUCTURE AND OPERATION .....................33

Positive Crankcase Ventilation ................................33

On Board Refueling Vapor Recovery (ORVR) ........34

SYSTEM ............................................................35

ENGINE CONTROL SYSTEM ........................ ...........35

ENGINE CONTROL SYSTEM : System Diagram ....35

ENGINE CONTROL SYSTEM : System Descrip-

tion ...........................................................................

35

DIRECT INJECTION GASOLINE SYSTEM .......... ....36

DIRECT INJECTION GASOLINE SYSTEM :

System Diagram .....................................................

36

Revision: 2010 May2011 QX56

Page 2031 of 5598

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

P1553 BATTERY CURRENT SENSOR ......... ..420

DTC Logic ........................................................... ..420

Diagnosis Procedure .............................................420

Component Inspection (Battery Current Sensor) ..423

P1554 BATTERY CURRENT SENSOR ...........424

DTC Logic ........................................................... ..424

Component Function Check ..................................424

Diagnosis Procedure .............................................425

Component Inspection (Battery Current Sensor) ..427

P1556, P1557 BATTERY TEMPERATURE

SENSOR ...........................................................

428

DTC Logic ........................................................... ..428

Diagnosis Procedure .............................................428

Component Inspection (Battery Temprature Sen-

sor) ........................................................................

430

P1564 ASCD STEERING SWITCH ..................431

DTC Logic ........................................................... ..431

Diagnosis Procedure .............................................431

Component Inspection (ASCD Steering Switch) ...433

P1564 ICC STEERING SWITCH ......................434

DTC Logic ........................................................... ..434

Diagnosis Procedure .............................................434

Component Inspection (ICC Steering Switch) .......436

P1568 ICC FUNCTION .....................................437

DTC Logic ........................................................... ..437

Diagnosis Procedure .............................................437

P1572 ASCD BRAKE SWITCH .......................438

DTC Logic ........................................................... ..438

Diagnosis Procedure .............................................439

Component Inspection (ASCD Brake Switch) .......442

Component Inspection (Stop Lamp Switch) ..........442

P1572 ICC BRAKE SWITCH ...........................443

DTC Logic ........................................................... ..443

Diagnosis Procedure .............................................444

Component Inspection (ICC Brake Switch) ...........445

Component Inspection (Stop Lamp Switch) ..........446

P1574 ASCD VEHICLE SPEED SENSOR ......447

Description .......................................................... ..447

DTC Logic .............................................................447

Diagnosis Procedure .............................................447

P1574 ICC VEHICLE SPEED SENSOR ..........449

Description .......................................................... ..449

DTC Logic .............................................................449

Diagnosis Procedure .............................................449

P1606 VVEL CONTROL MODULE ..................451

DTC Logic ........................................................... ..451

Diagnosis Procedure .............................................451

P1607 VVEL CONTROL MODULE ..................452

DTC Logic ........................................................... ..452

Diagnosis Procedure .............................................452

P1608 VVEL SENSOR POWER SUPPLY ......453

DTC Logic ............................................................ ..453

Diagnosis Procedure .............................................453

P1805 BRAKE SWITCH .................................455

DTC Logic ..............................................................455

Diagnosis Procedure .............................................455

Component Inspection (Stop Lamp Switch) ..........456

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ....................................................

458

DTC Logic ..............................................................458

Diagnosis Procedure .............................................458

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ......................................................

460

Description ........................................................... ..460

DTC Logic ..............................................................460

Diagnosis Procedure .............................................460

Component Inspection ...........................................462

Special Repair Requirement ..................................463

P2118 THROTTLE CONTROL MOTOR .........464

DTC Logic ..............................................................464

Diagnosis Procedure .............................................464

Component Inspection (Electric Throttle Control

Motor) ....................................................................

465

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR .....................................................

466

DTC Logic ..............................................................466

Diagnosis Procedure .............................................466

P2122, P2123 APP SENSOR .........................468

DTC Logic ..............................................................468

Diagnosis Procedure .............................................468

Component Inspection (Accelerator Pedal Posi-

tion Sensor) ...........................................................

470

P2127, P2128 APP SENSOR .........................471

DTC Logic ..............................................................471

Diagnosis Procedure .............................................471

Component Inspection (Accelerator Pedal Posi-

tion Sensor) ...........................................................

474

P2135 TP SENSOR .........................................475

DTC Logic ..............................................................475

Diagnosis Procedure .............................................475

Component Inspection (Throttle Position Sensor) ..476

P2138 APP SENSOR ......................................478

DTC Logic ..............................................................478

Diagnosis Procedure .............................................478

Component Inspection (Accelerator Pedal Posi-

tion Sensor) ...........................................................

481

P2539, P2541, P2542 LOW FUEL PRES-

SURE SENSOR ...............................................

483

DTC Logic ..............................................................483

Diagnosis Procedure .............................................483

Component Inspection ...........................................485

Revision: 2010 May2011 QX56

Page 2032 of 5598

EC-8

P2A00, P2A03 A/F SENSOR 1 .......................487

DTC Logic ............................................................ ..487

Diagnosis Procedure .............................................487

ASCD BRAKE SWITCH ................................. .490

Component Function Check ................................ ..490

Diagnosis Procedure .............................................490

Component Inspection (ASCD Brake Switch) .......491

ASCD INDICATOR ..........................................492

Component Function Check ................................ ..492

Diagnosis Procedure .............................................492

ELECTRICAL LOAD SIGNAL .........................493

Description ........................................................... ..493

Component Function Check ..................................493

Diagnosis Procedure .............................................493

ELECTRICALLY-CONTROLLED COOLING

FAN COUPLING ..............................................

495

Component Function Check ................................ ..495

Diagnosis Procedure .............................................495

FUEL INJECTOR .............................................498

Component Function Check ................................ ..498

Diagnosis Procedure .............................................498

Component Inspection ...........................................499

HIGH PRESSURE FUEL PUMP ......................501

Component Function Check ................................ ..501

Diagnosis Procedure .............................................501

Component Inspection ...........................................502

ICC BRAKE SWITCH ......................................503

Component Function Check ................................ ..503

Diagnosis Procedure .............................................503

Component Inspection (ICC Brake Switch) ...........505

IGNITION SIGNAL ...........................................506

Component Function Check ................................ ..506

Diagnosis Procedure .............................................506

Component Inspection (Ignition Coil with Power

Transistor) .............................................................

509

Component Inspection (Condenser) ......................510

INFORMATION DISPLAY (ASCD) ..................511

Component Function Check ................................ ..511

Diagnosis Procedure .............................................511

LOW PRESSURE FUEL PUMP ......................512

Component Function Check ................................ ..512

Diagnosis Procedure .............................................512

Component Inspection (Low Pressure Fuel Pump)

..

513

Component Inspection (FPCM) .............................514

MALFUNCTION INDICATOR LAMP ...............515

Component Function Check ................................ ..515

Diagnosis Procedure .............................................515

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

516

Component Function Check ................................ .516

Diagnosis Procedure .............................................516

Component Inspection (EVAP Vapor Cut Valve) . .518

REFRIGERANT PRESSURE SENSOR ......... ..520

Component Function Check ................................ .520

Diagnosis Procedure .............................................520

SNOW MODE SWITCH ....................................522

Description ........................................................... .522

Component Function Check .................................522

Diagnosis Procedure .............................................522

Component Inspection ..........................................523

SYMPTOM DIAGNOSIS ...........................524

ENGINE CONTROL SYSTEM SYMPTOMS .. ..524

Symptom Table .................................................... .524

NORMAL OPERATING CONDITION ...............529

Description ........................................................... .529

PERIODIC MAINTENANCE ......................530

IDLE SPEED .......................... ...........................530

Inspection ............................................................. .530

IGNITION TIMING .............................................531

Inspection ............................................................. .531

EVAP LEAK CHECK ........................................532

Inspection ............................................................. .532

POSITIVE CRANKCASE VENTILATION .........534

Inspection ............................................................. .534

REMOVAL AND INSTALLATION .............535

ECM ................................................................ ..535

Removal and Installation ...................................... .535

VVEL CONTROL MODULE .............................536

Removal and Installation ...................................... .536

FUEL PUMP CONTROL MODULE (FPCM) ....537

Removal and Installation ...................................... .537

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

538

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

538

Idle Speed ............................................................ .538

Ignition Timing .......................................................538

Calculated Load Value ..........................................538

Mass Air Flow Sensor ...........................................538

Revision: 2010 May2011 QX56

Page 2043 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEC-19

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000006217657

1. ASCD steering switch

ICC steering switch 2. Snow mode switch 3. Fu INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEC-19

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000006217657

1. ASCD steering switch

ICC steering switch 2. Snow mode switch 3. Fu](/img/42/57033/w960_57033-2042.png)

COMPONENT PARTSEC-19

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000006217657

1. ASCD steering switch

ICC steering switch 2. Snow mode switch 3. Fuel level sensor unit and fuel pump

assembly (with fuel tank temperature

sensor)

4. Fuel pump control module (FPCM) 5. EVAP canister vent control valve 6. EVAP canister

7. EVAP control system pressure sen- sor 8. Stop lamp switch 9. ASCD brake switch

ICC brake switch

10. Accelerator pedal position sensor

JSBIA0606ZZ

Component Reference

ECM EC-23, "

ECM"

Malfunction indicator lamp (MIL)EC-30, "Malfunction Indicator Lamp (MIL)"

Ignition coil with power transistorEC-29, "Ignition Coil With Power Transistor"

Accelerator pedal position sensorEC-21, "Accelerator Pedal Position Sensor"

Mass air flow sensor

EC-31, "Mass Air Flow Sensor (With Intake Air Temperature Sen-

sor)"Intake air temperature sensor

Electric throttle control actuator

EC-23, "

Electric Throttle Control Actuator"Throttle control motor relay

Throttle control motor

Throttle position sensor

Crankshaft position sensorEC-23, "

Crankshaft Position Sensor"

Camshaft position sensorEC-22, "Camshaft Position Sensor"

Engine coolant temperature sensorEC-25, "Engine Coolant Temperature Sensor"

Revision: 2010 May2011 QX56

Page 2044 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-20

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

High pressure fuel pump

EC-28, "High Pressure Fuel Pump"

Low pressure fuel pumpEC-30, "Low Pressure Fuel Pump"

Fuel pump control module (FPCM)EC-2 INFINITI QX56 2011 Factory Service Manual

EC-20

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

High pressure fuel pump

EC-28, "High Pressure Fuel Pump"

Low pressure fuel pumpEC-30, "Low Pressure Fuel Pump"

Fuel pump control module (FPCM)EC-2](/img/42/57033/w960_57033-2043.png)

EC-20

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

High pressure fuel pump

EC-28, "High Pressure Fuel Pump"

Low pressure fuel pumpEC-30, "Low Pressure Fuel Pump"

Fuel pump control module (FPCM)EC-27, "Fuel Pump Control Module"

Fuel rail pressure sensorEC-27, "Fuel Rail Pressure Sensor"

Low fuel pressure sensorEC-30, "Low Fuel Pressure Sensor"

Fuel injectorEC-26, "Fuel Injector"

Fuel level sensorEC-26, "Fuel Level Sensor"

Fuel tank temperature sensorEC-27, "Fuel Tank Temperature Sensor"

A/F sensor 1

EC-21, "Air Fuel Ratio (A/F) Sensor 1"A/F sensor 1 heater

Heated oxygen sensor 2EC-27, "

Heated Oxygen Sensor 2"Heated oxygen sensor 2 heater

Manifold absolute pressure sensorEC-31, "

Manifold Absolute Pressure Sensor"

Knock sensorEC-30, "Knock Sensor"

Engine oil temperature sensorEC-25, "Engine Oil Temperature Sensor"

Power steering pressure sensorEC-31, "Power Steering Pressure (PSP) Sensor"

Electrically-controlled cooling fan coupling EC-24, "Electrically-controlled cooling fan coupling"

Intake valve timing control solenoid valveEC-29, "Intake Valve Timing Control Solenoid Valve"

VVEL control moduleEC-32, "VVEL Control Module"

VVEL actuator motor relayEC-32, "VVEL Actuator Motor Relay"

VVEL actuator motorEC-32, "VVEL Actuator Motor"

VVEL control shaft position sensor EC-32, "VVEL Control Shaft Position Sensor"

EVAP control system pressure sensor EC-26, "EVAP Control System Pressure Sensor"

EVAP canister vent control valveEC-26, "EVAP Canister Vent Control Valve"

EVAP canister purge volume control solenoid valveEC-26, "EVAP Canister Purge Volume Control Solenoid Valve"

Battery current sensor (with battery temperature sensor)EC-22, "Battery Current Sensor (With Battery Temperature Sen-

sor)"

Refrigerant pressure sensor

EC-32, "Refrigerant Pressure Sensor"

Stop lamp switch

EC-21, "ASCD Brake Switch & Stop Lamp Switch"ASCD brake switch

ASCD steering switchEC-21, "

ASCD Steering Switch"

Information displayEC-49, "AUTMATIC SPEED CONTROL DEVICE (ASCD) : Switch

Name and Function"

Stop lamp switch

EC-29, "ICC Brake Switch & Stop Lamp Switch"ICC brake switch

ICC steering switchEC-29, "

ICC Steering Switch"

Component Reference

Revision: 2010 May2011 QX56

Page 2045 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEC-21

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Accelerator Pedal

Position SensorINFOID:0000000006217658

The accelerator pedal position (APP) sensor is installed INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEC-21

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Accelerator Pedal

Position SensorINFOID:0000000006217658

The accelerator pedal position (APP) sensor is installed](/img/42/57033/w960_57033-2044.png)

COMPONENT PARTSEC-21

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Accelerator Pedal

Position SensorINFOID:0000000006217658

The accelerator pedal position (APP) sensor is installed on the

accelerator pedal assembly. The sensor detects the accelerator

position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometer which transform the accelerator pedal

position into output voltage, and emit the voltage signals to the ECM.

The ECM judges the current opening angle of the accelerator pedal

from these signals and controls the throttle control motor based on

these signals.

Idle position of the accelerator pedal is determined by the ECM

receiving the signal from the accelerator pedal position sensor. The

ECM uses this signal for engine operations such as fuel cut.

Air Fuel Ratio (A/F) Sensor 1INFOID:0000000006217659

DESCRIPTION

The sensor element of the A/F sensor 1 is composed an electrode layer, which transports ions. It has a heater

in the element.

The sensor is capable of precise measurement = 1, but also in the lean and rich range. Together with its

control electronics, the sens or outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at the sensor cell. An electrode layer is

applied voltage, and this current relative oxygen density in lean. Also this current relative hydrocarbon density

in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of approxi-

mately 760 °C (1,400 °F).

A/F SENSOR 1 HEATER

A/F sensor 1 heater is integrated in the sensor.

The ECM performs ON/OFF duty control of the A/F sensor 1 heater corresponding to the engine operating

condition to keep the temperature of A/F s ensor 1 element within the specified range.

ASCD Brake Switch & Stop Lamp Switch INFOID:0000000006217660

Stop lamp switch and ASCD brake switch are installed to brake pedal bracket.

When the brake pedal is depressed, ASCD brake switch is turned OFF and stop lamp switch is turned ON.

ECM detects the state of the brake pedal by those two types of input (ON/OFF signal).

ASCD Steering SwitchINFOID:0000000006217661

ASCD steering switch has variant values of electrical resistance for each button. ECM reads voltage variation

of switch, and determines which button is operated.

ASCD IndicatorsINFOID:0000000006217662

ASCD operation status is indicated by CRUISE indicator in combination meter.

ECM transmits the ASCD status signal to the combi nation meter via CAN communication according to ASCD

operation.

PBIB1741E

JSBIA0527GB

Revision: 2010 May2011 QX56

Page 2072 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-48

< SYSTEM DESCRIPTION >[VK56VD]

SYSTEM

AUTOMATIC SPEED CONTROL DEVI CE (ASCD) : System Diagram

INFOID:0000000006217715

AUTOMATIC SPEED CONTROL DEVICE (ASCD) : System DescriptionINFOID:000000000 INFINITI QX56 2011 Factory Service Manual

EC-48

< SYSTEM DESCRIPTION >[VK56VD]

SYSTEM

AUTOMATIC SPEED CONTROL DEVI CE (ASCD) : System Diagram

INFOID:0000000006217715

AUTOMATIC SPEED CONTROL DEVICE (ASCD) : System DescriptionINFOID:000000000](/img/42/57033/w960_57033-2071.png)

EC-48

< SYSTEM DESCRIPTION >[VK56VD]

SYSTEM

AUTOMATIC SPEED CONTROL DEVI CE (ASCD) : System Diagram

INFOID:0000000006217715

AUTOMATIC SPEED CONTROL DEVICE (ASCD) : System DescriptionINFOID:0000000006217716

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM via the CAN communication line

BASIC ASCD SYSTEM

Automatic Speed Control Device (ASCD) allows a dr iver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can be set the vehicle speed in the set speed range.

ECM controls throttle angle of electric th rottle control actuator to regulate engine speed.

Operation status of ASCD is indicated in combination meter.

If any malfunction occurs in the ASCD system, it automatically deactivates the ASCD control.

Refer to EC-49, "

AUTMATIC SPEED CONTROL DEVICE (A SCD) : Switch Name and Function" for ASCD

operating instructions.

CAUTION:

Always drive vehicle in a safe manner according to traffic conditions and obey all traffic laws.

CAN COMMUNICATION

CAN COMMUNICATION : System DescriptionINFOID:0000000006217718

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Refer to LAN-28, "

CAN COMMUNICATION SYSTEM : CAN Communication Signal Chart", about CAN com-

munication for detail.

JPBIA3272GB

Sensor Input signal to ECM ECM function Actuator

ASCD steering switch ASCD steering switch operation

ASCD vehicle speed control Electric throttle control ac-

tuator

Combination meter

ASCD brake switch

Brake pedal operation

Sto p l am p s w it ch

TCM Park/neutral position signal

Output shaft revolution signal*

Combination meter Vehicle speed signal*

Revision: 2010 May2011 QX56

Page 2091 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger](/img/42/57033/w960_57033-2090.png)

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFF Indicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the blower fan

ON signal.

BRAKE SW ON/OFF Indicates [ON/OFF] condition from the stop lamp

switch signal.

IGN TIMING BTDC Indicates the ignition timing computed by ECM ac-

cording to the input signals. When the engine is stopped,

a certain value is indicated.

COMBUSTION — These items are displayed but are not applicable to

this model.

CAL/LD VALUE % “Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW g/s Indicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V % Indicates the EVAP canister purge volume control

solenoid valve control value computed by the ECM

according to the input signals.

The opening becomes larger as the value increas-

es.

INT/V SOL (B1)

% The control value of the intake valve timing control

solenoid valve (determined by ECM according to

the input signals) is indicated.

The advance angle becomes larger as the value increases.

INT/V SOL (B2)

AIR COND RLY ON/OFF

The air conditioner relay control condition (deter-

mined by ECM according to the input signals) is in-

dicated.

VENT CONT/V ON/OFF The control condition of the EVAP canister vent

control valve (determined by ECM according to the

input signals) is indicated.

ON: Closed

OFF: Open

THRTL RELAY ON/OFF Indicates the throttle co

ntrol motor relay control

condition determined by the ECM according to the

input signals.

A/F S1 HTR (B1)

% Air fuel ratio (A/F) sensor 1 heater control value

computed by ECM according to the input signals.

The current flow to the heater becomes larger as the value increases.

A/F S1 HTR (B2)

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals.

HO2S2 HTR (B2)

ALT DUTY SIG ON/OFF The control condition of the power generation volt-

age variable control (determined by ECM accord-

ing to the input signals) is indicated.

ON: Power generation voltage variable control is

active.

OFF: Power generation voltage variable control is

inactive.

I/P PULLY SPD rpm Indicates the engine speed computed from the in-

put speed sensor signal.

Monitored item Unit Description Remarks

Revision: 2010 May2011 QX56