service INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2419 of 5598

![INFINITI QX56 2011 Factory Service Manual

P1091 VVEL ACTUATOR MOTOR RELAYEC-395

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace.

9.REPLACE VVEL CONTR INFINITI QX56 2011 Factory Service Manual

P1091 VVEL ACTUATOR MOTOR RELAYEC-395

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace.

9.REPLACE VVEL CONTR](/img/42/57033/w960_57033-2418.png)

P1091 VVEL ACTUATOR MOTOR RELAYEC-395

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace.

9.REPLACE VVEL CONTROL MODULE

1. Replace VVEL control module.

2. Perform additional service when replacing VVEL control module. Refer to EC-144, "

Work Procedure".

>> GO TO 10.

10.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Erase DTC.

3. Perform DTC Confirmation Procedure. See EC-393, "

DTC Logic".

Is the DTC P1091 displayed again?

YES >> Replace ECM. Refer to EC-535, "Removal and Installation".

NO >> INSPECTION END

Component Inspection (VVE L Actuator Motor Relay)INFOID:0000000006217902

1.CHECK VVEL ACTUATOR MOTOR RELAY

1. Turn ignition switch OFF.

2. Remove VVEL actuator motor relay.

3. Check the continuity between VVEL actuator motor relay termi- nals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace VVEL actuator motor relay.

Terminal Condition Continuity 3 and 5 12V direct current supply between

terminals 1 and 2

Existed

No current supply Not existed

JMBIA0876ZZ

Revision: 2010 May2011 QX56

Page 2513 of 5598

![INFINITI QX56 2011 Factory Service Manual

P2A00, P2A03 A/F SENSOR 1EC-489

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Rep INFINITI QX56 2011 Factory Service Manual

P2A00, P2A03 A/F SENSOR 1EC-489

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Rep](/img/42/57033/w960_57033-2512.png)

P2A00, P2A03 A/F SENSOR 1EC-489

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

8.CHECK A/F SENSOR 1 HEATER

Refer to EC-182, "

Component Inspection (A/F Sensor 1 Heater)".

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 10.

9.CHECK INTERMITTENT INCIDENT

Perform GI-40, "

Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 10.

NO >> Repair or replace malfunctioning part.

10.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to EX-5, "

Exploded View".

CAUTION:

Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

Before installing new A/F senso r, clean exhaust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant

(commercial service tool).

Will CONSULT-III be used?

YES >> GO TO 11.

NO >> GO TO 12.

11 .CONFIRM A/F ADJUSTMENT DATA

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR” mode with CONSULT-III.

3. Check that “0.000” is di splayed on CONSULT-III screen.

Is

“0.000” displayed?

YES >> INSPECTION END

NO >> GO TO 12.

12.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

Clear the mixture ratio self-learning value. Refer to EC-152, "

Work Procedure".

Will CONSULT-III be used?

YES >> GO TO 13.

NO >> INSPECTION END

13.CONFIRM A/F ADJUSTMENT DATA

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR” mode with CONSULT-III.

3. Check that “0.000” is di splayed on CONSULT-III screen.

>> INSPECTION END

DTC A/F sensor 1 ECM

Continuity

Bank Connector Terminal Connector Terminal

P2A00 1 F67 6 F11094

Existed

P2A03 2 F68 6 74

Revision: 2010 May2011 QX56

Page 2554 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-530

< PERIODIC MAINTENANCE >[VK56VD]

IDLE SPEED

PERIODIC MAINTENANCE

IDLE SPEED

InspectionINFOID:0000000006218030

1.CHECK IDLE SPEED

WITH CONSULT-III

Check idle speed in “DATA MONITOR” mode w INFINITI QX56 2011 Factory Service Manual

EC-530

< PERIODIC MAINTENANCE >[VK56VD]

IDLE SPEED

PERIODIC MAINTENANCE

IDLE SPEED

InspectionINFOID:0000000006218030

1.CHECK IDLE SPEED

WITH CONSULT-III

Check idle speed in “DATA MONITOR” mode w](/img/42/57033/w960_57033-2553.png)

EC-530

< PERIODIC MAINTENANCE >[VK56VD]

IDLE SPEED

PERIODIC MAINTENANCE

IDLE SPEED

InspectionINFOID:0000000006218030

1.CHECK IDLE SPEED

WITH CONSULT-III

Check idle speed in “DATA MONITOR” mode with CONSULT-III.

WITH GST

Check idle speed with Service $01 of GST.

>> INSPECTION END

Revision: 2010 May2011 QX56

Page 2556 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-532

< PERIODIC MAINTENANCE >[VK56VD]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000006267340

CAUTION:

Do not use compressed air or a high pressure pump.

Do not exceed 4.12 kPa (0.042 INFINITI QX56 2011 Factory Service Manual

EC-532

< PERIODIC MAINTENANCE >[VK56VD]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000006267340

CAUTION:

Do not use compressed air or a high pressure pump.

Do not exceed 4.12 kPa (0.042](/img/42/57033/w960_57033-2555.png)

EC-532

< PERIODIC MAINTENANCE >[VK56VD]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000006267340

CAUTION:

Do not use compressed air or a high pressure pump.

Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in EVAP system.

NOTE:

Do not start engine.

Improper installation of EVAP service port adapter (com mercial service tool) to the EVAP service port may

cause a leak.

WITH CONSULT-III

1. To locate the EVAP leak, install EVAP service port adapter (com- mercial service tool) and pressure pump to EVAP service port.

2. Turn ignition switch ON.

3. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

4. Touch “START”. A bar graph (Pressure indicating display) will appear on the screen.

5. Apply positive pressure to the EVAP system until the pressure indicator reaches the middle of the bar graph.

6. Remove EVAP service port adapter (commercial service tool) and hose with pressure pump.

7. Locate the leak using a leak detector (commercial service tool). Refer to EC-45, "

EVAPORATIVE EMISSION SYSTEM : System

Diagram".

WITHOUT CONSULT-III

1. To locate the EVAP leak, install EVAP service port adapter (com-

mercial service tool) and pressure pump to EVAP service port.

2. Apply battery voltage between the terminals of EVAP canister vent control valve to ma ke a closed EVAP system.

3. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to 2.76 kPa (0.014 to

0.028 kg/cm

2, 0.2 to 0.4 psi).

4. Remove EVAP service port adapter (commercial service tool) and hose with pressure pump.

SEF462UA

SEF200U

SEF462UA

Revision: 2010 May2011 QX56

Page 2557 of 5598

![INFINITI QX56 2011 Factory Service Manual

EVAP LEAK CHECKEC-533

< PERIODIC MAINTENANCE > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Locate the leak using a leak detector (commercial service tool).

Refer to EC-45, "

EVAPORATIVE EMISSION SYS INFINITI QX56 2011 Factory Service Manual

EVAP LEAK CHECKEC-533

< PERIODIC MAINTENANCE > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Locate the leak using a leak detector (commercial service tool).

Refer to EC-45, "

EVAPORATIVE EMISSION SYS](/img/42/57033/w960_57033-2556.png)

EVAP LEAK CHECKEC-533

< PERIODIC MAINTENANCE > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Locate the leak using a leak detector (commercial service tool).

Refer to EC-45, "

EVAPORATIVE EMISSION SYSTEM : System

Diagram".

SEF200U

Revision: 2010 May2011 QX56

Page 2559 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-535

< REMOVAL AND INSTALLATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

REMOVAL AND INSTALLATION

ECM

Removal and InstallationINFOID:0000000006218034

REMOVAL

1. Remove the battery and battery INFINITI QX56 2011 Factory Service Manual

ECM

EC-535

< REMOVAL AND INSTALLATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

REMOVAL AND INSTALLATION

ECM

Removal and InstallationINFOID:0000000006218034

REMOVAL

1. Remove the battery and battery](/img/42/57033/w960_57033-2558.png)

ECM

EC-535

< REMOVAL AND INSTALLATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

REMOVAL AND INSTALLATION

ECM

Removal and InstallationINFOID:0000000006218034

REMOVAL

1. Remove the battery and battery tray. Refer to

PG-164, "Removal and Installation".

2. Disconnect ECM harness connectors (1) as shown in the figure.

3. Remove ECM bracket bolts (A).

4. Separate ECM (2) and ECM bracket (3).

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Must be perform additi onal service when replacing ECM. Refer to EC-143, "

Work Procedure".

JSBIA0307ZZ

Revision: 2010 May2011 QX56

Page 2560 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-536

< REMOVAL AND INSTALLATION >[VK56VD]

VVEL CONTROL MODULE

VVEL CONTROL MODULE

Removal and InstallationINFOID:0000000006218035

REMOVAL

1. Disconnect VVEL control module harness connector.

2. Rem INFINITI QX56 2011 Factory Service Manual

EC-536

< REMOVAL AND INSTALLATION >[VK56VD]

VVEL CONTROL MODULE

VVEL CONTROL MODULE

Removal and InstallationINFOID:0000000006218035

REMOVAL

1. Disconnect VVEL control module harness connector.

2. Rem](/img/42/57033/w960_57033-2559.png)

EC-536

< REMOVAL AND INSTALLATION >[VK56VD]

VVEL CONTROL MODULE

VVEL CONTROL MODULE

Removal and InstallationINFOID:0000000006218035

REMOVAL

1. Disconnect VVEL control module harness connector.

2. Remove the fix bolts. And then remove VVEL control module.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Must be perform additional

service when replacing VVEL control module. Refer to EC-144, "

Work Pro-

cedure".

Revision: 2010 May2011 QX56

Page 2562 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:000000000621 INFINITI QX56 2011 Factory Service Manual

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:000000000621](/img/42/57033/w960_57033-2561.png)

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000006218038

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Ignition TimingINFOID:0000000006218039

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000006218040

Mass Air Flow SensorINFOID:0000000006218041

*: Engine is warmed up to normal operating temperature and running under no load.Condition Specification

No load* (in P or N position) 600 ± 50 rpm

Condition Specification

No load* (in P or N position) 12 ± 2 °BTDC

Condition Specification (U sing CONSULT-III or GST)

At idle 5 – 35%

At 2,500 rpm 5 – 35%

Supply voltageBattery voltage (11 – 14 V)

Output voltage at idle 0.9 – 1.1 V*

Mass air flow (Using CONSULT-III or GST) 1.0 – 5.0 g/s at idle*

7.0 – 20.0 g/s at 2,500 rpm*

Revision: 2010 May2011 QX56

Page 2563 of 5598

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Drain Engine Coolant and Engine

Oil ..............................................................................

4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Handling High Pressure Fuel Sys-

tem ............................................................................

4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment ..........................................................................

4

Precaution for Assembly and Installation ..................4

Parts Requiring Angle Tightening .............................5

Precaution for Liquid Gasket .....................................5

Definitions of Bank Names ........................................6

PREPARATION ............................................7

PREPARATION .............................................. .....7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................9

BASIC INSPECTION ...................................12

CAMSHAFT VALVE CLEARANCE ............... ....12

Inspection ............................................................ ....12

COMPRESSION PRESSURE ............................16

Inspection ............................................................ ....16

SYMPTOM DIAGNOSIS ..............................18

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

18

NVH Troubleshooting - Engine Noise .............. ....18

Use the Chart Below to Help You Find the C

ause of the Symptom ........................................ ....

19

PERIODIC MAINTENANCE ........................20

DRIVE BELTS ...................................................20

Exploded View ..................................................... ....20

Checking ..................................................................20

Tension Adjustment ................................................20

Removal and Installation .........................................20

Inspection ................................................................21

AIR CLEANER FILTER .....................................22

Exploded View .........................................................22

Removal and Installation .........................................22

SPARK PLUG ...................................................23

Exploded View .........................................................23

Removal and Installation .........................................23

Inspection ................................................................24

REMOVAL AND INSTALLATION ...............25

ENGINE COVER ...............................................25

Exploded View ..................................................... ....25

Removal and Installation .........................................25

DRIVE BELT AUTO TENSIONER AND IDLER

PULLEY .............................................................

26

Exploded View .........................................................26

Removal and Installation .........................................26

AIR CLEANER AND AIR DUCT .......................27

Exploded View .........................................................27

Removal and Installation .........................................27

Inspection ................................................................28

IGNITION COIL .................................................29

Exploded View .........................................................29

Removal and Installation .........................................29

INTAKE MANIFOLD .........................................30

Exploded View .........................................................30

Revision: 2010 May2011 QX56

Page 2564 of 5598

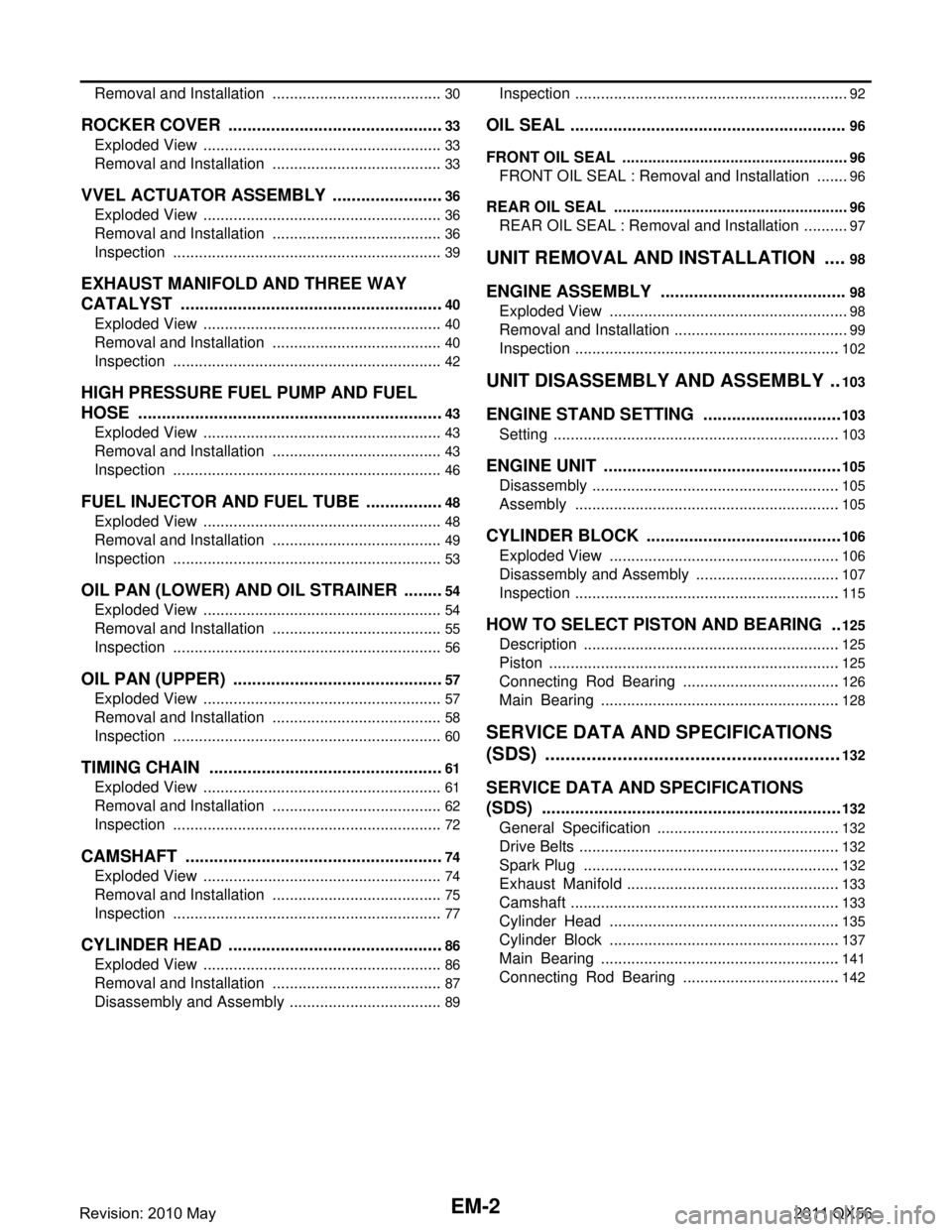

EM-2

Removal and Installation ........................................30

ROCKER COVER ..............................................33

Exploded View ..................................................... ...33

Removal and Installation ........................................33

VVEL ACTUATOR ASSEMBLY ........................36

Exploded View ..................................................... ...36

Removal and Installation ........................................36

Inspection ...............................................................39

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

40

Exploded View ..................................................... ...40

Removal and Installation ........................................40

Inspection ...............................................................42

HIGH PRESSURE FUEL PUMP AND FUEL

HOSE .................................................................

43

Exploded View ..................................................... ...43

Removal and Installation ........................................43

Inspection ...............................................................46

FUEL INJECTOR AND FUEL TUBE .................48

Exploded View ..................................................... ...48

Removal and Installation ........................................49

Inspection ...............................................................53

OIL PAN (LOWER) AND OIL STRAINER .........54

Exploded View ..................................................... ...54

Removal and Installation ........................................55

Inspection ...............................................................56

OIL PAN (UPPER) .......................................... ...57

Exploded View ..................................................... ...57

Removal and Installation ........................................58

Inspection ...............................................................60

TIMING CHAIN ............................................... ...61

Exploded View ..................................................... ...61

Removal and Installation ........................................62

Inspection ...............................................................72

CAMSHAFT .......................................................74

Exploded View ..................................................... ...74

Removal and Installation ........................................75

Inspection ...............................................................77

CYLINDER HEAD ..............................................86

Exploded View ..................................................... ...86

Removal and Installation ........................................87

Disassembly and Assembly ....................................89

Inspection ............................................................. ...92

OIL SEAL ...........................................................96

FRONT OIL SEAL .................................................. ...96

FRONT OIL SEAL : Removal and Installation ........96

REAR OIL SEAL .................................................... ...96

REAR OIL SEAL : Removal and Installation ...........97

UNIT REMOVAL AND INSTALLATION ....98

ENGINE ASSEMBL Y ..................................... ...98

Exploded View ..................................................... ...98

Removal and Installation .........................................99

Inspection ..............................................................102

UNIT DISASSEMBLY AND ASSEMBLY ..103

ENGINE STAND SETTING ..............................103

Setting .................................................................. .103

ENGINE UNIT ...................................................105

Disassembly ......................................................... .105

Assembly ..............................................................105

CYLINDER BLOCK ..........................................106

Exploded View ..................................................... .106

Disassembly and Assembly ..................................107

Inspection ..............................................................115

HOW TO SELECT PISTON AND BEARING ...125

Description ........................................................... .125

Piston ....................................................................125

Connecting Rod Bearing .....................................126

Main Bearing ........................................................128

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

132

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

132

General Specification .......................................... .132

Drive Belts .............................................................132

Spark Plug ............................................................132

Exhaust Manifold ..................................................133

Camshaft ...............................................................133

Cylinder Head ......................................................135

Cylinder Block ......................................................137

Main Bearing ........................................................141

Connecting Rod Bearing .....................................142

Revision: 2010 May2011 QX56