INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3811 of 5598

MWI-68

< DTC/CIRCUIT DIAGNOSIS >

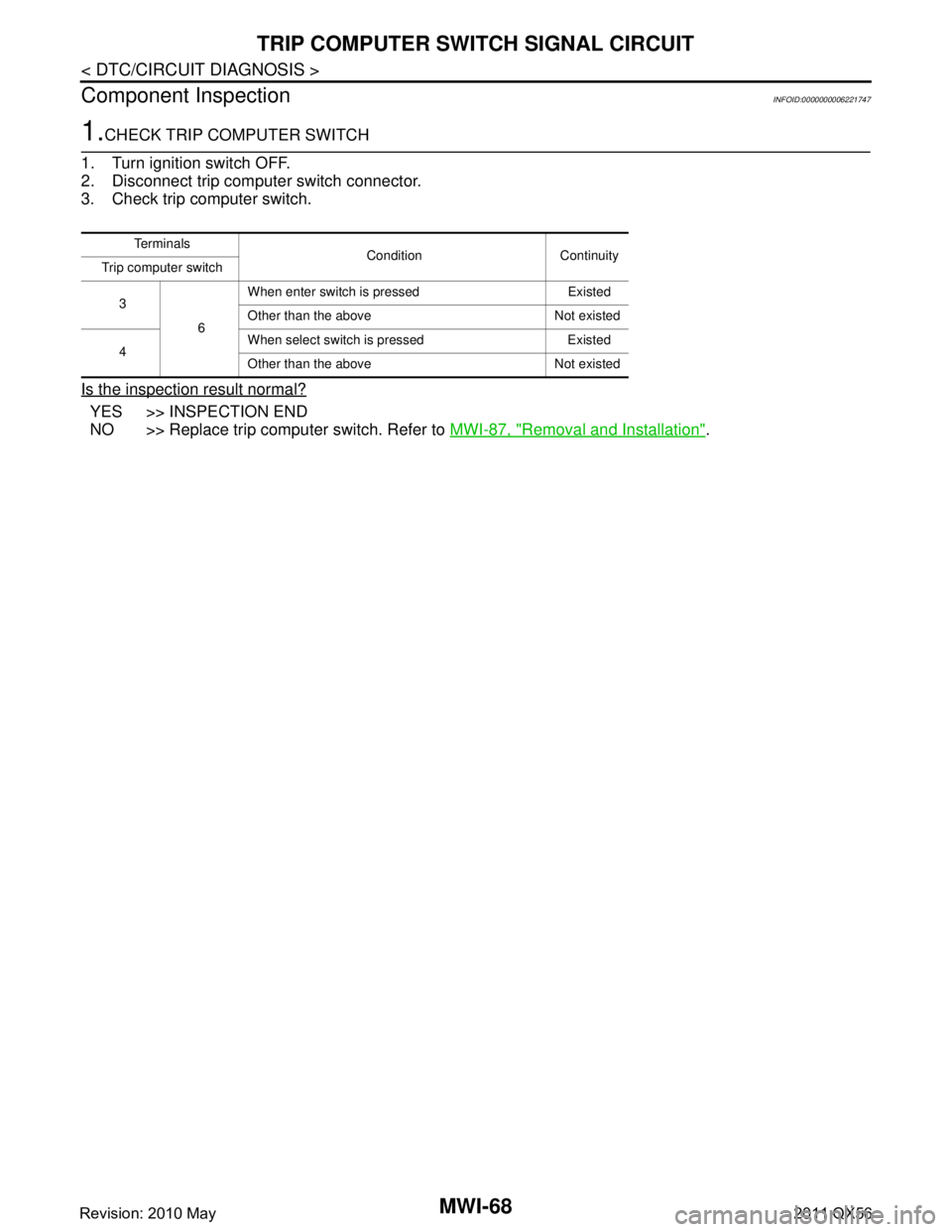

TRIP COMPUTER SWITCH SIGNAL CIRCUIT

Component Inspection

INFOID:0000000006221747

1.CHECK TRIP COMPUTER SWITCH

1. Turn ignition switch OFF.

2. Disconnect trip computer switch connector.

3. Check trip computer switch.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace trip computer switch. Refer to MWI-87, "

Removal and Installation".

Te r m i n a l s

Condition Continuity

Trip computer switch

3 6When enter switch is pressed Existed

Other than the above Not existed

4 When select switch is pressed Existed

Other than the above Not existed

Revision: 2010 May2011 QX56

Page 3812 of 5598

MWI

FUEL LEVEL SENSOR SIGNAL CIRCUITMWI-69

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

FUEL LEVEL SENSOR SIGNAL CIRCUIT

Component Function CheckINFOID:0000000006221748

1.CHECK COMBINATION METER OUTPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and compare the “FUEL ME TER” monitor value with the fuel

gauge reading on the combination meter.

Does monitor value match fuel gauge reading?

YES >> INSPECTION END

NO >> Replace combination meter. Refer to MWI-85, "

Removal and Installation".

Diagnosis ProcedureINFOID:0000000006221749

1.CHECK COMBINATION METER INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector and ground.

Does it match fuel gauge reading?

YES >> GO TO 2.

NO >> Replace the combination meter. Refer to MWI-85, "

Removal and Installation".

2.CHECK FUEL LEVEL SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and fuel level sensor unit connector.

3. Check continuity between combination meter harnes s connector and fuel level sensor unit harness con-

nector.

4. Check continuity between combination meter harness connector and ground.

Fuel gauge indication position Reference value of data monitor [L] 1 Approx. 101.8

3/4 Approx. 77.3

1/2 Approx. 52.3

1/4 Approx. 27.3 0Approx. 2.3

Te r m i n a l s

Vo l ta g e

(Approx.)

(+) (

−)

Combination meter

Ground

Connector Terminal

M34 34

JSNIA3013ZZ

Combination meter Fuel level sensor unit Continuity

Connector Terminal Connector Terminal

M34 34 C5 2 Existed

Revision: 2010 May2011 QX56

Page 3813 of 5598

MWI-70

< DTC/CIRCUIT DIAGNOSIS >

FUEL LEVEL SENSOR SIGNAL CIRCUIT

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

Check continuity between fuel level sensor unit harness connector and combination meter harness connector.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

Component InspectionINFOID:0000000006221750

1.REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to FL-5, "

Removal and Installation".

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is contact with stopper.

Is inspection result OK?

YES >> INSPECTION END

NO >> Replace fuel level sensor unit and fuel pump. Refer to FL-5, "

Removal and Installation".

Combination meter

GroundContinuity

Connector Terminal

M34 34 Not existed

Fuel level sensor unit Combination meter Continuity

Connector Terminal Connector Terminal

C5 5 M34 24 Existed

Te r m i n a l s ConditionResistance (

Ω)

(Approx.) Height [mm (in)]

Fuel level sensor unit

25 Full

* (A)

46.0 282 (11.10)

Empty

* (B) 278.0 29 (1.14)

JSNIA3018ZZ

Revision: 2010 May2011 QX56

Page 3814 of 5598

MWI

OIL PRESSURE SWITCH SIGNAL CIRCUIT

MWI-71

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B A

O P

OIL PRESSURE SWITCH SIGNAL CIRCUIT

Component Function CheckINFOID:0000000006221751

1.CHECK COMBINATION METER INPUT SIGNAL

Select the “Data Monitor” for the “METER/M& A” and check the “OIL W/L” monitor value.

>> INSPECTION END

Diagnosis ProcedureINFOID:0000000006221752

1.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and oil pressure switch connector.

3. Check continuity between IPDM E/R harness c onnector and oil pressure switch harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

Component InspectionINFOID:0000000006221753

1.CHECK OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.

Is the inspection result normal?

YES >> INSPECTION END

“OIL W/L”

Ignition switch ON : On

Engine running : Off

Te r m i n a l s Continuity

(+) (

−)

IPDM E/R Oil pressure switch

Connector Terminal Connector Terminal E1324E2061Existed

Te r m i n a l s Continuity

(+) (

−)

IPDM E/R Ground

Connector Terminal

E13 24 Not existed

Condition Continuity

Engine stopped Existed Engine running Not existed

ELF0044D

Revision: 2010 May2011 QX56

Page 3815 of 5598

MWI-72

< DTC/CIRCUIT DIAGNOSIS >

OIL PRESSURE SWITCH SIGNAL CIRCUIT

NO >> Replace oil pressure switch. Refer to EM-58, "Removal and Installation".

Revision: 2010 May2011 QX56

Page 3816 of 5598

MWI

WASHER LEVEL SWITCH SIGNAL CIRCUITMWI-73

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

WASHER LEVEL SWITCH SIGNAL CIRCUIT

Diagnosis ProcedureINFOID:0000000006221754

1.CHECK WASHER LEVEL SWITCH SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and washer level switch connector.

3. Check continuity between combination meter har ness connector and washer level switch harness con-

nector.

4. Check continuity between combination meter harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK WASHER LEVEL SWITCH GROUND CIRCUIT

Check continuity between washer level switch connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

Component InspectionINFOID:0000000006221755

1.CHECK WASHER LEVEL SWITCH

1. Turn ignition switch OFF.

2. Disconnect washer level switch connector.

3. Check washer level switch.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace washer level switch. Refer to WW-62, "

Removal and Installation".

Te r m i n a l s

Continuity

Combination meter Washer level switch

Connector Terminal Connector Terminal M34 29 E54 1 Existed

Te r m i n a l s Continuity

Combination meter

Ground

Connector Terminal

M34 29 Not existed

Te r m i n a l s Continuity

Washer level switch

Ground

Connector Terminal

E54 2 Existed

Te r m i n a l s Condition Continuity

Washer level switch

12 Washer level switch ON Existed

Washer level switch OFF Not existed

Revision: 2010 May2011 QX56

Page 3817 of 5598

MWI-74

< DTC/CIRCUIT DIAGNOSIS >

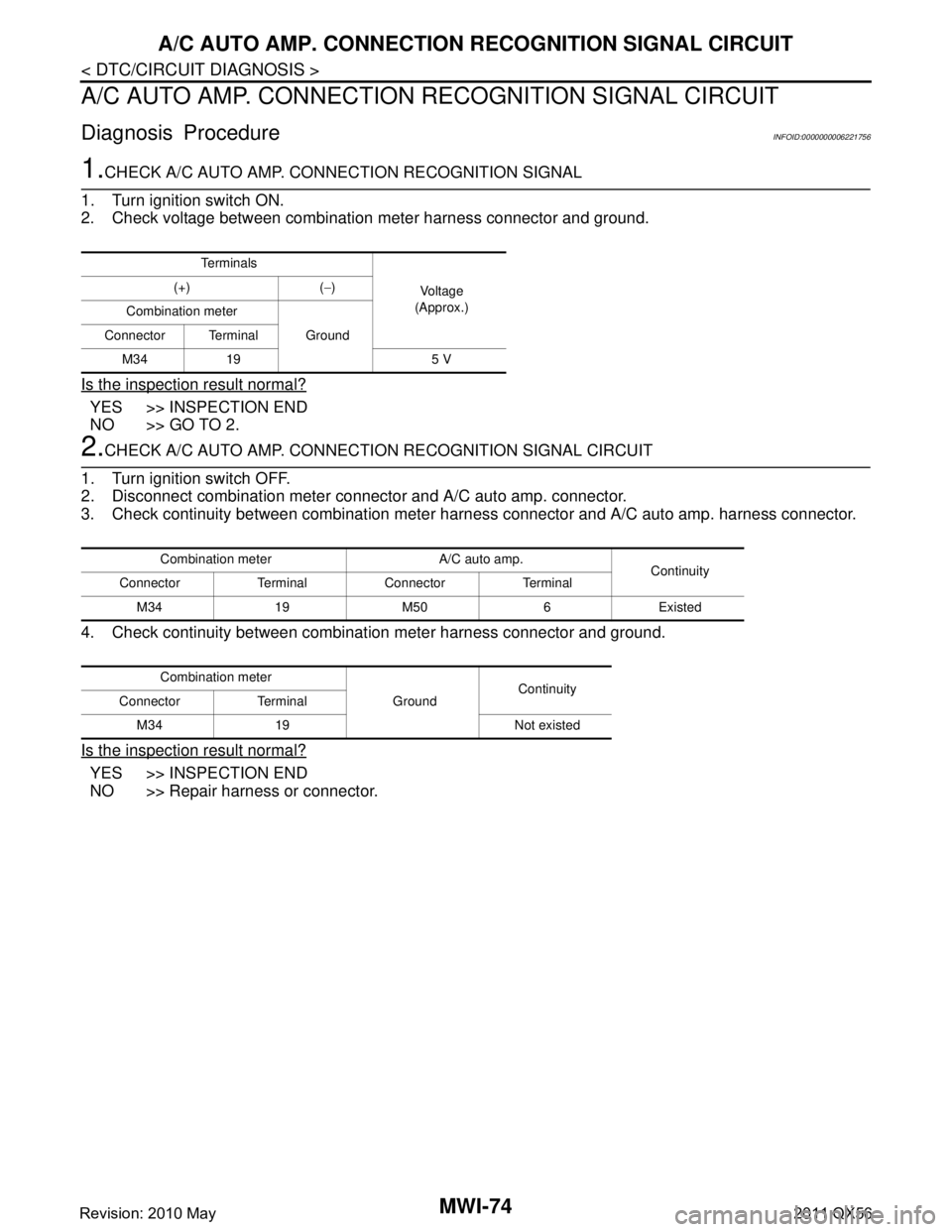

A/C AUTO AMP. CONNECTION RECOGNITION SIGNAL CIRCUIT

A/C AUTO AMP. CONNECTION RECOGNITION SIGNAL CIRCUIT

Diagnosis ProcedureINFOID:0000000006221756

1.CHECK A/C AUTO AMP. CONNECTION RECOGNITION SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK A/C AUTO AMP. CONNECTION RECOGNITION SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and A/C auto amp. connector.

3. Check continuity between combination meter harness connector and A/C auto amp. harness connector.

4. Check continuity between combination meter harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

Te r m i n a l s

Vo l ta g e

(Approx.)

(+) (

−)

Combination meter Ground

Connector Terminal

M34 19 5 V

Combination meter A/C auto amp. Continuity

Connector Terminal Connector Terminal

M34 19 M50 6 Existed

Combination meter GroundContinuity

Connector Terminal

M34 19 Not existed

Revision: 2010 May2011 QX56

Page 3818 of 5598

MWI

THE FUEL GAUGE INDICATOR DOES NOT OPERATE

MWI-75

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B A

O P

SYMPTOM DIAGNOSIS

THE FUEL GAUGE INDICA TOR DOES NOT OPERATE

DescriptionINFOID:0000000006221757

Fuel gauge will not indicate from a certain position.

Diagnosis ProcedureINFOID:0000000006221758

1.CHECK COMBINATION METER OUTPUT SIGNAL

1. Connect CONSULT-III.

2. Select the “Data Monitor” for the “METER/M&A” and compare the “FUEL METER” monitor value with the

fuel gauge reading on the combination meter. Refer to MWI-69, "

Component Function Check".

Does monitor value match fuel gauge reading?

YES >> GO TO 2.

NO >> Replace combination meter. Refer to MWI-85, "

Removal and Installation".

2.CHECK FUEL LEVEL SENSOR SIGNAL CIRCUIT

Check the fuel level sensor signal circuit. Refer to MWI-69, "

DiagnosisProcedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK FUEL LEVEL SENSOR UNIT

Perform a unit check for the fuel level sensor unit. Refer to MWI-70, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace fuel level sensor unit. Refer to FL-5, "

Removal and Installation".

4.CHECK FLOAT INTERFERENCE

Check that the float arm interferes with or binds to other components in the fuel tank.

Is the inspection result normal?

YES >> Replace combination meter. Refer to MWI-85, "Removal and Installation".

NO >> Repair or replace malfunctioning parts.

Revision: 2010 May2011 QX56

Page 3819 of 5598

MWI-76

< SYMPTOM DIAGNOSIS >

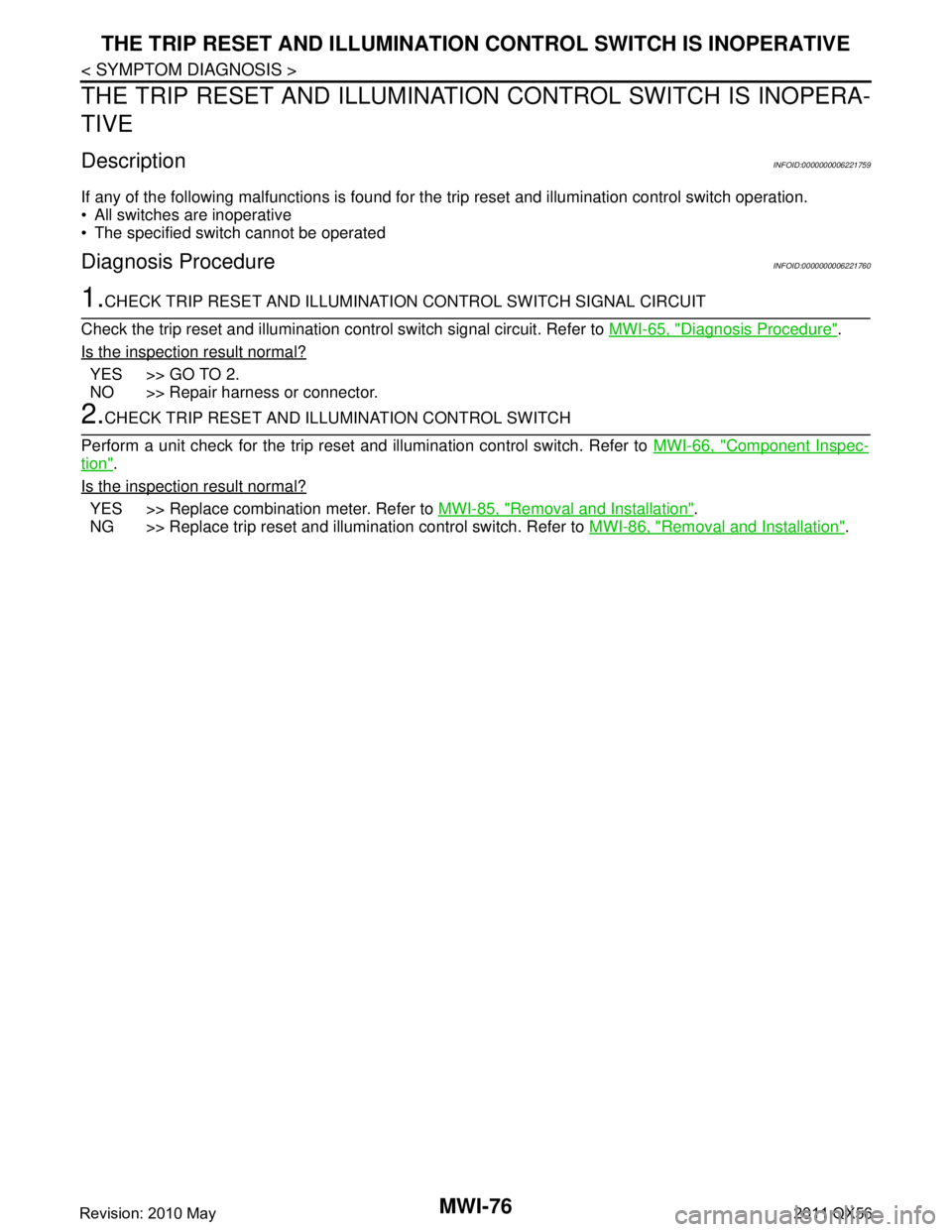

THE TRIP RESET AND ILLUMINATION CONTROL SWITCH IS INOPERATIVE

THE TRIP RESET AND ILLUMINATION CONTROL SWITCH IS INOPERA-

TIVE

DescriptionINFOID:0000000006221759

If any of the following malfunctions is found for t he trip reset and illumination control switch operation.

All switches are inoperative

The specified switch cannot be operated

Diagnosis ProcedureINFOID:0000000006221760

1.CHECK TRIP RESET AND ILLUMINATI ON CONTROL SWITCH SIGNAL CIRCUIT

Check the trip reset and illumination cont rol switch signal circuit. Refer to MWI-65, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK TRIP RESET AND ILLU MINATION CONTROL SWITCH

Perform a unit check for the trip reset and illumination control switch. Refer to MWI-66, "

Component Inspec-

tion".

Is the inspection result normal?

YES >> Replace combination meter. Refer to MWI-85, "Removal and Installation".

NG >> Replace trip reset and illumination control switch. Refer to MWI-86, "

Removal and Installation".

Revision: 2010 May2011 QX56

Page 3820 of 5598

MWI

THE TRIP COMPUTER SWITCH IS INOPERATIVEMWI-77

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

THE TRIP COMPUTER SW ITCH IS INOPERATIVE

DescriptionINFOID:0000000006221761

If any of the following malfunctions is f ound for the trip computer switch operation.

All switches are inoperative

The specified switch cannot be operated

Diagnosis ProcedureINFOID:0000000006221762

1.CHECK TRIP COMPUTER SWITCH SIGNAL CIRCUIT

Check the trip computer switch signal circuit. Refer to MWI-67, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK TRIP COMPUTER SWITCH

Perform a unit check for the trip computer switch. Refer to MWI-68, "

Component Inspection".

Is the inspection result normal?

YES >> Replace combination meter. Refer to MWI-85, "Removal and Installation".

NG >> Replace trip computer switch. Refer to MWI-87, "

Removal and Installation".

Revision: 2010 May2011 QX56