air conditioning INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2490 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

EC-466

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

DTC LogicINFOID:0000000006217970

DTC DETECTION LOGIC

DTC CONFIRMATION PROCED INFINITI QX56 2011 Factory Workshop Manual

EC-466

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

DTC LogicINFOID:0000000006217970

DTC DETECTION LOGIC

DTC CONFIRMATION PROCED](/img/42/57033/w960_57033-2489.png)

EC-466

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

DTC LogicINFOID:0000000006217970

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROC EDURE FOR MALFUNCTION A AND B

1. Turn ignition switch ON and wait at least 1 second.

2. Selector lever position is D and wait at least 3 seconds.

3. Selector lever position is P.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Turn ignition switch ON and wait at least 1 second.

6. Selector lever position is D and wait at least 3 seconds.

7. Selector lever position is P.

8. Turn ignition switch OFF, wait at least 10 seconds, and then turn ON.

9. Check DTC.

Is DTC detected?

YES >> Go to EC-466, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION C

1. Turn ignition switch ON and wait at least 1 second.

2. Selector lever position is D and wait at least 3 seconds.

3. Selector lever position is N or P.

4. Start engine and let it idle for 3 seconds.

5. Check DTC.

Is DTC detected?

YES >> Go to EC-466, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006217971

1.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Turn ignition switch OFF.

2. Remove the intake air duct.

3. Check if foreign matter is caught between the throttle valve and the housing.

Is the inspection result normal?

YES >> GO TO 2.

DTC No. Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P2119 ETC ACTR-B1

(Electric throttle control actuator) A)

Electric throttle control actuator does not

function properly due to the return spring

malfunction.

Electric throttle control actuator

B) Throttle valve opening angle in fail-safe

mode is not in specified range.

C) ECM detects that the throttle valve is stuck

open.

Revision: 2010 May2011 QX56

Page 2499 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

P2135 TP SENSOREC-475

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2135 TP SENSOR

DTC LogicINFOID:0000000006217978

DTC DETECTION LOGIC

NOTE:

If DTC P2135 is displayed with DTC INFINITI QX56 2011 Factory Workshop Manual

P2135 TP SENSOREC-475

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2135 TP SENSOR

DTC LogicINFOID:0000000006217978

DTC DETECTION LOGIC

NOTE:

If DTC P2135 is displayed with DTC](/img/42/57033/w960_57033-2498.png)

P2135 TP SENSOREC-475

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2135 TP SENSOR

DTC LogicINFOID:0000000006217978

DTC DETECTION LOGIC

NOTE:

If DTC P2135 is displayed with DTC P0643, perfo

rm the trouble diagnosis for DTC P0643. Refer to EC-

381, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confi rm that battery voltage is 8 V or more at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected?

YES >> Go to EC-475, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006217979

1.CHECK THROTTLE POSITION SEN SOR POWER SUPPLY CIRCUIT-I

1. Disconnect electric throttle c ontrol actuator harness connector.

2. Turn ignition switch ON.

3. Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

2.CHECK THROTTLE POSITI ON SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ECM harness con-

nector.

DTC No. Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P2135 TP SENSOR-B1

(Throttle position sensor circuit

range/performance) Rationally incorrect voltage is sent to

ECM compared with the signals from

TP sensor 1 and TP sensor 2. Harness or connector

(TP sensor 1 or 2 circuit is open or shorted.)

Electric throttle control actuator

(TP sensor 1 or 2)

Electric throttle control actuator Ground Voltage (V)

Connector Terminal

F66 2 Ground Approx. 5

Revision: 2010 May2011 QX56

Page 2511 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

P2A00, P2A03 A/F SENSOR 1EC-487

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2A00, P2A03 A/F SENSOR 1

DTC LogicINFOID:0000000006217987

DTC DETECTION LOGIC

To judge the malfunct INFINITI QX56 2011 Factory Workshop Manual

P2A00, P2A03 A/F SENSOR 1EC-487

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2A00, P2A03 A/F SENSOR 1

DTC LogicINFOID:0000000006217987

DTC DETECTION LOGIC

To judge the malfunct](/img/42/57033/w960_57033-2510.png)

P2A00, P2A03 A/F SENSOR 1EC-487

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2A00, P2A03 A/F SENSOR 1

DTC LogicINFOID:0000000006217987

DTC DETECTION LOGIC

To judge the malfunction, the A/F signal computed by ECM fr

om the A/F sensor 1 signal is monitored so it will

not shift to LEAN side or RICH side.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Clear the mixture ratio self-learning value. Refer to EC-152, "

Work Procedure".

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for 1 minute under no load.

6. Let engine idle for 1 minute.

7. Keep engine speed between 2,500 and 3,000 rpm for 20 minutes.

8. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-487, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006217988

1.RETIGHTEN A/F SENSOR 1

Loosen and retighten the A/F sensor 1. Refer to EX-5, "

Exploded View".

>> GO TO 2.

2.CHECK A/F SENSOR 1 CONNECTOR

1. Disconnect A/F sensor 1 harness connector.

2. Check that water is not inside connectors.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness connector.

3.CHECK FOR INTAKE AIR LEAKAGE

1. Reconnect A/F sensor 1 harness connector.

2. Start engine and run it at idle.

DTC No. Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P2A00 A/F SENSOR1 (B1)

(Air fuel ratio (A/F) sensor 1 (bank 1)

circuit range/performance) The output voltage computed by ECM from

the A/F sensor 1 signal shifts to the lean side

for a specified period.

The A/F signal computed by ECM from the

A/F sensor 1 signal shifts to the rich side for

a specified period. A/F sensor 1

A/F sensor 1 heater

Fuel pressure

Fuel injector

Intake air leaks

P2A03 A/F SENSOR1 (B2)

(Air fuel ratio (A/F) sensor 1 (bank 2)

circuit range/performance)

Revision: 2010 May2011 QX56

Page 2572 of 5598

EM-10

< PREPARATION >

PREPARATION

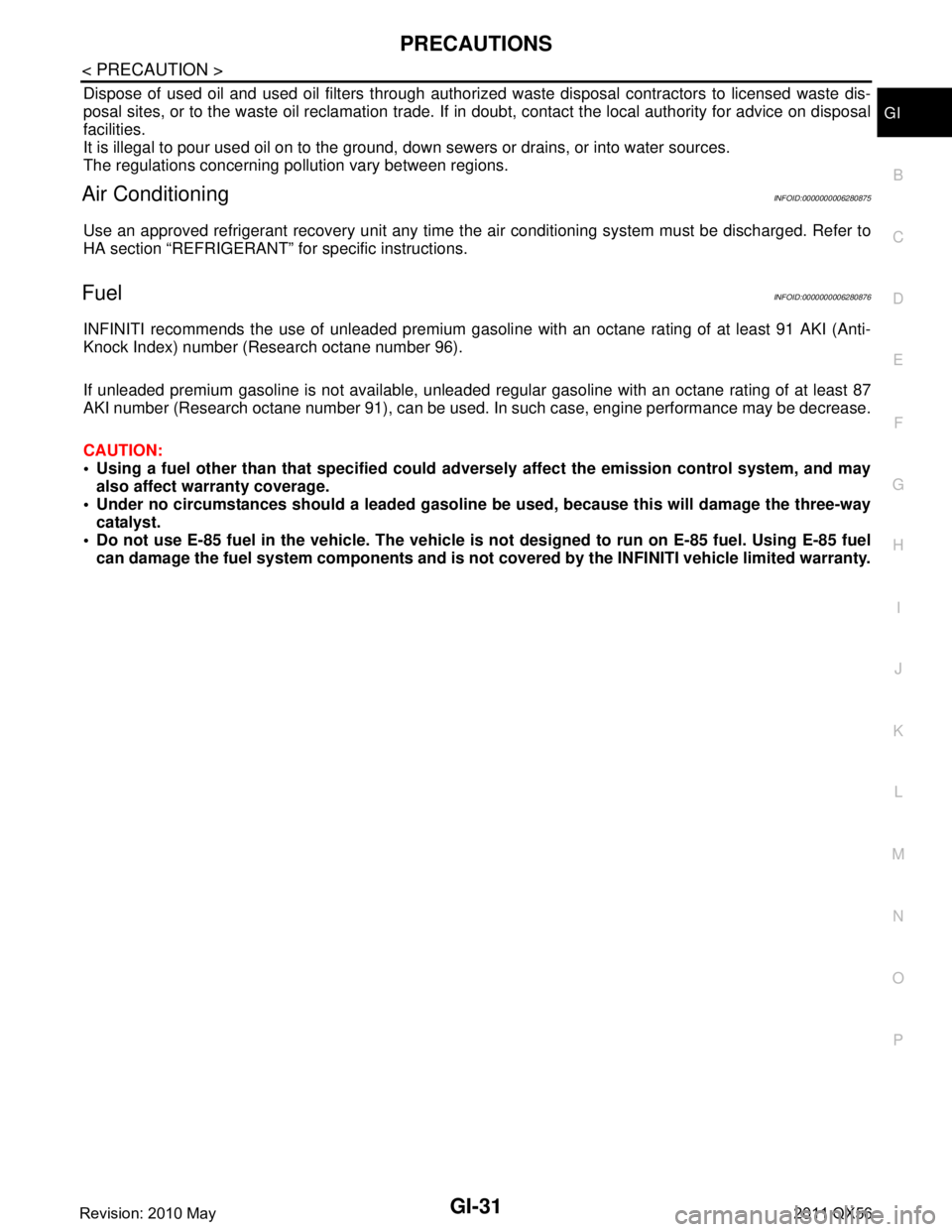

(—)

Pilot bushing pullerRemoving pilot converter

(—)

Valve seat cutter set Finishing valve seat (EXH) dimensions

(—)

Piston ring expander Removing and installing piston ring

(—)

Valve guide drift Removing and installing valve guide (EXH)

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

(—)

Valve guide reamer (A): Reaming valve guide (EXH) inner hole

(B): Reaming hole for oversize valve guide

(EXH)

c: 6.0 mm (0.236 in) dia.

d: 10.2 mm (0.402 in) dia.

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads be-

fore installing a new heated oxygen sensor (Use

with anti-seize lubricant shown below.)

a: J-43897-18 (18 mm dia.) for zirconia heat-

ed oxygen sensor and air fuel ratio sensor

b: J-43897-12 (12 mm dia.) for titania heated

oxygen sensor and air fuel ratio sensor

(—)

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads

(Kent-Moore No.)

Tool name

Description

NT045

S-NT048

S-NT030

JPBIA0400ZZ

JPBIA0401ZZ

AEM488

AEM489

Revision: 2010 May2011 QX56

Page 2965 of 5598

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector Symbols ............................................. ......9

Sample/Wiring Diagram -Example- .........................10

Connector Information .............................................12

ABBREVIATIONS .......................................... ....14

Abbreviation List .................................................. ....14

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

19

Description .......................................................... ....19

Tightening Torque Table (New Standard Includ-

ed) ...........................................................................

19

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ................................................

22

Recommended Chemical Products and Sealants ....22

VEHICLE INFORMATION ............................23

IDENTIFICATION INFORMATION ................. ....23

Model Variation ................................................... ....23

Information About Identification or Model Code ......23

Dimensions .............................................................25

Wheels & Tires ........................................................25

PRECAUTION ..............................................26

PRECAUTIONS .................................................26

Description ........................................................... ....26

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

26

Precautions For Xenon Headlamp Service .............26

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

27

Precaution for Procedure without Cowl Top Cover ....27

General Precautions ................................................27

Three Way Catalyst .................................................29

Multiport Fuel Injection System or Engine Control

System .....................................................................

29

Hoses ......................................................................29

Engine Oils ..............................................................30

Air Conditioning .......................................................31

Fuel ..........................................................................31

LIFTING POINT .................................................32

Pantograph Jack ......................................................32

Garage Jack and Safety Stand ................................32

2-Pole Lift ................................................................33

TOW TRUCK TOWING .....................................34

Tow Truck Towing ...................................................34

Vehicle Recovery (Freeing a Stuck Vehicle) ...........34

BASIC INSPECTION ...................................36

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

36

Work Flow ............................................................ ....36

Control Units and Electrical Parts ............................36

How to Check Terminal ...........................................37

Intermittent Incident .................................................40

Circuit Inspection .....................................................43

CONSULT-III/GST CHECKING SYSTEM .........48

Description ...............................................................48

CONSULT-III Function and System Application*1 ....48

Revision: 2010 May2011 QX56

Page 2978 of 5598

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

ABBREVIATIONS

Abbreviation ListINFOID:0000000006280882

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION

A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position ATF Automatic transmission fluid AV Audio visual

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously Variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: 2010 May2011 QX56

Page 2995 of 5598

PRECAUTIONSGI-31

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Dispose of used oil and used oil filters through authorized waste disposal contractors to licensed waste dis-

posal sites, or to the waste oil reclamation trade. If in doubt, contact the local authority for advice on disposal

facilities.

It is illegal to pour used oil on to the ground, dow n sewers or drains, or into water sources.

The regulations concerning po llution vary between regions.

Air ConditioningINFOID:0000000006280875

Use an approved refrigerant recovery unit any time t he air conditioning system must be discharged. Refer to

HA section “REFRIGERANT” fo r specific instructions.

FuelINFOID:0000000006280876

INFINITI recommends the use of unleaded premium gasoli ne with an octane rating of at least 91 AKI (Anti-

Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, unleaded r egular gasoline with an octane rating of at least 87

AKI number (Research octane number 91), can be used. In such case, engine performance may be decrease.

CAUTION:

Using a fuel other than that specified could ad versely affect the emission control system, and may

also affect warranty coverage.

Under no circumstances should a leaded gasoline be used, because this will damage the three-way

catalyst.

Do not use E-85 fuel in the vehicle . The vehicle is not designed to run on E-85 fuel. Using E-85 fuel

can damage the fuel system components and is not covered by the INFINITI vehicle limited warranty.

Revision: 2010 May2011 QX56

Page 3029 of 5598

INSPECTION AND ADJUSTMENTGI-65

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PINSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Re-

quired Procedure After Battery Disconnection

INFOID:0000000006344676

*: Not equipped. SYSTEM ITEM REFERENCE

Front automatic air

conditioning system Temperature setting trimmer (Front)

HAC-68, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Temperature Setting Trimmer

(Front)"

Foot position setting trimmer

HAC-68, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Foot Position Setting Trimmer"

Inlet port memory function* —

Inlet port memory function (FRE)

HAC-69, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Inlet Port Memory

Function (FRE)"

Inlet port memory function (REC) HAC-69, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Inlet Port Memory Function (REC)"

ACCS (Advanced Cli-

mate Control System)Exhaust gas / outside odor detecting sensor sensitivity adjustment func-

tion

HAC-70, "

ACCS (ADVANCED

CLIMATE CONTROL SYSTEM) :

Exhaust Gas / Outside Odor De-

tecting Sensor Sensitivity Adjust-

ment Function"

Auto intake switch interlocking movement change function

HAC-70, "

ACCS (ADVANCED

CLIMATE CONTROL SYSTEM) :

Auto Intake Switch Interlocking

Movement Change Function"

Clean switch interlocking movement change function* —

Rear automatic air

conditioning system Temperature setting trimmer (Rear) HAC-69, "

REAR AUTOMATIC AIR

CONDITIONING SYSTEM : Tem-

perature Setting

Trimmer (Rear)"

Automatic drive posi-

tioner Automatic drive positioner system ADP-51, "

ADDITIONAL SERVICE

WHEN REMOVING BATTERY

NEGATIVE TERMINAL : Descrip-

tion"

Power window control Power window control system

PWC-31, "Description"

Sunroof system* Sunroof system —

Sunshade system* Sunshade system —

Rear view monitor* Rear view monitor predictive course line center position adjustment —

Around view monitor Predictive course line center position adjustment AV- 111 , "

Description"

Automatic back door

systemAutomatic back door system DLK-80, "

ADDITIONAL SERVICE

WHEN REMOVING BATTERY

NEGATIVE TERMINAL : Descrip-

tion"

Engine oil level read* Engine oil level read —

Revision: 2010 May2011 QX56

Page 3057 of 5598

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HA

A

B

HA

N

O P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precautions For Refrigerant System Service ............4

Service Equipment ....................................................6

PREPARATION ............................................9

PREPARATION .............................................. .....9

Special Service Tool ........................................... ......9

Commercial Service Tool ........................................12

Sealant or/and Lubricant .........................................12

SYSTEM DESCRIPTION .............................13

COMPONENT PARTS ................................... ....13

Component Parts Location .................................. ....13

Component Description ...........................................13

SYSTEM .............................................................14

System Diagram .................................................. ....14

System Description .................................................14

BASIC INSPECTION ...................................16

DIAGNOSIS AND REPAIR WORKFLOW ..... ....16

Work Flow ........................................................... ....16

REFRIGERANT ..................................................18

Description .......................................................... ....18

Leak Test ................................................................18

Recycle Refrigerant .................................................20

Charge Refrigerant ..................................................20

LUBRICANT ................................................... ....22

Description .......................................................... ....22

Inspection ............................................................ ....22

Perform Lubricant Return Operation .......................22

Lubricant Adjusting Procedure for Components

Replacement Except Compressor ...........................

22

Lubricant Adjusting Procedure for Compressor

Replacement ...........................................................

23

PERFORMANCE TEST ....................................25

Inspection ................................................................25

SYMPTOM DIAGNOSIS ..............................27

REFRIGERATION SYSTEM SYMPTOMS ........27

Trouble Diagnosis For Unusual Pressure ............ ....27

Symptom Table .......................................................27

NOISE ................................................................29

Symptom Table .......................................................29

REMOVAL AND INSTALLATION ...............30

COMPRESSOR .................................................30

Exploded View ..................................................... ....30

COMPRESSOR ..........................................................30

COMPRESSOR : Removal and Installation ............30

MAGNET CLUTCH ................................................ ....31

MAGNET CLUTCH : Removal and Installation of

Compressor Clutch ..................................................

31

Inspection ................................................................32

COOLER PIPE AND HOSE ..............................33

Exploded View .........................................................33

HIGH-PRESSURE FLEXIBLE HOSE ........................34

HIGH-PRESSURE FLEXIBLE HOSE : Removal

and Installation .................................................... ....

34

LOW-PRESSURE FLEXIBLE HOSE ..................... ....35

LOW-PRESSURE FLEXIBLE HOSE : Removal

and Installation ........................................................

35

HIGH-PRESSURE PIPE ............................................35

Revision: 2010 May2011 QX56

Page 3060 of 5598

HA-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006276138

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Refrigerant System ServiceINFOID:0000000006276139

GENERAL REFRIGERANT PRECAUTION

WARNING:

Never breathe A/C refrigerant an d lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved reco very/recycling equipment to discharge HFC-134a (R-134a) refrigerant.

Ventilate work area before resuming service if acci dental system discharge occurs. Additional health

and safety information may be obtained from refrigerant and lubricant manufacturers.

Never release refrigerant into the air. Use appro ved recovery/recycling recharging equipment to cap-

ture the refrigerant each time an ai r conditioning system is discharged.

Wear always eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

Never store or heat refrigerant containers above 52 °C (126 °F).

Never heat a refrigerant container with an open flame; Place the bottom of the container in a warm

pail of water if container warming is required.

Never intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: pois onous gas is produced if refrigerant burns.

Refrigerant displaces oxygen, therefore be certain to work in well ventilated areas to prevent suffo-

cation.

Never pressure test or leakage test HFC-134a (R- 134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combusti ble at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

WORKING WITH HFC-134a (R-134a)

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) re frigerant are not compatible. These regrigerants

must never be mixed, even in the smallest amount s. Compressor malfunction is likely occur if the

refrigerants are mixed.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lu bricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precauti ons must be observed:

- Cap (seal) immediately the compon ent to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before co nnecting the components when installing refrig-

erant components to a vehicle. Connect all refr igerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed contai ner. Reseal immediately containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

PIIB3706J

Revision: 2010 May2011 QX56