sensor INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2616 of 5598

EM-54

< REMOVAL AND INSTALLATION >

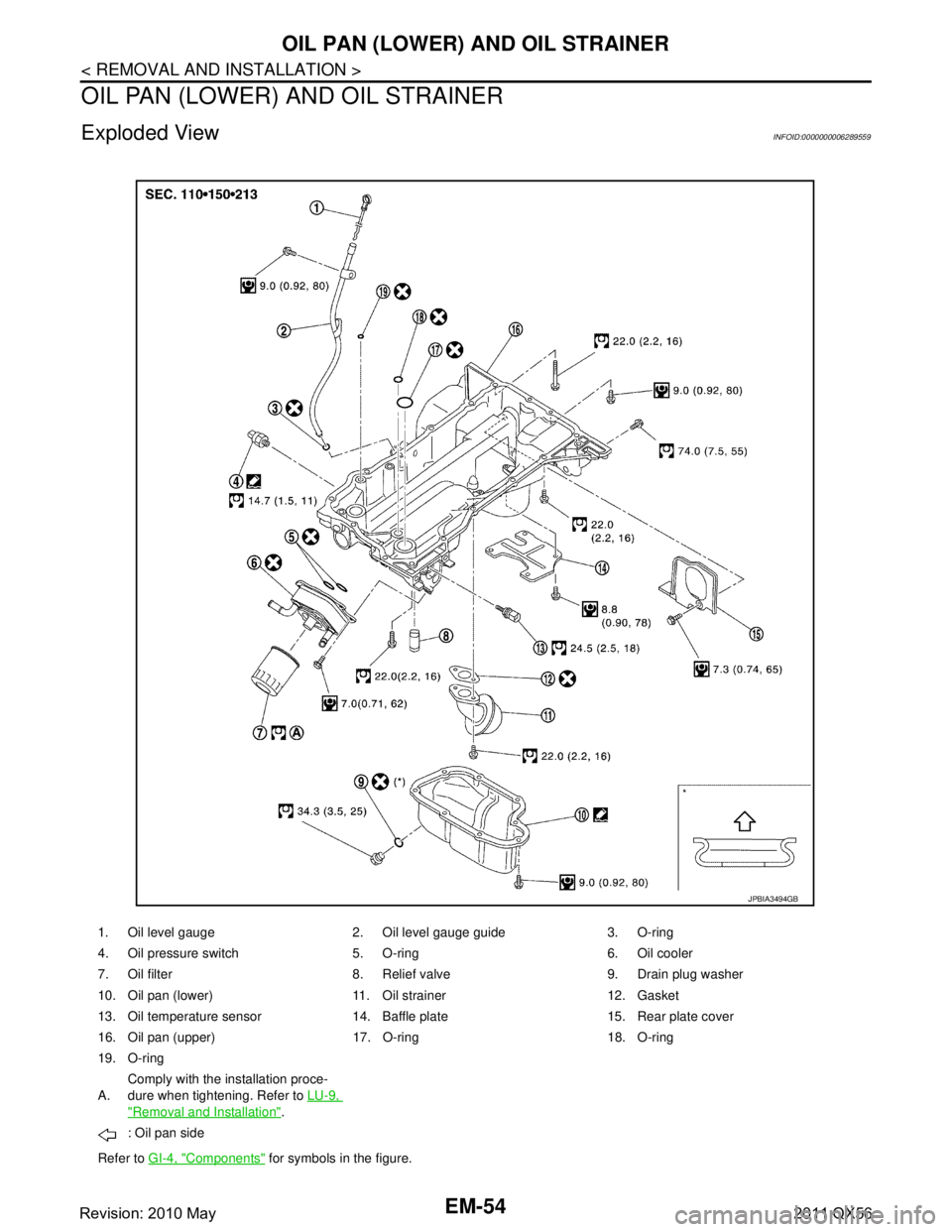

OIL PAN (LOWER) AND OIL STRAINER

OIL PAN (LOWER) AND OIL STRAINER

Exploded ViewINFOID:0000000006289559

1. Oil level gauge 2. Oil level gauge guide 3. O-ring

4. Oil pressure switch 5. O-ring 6. Oil cooler

7. Oil filter 8. Relief valve 9. Drain plug washer

10. Oil pan (lower) 11. Oil strainer 12. Gasket

13. Oil temperature sensor 14. Baffle plate 15. Rear plate cover

16. Oil pan (upper) 17. O-ring 18. O-ring

19. O-ring

A.Comply with the installation proce-

dure when tightening. Refer to

LU-9,

"Removal and Installation".

: Oil pan side

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3494GB

Revision: 2010 May2011 QX56

Page 2619 of 5598

OIL PAN (UPPER)EM-57

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

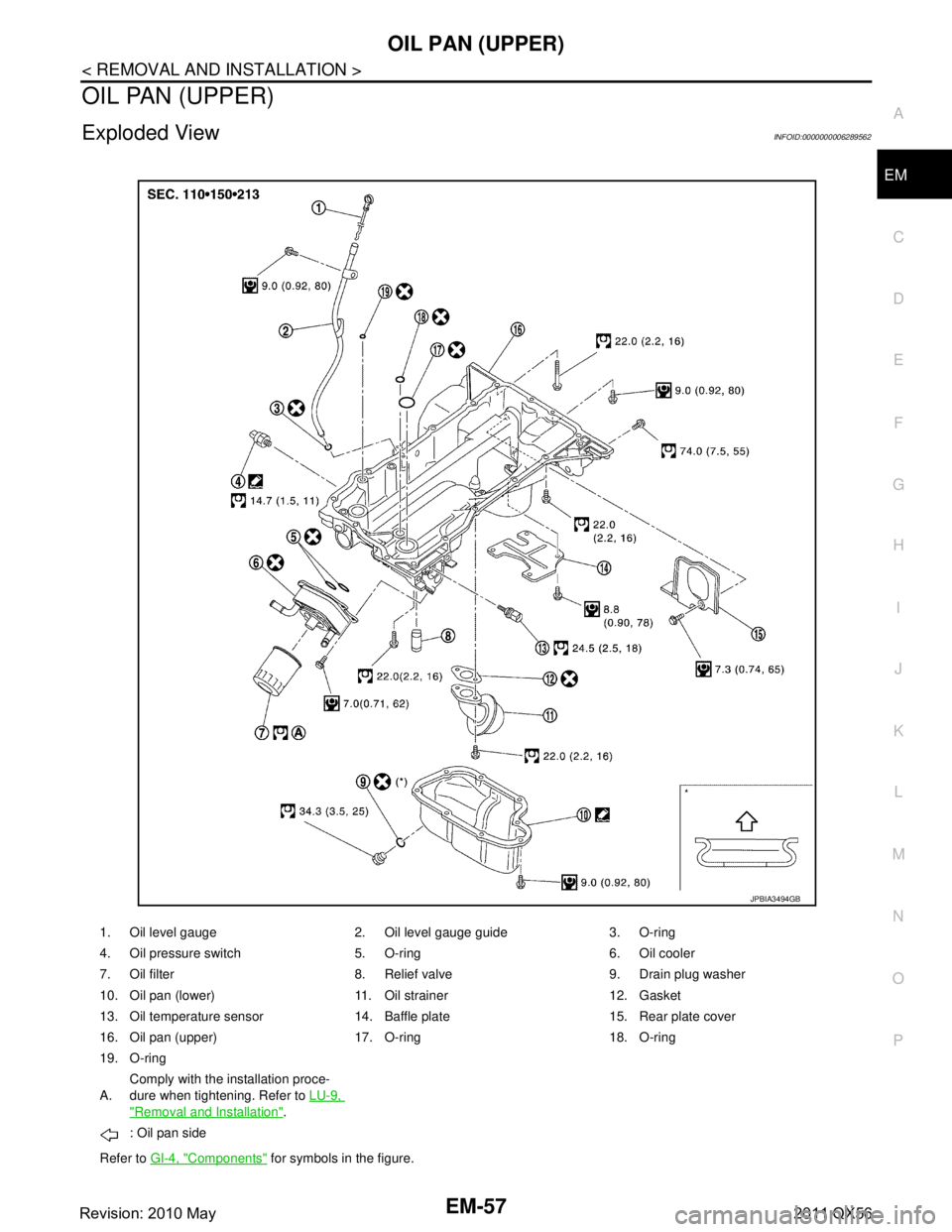

OIL PAN (UPPER)

Exploded ViewINFOID:0000000006289562

1. Oil level gauge 2. Oil level gauge guide 3. O-ring

4. Oil pressure switch 5. O-ring 6. Oil cooler

7. Oil filter 8. Relief valve 9. Drain plug washer

10. Oil pan (lower) 11. Oil strainer 12. Gasket

13. Oil temperature sensor 14. Baffle plate 15. Rear plate cover

16. Oil pan (upper) 17. O-ring 18. O-ring

19. O-ring

A.

Comply with the installation proce-

dure when tightening. Refer to

LU-9,

"Removal and Installation".

: Oil pan side

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3494GB

Revision: 2010 May2011 QX56

Page 2620 of 5598

EM-58

< REMOVAL AND INSTALLATION >

OIL PAN (UPPER)

Removal and Installation

INFOID:0000000006289563

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain engine oil when engine is hot.

1. Remove oil filter. Refer to LU-9, "

Removal and Installation".

2. Remove oil cooler. Refer to LU-11, "

Exploded View".

3. Move A/C compressor to the position without the hindrance for work. Refer to HA-30, "

Exploded View".

4. Remove oil level gauge and oil level gauge guide.

5. Remove oil pressure switch and oil temperature sensor if necessary.

6. Remove rear plate cover.

7. Remove protector A and protector B. Refer to SCS-32, "

FRONT TUBE ASSEMBLY : Exploded View".

8. Remove front suspension rear cross member. Refer to TM-205, "

2WD : Exploded View" (2WD models) or

TM-208, "

4WD : Exploded View" (4WD models).

9. Remove steering gear assembly. Refer to ST-41, "

Exploded View".

10. Remove front final drive assembly. Refer to DLN-162, "

Exploded View".

11. Remove oil pan (lower). Refer to EM-54, "

Exploded View".

12. Remove oil strainer. Refer to EM-54, "

Exploded View".

13. Remove bolts fixing oil pan (upper) to transmission assembly.

14. Remove oil pan (upper) as per the following:

a. Loosen mounting bolts in the reverse order as shown in the fig- ure with power tool to remove.

NOTE:

Disregard No. 9, 16 when loosening.

b. Insert a suitable tool into the notch at oil pan (upper) (1) as shown.

Pry off case by moving a suitable tool.

CAUTION:

Be careful not to damage the mating surfaces.

15. Remove O-ring from bottom of cylinder block and oil pump.

16. Remove oil pressure switch and oil temperature sensor, if necessary.

INSTALLATION

1. Install oil pan (upper) as per the following:

: Engine front

JPBIA3502ZZ

: Engine front

JPBIA2299ZZ

Revision: 2010 May2011 QX56

Page 2624 of 5598

EM-62

< REMOVAL AND INSTALLATION >

TIMING CHAIN

Removal and Installation

INFOID:0000000006289566

REMOVAL

1. Release fuel pressure. Refer to EC-153, "Work Procedure".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

3. Remove fan shroud (lower). Refer to CO-13, "

Exploded View".

4. Remove fan bracket. Refer to CO-16, "

Exploded View".

5. Remove drive belt auto-tensioner. Refer to EM-26, "

Exploded View".

6. Remove oil level gauge and oil level gauge guide. Refer to EM-57, "

Exploded View".

7. Move power steering oil pump to the posit ion without the hindrance for work. Refer to ST-48, "

Exploded

View".

8. Remove alternator, alternator bracket and alternator stay. Refer to CHG-25, "

Exploded View".

9. Move power steering reservoir tank to the position without the hindrance for work, and then remove Res- ervoir tank bracket. Refer to ST-54, "

Exploded View".

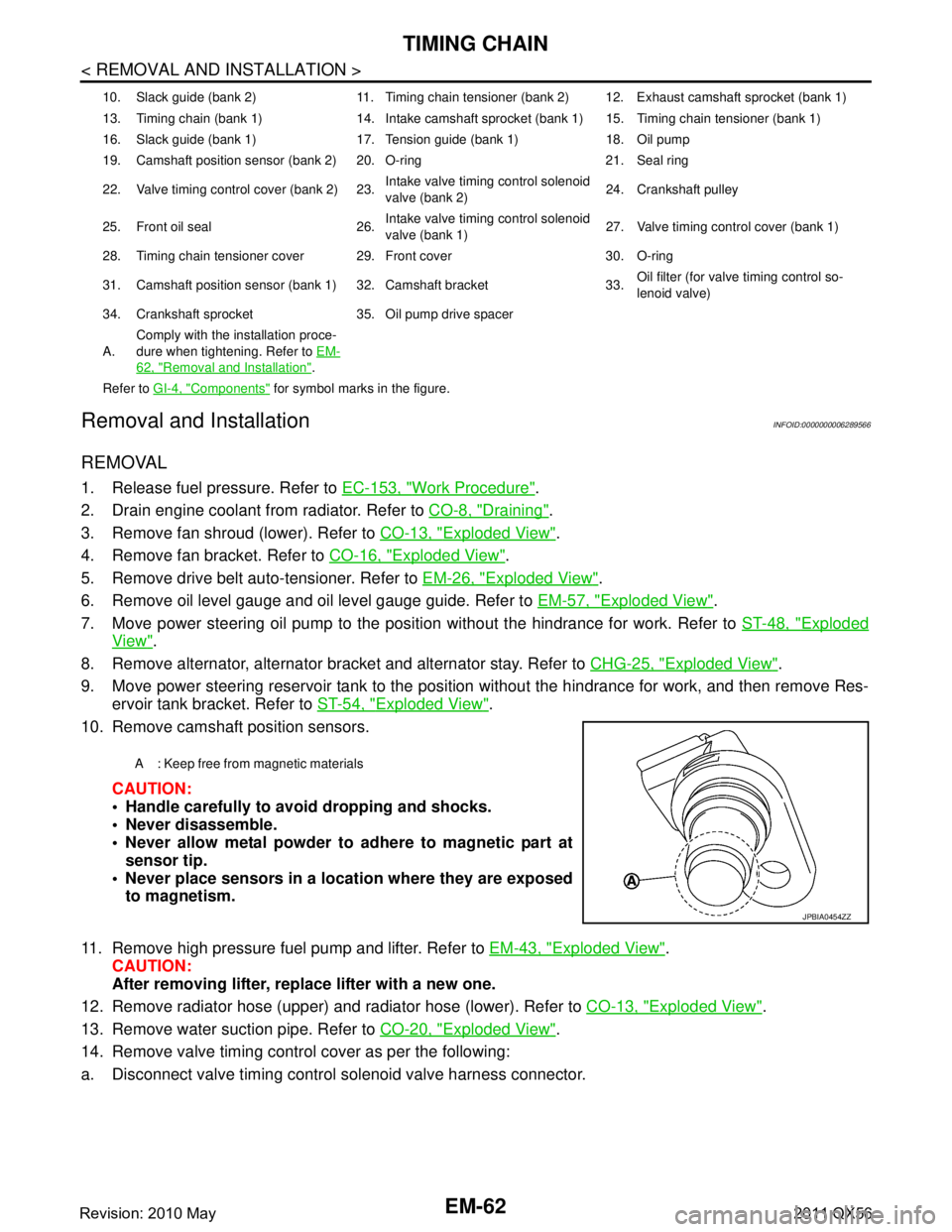

10. Remove camshaft position sensors.

CAUTION:

Handle carefully to avoid dropping and shocks.

Never disassemble.

Never allow metal powder to adhere to magnetic part atsensor tip.

Never place sensors in a lo cation where they are exposed

to magnetism.

11. Remove high pressure fuel pump and lifter. Refer to EM-43, "

Exploded View".

CAUTION:

After removing lifter, replace lifter with a new one.

12. Remove radiator hose (upper) and radiator hose (lower). Refer to CO-13, "

Exploded View".

13. Remove water suction pipe. Refer to CO-20, "

Exploded View".

14. Remove valve timing control cover as per the following:

a. Disconnect valve timing control solenoid valve harness connector.

10. Slack guide (bank 2) 11. Timing chain tensioner (bank 2) 12. Exhaust camshaft sprocket (bank 1)

13. Timing chain (bank 1) 14. Intake camshaft sprocket (bank 1) 15. Timing chain tensioner (bank 1)

16. Slack guide (bank 1) 17. Tension guide (bank 1) 18. Oil pump

19. Camshaft position sensor (bank 2) 20. O-ring 21. Seal ring

22. Valve timing control cover (bank 2) 23. Intake valve timing control solenoid

valve (bank 2)24. Crankshaft pulley

25. Front oil seal 26. Intake valve timing control solenoid

valve (bank 1)27. Valve timing control cover (bank 1)

28. Timing chain tensioner cover 29. Front cover 30. O-ring

31. Camshaft position sensor (bank 1) 32. Camshaft bracket 33. Oil filter (for valve timing control so-

lenoid valve)

34. Crankshaft sprocket 35. Oil pump drive spacer

A. Comply with the installation proce-

dure when tightening. Refer to

EM-

62, "Removal and Installation".

Refer to GI-4, "

Components" for symbol marks in the figure.

A : Keep free from magnetic materials

JPBIA0454ZZ

Revision: 2010 May2011 QX56

Page 2634 of 5598

EM-72

< REMOVAL AND INSTALLATION >

TIMING CHAIN

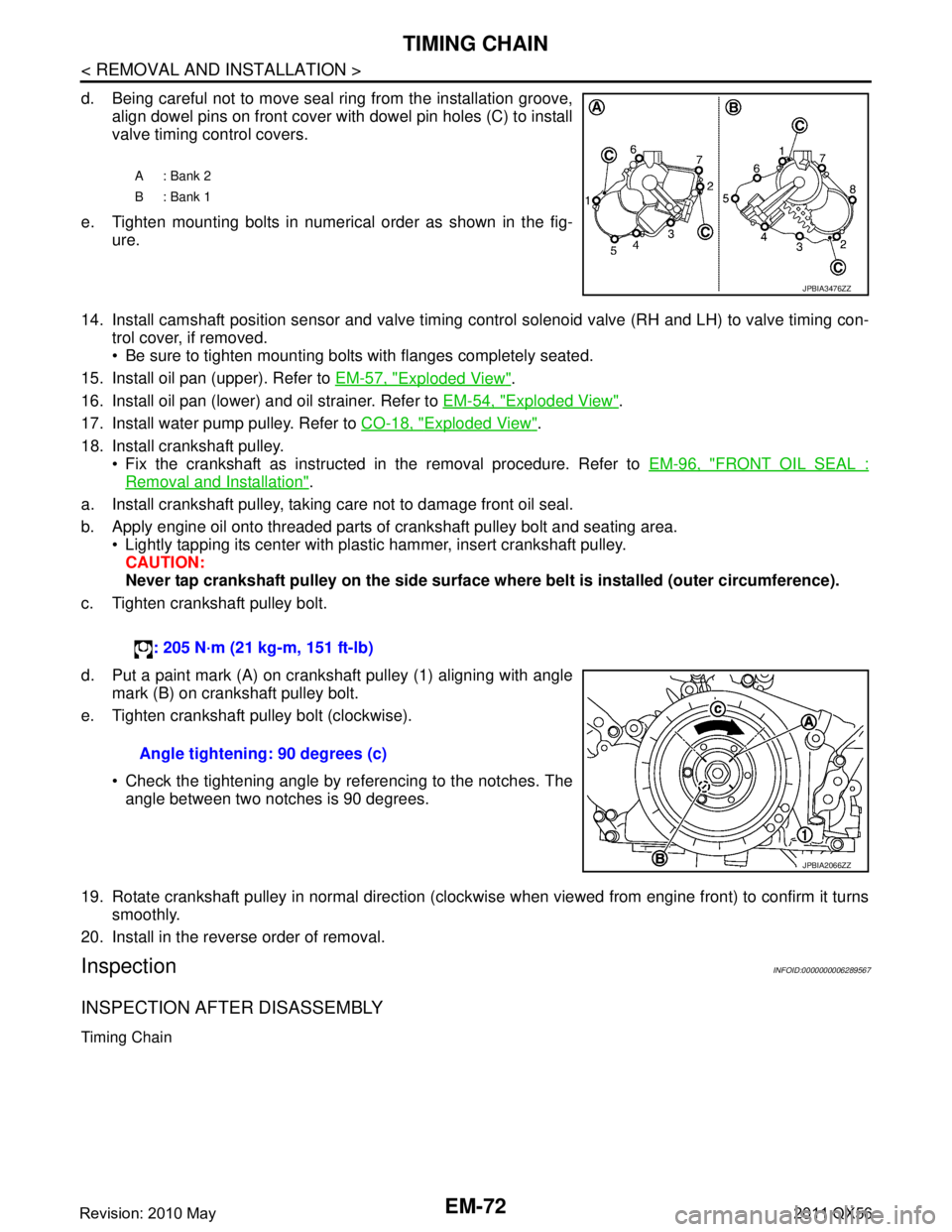

d. Being careful not to move seal ring from the installation groove,align dowel pins on front cover with dowel pin holes (C) to install

valve timing control covers.

e. Tighten mounting bolts in numerical order as shown in the fig- ure.

14. Install camshaft position sensor and valve timing c ontrol solenoid valve (RH and LH) to valve timing con-

trol cover, if removed.

Be sure to tighten mounting bolts with flanges completely seated.

15. Install oil pan (upper). Refer to EM-57, "

Exploded View".

16. Install oil pan (lower) and oil strainer. Refer to EM-54, "

Exploded View".

17. Install water pump pulley. Refer to CO-18, "

Exploded View".

18. Install crankshaft pulley. Fix the crankshaft as instructed in the removal procedure. Refer to EM-96, "

FRONT OIL SEAL :

Removal and Installation".

a. Install crankshaft pulley, taking care not to damage front oil seal.

b. Apply engine oil onto threaded parts of crankshaft pulley bolt and seating area. Lightly tapping its center with plastic hammer, insert crankshaft pulley.

CAUTION:

Never tap crankshaft pulley on the side surface wh ere belt is installed (outer circumference).

c. Tighten crankshaft pulley bolt.

d. Put a paint mark (A) on crankshaft pulley (1) aligning with angle mark (B) on crankshaft pulley bolt.

e. Tighten crankshaft pulley bolt (clockwise).

Check the tightening angle by referencing to the notches. Theangle between two notches is 90 degrees.

19. Rotate crankshaft pulley in normal direction (clockwise when viewed from engine front) to confirm it turns smoothly.

20. Install in the reverse order of removal.

InspectionINFOID:0000000006289567

INSPECTION AFTER DISASSEMBLY

Timing Chain

A: Bank 2

B: Bank 1

JPBIA3476ZZ

: 205 N·m (21 kg-m, 151 ft-lb)

Angle tightening: 90 degrees (c)

JPBIA2066ZZ

Revision: 2010 May2011 QX56

Page 2636 of 5598

EM-74

< REMOVAL AND INSTALLATION >

CAMSHAFT

CAMSHAFT

Exploded ViewINFOID:0000000006289568

1.VVEL actuator motor assembly

(bank 2) 2. Gasket 3.

VVEL actuator ho

using assembly

(bank 2)

4. Washer 5. VVEL ladder as sembly (bank 2) 6. Exhaust camshaft (bank 2)

7. Cylinder head (bank 2) 8. Cylinder head (bank 1) 9. Exhaust camshaft (bank 1)

10. VVEL ladder assembly (bank 1) 11. VVEL actuator housing assembly

(bank 1)12. Gasket

13. VVEL actuator motor assembly

(bank 1) 14.

VVEL control shaft

position sensor

(bank 1) 15.

VVEL control shaft

position sensor

(bank 2)

A. Comply with the installation proce-

dure when tightening. Refer to

EM-

75, "Removal and Installation".B. View B C. View C

Refer to GI-4, "

Components" for symbols in the figure.

JSBIA0403GB

Revision: 2010 May2011 QX56

Page 2637 of 5598

CAMSHAFTEM-75

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Removal and InstallationINFOID:0000000006289569

REMOVAL

CAUTION:

Never loosen adjusting bolts (A), mounting bolt

s (black color) (B) of VVEL ladder assembly and

mounting bolts (C) of VVEL control shaft position sen sor. If loosened, the stroke of cam lift becomes

out of adjustment. In such case, replacement of VVEL ladder assembly and cylinder head assembly

is required.

Never loosen the mounting bolts (C) of the VVEL control shaft position sensor. VVEL control shaft

position sensor mounting bolts are required to be loosened for adjustment only when using a new

VVEL ladder assembly. Refer to EC-150, "

Work Procedure".

NOTE:

VVEL ladder assembly cannot be replaced as a singl e part, because it is machined together with cylinder

head assembly.

1. Remove VVEL actuator motor assembly. Refer to EM-36, "

Exploded View".

2. Remove rocker covers (bank 1 and bank 2). Refer to EM-33, "

Exploded View".

3. Remove VVEL actuator housing assembly. Refer to EM-36, "

Exploded View".

4. Remove front cover, camshaft sprockets, and timing chains. Refer to EM-61, "

Exploded View".

5. Remove VVEL ladder assembly.

JPBIA3512ZZ

VVEL control shaft positi on sensor mounting bolt

: 7.0 N·m (0.71 kg-m, 62 in-lb)

Revision: 2010 May2011 QX56

Page 2639 of 5598

CAMSHAFTEM-77

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

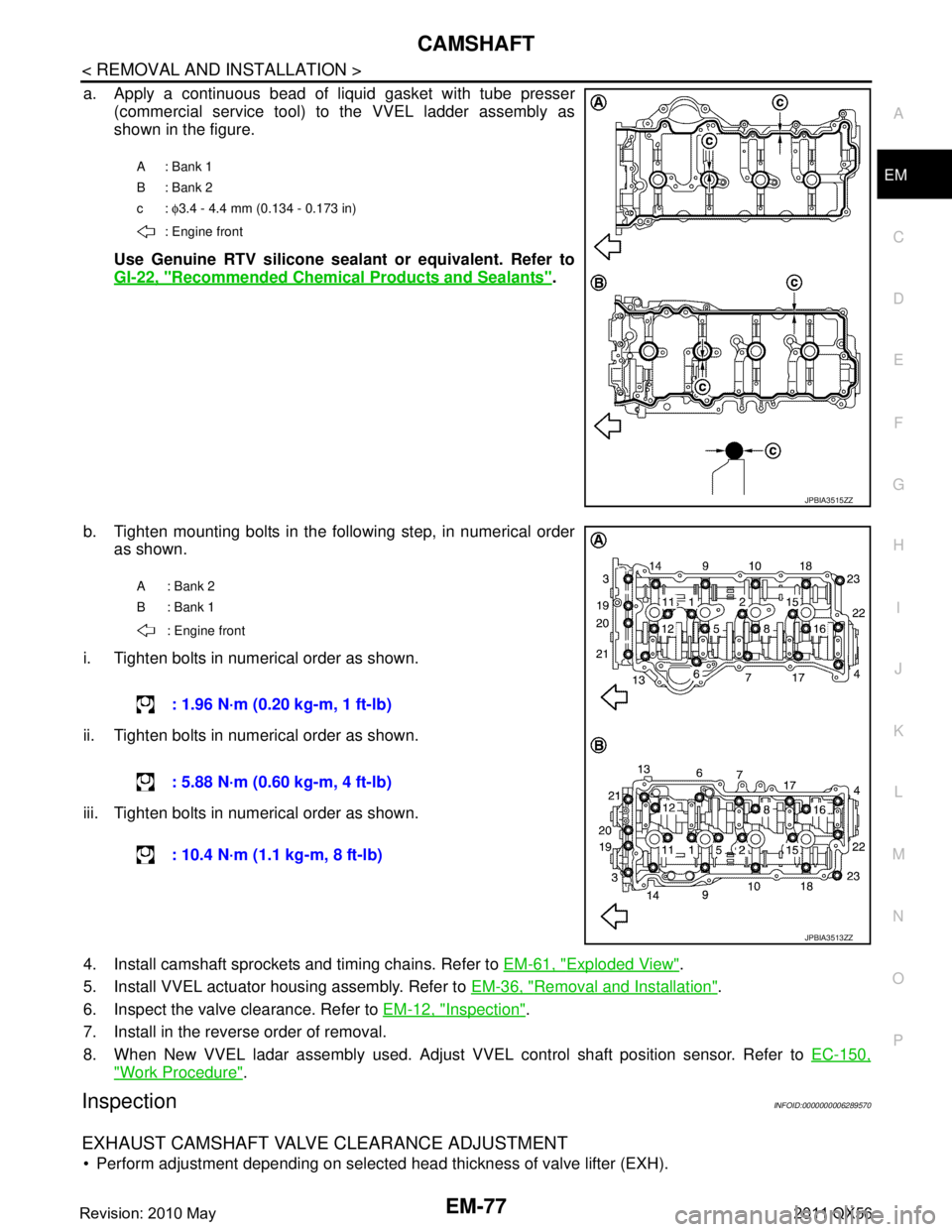

a. Apply a continuous bead of liquid gasket with tube presser

(commercial service tool) to the VVEL ladder assembly as

shown in the figure.

Use Genuine RTV silicone seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

b. Tighten mounting bolts in the following step, in numerical order as shown.

i. Tighten bolts in numerical order as shown.

ii. Tighten bolts in numerical order as shown.

iii. Tighten bolts in numerical order as shown.

4. Install camshaft sprockets and timing chains. Refer to EM-61, "

Exploded View".

5. Install VVEL actuator housing assembly. Refer to EM-36, "

Removal and Installation".

6. Inspect the valve clearance. Refer to EM-12, "

Inspection".

7. Install in the reverse order of removal.

8. When New VVEL ladar assembly used. Adjust VVEL control shaft position sensor. Refer to EC-150,

"Work Procedure".

InspectionINFOID:0000000006289570

EXHAUST CAMSHAFT VALVE CLEARANCE ADJUSTMENT

Perform adjustment depending on selected head thickness of valve lifter (EXH).

A: Bank 1

B: Bank 2

c: φ3.4 - 4.4 mm (0.134 - 0.173 in)

: Engine front

JPBIA3515ZZ

A: Bank 2

B: Bank 1

: Engine front

: 1.96 N·m (0.20 kg-m, 1 ft-lb)

: 5.88 N·m (0.60 kg-m, 4 ft-lb)

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

JPBIA3513ZZ

Revision: 2010 May2011 QX56

Page 2648 of 5598

EM-86

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

CYLINDER HEAD

Exploded ViewINFOID:0000000006289571

CAUTION:

A high degree of precision is required for a valve on the intake side. Never remove the valve related

parts unless necessary.

1. Valve lifter (EXH) 2. Valve collet (EXH) 3. Valve spring retainer (EXH)

4. Valve oil seal (EXH) 5. Valve spring (with valve spring seat)

(EXH)6. Valve guide (EXH)

7. Spark plug 8. Valve lifter (INT) 9. Valve collet (INT)

10. Valve spring retainer (INT) 11. Valve oil seal (INT) 12. Valve spring (with valve spring seat)

(INT)

13. Cylinder head bolt 14. Cylinder head (bank 2) 15. Valve seat (EXH)

16. Valve (EXH) 17. Cylinder head gasket (bank 2) 18. Oil filter (for VVEL ladder assembly)

19. Cylinder block 20. Valve (INT) 21. Valve seat (INT)

22. Cylinder head gasket (bank 1) 23. Cylinder head (bank 1) 24. Engine coolant temperature sensor

A. Comply with the installation proce-

dure when tightening. Refer to

EM-

87, "Removal and Installation".

Refer to GI-4, "

Components" for symbol marks in the figure.

JPBIA3524GB

Revision: 2010 May2011 QX56

Page 2668 of 5598

EM-106

< UNIT DISASSEMBLY AND ASSEMBLY >

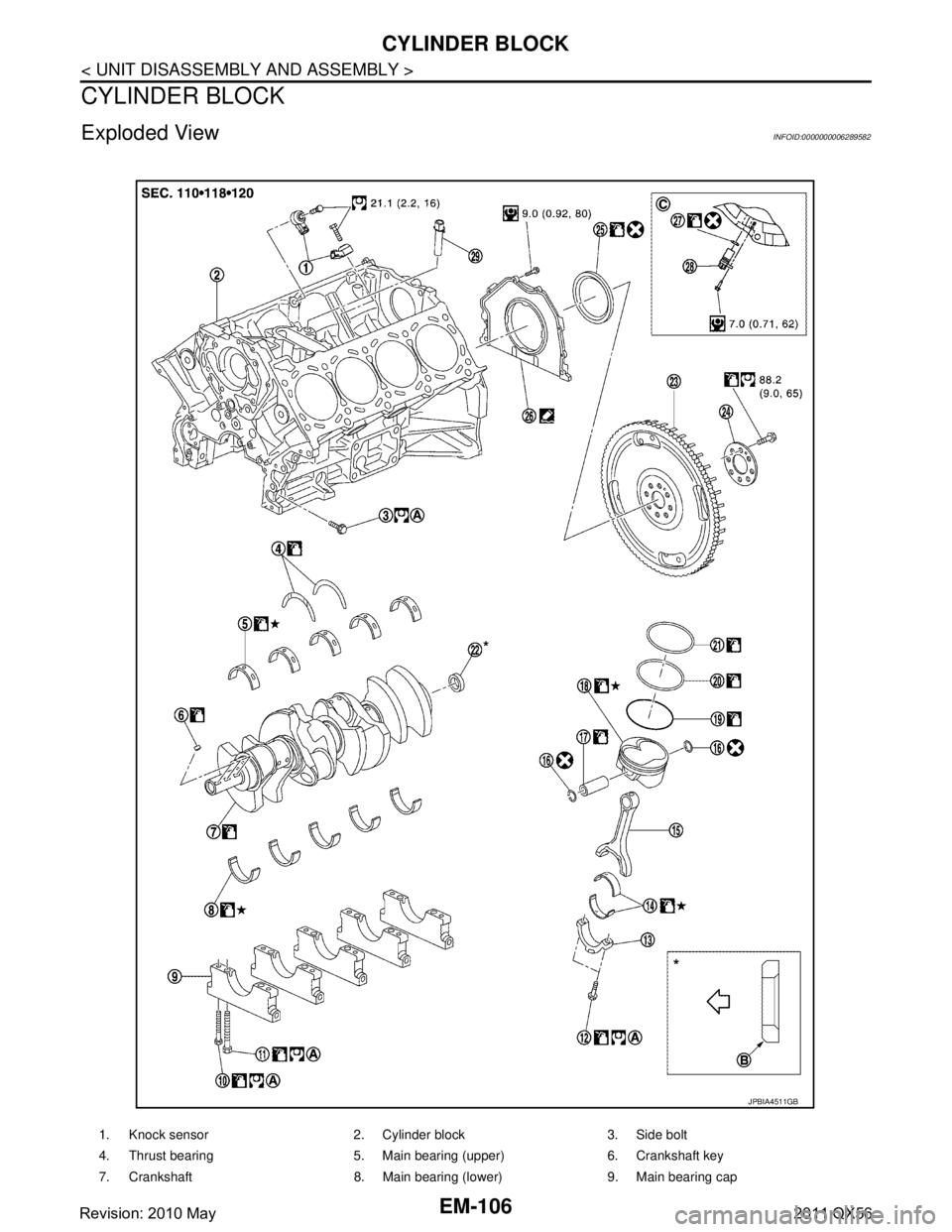

CYLINDER BLOCK

CYLINDER BLOCK

Exploded ViewINFOID:0000000006289582

1. Knock sensor 2. Cylinder block 3. Side bolt

4. Thrust bearing 5. Main bearing (upper) 6. Crankshaft key

7. Crankshaft 8. Main bearing (lower) 9. Main bearing cap

JPBIA4511GB

Revision: 2010 May2011 QX56