sensor INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2669 of 5598

CYLINDER BLOCKEM-107

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Disassembly and AssemblyINFOID:0000000006289583

DISASSEMBLY

1. Remove the following parts:

Oil pans (lower and upper): Refer to EM-54, "

Exploded View" and EM-57, "Exploded View".

Front cover and timing chain: Refer to EM-61, "

Exploded View".

Cylinder head: Refer to EM-86, "

Exploded View".

2. Remove knock sensor. CAUTION:

Carefully handle knock sensor avoiding shocks.

3. Remove oil filter (for VVEL ladder assembly ) from cylinder block, if necessary. Refer to EM-86, "

Exploded

View".

4. Remove piston and connecting rod assembly as per the following: Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer to

EM-115, "

Inspection".

CAUTION:

Be careful not to drop connecting r od bearing, and to scratch the surface.

a. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

b. Loosen mounting bolts, and remove connecting rod bearing cap.

c. Using a hammer handle (A) or similar tool, push piston and con- necting rod assembly out to the cylinder head side.

CAUTION:

Be careful not to damage the cylinder wall and crankshaft

pin, resulting from an interf erence of the connecting rod big

end.

5. Remove connecting rod bearings from connecting rod and connecting rod bearing cap.

CAUTION:

Be careful not to drop connecting rod bearing, and to scratch the surface.

Identify installation positions, and store them without mixing them up.

6. Remove piston rings from piston. Before removing piston rings, check the piston ring side clearance. Refer to EM-115, "

Inspection".

10. Main bearing cap sub bolt 11. Main bearing cap bolt 12. Connecting rod cap bolt

13. Connecting rod cap 14. Connecting rod bearing 15. Connecting rod

16. Snap ring 17. Piston pin 18. Piston

19. Oil ring 20. Second ring 21. Top ring

22. Pilot converter 23. Drive plate 24. Reinforcement plate

25. Rear oil seal 26. Rear oil seal retainer 27. O-ring

28. Crankshaft position sensor (POS) 29. Cylinder block heater (for Canada)

A.Comply with the assembly procedure

when tightening. Refer to

EM-107

.B. Chamfered C. Installed on transmission

: Crankshaft side

Refer to GI-4, "

Components" for symbol marks in the figure.

JPBIA2475ZZ

Revision: 2010 May2011 QX56

Page 2677 of 5598

![INFINITI QX56 2011 Factory Service Manual

CYLINDER BLOCKEM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

f. Tighten connecting rod bolts. (clockwise)

CAUTION:

Always use the angle wrench [SST: KV10112100 (B T8653-A)]. INFINITI QX56 2011 Factory Service Manual

CYLINDER BLOCKEM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

f. Tighten connecting rod bolts. (clockwise)

CAUTION:

Always use the angle wrench [SST: KV10112100 (B T8653-A)].](/img/42/57033/w960_57033-2676.png)

CYLINDER BLOCKEM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

f. Tighten connecting rod bolts. (clockwise)

CAUTION:

Always use the angle wrench [SST: KV10112100 (B T8653-A)]. Never make judgment by visual

inspection.

After tightening connecting rod bolts, c heck that crankshaft rotates smoothly.

Check the connecting rod side clearance. Refer to EM-115, "

Inspection".

16. Install knock sensors (1). Install knock sensors in the direction shown in the figure.

After installing knock sens or, connect harness connector, and

lay it out to front of the engine.

CAUTION:

Never tighten mounting bolts while holding connector.

If any impact by dropping is applied to knock sensor,

replace it with new one.

NOTE:

Check that there is no foreign material on the cylinder block

mating surface and the back surface of knock sensor.

Check that knock sensor does not interfere with other parts.

17. Install oil filter (for VVEL ladder assembly).

18. Install drive plate. Install drive plate (4) and reinforcement plate (3) as shown inthe figure.

When installing drive plate to crankshaft (1), be sure to cor- rectly align crankshaft side dowel pin and drive plate side

dowel pin hole.

CAUTION:

If these are not aligned correct ly, engine runs roughly and

“MIL” illuminates.

Holding ring gear with the ring gear stopper [SST: KV10119200 (J-49277)].

Tighten the mounting bolts crosswise over several times.

19. Assemble in the reverse order of disassembly.

InspectionINFOID:0000000006289584

CRANKSHAFT END PLAY

Measure the clearance between thrust bearings and crankshaft arm when crankshaft is moved fully forward or backward with a dial

indicator (A).

If the measured value exceeds t he limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also. : 19.6 N·m (2.0 kg-m, 14.5 ft-lb)

Angle tightening: 90 degrees

: Engine front

2 : Pilot converter

A : Rounded : Engine front

JPBIA4515ZZ

JPBIA2275ZZ

Standard and limit : Refer to EM-137, "CylinderBlock".

JPBIA2477ZZ

Revision: 2010 May2011 QX56

Page 2707 of 5598

PREPARATIONEX-3

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

PREPARATION

PREPARATION

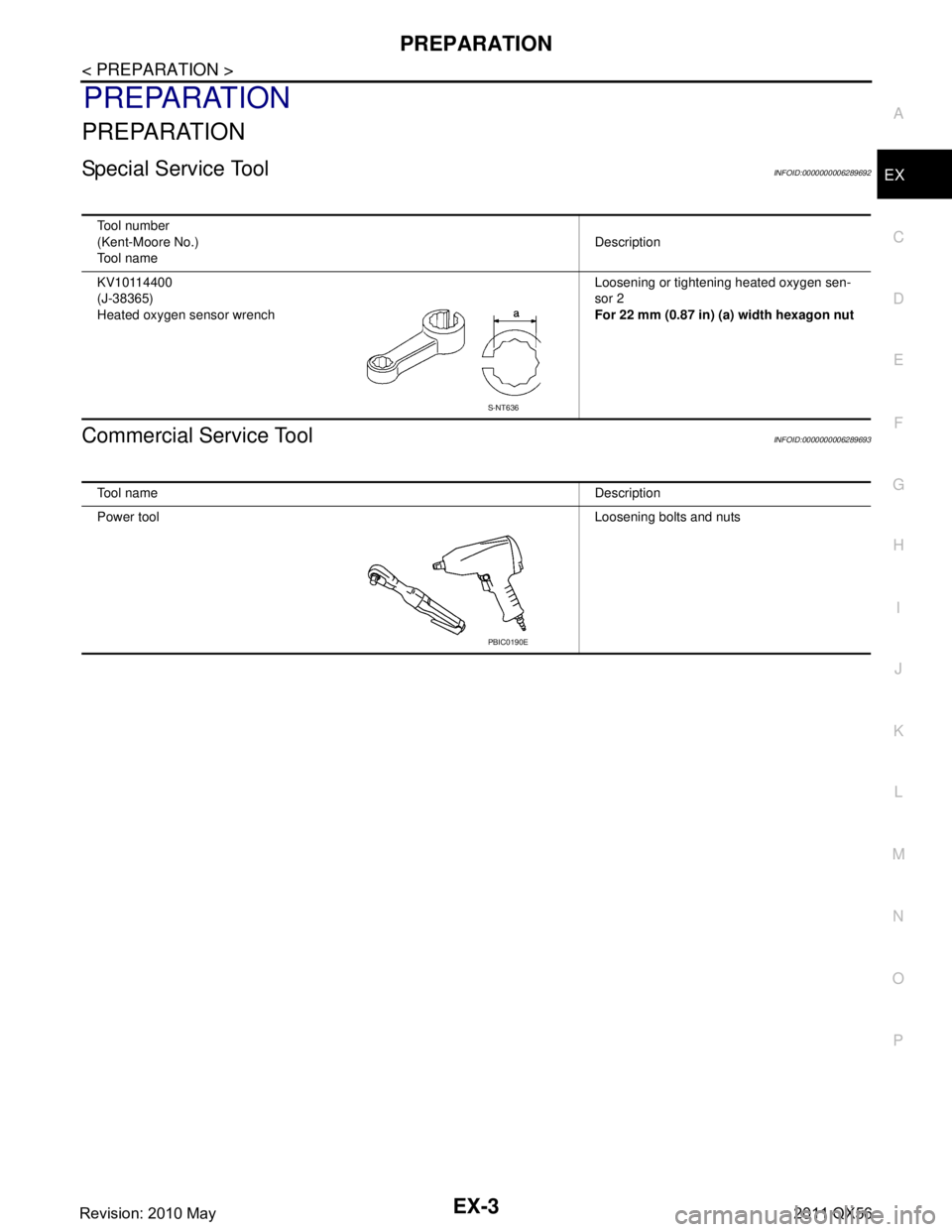

Special Service ToolINFOID:0000000006289692

Commercial Service ToolINFOID:0000000006289693

Tool number

(Kent-Moore No.)

Tool name

Description

KV10114400

(J-38365)

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sor 2

For 22 mm (0.87 in) (a) width hexagon nut

S-NT636

Tool name

Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: 2010 May2011 QX56

Page 2709 of 5598

EXHAUST SYSTEMEX-5

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

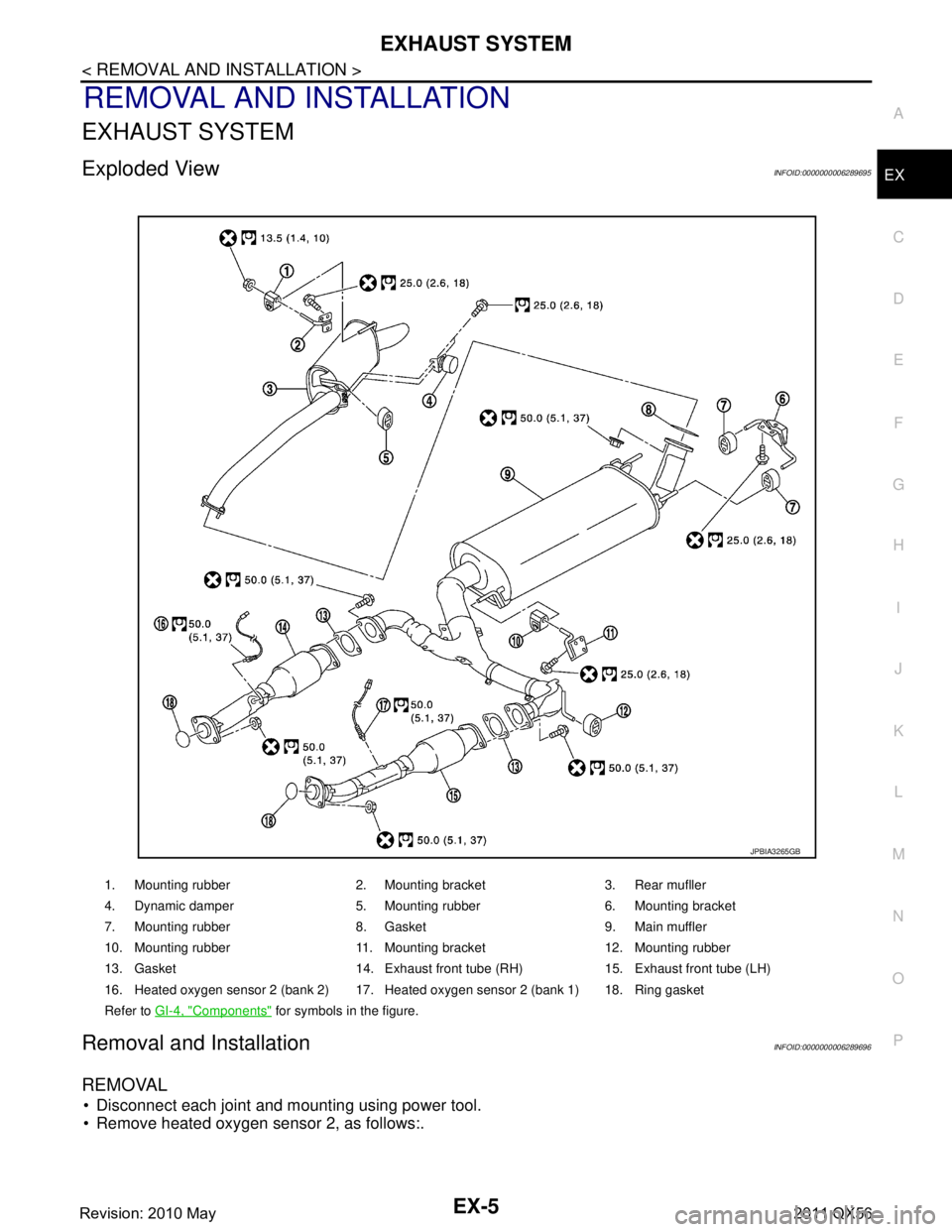

REMOVAL AND INSTALLATION

EXHAUST SYSTEM

Exploded ViewINFOID:0000000006289695

Removal and InstallationINFOID:0000000006289696

REMOVAL

Disconnect each joint and mounting using power tool.

Remove heated oxygen sens

or 2, as follows:.

1. Mounting rubber 2. Mounting bracket 3. Rear mufller

4. Dynamic damper 5. Mounting rubber 6. Mounting bracket

7. Mounting rubber 8. Gasket 9. Main muffler

10. Mounting rubber 11. Mounting bracket 12. Mounting rubber

13. Gasket 14. Exhaust front tube (RH) 15. Exhaust front tube (LH)

16. Heated oxygen sensor 2 (bank 2) 17. Heated oxygen sensor 2 (bank 1) 18. Ring gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3265GB

Revision: 2010 May2011 QX56

Page 2710 of 5598

![INFINITI QX56 2011 Factory Service Manual

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

- Using heated oxygen sensor wrench [SST: KV10114400] (C),removal heated oxygen sensor 2.

INSTALLATION

Note the following items, and install in the re INFINITI QX56 2011 Factory Service Manual

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

- Using heated oxygen sensor wrench [SST: KV10114400] (C),removal heated oxygen sensor 2.

INSTALLATION

Note the following items, and install in the re](/img/42/57033/w960_57033-2709.png)

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

- Using heated oxygen sensor wrench [SST: KV10114400] (C),removal heated oxygen sensor 2.

INSTALLATION

Note the following items, and install in the reverse order of removal.

Temporarily tighten bolts and nuts when installing exhaust pipe assembly. Tighten them to the specifiedtorque when connecting the vehicle rear to the vehicle front.

CAUTION:

Always replace exhaust tube gasket s with new ones when reassembling.

If heat insulator is badly deformed, repair or re place it. If deposits such as mud pile up on the heat

insulator, remove them.

When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

Check each part for unusual interference, and then tighten them to the specified torque.

When installing each moun ting rubber, avoid twisting or unusua l extension in up/down and right/left

directions.

InspectionINFOID:0000000006289697

INSPECTION AFTER INSTALLATION

Check clearance between tail tube and rear bumper is even.

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue stress. Improper installation could result in excessive noise and vibration.

A: Bank 1

B: Bank 2

: Vehicle front

JPBIA3395ZZ

Revision: 2010 May2011 QX56

Page 2712 of 5598

EXL-2

EXTERIOR LAMP BATTERY SAVER SYSTEM :

System Description .................................................

21

DIAGNOSIS SYSTEM (BCM) ............................22

COMMON ITEM ..................................................... ...22

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) ................................................. ...

22

HEADLAMP ........................................................... ...23

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ..........................................................

23

FLASHER ............................................................... ...25

FLASHER : CONSULT-III Function (BCM -

FLASHER) ..............................................................

25

DIAGNOSIS SYSTEM (IPDM E/R) ....................27

Diagnosis Description .......................................... ...27

CONSULT-III Function (IPDM E/R) ........................29

DIAGNOSIS SYSTEM (AFS) .............................32

CONSULT-III Function (ADAPTIVE LIGHT) ........ ...32

ECU DIAGNOSIS INFORMATION ..............34

BCM, IPDM E/R .............................................. ...34

List of ECU Reference ......................................... ...34

AFS CONTROL UNIT ........................................35

Reference Value .................................................. ...35

Fail-Safe .................................................................38

DTC Inspection Priority Chart .................................39

DTC Index ..............................................................39

WIRING DIAGRAM .....................................40

EXTERIOR LIGHTING SYSTEM .................... ...40

Wiring Diagram .................................................... ...40

BASIC INSPECTION ...................................59

DIAGNOSIS AND REPAIR WORKFLOW ...... ...59

Work Flow ............................................................ ...59

INSPECTION AND ADJUSTMENT ...................61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) .............. ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) : De-

scription ..................................................................

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) : Special

Repair Requirement ...............................................

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) ................... ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) : Descrip-

tion ....................................................................... ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) : Special

Repair Requirement ............................................. ...

61

LEVELIZER ADJUSTMENT ......................................61

LEVELIZER ADJUSTMENT : Description ..............61

LEVELIZER ADJUSTMENT : Special Repair Re-

quirement ............................................................. ...

61

DTC/CIRCUIT DIAGNOSIS ........................63

B2503, B2504 SWIVEL ACTUATOR ............. ...63

DTC Logic ............................................................ ...63

Diagnosis Procedure ...............................................64

Component Inspection ............................................67

B2513 HEIGHT SENSOR UNUSUAL [FR] .......68

DTC Logic ............................................................ ...68

Diagnosis Procedure ...............................................68

B2514 HEIGHT SENSOR UNUSUAL [RR] .......71

DTC Logic ............................................................ ...71

Diagnosis Procedure ...............................................71

B2516 SHIFT SIGNAL [P, R] ............................74

DTC Logic ............................................................ ...74

Diagnosis Procedure ...............................................74

B2517 VEHICLE SPEED SIGNAL ....................75

DTC Logic ............................................................ ...75

Diagnosis Procedure ...............................................75

B2519 LEVELIZER CALIBRATION ..................76

DTC Logic ............................................................ ...76

Diagnosis Procedure ...............................................76

B2521 ECU CIRCUIT ........................................77

DTC Logic ............................................................ ...77

Diagnosis Procedure ...............................................77

C0126 STEERING ANGLE SENSOR SIGNAL ...80

DTC Logic ............................................................ ...80

Diagnosis Procedure ...............................................80

C0428 STEERING ANGLE SENSOR CALI-

BRATION ...........................................................

81

DTC Logic ............................................................ ...81

Diagnosis Procedure ...............................................81

U1000 CAN COMM CIRCUIT ............................82

Description ........................................................... ...82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

U1010 CONTROL UNIT (CAN) .........................83

DTC Logic ............................................................ ...83

Diagnosis Procedure ...............................................83

POWER SUPPLY AND GROUND CIRCUIT .....84

AFS CONTROL UNIT ............................................. ...84

AFS CONTROL UNIT : Diagnosis Procedure .........84

Revision: 2010 May2011 QX56

Page 2713 of 5598

EXL-3

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

EXTERIOR LAMP FUSE ................................ ....85

Diagnosis Procedure ........................................... ....85

HEADLAMP (HI) CIRCUIT .................................86

Component Function Check ................................ ....86

Diagnosis Procedure ...............................................86

HEADLAMP (LO) CIRCUIT ................................88

Component Function Check ................................ ....88

Diagnosis Procedure ...............................................88

XENON HEADLAMP ..........................................90

Diagnosis Procedure ........................................... ....90

HEADLAMP LEVELIZER CIRCUIT ...................91

Component Function Check ................................ ....91

Diagnosis Procedure ...............................................91

HEADLAMP AIMING SYSTEM (MANUAL) .......93

Component Inspection ........................................ ....93

FRONT FOG LAMP CIRCUIT ............................94

Component Function Check ................................ ....94

Diagnosis Procedure ...............................................94

PARKING LAMP CIRCUIT ............................. ....96

Component Function Check ................................ ....96

Diagnosis Procedure ...............................................96

FRONT SIDE MARKER LAMP CIRCUIT ...........98

Component Function Check ................................ ....98

Diagnosis Procedure ...............................................98

TURN SIGNAL LAMP CIRCUIT .........................99

Component Function Check ................................ ....99

Diagnosis Procedure ...............................................99

OPTICAL SENSOR ..........................................102

Component Function Check ................................ ..102

Diagnosis Procedure .............................................102

HAZARD SWITCH .......................................... ..105

Component Function Check ................................ ..105

Diagnosis Procedure .............................................105

AFS SWITCH ....................................................107

Component Function Check ................................ ..107

Diagnosis Procedure .............................................107

Component Inspection ..........................................108

TAIL LAMP CIRCUIT .......................................109

BODY SIDE ........................................................... ..109

BODY SIDE : Component Function Check ...........109

BODY SIDE : Diagnosis Procedure ......................109

BACK DOOR SIDE ................................................ ..110

BACK DOOR SIDE : Component Function Check ..110

BACK DOOR SIDE : Diagnosis Procedure ...........111

LICENSE PLATE LAMP CIRCUIT ...................112

Component Function Check ................................ ..112

Diagnosis Procedure .............................................112

SYMPTOM DIAGNOSIS ............................113

EXTERIOR LIGHTING SYSTEM SYMPTOMS .113

Symptom Table ................................................... ..113

NORMAL OPERATING CONDITION .............116

Description .............................................................116

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM ..............................................

117

Description .............................................................117

Diagnosis Procedure .............................................117

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ...................................................

118

Description ........................................................... ..118

Diagnosis Procedure .............................................118

PARKING, LICENSE PLATE, SIDE MARKER

AND TAIL LAMPS ARE NOT TURNED ON ...

119

Description .............................................................119

Diagnosis Procedure .............................................119

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ...................................................

120

Description ........................................................... ..120

Diagnosis Procedure .............................................120

PERIODIC MAINTENANCE ......................121

HEADLAMP AIMING ADJUSTMENT .............121

description ........................................................... ..121

Aiming Adjustment Procedure ...............................122

FRONT FOG LAMP AIMING ADJUSTMENT .123

Description .............................................................123

Aiming Adjustment Procedure ...............................123

REMOVAL AND INSTALLATION .............125

FRONT COMBINATION LAMP ......................125

Exploded View ..................................................... ..125

Removal and Installation .......................................125

Replacement .........................................................126

Disassembly and Assembly ...................................127

FRONT FOG LAMP ........................................128

Exploded View .......................................................128

Removal and Installation .......................................128

Replacement .........................................................128

SIDE TURN SIGNAL LAMP ............................130

Exploded View .......................................................130

Removal and Installation .......................................130

OPTICAL SENSOR .........................................131

Exploded View .......................................................131

Removal and Installation .......................................131

LIGHTING & TURN SIGNAL SWITCH ...........132

Exploded View .......................................................132

Revision: 2010 May2011 QX56

Page 2714 of 5598

EXL-4

HAZARD SWITCH ...........................................133

Exploded View ..................................................... ..133

AFS SWITCH ...................................................134

Exploded View ..................................................... ..134

Removal and Installation .......................................134

AFS CONTROL UNIT ......................................135

Exploded View ..................................................... ..135

Removal and Installation .......................................135

HEIGHT SENSOR ............................................136

Exploded View ..................................................... ..136

Removal and Installation .......................................136

REAR COMBINATION LAMP .........................138

Exploded View ..................................................... ..138

Removal and Installation .......................................138

HIGH-MOUNTED STOP LAMP .......................140

Exploded View ..................................................... .140

Removal and Installation .......................................140

BACK-UP LAMP ............................................ ..141

Exploded View ..................................................... .141

Removal and Installation .......................................141

Replacement .........................................................142

LICENSE PLATE LAMP ...................................143

Exploded View ..................................................... .143

Removal and Installation .......................................143

Replacement .........................................................143

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

145

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

145

Bulb Specifications ............................................... .145

Revision: 2010 May2011 QX56

Page 2715 of 5598

![INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO](/img/42/57033/w960_57033-2714.png)

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006450052

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2010 May2011 QX56

Page 2717 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

*1: With headlamp aiming control system (manual) models

*2: With AFS system models

EXTERIOR LIGHTING SYSTEM INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

*1: With headlamp aiming control system (manual) models

*2: With AFS system models

EXTERIOR LIGHTING SYSTEM](/img/42/57033/w960_57033-2716.png)

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

*1: With headlamp aiming control system (manual) models

*2: With AFS system models

EXTERIOR LIGHTING SYSTEM : Component DescriptionINFOID:0000000006213888

1. Combination meter 2. BCM

Refer to BCS-4, "

BODY CONTROL

SYSTEM : Compon ent Parts Loca-

tion"

3. Optical sensor

4. IPDM E/R Refer to PCS-4, "

Component Parts

Location"

5. ECM

Refer to EC-16, "

Component Parts

Location"

6. Parking lamp

7. Front turn signal lamp 8. Front fog lamp 9. Headlamp

10. Front side marker lamp 11. Combination switch 12. Headlamp aiming switch*

1

13. Front door switch (driver side) 14.

Steering angle sensor*2

Refer to BRC-10, "Component Parts

Location"

15. License plate lamp

16. Tail lamp 17. Rear turn signal lamp 18. Rear side marker lamp

19. Hazard switch 20. Side turn signal lamp 21. Headlamp swivel actuator

22. Headlamp aiming motor 23. AFS switch*

224.Rear height sensor*2

25.AFS control unit*226.Front height sensor*2

A. Front combination lamp (back) B. View with instrument driver lower

panel (LH)C. Rear suspension member (RH)

D. View with instrument lower cover E. Front suspension arm (RH)

Part Description

BCM Controls the exterior lighting system.

ECM*

1Transmits engine speed signal to AFS control unit. (via CAN communication)

TCM*

1Transmits Shift position signal to AFS control unit. (via CAN communication)

IPDM E/R Controls the integrated relay, and supplies voltage to the load according to the request

from BCM (via CAN communication).

AFS control unit*

1AFS control unit judges the vehicle condition from each signal. AFS control unit con-

trols AFS function and the headlamp aiming.

Combination meter Outputs the vehicle speed signal (8-pulse) to AFS control unit.

Blinks the turn signal indicator lamp and outputs the turn signal operating sound with

integrated buzzer according to the request from BCM (via CAN communication).

Turns the tail lamp indicator lamp and high beam indicator lamp ON according to the

request from BCM (via CAN communication).

Turns the AFS OFF indicator lamp ON/OFF /blinking according to the request from

AFS control unit (via CAN communication).

Headlamp assembly Xenon bulb Refer to

EXL-8, "

FRONT COMBINATION LAMP : Xenon Headlamp".

HID control unit Refer to EXL-9, "

FRONT COMBINATION LAMP : HID control unit".

High beam solenoid Refer to EXL-9, "

FRONT COMBINATION LAMP : High Beam Solenoid".

Aiming motor Refer to EXL-9, "

FRONT COMBINATION LAMP : Aiming Motor".

Swivel actuator*

1Refer to EXL-9, "FRONT COMBINATION LAMP : Swivel Actuator".

Height sensor*

1

The height sensor is installed to the front suspension member and rear suspension member.

The height sensor detects the suspension arm displacement as the vehicle height change.

The height sensor transmits the height sensor signal to AFS control unit.

NOTE:

The sensor angle of the unloaded vehicle position is the reference value.

Optical sensor Optical sensor converts the outside brightness (lux) to voltage and transmits the opti-

cal sensor signal to BCM.

Revision: 2010 May2011 QX56