INFINITI QX56 2011 Factory Manual Online

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 81 of 5598

ADP-72

< DTC/CIRCUIT DIAGNOSIS >

RECLINING SWITCH

NO >> Repair or replace harness or connector.

3.CHECK RECLINING SWITCH

Refer to ADP-72, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace power seat switch.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006248362

1.CHECK RECLINING SWITCH

1. Turn ignition switch OFF.

2. Disconnect power seat switch (reclining switch) connector.

3. Check continuity between power seat switch (reclining switch) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace power seat switch.

Power seat switch (Reclining switch) Condition Continuity

Te r m i n a l

9 43Reclining switch (backward)

Operate Existed

Release Not existed

25 Reclining switch (forward) Operate Existed

Release Not existed

Revision: 2010 May2011 QX56

Page 82 of 5598

LIFTING SWITCH (FRONT)ADP-73

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

LIFTING SWITCH (FRONT)

Component Function CheckINFOID:0000000006248363

1.CHECK FUNCTION

1. Select “LIFT FR SW-UP”, “LIFT FR SW-DN” in “Data monitor” mode with CONSULT-III.

2. Check lifting switch (front) signal under the following conditions.

Is the indication normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-73, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248364

1.CHECK LIFTING SWITCH (FRONT) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect power seat switch connector.

3. Turn ignition switch ON.

4. Check voltage between power seat switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK LIFTING SWITCH (FRONT) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check continuity between driver seat control uni t harness connector and power seat switch harness con-

nector.

4. Check continuity between driver s eat control unit harness connector and ground.

Is the inspection result normal?

YES >> Replace driver seat control unit.

Monitor item Condition Status

LIFT FR SW-UP Lifting switch front (up) Operate ON

Release OFF

LIFT FR SW-DN Lifting switch front (down) Operate ON

Release OFF

(+)

(-)Voltage (V)

(Approx.)

Power seat switch

Connector Terminals

B459 10

Ground 12

26

Driver seat control unit Power seat switch Continuity

Connector Terminal Connector Terminal

B452 10

B459 10

Existed

26 26

Driver seat control unit GroundContinuity

Connector Terminal

B452 10

Not existed

26

Revision: 2010 May2011 QX56

Page 83 of 5598

ADP-74

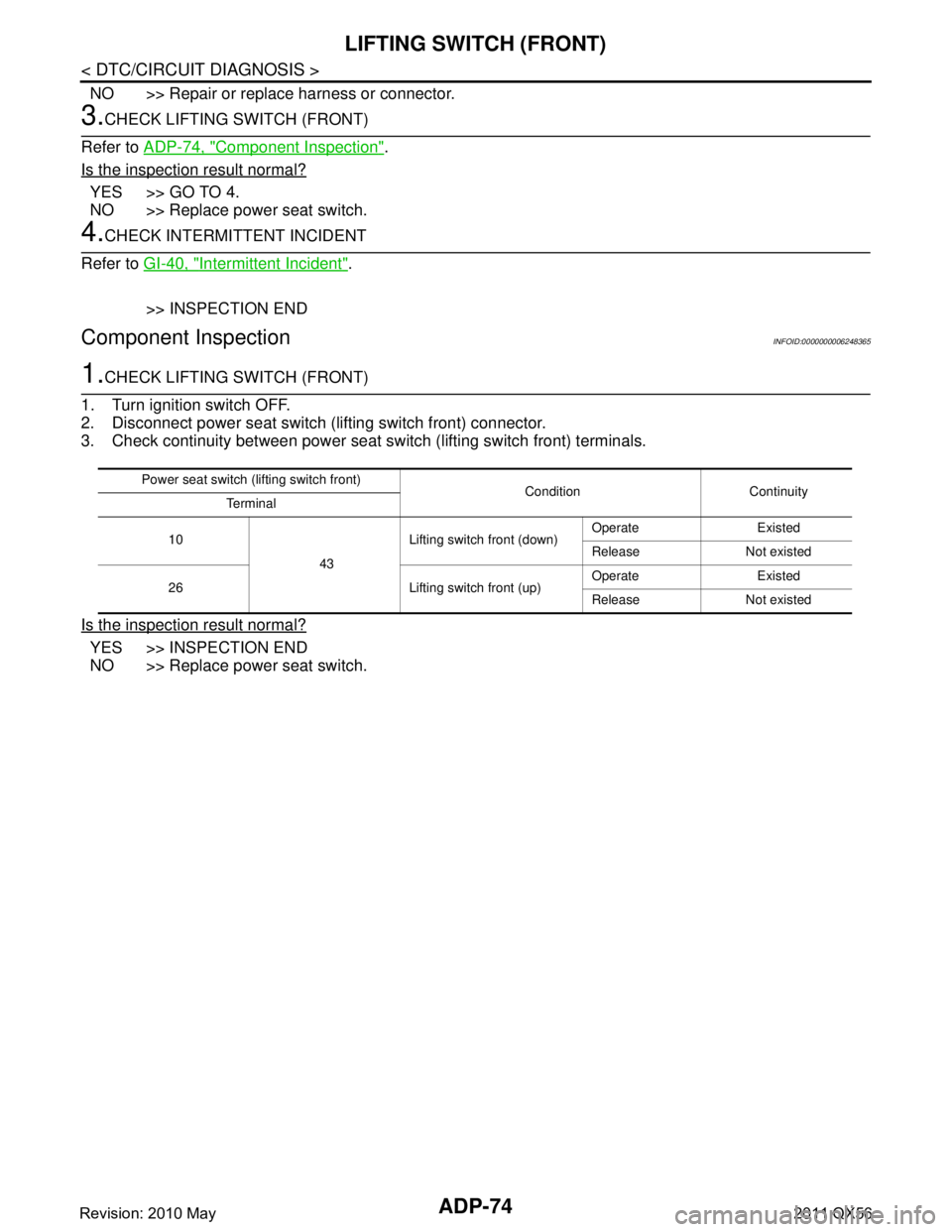

< DTC/CIRCUIT DIAGNOSIS >

LIFTING SWITCH (FRONT)

NO >> Repair or replace harness or connector.

3.CHECK LIFTING SWITCH (FRONT)

Refer to ADP-74, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace power seat switch.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006248365

1.CHECK LIFTING SWITCH (FRONT)

1. Turn ignition switch OFF.

2. Disconnect power seat switch (lifting switch front) connector.

3. Check continuity between power seat switch (lifting switch front) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace power seat switch.

Power seat switch (lifting switch front) Condition Continuity

Te r m i n a l

10 43Lifting switch front (down)

Operate Existed

Release Not existed

26 Lifting switch front (up) Operate Existed

Release Not existed

Revision: 2010 May2011 QX56

Page 84 of 5598

LIFTING SWITCH (REAR)ADP-75

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

LIFTING SWITCH (REAR)

Component Function CheckINFOID:0000000006248366

1.CHECK FUNCTION

1. Select “LIFT RR SW-UP”, “LIFT RR SW-DN” in “Data monitor” mode with CONSULT-III.

2. Check lifting switch (rear) signal under the following conditions.

Is the indication normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-75, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248367

1.CHECK LIFTING SWITCH (REAR) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect power seat switch connector.

3. Turn ignition switch ON.

4. Check voltage between power seat switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK LIFTING SWITCH (REAR) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check continuity between driver seat control uni t harness connector and power seat switch harness con-

nector.

4. Check continuity between driver s eat control unit harness connector and ground.

Is the inspection result normal?

YES >> Replace driver seat control unit.

Monitor item Condition Status

LIFT RR SW-UP Lifting switch rear (up) Operate ON

Release OFF

LIFT RR SW-DN Lifting switch rear (down) Operate ON

Release OFF

(+)

(-)Voltage (V)

(Approx.)

Power seat switch

Connector Terminals

B459 11

Ground 12

27

Driver seat control unit Power seat switch Continuity

Connector Terminal Connector Terminal

B452 11

B459 11

Existed

27 27

Driver seat control unit GroundContinuity

Connector Terminal

B452 11

Not existed

27

Revision: 2010 May2011 QX56

Page 85 of 5598

ADP-76

< DTC/CIRCUIT DIAGNOSIS >

LIFTING SWITCH (REAR)

NO >> Repair or replace harness or connector.

3.CHECK LIFTING SWITCH (REAR)

Refer to ADP-76, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace power seat switch.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006248368

1.CHECK LIFTING SWITCH (REAR)

1. Turn ignition switch OFF.

2. Disconnect power seat switch (lifting switch rear) connector.

3. Check continuity between power seat switch (lifting switch rear) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace power seat switch.

Power seat switch (lifting switch rear) Condition Continuity

Te r m i n a l

11 43Lifting switch rear (down)

Operate Existed

Release Not existed

27 Lifting switch rear (up) Operate Existed

Release Not existed

Revision: 2010 May2011 QX56

Page 86 of 5598

TILT SWITCHADP-77

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

TILT SWITCH

Component Function CheckINFOID:0000000006248369

1.CHECK FUNCTION

1. Select “TILT SW-UP”, “TILT SW-DOWN” in “Data monitor” mode with CONSULT-III.

2. Check tilt switch signal under the following conditions.

Is the indication normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-77, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248370

1.CHECK TILT SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect tilt & telescopic switch connector.

3. Turn ignition switch ON.

4. Check voltage between tilt & telesc opic switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK TILT SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit connector.

3. Check continuity between automatic drive positioner control unit harness connector and tilt & telescopic

switch harness connector.

4. Check continuity between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES >> Replace automatic drive positioner control unit.

Monitor item Condition Status

TILT SW-UP Tilt switch (up) Operate ON

Release OFF

TILT SW-DOWN Tilt switch (down) Operate ON

Release OFF

(+)

(-)Voltage (V)

(Approx.)

Tilt & telescopic switch

Connector Terminals

M102 2

Ground 5

3

Automatic drive positioner control unit Tilt & telescopic switch Continuity

Connector Terminal Connector Terminal

M75 1

M102 2

Existed

13 3

Automatic drive positioner control unit GroundContinuity

Connector Terminal

M75 1

Not existed

13

Revision: 2010 May2011 QX56

Page 87 of 5598

ADP-78

< DTC/CIRCUIT DIAGNOSIS >

TILT SWITCH

NO >> Repair or replace harness or connector.

3.CHECK TILT SWITCH

Refer to ADP-78, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace tilt & telescopic switch.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006248371

1.CHECK TILT SWITCH

1. Turn ignition switch OFF.

2. Disconnect tilt & telescopic switch connector.

3. Check continuity between tilt & telescopic switch terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace tilt & telescopic switch.

Tilt switch Condition Continuity

Te r m i n a l

2 1Tilt switch (upward)

Operate Existed

Release Not existed

3 Tilt switch (downward) Operate Existed

Release Not existed

Revision: 2010 May2011 QX56

Page 88 of 5598

TELESCOPIC SWITCHADP-79

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

TELESCOPIC SWITCH

Component Function CheckINFOID:0000000006248372

1.CHECK FUNCTION

1. Select “TELESCO SW-FR”, “TELESCO SW-RR” in “Data monitor” mode with CONSULT-III.

2. Check telescopic switch signal under the following conditions.

Is the indication normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-79, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248373

1.CHECK TELESCOPIC SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect tilt & telescopic switch connector.

3. Turn ignition switch ON.

4. Check voltage between tilt & telesc opic switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK TELESCOPIC SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit connector.

3. Check continuity between automatic drive positioner control unit harness connector and tilt & telescopic

switch harness connector.

4. Check continuity between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES >> Replace automatic drive positioner control unit.

Monitor item Condition Status

TELESCO SW-FR Telescopic switch (forward) Operate ON

Release OFF

TELESCO SW-RR Telescopic switch (backward) Operate ON

Release OFF

(+)

(-)Voltage (V)

(Approx.)

Tilt & telescopic switch

Connector Terminals

M102 5

Ground 5

4

Automatic drive positioner control unit Tilt & telescopic switch Continuity

Connector Terminal Connector Terminal

M75 7

M102 5

Existed

19 4

Automatic drive positioner control unit GroundContinuity

Connector Terminal

M75 7

Not existed

19

Revision: 2010 May2011 QX56

Page 89 of 5598

ADP-80

< DTC/CIRCUIT DIAGNOSIS >

TELESCOPIC SWITCH

NO >> Repair or replace harness or connector.

3.CHECK TELESCOPIC SWITCH

Refer to ADP-80, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace tilt & telescopic switch.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006248374

1.CHECK TELESCOPIC SWITCH

1. Turn ignition switch OFF.

2. Disconnect tilt & telescopic switch connector.

3. Check continuity between tilt & telescopic switch terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace tilt & telescopic switch.

Telescopic switch Condition Continuity

Te r m i n a l

5 1Telescopic switch (forward)

Operate Existed

Release Not existed

4 Telescopic switch (backward) Operate Existed

Release Not existed

Revision: 2010 May2011 QX56

Page 90 of 5598

SEAT MEMORY SWITCHADP-81

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

SEAT MEMORY SWITCH

Component Function CheckINFOID:0000000006248375

1.CHECK FUNCTION

1. Select “MEMORY SW 1”, “MEMORY SW 2”, “SET SW” in “Data monitor” mode with CONSULT-III.

2. Check seat memory switch signal under the following conditions.

Is the indication normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-81, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248376

1.CHECK SEAT MEMORY SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect seat memory switch connector.

3. Turn ignition switch ON.

4. Check voltage between seat memory switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK SEAT MEMORY SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check continuity between driver seat control unit harness connector and seat memory switch harness

connector.

4. Check continuity between driver s eat control unit harness connector and ground.

Monitor item Condition Status

MEMORY SW 1 Memory switch 1 Push ON

Release OFF

MEMORY SW 2 Memory switch 2 Push ON

Release OFF

SET SW Set switch Push ON

Release OFF

(+)

(-)Voltage (V)

(Approx.)

Seat memory switch

Connector Terminals

D13 1

Ground 5

2

3

Driver seat control unit Seat memory switch

Continuity

Connector Terminal Connector Terminal

B452 6

D13 2

Existed

22 1

28 3

Revision: 2010 May2011 QX56