check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3729 of 6020

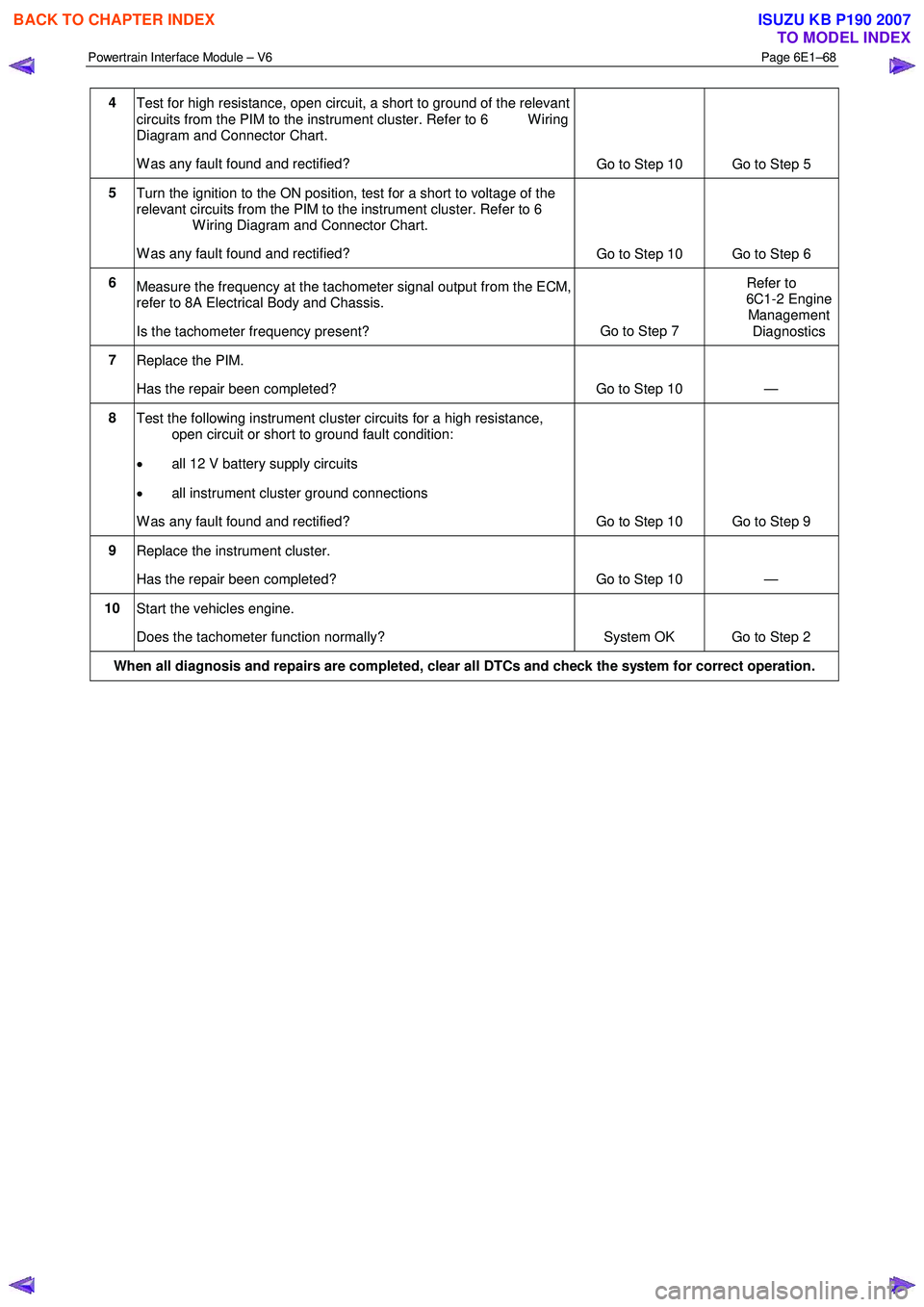

Powertrain Interface Module – V6 Page 6E1–68

4

Test for high resistance, open circuit, a short to ground of the relevant

circuits from the PIM to the instrument cluster. Refer to 6 W iring

Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 10 Go to Step 5

5

Turn the ignition to the ON position, test for a short to voltage of the

relevant circuits from the PIM to the instrument cluster. Refer to 6

W iring Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 10 Go to Step 6

6

Measure the frequency at the tachometer signal output from the ECM,

refer to 8A Electrical Body and Chassis.

Is the tachometer frequency present? Go to Step 7 Refer to

6C1-2 Engine Management

Diagnostics

7 Replace the PIM.

Has the repair been completed? Go to Step 10 —

8 Test the following instrument cluster circuits for a high resistance,

open circuit or short to ground fault condition:

• all 12 V battery supply circuits

• all instrument cluster ground connections

W as any fault found and rectified? Go to Step 10 Go to Step 9

9 Replace the instrument cluster.

Has the repair been completed? Go to Step 10 —

10 Start the vehicles engine.

Does the tachometer function normally? System OK Go to Step 2

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3730 of 6020

Powertrain Interface Module – V6 Page 6E1–69

10.4 Temperature Gauge Diagnostics

Circuit Description

The powertrain interface module (PIM) receives engine temperature status via the GM Lan serial data bus from the

engine control module (ECM) it is then sent to the instrument cluster by the PIM via a hard wired connection to drive the

temperature gauge to the appropriate position. Some of these components do not set a DTC, in the event of a

component failure. The following diagnostic procedures are devised to assist in these cases.

Additional Information

• Refer to 7.2 Diagnostic System Check to monitor DTC’s.

• Refer to 8A Electrical Body and Chassis for the following information:

• ECM wiring diagram.

• Refer to 6 W iring Diagram and Connector Chart for the following information:

• PIM connector illustration and terminal assignment, and

• PIM wiring diagram.

• For intermittent faults, refer to Intermittent Fault Conditions.

• Check for an intermittent fault in the wiring harness or connectors, if a fault cannot be found the system is

serviceable.

Since fault conditions in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 This step tests for DTC’s in the overall system.

2 This step uses the instrument cluster self test to check the function of the temperature gauge.

3 This step uses Tech 2 to drive the temperature gauge.

6 This step tests for set DTC’s in the ECM.

11 This step tests the in-vehicle function of the temperature gauge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3731 of 6020

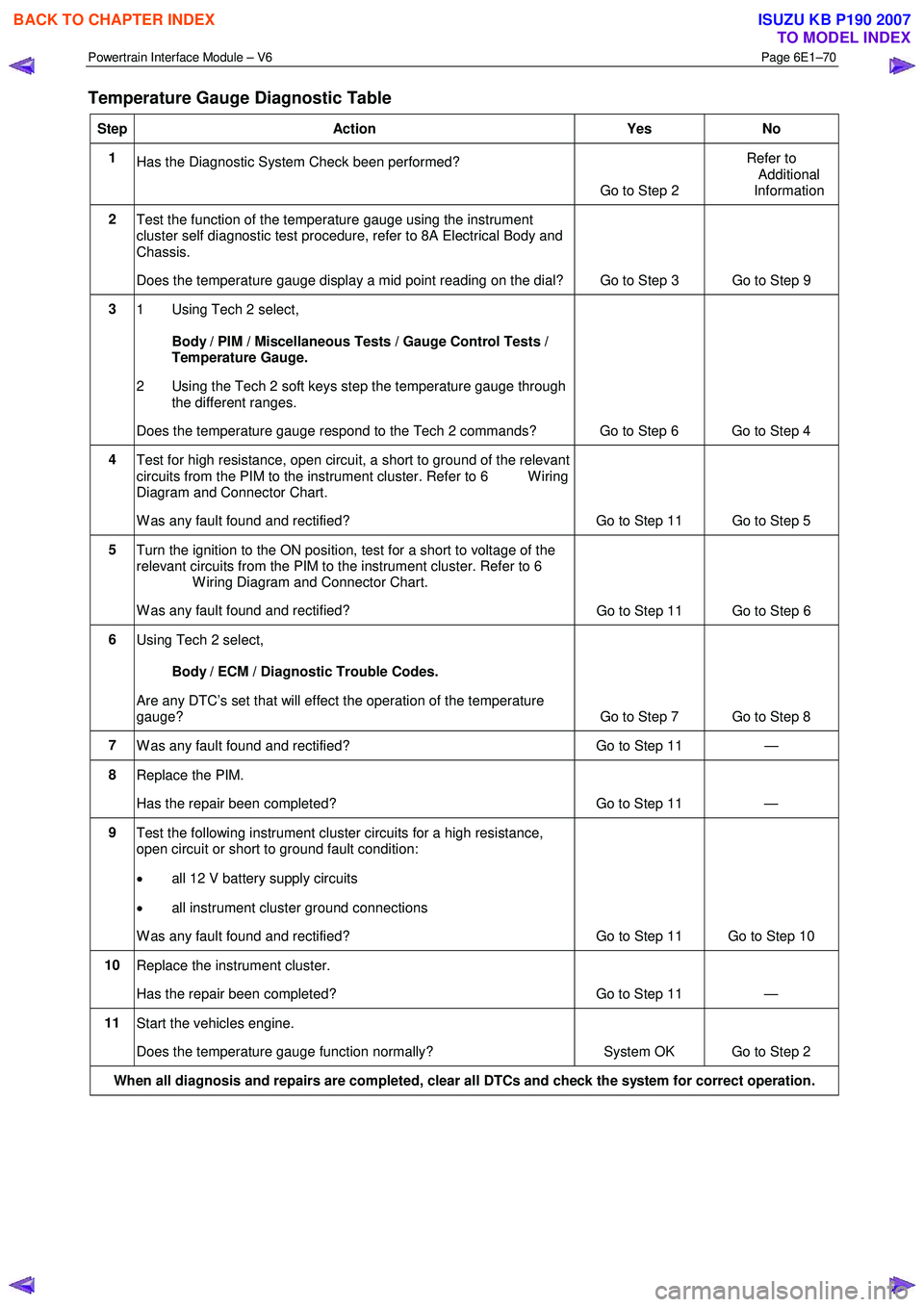

Powertrain Interface Module – V6 Page 6E1–70

Temperature Gauge Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

Additional

Information

2 Test the function of the temperature gauge using the instrument

cluster self diagnostic test procedure, refer to 8A Electrical Body and

Chassis.

Does the temperature gauge display a mid point reading on the dial? Go to Step 3 Go to Step 9

3

1 Using Tech 2 select,

Body / PIM / Miscellaneous Tests / Gauge Control Tests /

Temperature Gauge.

2 Using the Tech 2 soft keys step the temperature gauge through the different ranges.

Does the temperature gauge respond to the Tech 2 commands? Go to Step 6 Go to Step 4

4 Test for high resistance, open circuit, a short to ground of the relevant

circuits from the PIM to the instrument cluster. Refer to 6 W iring

Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 11 Go to Step 5

5 Turn the ignition to the ON position, test for a short to voltage of the

relevant circuits from the PIM to the instrument cluster. Refer to 6

W iring Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 11 Go to Step 6

6

Using Tech 2 select,

Body / ECM / Diagnostic Trouble Codes.

Are any DTC’s set that will effect the operation of the temperature

gauge? Go to Step 7 Go to Step 8

7 W as any fault found and rectified? Go to Step 11 —

8 Replace the PIM.

Has the repair been completed? Go to Step 11 —

9 Test the following instrument cluster circuits for a high resistance,

open circuit or short to ground fault condition:

• all 12 V battery supply circuits

• all instrument cluster ground connections

W as any fault found and rectified? Go to Step 11 Go to Step 10

10 Replace the instrument cluster.

Has the repair been completed? Go to Step 11 —

11 Start the vehicles engine.

Does the temperature gauge function normally? System OK Go to Step 2

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3740 of 6020

Powertrain Interface Module – V6 Page 6E1–79

13 Powertrain Interface Module –

Tech 2 Functions

13.1 Introduction

Do not use a Tech 2 that displays faulty data;

have the Tech 2 repaired. The use of a faulty

Tech 2 can result in misdiagnosis and the

unnecessary replacement of parts.

From the Main Menu, having selected Diagnostics / 2006 / RA Rodeo / Body , the Tech 2 functions for the Powertrain

Interface, include:

F0: Diagnostic Trouble Codes

F1: Diagnostic Data Display

F2: Snapshot

F3: Miscellaneous Tests

F4: Additional Functions

F5: Program

F6: Security

13.2 Tech 2 Functions

F0: Diagnostic Trouble Codes

W hen this test mode is initiated, DTCs stored by the ECM can be displayed or cleared. W hen entered, there are two

additional modes for selection:

F0: Read DTC Info Ordered By Priority : All DTCs stored in the ECM will be displayed.

F1: Clear DTC Information : Clears all current DTCs in the ECM and TCM memories.

F1: Diagnostic Data Display

• Use the Tech 2 Data List under the following conditions:

• The Diagnostic System Check – V6 Engine has been completed.

• The On-Board Diagnostics are functioning correctly.

• No DTCs are present.

NOTE

The values quoted in the following data list are

only intended to provide the Technician with an

indication of the values to be expected.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3742 of 6020

Powertrain Interface Module – V6 Page 6E1–81

13.3 Powertrain Interface Module Data List

Diagnostic Data Display

Tech 2 Display Units Displayed Switch On Switch Off

AC Switch On/Off On Off

Cruise Cancel Switch Active/Inactive Active Inactive

Cruise Resume Switch Active/Inactive Active Inactive

Cruise Set Switch Active/Inactive Active Inactive

Cruise Main Switch Active/Inactive Active Inactive

Cruise Control Set Lamp On/Off On Off

Cruise Control On Lamp On/Off On Off

Power Drive Switch On/Off On Off

Power Drive Lamp On/Off On Off

3rd Start Switch On/Off On Off

3rd Start Lamp On/Off On Off

4W D Low Gear Active/Inactive Active Inactive

G-Sensor V 2.43 2.43

G-Sensor Pa 0.027 0.027

Engine Speed RPM 152 1093

Coolant temperature Input °C 35 25

Coolant Temperature % 70 70

Fuel Level Input % 26 26

Fuel Level % 43 43

Alternator Lamp On/Off On Off

Oil Pressure Lamp On/Off On Off

SVS Lamp (Service Vehicle soon) On/Off On Off

Check transmission MIL On/Off On Off

Transmission Oil Temperature Lamp On/Off On Off

LED [ - P - ] On/Off On Off

LED [ - R - ] On/Off On Off

LED [ - N - ] On/Off On Off

LED [ - D - ] On/Off On Off

LED [ - 3 - ] On/Off On Off

LED [ - 2 - ] On/Off On Off

LED [ - 1 - ] On/Off On Off

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3765 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–5

Clean and Inspect

Do not use solvents on neoprene seals,

composition faced clutch plates or thrust

washers as damage to parts may occur.

After complete disassembly of a component, wash all metal parts in a clean solvent and dry with compressed air. Blow

oil passages out and check to make sure they are not obstructed, small passages should be checked with tag wire. All

parts should be inspected to determine if replacement is required.

Pay particular attention to the following:

• Inspect linkage and pivot points for excessive wear.

• Bearing and thrust surfaces of all parts should be checked for excessive wear and scoring.

• Check for broken seal rings, damaged ring lands and damaged threads.

• Inspect seals for damage.

• Mating surfaces of castings should be checked for burrs. Irregularities may be removed by lapping the surface with

emery paper laid on a flat surface, such as a piece of plate glass.

• Castings should be checked for cracks and porosity.

1.3 7C2 Automatic Transmission – 4L60E –

Electrical Diagnosis

For transmissions fitted to V6 engines, the electrical diagnosis is in this Section. A new electrical circuit and control

module has been introduced for automatic transmissions fitted to the V6 engines.

1.4 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Information contained in 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis will assist in the

diagnosis of the mechanical and hydraulic components in the 4L60E automatic transmission, while the transmission

remains installed on the vehicle.

Examples of the type of diagnostic information contained within this section are:

• transmission functional test,

• line pressure information,

• transmission fluid diagnosis,

• symptom diagnosis and

• shift speed charts.

1.5 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing

Information in 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing covers transmission fluid level checking, as

well as specific information for servicing some components while the transmission remains installed on the vehicle. This

Section also covers the transmission removal and reinstallation to the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3772 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–12

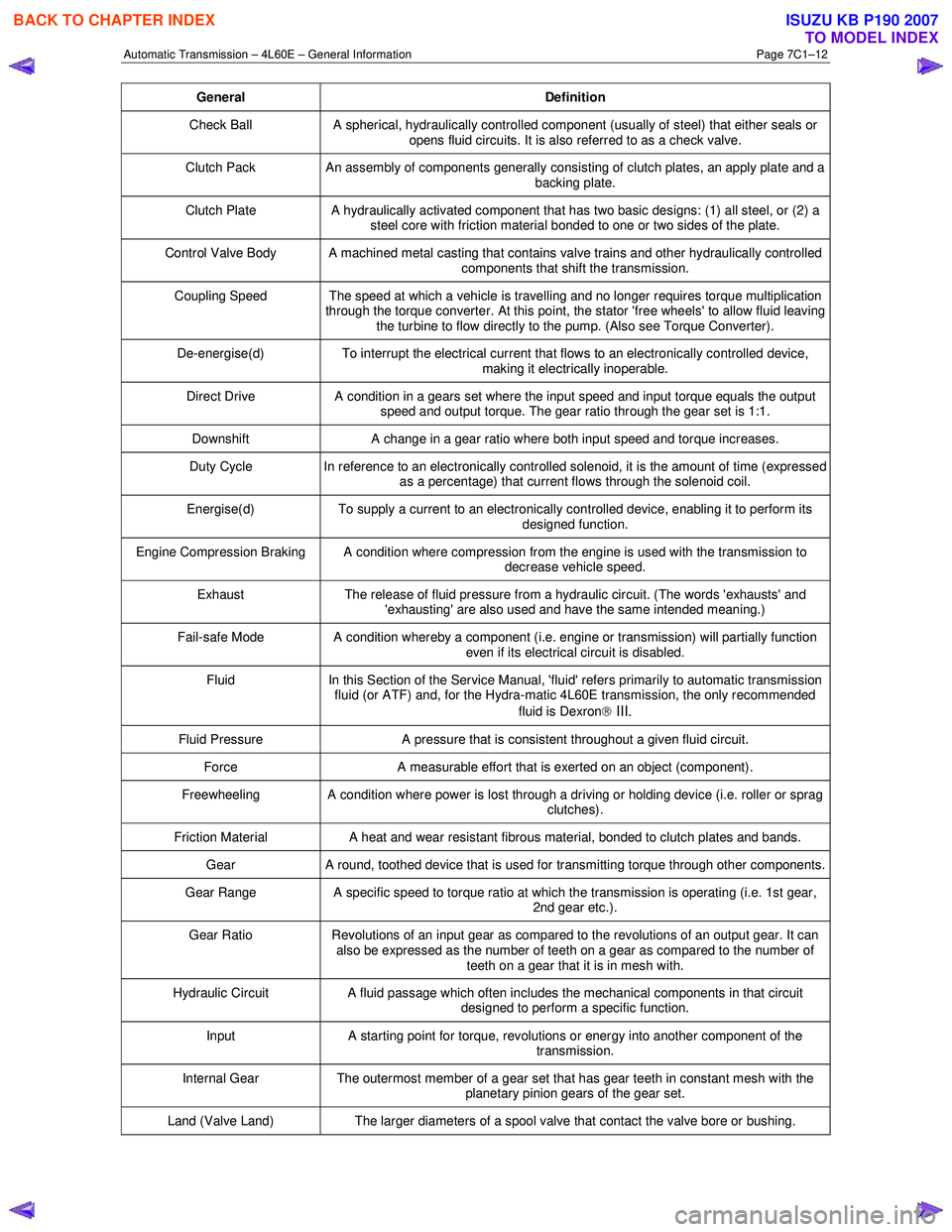

General Definition

Check Ball A spherical, hydraulically controlled component (usually of steel) that either seals or

opens fluid circuits. It is also referred to as a check valve.

Clutch Pack An assembly of components generally consisting of clutch plates, an apply plate and a

backing plate.

Clutch Plate A hydraulically activated component that has two basic designs: (1) all steel, or (2) a

steel core with friction material bonded to one or two sides of the plate.

Control Valve Body A machined metal casting that contains valve trains and other hydraulically controlled components that shift the transmission.

Coupling Speed The speed at which a vehicle is travelling and no longer requires torque multiplication through the torque converter. At this point, the stator 'free wheels' to allow fluid leaving

the turbine to flow directly to the pump. (Also see Torque Converter).

De-energise(d) To interrupt the electrical current that flows to an electronically controlled device,

making it electrically inoperable.

Direct Drive A condition in a gears set where the input speed and input torque equals the output

speed and output torque. The gear ratio through the gear set is 1:1.

Downshift A change in a gear ratio where both input speed and torque increases.

Duty Cycle In reference to an electronically controlled solenoid, it is the amount of time (expressed

as a percentage) that current flows through the solenoid coil.

Energise(d) To supply a current to an electronically controlled device, enabling it to perform its

designed function.

Engine Compression Braking A condition where compression from the engine is used with the transmission to decrease vehicle speed.

Exhaust The release of fluid pressure from a hydraulic circuit. (The words 'exhausts' and

'exhausting' are also used and have the same intended meaning.)

Fail-safe Mode A condition whereby a component (i.e. engine or transmission) will partially function even if its electrical circuit is disabled.

Fluid In this Section of the Service Manual, 'fluid' refers primarily to automatic transmission

fluid (or ATF) and, for the Hydra-matic 4L60E transmission, the only recommended

fluid is Dexron

III.

Fluid Pressure A pressure that is consistent throughout a given fluid circuit.

Force A measurable effort that is exerted on an object (component).

Freewheeling A condition where power is lost through a driving or holding device (i.e. roller or sprag

clutches).

Friction Material A heat and wear resistant fibrous material, bonded to clutch plates and bands.

Gear A round, toothed device that is used for transmitting torque through other components.

Gear Range A specific speed to torque ratio at which the transmission is operating (i.e. 1st gear,

2nd gear etc.).

Gear Ratio Revolutions of an input gear as compared to the revolutions of an output gear. It can

also be expressed as the number of teeth on a gear as compared to the number of

teeth on a gear that it is in mesh with.

Hydraulic Circuit A fluid passage which often includes the mechanical components in that circuit

designed to perform a specific function.

Input A starting point for torque, revolutions or energy into another component of the

transmission.

Internal Gear The outermost member of a gear set that has gear teeth in constant mesh with the

planetary pinion gears of the gear set.

Land (Valve Land) The larger diameters of a spool valve that contact the valve bore or bushing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3777 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–17

7 Transmission Specifications

7.1 General

Type

Hydra-matic 4L60E

Special Features

Electronically controlled shift pattern, feel and torque

Converter clutch operation

Overdrive 4th speed range

Selector Location ..................................................................................Floor mounted console

Gear Ratios Park (P) ....................................................................................................................... ........... –

Reverse (R) .................................................................................................................... ... 2.29

Neutral (N) .............................................................................................................................. –

Drive (D – 4) .................................................................................................................. ...... 0.7

Drive (D – 3) .................................................................................................................. ...... 1.0

Second (2) ......................................................................................................................... 1.63

First (1) ...................................................................................................................... ........ 3.06

Shift Speeds Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Oil Pressure

Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Torque Converter

Number of Elements .................................................................. 3 plus torque converter clutch

Torque Converter Diameter and End Play

HFV6 ........................................................................................................................... 258 mm

End Play .............................................................................................................. 0.1 – 0.5 mm

Lubricant

Type recommended ................................................................................................ Dexron

® III

Capacity......................... Nominal only. Check when transmission is at operating temperature

Service Refill ............................................................................................................... 4. 8 litres

Total (Dry)................................................................................................................... 8 .8 litres

Fluid Cooling.....................................Transmission fluid to engine coolant in one radiator tank

Clutches and Band 2 – 4 Band:

Type........................................................................................... Composition lined, steel band

Operation: ..................................................................................................................... .. Servo

Adjustment: ................................................................................................ Selective Apply Pin

Pin Size and Identification.

65.82 – 66.12 mm ...................................................................................................... 1 Groove

67.23 – 67.53 mm ...................................................................................................... 2 Groove

68.64 – 68.94 mm ....................................................................................................No Groove

Reverse Input Clutch Type................................................................................................................Multiple we t disc

Backing plate ........................................................................................................ (1) Select ive

Clutch plate (numbers):

Steel ....................................................................................................................................... 4

Composition............................................................................................................................ 4

Belleville ..................................................................................................................... ............ 1

Backing Plate ........................................................................................................ 1 (Selecti ve)

Backing plate, identification and thickness:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3785 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–25

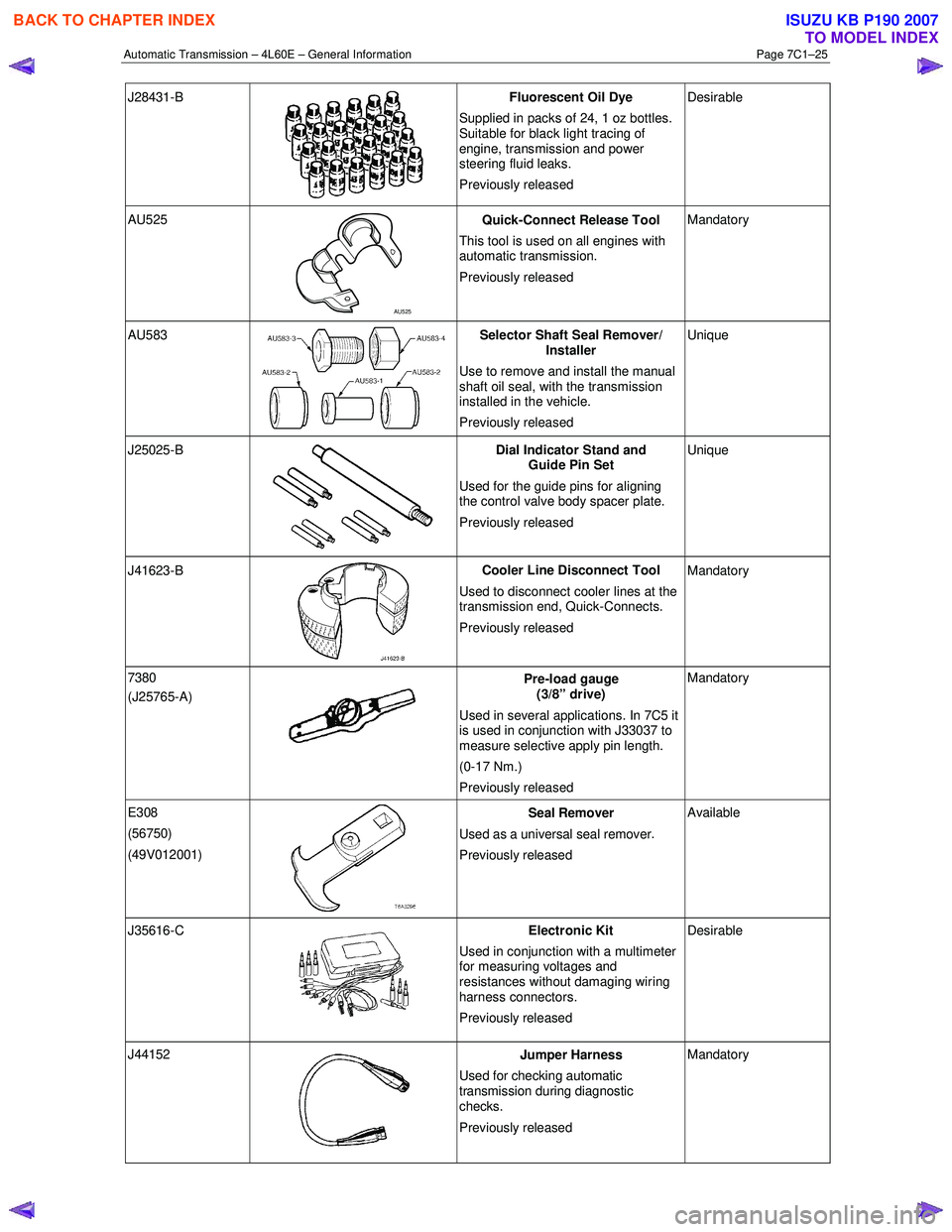

J28431-B

Fluorescent Oil Dye

Supplied in packs of 24, 1 oz bottles.

Suitable for black light tracing of

engine, transmission and power

steering fluid leaks.

Previously released Desirable

AU525

AU525 Quick-Connect Release Tool

This tool is used on all engines with

automatic transmission.

Previously released Mandatory

AU583 Selector Shaft Seal Remover/

Installer

Use to remove and install the manual

shaft oil seal, with the transmission

installed in the vehicle.

Previously released Unique

J25025-B

Dial Indicator Stand and

Guide Pin Set

Used for the guide pins for aligning

the control valve body spacer plate.

Previously released Unique

J41623-B

Cooler Line Disconnect Tool

Used to disconnect cooler lines at the

transmission end, Quick-Connects.

Previously released Mandatory

7380

(J25765-A)

Pre-load gauge

(3/8” drive)

Used in several applications. In 7C5 it

is used in conjunction with J33037 to

measure selective apply pin length.

(0-17 Nm.)

Previously released Mandatory

E308

(56750)

(49V012001)

Seal Remover

Used as a universal seal remover .

Previously released Available

J35616-C

Electronic Kit

Used in conjunction with a multimeter

for measuring voltages and

resistances without damaging wiring

harness connectors.

Previously released Desirable

J44152

Jumper Harness

Used for checking automatic

transmission during diagnostic

checks.

Previously released Mandatory

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3813 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–27

4 Diagnostics

4.1 Introduction

The transmission diagnostic procedure is organised in a logical structure that begins with the diagnostic system check

and as such must always be used as the starting point. The diagnostic system check directs the technician to the logical

steps necessary to diagnose a transmission driveability fault condition.

4.2 Basic Knowledge Required

A lack of basic understanding regarding

electronics, electrical wiring circuits and use

of electrical circuit testing tools when

performing any diagnostic procedure, could

result in incorrect diagnostic results or

damage to system components.

Understanding of the following is required to perform any of the diagnostic procedures detailed in this Service

Information:

• Basic electronics,

• Electrical wiring circuits,

• Electrical circuits testing, and

• Correct use of basic system diagnostic tools.

4.3 Diagnostic Precautions

When tests are required on connector

terminals, use the adapters in connector

adaptor kit J35616-C to prevent damage to

terminals.

The following precautions must be observed when performing all diagnostic procedures. Otherwise, incorrect diagnostic

results or damage to system components will occur:

1 Disconnection of the battery affects certain vehicle electronic systems.

2 Disconnect the battery negative lead when performing the following procedures:

• Disconnecting the electronic control module wiring harness connector/s or

• Charging the battery.

3 Disconnect the battery terminal ground lead and the electronic control module wiring harness connector before attempting any electric arc welding on the vehicle.

4 Do not start the engine if the battery terminal is not properly secured to the battery.

5 Do not disconnect or reconnect any of the following while the ignition is switched on or when the engine is running:

• Any electronic control module or system component electrical wiring connector, or

• Battery terminal leads.

6 Ensure that the correct procedure for disconnecting and connecting system electrical wiring harness connectors is always followed. For information on the correct procedure for disconnecting and connecting specific wiring

connectors, refer to 8A Electrical-Body and Chassis.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007