check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3651 of 6020

Battery Page 6D1-3–11

b W ait 15 seconds for the battery to recover.

8 If possible, set the selector to 50% of rapid discharge current (or three times the 20 hour discharge rate).

9 Apply the load test for 10 seconds and record the battery voltage. If one cell is faulty it will gas excessively or overheat. This indicates a faulty battery.

10 Recharge the battery if the voltage is at or below the minimum voltage specified by the HRD manufacturer (or 9.6 V).

11 Replace the battery if the voltage is below the minimum voltage specified by the HRD manufacturer (or below 9.6 V after the battery is charged and the test is repeated). Refer to 4.1 Battery.

12 Connect the battery positive terminal.

13 Connect the battery negative terminal.

Alternate Load Test

If HRD test equipment is not available, test the battery as follows:

1 Read and obey the safety precautions for working with batteries, refer to 2 Safety Precautions.

2 Ensure the state of the battery is at least 65% charged. Refer to 3.3 Hydrometer Test.

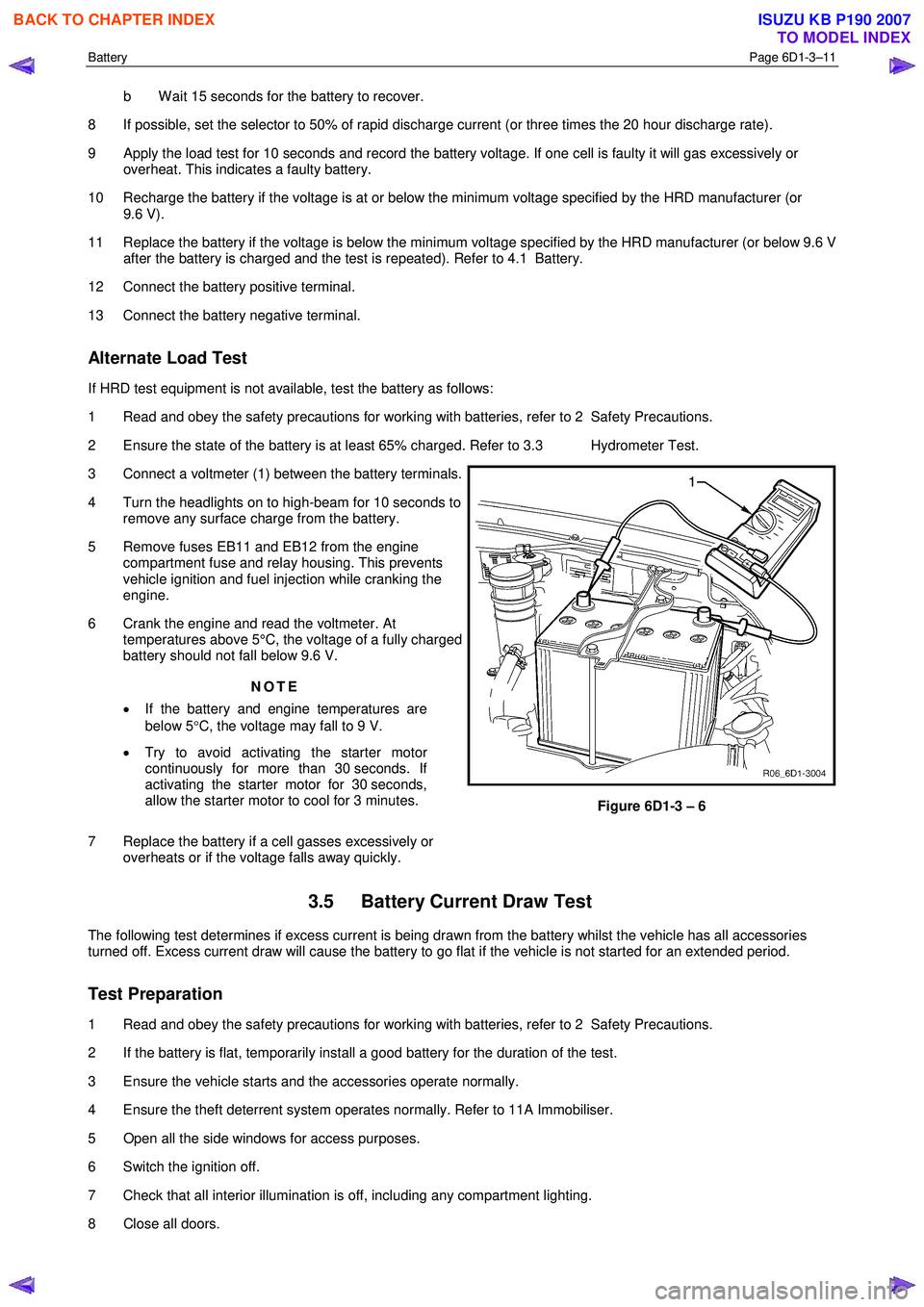

3 Connect a voltmeter (1) between the battery terminals.

4 Turn the headlights on to high-beam for 10 seconds to remove any surface charge from the battery.

5 Remove fuses EB11 and EB12 from the engine compartment fuse and relay housing. This prevents

vehicle ignition and fuel injection while cranking the

engine.

6 Crank the engine and read the voltmeter. At temperatures above 5°C, the voltage of a fully charged

battery should not fall below 9.6 V.

NOTE

• If the battery and engine temperatures are

below 5 °C, the voltage may fall to 9 V.

• Try to avoid activating the starter motor

continuously for more than 30 seconds. If

activating the starter motor for 30 seconds,

allow the starter motor to cool for 3 minutes.

7 Replace the battery if a cell gasses excessively or overheats or if the voltage falls away quickly.

Figure 6D1-3 – 6

3.5 Battery Current Draw Test

The following test determines if excess current is being drawn from the battery whilst the vehicle has all accessories

turned off. Excess current draw will cause the battery to go flat if the vehicle is not started for an extended period.

Test Preparation

1 Read and obey the safety precautions for working with batteries, refer to 2 Safety Precautions.

2 If the battery is flat, temporarily install a good battery for the duration of the test.

3 Ensure the vehicle starts and the accessories operate normally.

4 Ensure the theft deterrent system operates normally. Refer to 11A Immobiliser.

5 Open all the side windows for access purposes.

6 Switch the ignition off.

7 Check that all interior illumination is off, including any compartment lighting.

8 Close all doors.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3652 of 6020

Battery Page 6D1-3–12

9 Lock the doors and activate the theft deterrent system to arm the vehicle.

10 If the multimeter contains fuses, check they are serviceable.

Test Procedure

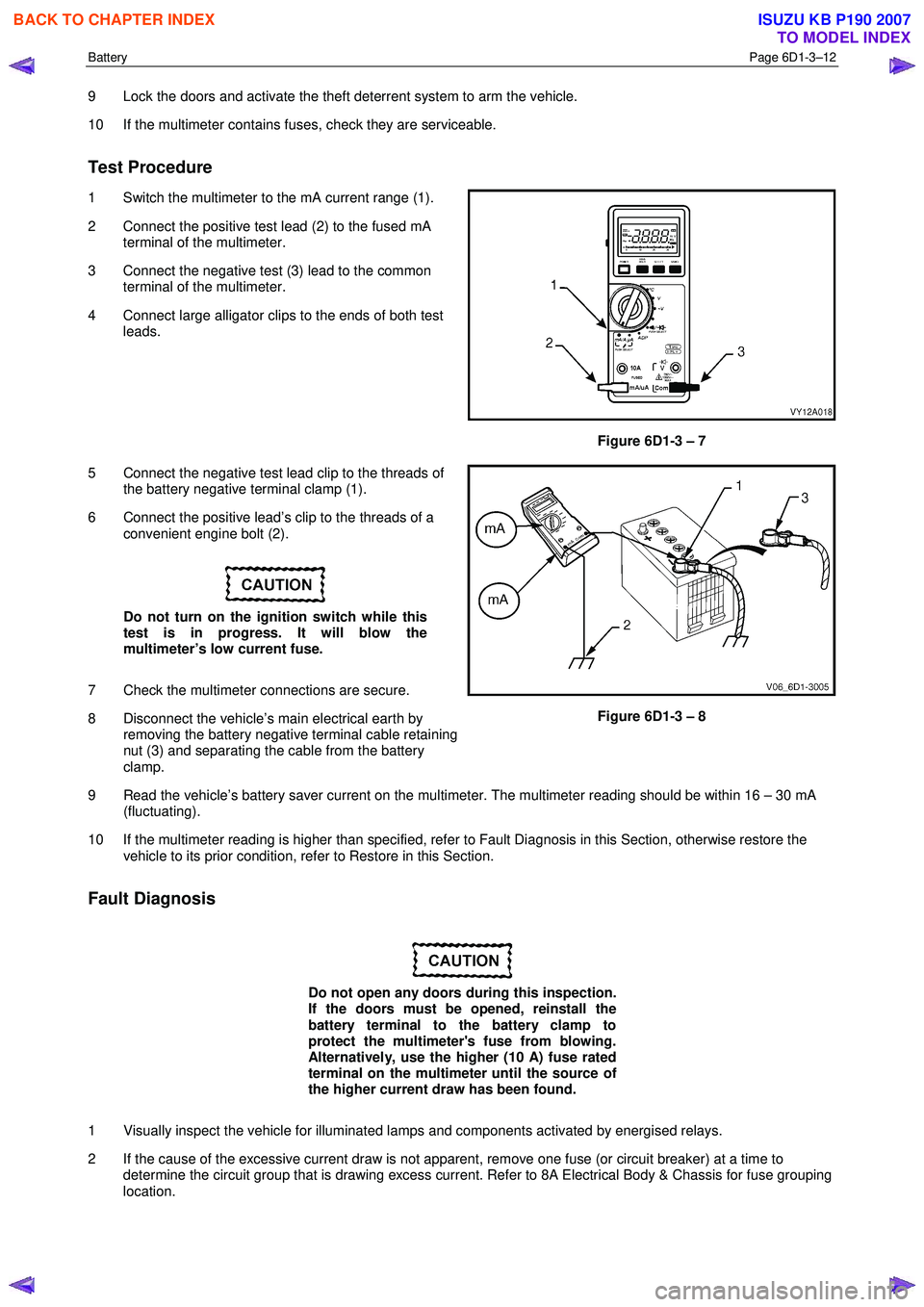

1 Switch the multimeter to the mA current range (1).

2 Connect the positive test lead (2) to the fused mA terminal of the multimeter.

3 Connect the negative test (3) lead to the common terminal of the multimeter.

4 Connect large alligator clips to the ends of both test leads.

Figure 6D1-3 – 7

5 Connect the negative test lead clip to the threads of the battery negative terminal clamp (1).

6 Connect the positive lead’s clip to the threads of a convenient engine bolt (2).

Do not turn on the ignition switch while this

test is in progress. It will blow the

multimeter’s low current fuse.

7 Check the multimeter connections are secure.

8 Disconnect the vehicle’s main electrical earth by removing the battery negative terminal cable retaining

nut (3) and separating the cable from the battery

clamp.

Figure 6D1-3 – 8

9 Read the vehicle’s battery saver current on the multimeter. The multimeter reading should be within 16 – 30 mA (fluctuating).

10 If the multimeter reading is higher than specified, refer to Fault Diagnosis in this Section, otherwise restore the vehicle to its prior condition, refer to Restore in this Section.

Fault Diagnosis

Do not open any doors during this inspection.

If the doors must be opened, reinstall the

battery terminal to the battery clamp to

protect the multimeter's fuse from blowing.

Alternatively, use the higher (10 A) fuse rated

terminal on the multimeter until the source of

the higher current draw has been found.

1 Visually inspect the vehicle for illuminated lamps and components activated by energised relays.

2 If the cause of the excessive current draw is not apparent, remove one fuse (or circuit breaker) at a time to determine the circuit group that is drawing excess current. Refer to 8A Electrical Body & Chassis for fuse grouping

location.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3657 of 6020

Battery Page 6D1-3–17

4 Turn off the ignition, lights and all other electrical loads.

5 Check the battery filler caps on both batteries are tight.

6 Place a wet cloth over the battery filler caps of each battery.

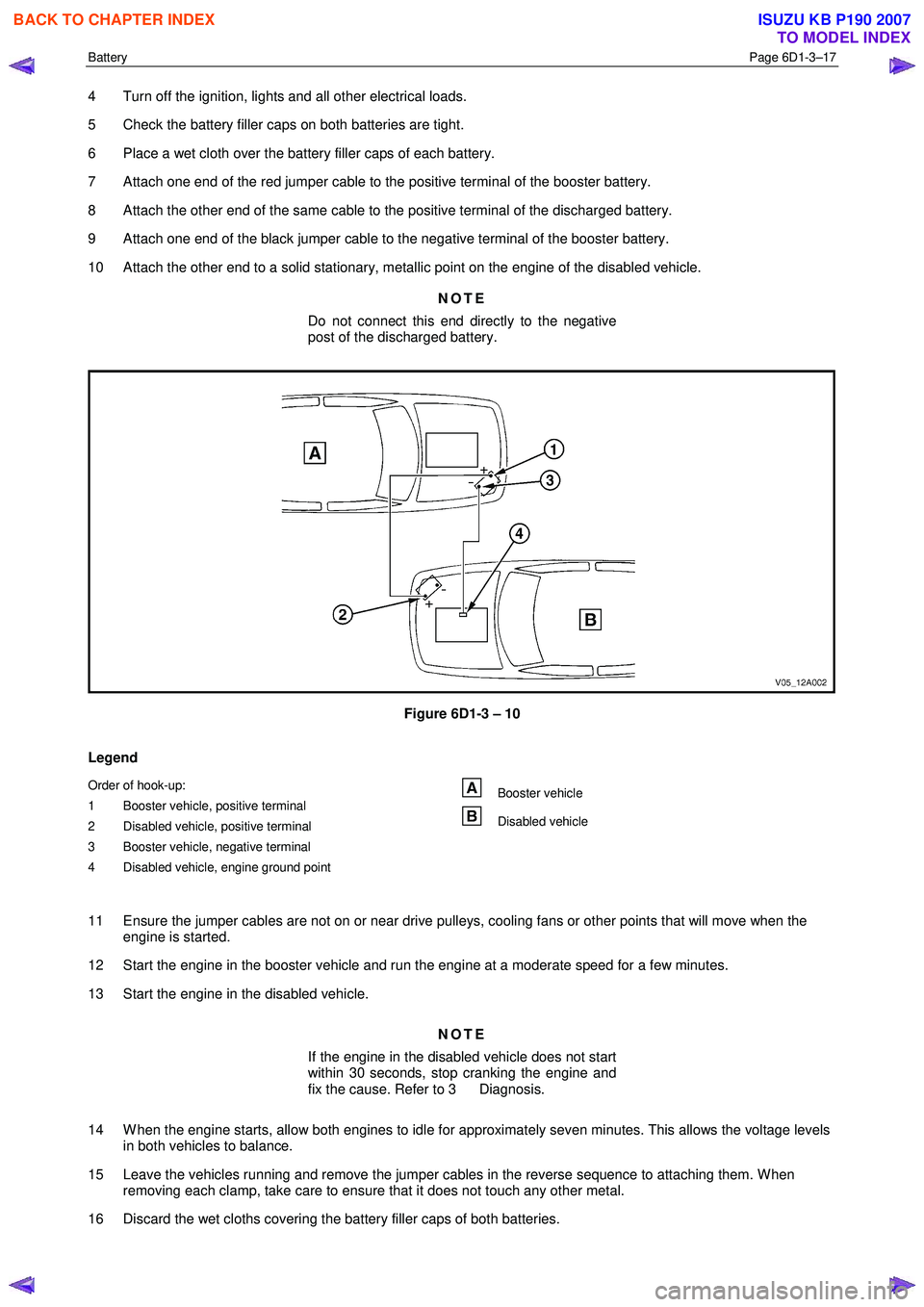

7 Attach one end of the red jumper cable to the positive terminal of the booster battery.

8 Attach the other end of the same cable to the positive terminal of the discharged battery.

9 Attach one end of the black jumper cable to the negative terminal of the booster battery.

10 Attach the other end to a solid stationary, metallic point on the engine of the disabled vehicle.

NOTE

Do not connect this end directly to the negative

post of the discharged battery.

Figure 6D1-3 – 10

Legend

Order of hook-up:

1 Booster vehicle, positive terminal

2 Disabled vehicle, positive terminal

3 Booster vehicle, negative terminal

4 Disabled vehicle, engine ground point Booster vehicle

Disabled vehicle

11 Ensure the jumper cables are not on or near drive pulleys, cooling fans or other points that will move when the engine is started.

12 Start the engine in the booster vehicle and run the engine at a moderate speed for a few minutes.

13 Start the engine in the disabled vehicle.

NOTE

If the engine in the disabled vehicle does not start

within 30 seconds, stop cranking the engine and

fix the cause. Refer to 3 Diagnosis.

14 W hen the engine starts, allow both engines to idle for approximately seven minutes. This allows the voltage levels in both vehicles to balance.

15 Leave the vehicles running and remove the jumper cables in the reverse sequence to attaching them. W hen removing each clamp, take care to ensure that it does not touch any other metal.

16 Discard the wet cloths covering the battery filler caps of both batteries.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3662 of 6020

Powertrain Interface Module – V6 Page 6E1–1

6E1

Powertrain Interface Module – V6

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 1.2 Warning

Caution and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ............................................................................................................ ...................6

1.1 General Description ............................................................................................................ ................................... 6

Serial Data Communication .................................................................................................................................. 6

Serial Data Layout.................................................................................................................................................. 8

1.2 Warning Caution and Notes .................................................................................................................................. 8

Definition of WARNING, CAUTION and NOTE Statements ............................................................................. .... 8

2 Component Location............................................................................................................................10

2.1 Engine Compartment............................................................................................................. .............................. 10

2.2 Interior................................................................................................................................................................... 11

3 Component Description and Operation ............................................................................................ .12

3.1 Powertrain Interface Module ............................................................................................................................... 12

3.2 Powertrain Interface Module Gateway Components ................................................................................. ....... 13

Engine Control Module........................................................................................................................................ 13

Immobiliser Control Unit ..................................................................................................................................... 13

Automatic Transmission Control Module .......................................................................................... ................ 13

3.3 Powertrain Interface Module Direct Input Switches.............................................................................. ............ 14

Cruise Control Switch.......................................................................................................................................... 14

Power Mode Switch – Automatic Transmission..................................................................................... ........... 14

3rd Start Switch – Automatic Transmission ....................................................................................................... 14

4 Diagnostics ...........................................................................................................................................15

4.1 Diagnostic General Descriptions................................................................................................ ........................ 15

Diagnostic Trouble Code (DTC) Tables........................................................................................... ................... 15

Diagnostic Trouble Codes (DTCs) ...................................................................................................................... 15

Tech 2 PIM Diagnostic Tests............................................................................................................................... 16

5 GM LAN Serial Communication Circuit ............................................................................................ ..17

6 Wiring Diagram and Connector Chart ................................................................................................18

6.1 Wiring Diagrams .................................................................................................................................................. 18

6.2 Connector Chart................................................................................................................................................... 20

6.3 Connector Information .......................................................................................................... .............................. 21

PIM Connector Pin Specifications ............................................................................................... ....................... 21

7 Diagnostics Starting Point ..................................................................................................................24

7.1 Diagnostic Requirements, Precautions and Preliminary Checks .................................................................... 24

Basic Knowledge Required ................................................................................................................................. 24

Basic Diagnostic Tools Required ................................................................................................ ....................... 24

Diagnostic Precautions ....................................................................................................................................... 24

Preliminary Checks.............................................................................................................................................. 25

7.2 Diagnostic System Check ........................................................................................................ ........................... 25

7.3 Powertrain Interface Module – Module Communication Check Failure Diagnostic Table............................. 27

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3673 of 6020

Powertrain Interface Module – V6 Page 6E1–12

3 Component Description and

Operation

3.1 Powertrain Interface Module

The powertrain interface module (PIM) is located behind the

right-hand lower hinge pillar trim.

Figure 6E1 – 5

The PIM performs the following functions:

• The PIM acts as the communication gateway between the GM LAN communications protocol and keyword 2000

protocol.

• The PIM converts analogue signals from the cruise control switches into digital serial data.

• The PIM upon inputs received from the engine control module (ECM), transmission control module (TCM) and

immobiliser control unit (ICU) controls the operation of the following instruments and warning lamps:

• Speedometer

• Tachometer

• Check Transmission Lamp

• 3

rd Gear Start Lamp

• Power Mode Switch Lamp

• Automatic Transmission Oil Temp Lamp

• Cruise Set Lamp

• Oil Pressure Lamp

• Service Vehicle Soon (SVS) Lamp

• Charge W arning Lamp

• PRNDL Lamps

• The PIM is responsible for authenticating the immobiliser control unit (ICU) prior to the engine control module

(ECM) authenticating the PIM. If any of these authentication processes fail, the vehicle will not start. For further

information on the immobiliser system, refer to 11A Immobiliser System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3682 of 6020

Powertrain Interface Module – V6 Page 6E1–21

6.3 Connector Information

PIM Connector Pin Specifications

Pin Description – Connector B-96

Figure 6E1 – 1

Pin No. Wire Colour Circuit

Description Function

1 P/W

A/T 3 Srt W rg

Lmp Auto Transmission 3rd Start W arning Lamp

2 P

A/T Pwr Dr

W rg Lmp Auto Transmission Power Drive W arning Lamp

3 O/L A/T Oil Tmp

W rg Lmp Auto Transmission Oil Temperature W arning Lamp

4 G/Y

Cru Set W rg

Lmp Cruise Set W arning Lamp

5

O/L SVS W rg Lmp Service Vehicle Soon W arning Lamp

6 W Eng Oil W rg

Lmp Engine Oil Pressure W arning Lamp holidays

7

W /L Batt W rg Lmp Battery Charge W arning Lamp

8 Y/B Eng Tmp Gau Engine Coolant Gauge

9 B/R Tac Gau Tacho Gauge – RW D/4W D (2-4) Control

10 W Imob Sig Immobiliser

11 — — Not Connected

12 — — Not Connected

13 L Sft Sel Pos D Shift Selector Position D

14 R/B Sft Sel Pos N Shift Selector Position N

15 R/Y Sft Sel Pos R Shift Selector Position R

16 Y/V Sft Sel Pos P Shift Selector Position P

17 — — Not Connected

18 G/Y A/T Chk W rg

Lmp Auto Transmission Check W arning Lamp

19 — — Not

Connected

20 — — Not Connected

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3685 of 6020

Powertrain Interface Module – V6 Page 6E1–24

7 Diagnostics Starting Point

7.1 Diagnostic Requirements, Precautions

and Preliminary Checks

Basic Knowledge Required

A lack of basic understanding of electronics,

electrical wiring circuits and use of electrical

circuit testing tools when performing the PIM

diagnostic procedures could result in

incorrect diagnostic results or damage to

components.

In addition, understanding of the Engine Management System is essential to prevent misdiagnosis and component

damage. Refer to 6C1-1 Engine Management – V6 – General Information.

Basic Diagnostic Tools Required

Use of incorrect electrical circuit diagnostic

tools when performing the PIM diagnostic

procedures could result in incorrect

diagnostic results or damage to components.

The following electrical circuit testing tools are required to perform the diagnostic procedures detailed in this Section:

• Tech 2.

• Test lamp, refer to 8A Electrical - Body and Chassis for further information.

• Digital multimeter with 10 M Ω impedance, refer to 8A Electrical - Body and Chassis for further information.

• Connector test adapter kit Tool No. J35616-A.

Diagnostic Precautions

In addition to the safety and precautionary

measures listed in 11.1 Safety and

Precautionary Measures, the following

diagnostic precautions must be observed

when performing any PIM diagnostic

procedure:

• Use only the test equipment specified in the diagnostic tables. Other test equipment may either give incorrect

results or damage serviceable components.

• Do not clear any DTCs unless instructed.

• The fault must be present when using the DTC Diagnostic Tables. Otherwise, misdiagnosis or replacement of

serviceable parts may occur.

• Always use connector adapters such as those contained in connector test adapter kit Tool No. J35616-A to prevent

connector terminal damage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3687 of 6020

Powertrain Interface Module – V6 Page 6E1–26

Step Action Yes No

4

Using Tech 2, attempt to communicate with the PIM.

Does Tech 2 communicate with the PIM? Go to Step 5 Refer to

7.3 Powertrain Interface Module –

Module

Communication Check Failure

Diagnostic Table

5 Using Tech 2, view and record all DTCs.

Does Tech 2 display any DTCs? Go to Step 6 Refer to

Intermittent Fault Conditions.

6 Does DTC C0550 fail this ignition cycle? Refer to

9.1 DTC

C0550 – PIM

Internal Fault

Diagnostic Table Go to Step 7

7 Does DTC U2100 fail this ignition cycle? Refer to

9.2 DTC

U2100 – No

Communication

W ith CAN Bus (High Speed) Diagnostic

Table Go to Step 8

8 Does DTC U2106 fail this ignition cycle? Refer to

9.4 DTC

U2106 – CAN Bus

No Communication

W ith Transmission Control Module Go to Step 9

9

Does DTC U2105 fail this ignition cycle? Refer to

9.3 DTC

U2105 – CAN Bus

No Communication

W ith Engine Control Module Diagnostic

Table Go to Step 10

10 Does Tech 2 display multiple DTCs? Refer to

the DTC Table of

the fault condition

that is most likely to

trigger multiple

DTCs. Refer to

4.1 Diagnostic General

Descriptions for information on

multiple DTCs fault condition Refer to the relevant

DTC table

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3688 of 6020

Powertrain Interface Module – V6 Page 6E1–27

7.3 Powertrain Interface Module – Module

Communication Check Failure

Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

7.2 Diagnostic System Check

2 Test the following PIM circuits for a high resistance, open circuit or

short to ground fault condition. Refer to 8A Electrical - Body and

Chassis for information on electrical diagnosis:

• 12 V battery supply circuit,

• 12 V ignition circuit, and

• ground circuit.

Has any fault been found and rectified? Go to Step 10 Go to Step 3

3 1 Disconnect the ECM harness connector.

2 Switch off the ignition for 10 seconds.

3 Using Tech 2, attempt to communicate with the PIM.

NOTE

Other DTCs may set when the ECM connector is

disconnected and the ignition is switched on. Disregard

DTCs that set under this condition on this DTC Table.

Does Tech 2 communicate with the PIM? Go to Step 4 For vehicles with

automatic

transmissions, go to

Step 5. For vehicles with manual

transmission go to Step 8

4 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Has the repair been completed? Go to Step 10 —

5 1 Disconnect the TCM harness connector.

2 Switch off the ignition for 10 seconds.

3 Using Tech 2, attempt to communicate with the PIM.

Does Tech 2 communicate with the PIM? Go to Step 6 Go to Step 8

6 Test serial data circuits between the TCM and ECM for a short to

voltage, short to ground or short together condition.

Has any fault been found and rectified? Go to Step 10 Go to Step 7

7 Replace the TCM. Refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing.

Has the repair been completed? Go to Step 10 —

8 Test serial data circuits between the PIM and ECM for vehicles with

manual transmission, or between the PIM and TCM for vehicles with

automatic transmission for a high resistance or open circuit fault

condition. Refer to 8A Electrical - Body and Chassis for information on

wiring circuit testing and repair.

Has any fault been found and rectified? Go to Step 10 Go to Step 9

9 Replace the PIM. Refer to 11.2 Powertrain Interface Module.

Has the repair been completed? Go to Step 10 —

10 Using Tech 2, attempt to communicate with the PIM.

Does Tech 2 communicate with the PIM? Go to Step 11 Refer to

7.2 Diagnostic System Check

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3690 of 6020

Powertrain Interface Module – V6 Page 6E1–29

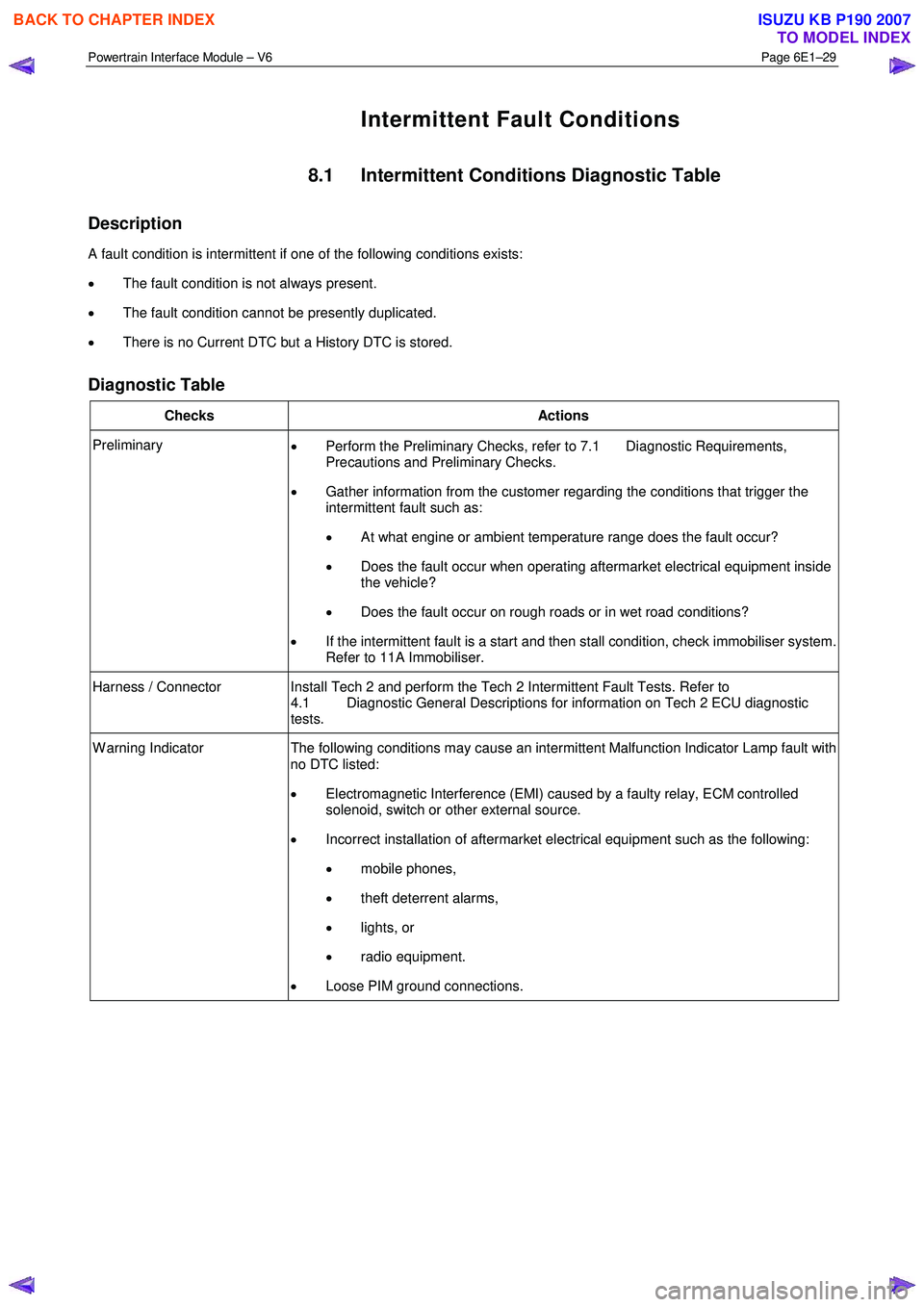

Intermittent Fault Conditions

8.1 Intermittent Conditions Diagnostic Table

Description

A fault condition is intermittent if one of the following conditions exists:

• The fault condition is not always present.

• The fault condition cannot be presently duplicated.

• There is no Current DTC but a History DTC is stored.

Diagnostic Table

Checks Actions

Preliminary

• Perform the Preliminary Checks, refer to 7.1 Diagnostic Requirements,

Precautions and Preliminary Checks.

• Gather information from the customer regarding the conditions that trigger the

intermittent fault such as:

• At what engine or ambient temperature range does the fault occur?

• Does the fault occur when operating aftermarket electrical equipment inside

the vehicle?

• Does the fault occur on rough roads or in wet road conditions?

• If the intermittent fault is a start and then stall condition, check immobiliser system.

Refer to 11A Immobiliser.

Harness / Connector Install Tech 2 and perform the Tech 2 Intermittent Fault Tests. Refer to 4.1 Diagnostic General Descriptions for information on Tech 2 ECU diagnostic

tests.

W arning Indicator The following conditions may cause an intermittent Malfunction Indicator Lamp fault with

no DTC listed:

• Electromagnetic Interference (EMI) caused by a faulty relay, ECM controlled

solenoid, switch or other external source.

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Loose PIM ground connections.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007