relay ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1756 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-139

DTC P0231 or P0232 (Flash Code 69)

Circuit Description

The ECM controls the fuel pump relay which supplies

power to the fuel pump in the fuel tank. The ECM

commands the fuel pump relay ON for a certain length

of time at ignition switch is ON with the engine OFF.

During the engine running it is continuously

commanded ON. If the ECM detects an improper

voltage level on the relay control circuit, DTC P0231 or

P0232 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects a low voltage condition on the fuel pump relay control circuit for longer than 3

second when the relay is commanded OFF. (DTC

P0231)

• The ECM detects a high voltage condition on the fuel pump relay control circuit for longer than 3

second when the relay is commanded ON. (DTC

P0232)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Notice: • The fuel pump relay is commanded ON for 12 seconds at ignition switch is ON with the engine

OFF.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0231

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition for 20 seconds while observing the DTC Information with a scan

tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Replace the fuel pump relay with the head light relay or replace with a known good relay.

3. Turn ON the ignition for 20 seconds while observing the DTC Information with a scan

tool.

Does the DTC fail this ignition? —

Go to Step 4 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1757 of 6020

6E-140 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Turn OFF the ignition.

2. Remove the fuel pump relay.

3. Probe the ignition voltage feed circuit of the relay coil side (pin 3 of X-13) with a test lamp

that is connected a known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 5 Go to Step 6

5 1. Test the control circuit between the ECM (pin

54 of C-58) and the relay (pin 5 of X-13) for

the following conditions:

• An open circuit

• A short to ground

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 8

6 Repair the open circuit or high resistance between

the ECM main relay (pin 1 of X-12) and the fuel

pump relay (pin 3 of X-13).

Did you complete the repair? —

Go to Step 11

—

71. Remove the fuel pump relay.

2. Inspect for an intermittent and for a poor connection on each relay terminal.

3. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 9

8 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

ECM (pin 54 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 10

9 Replace the fuel pump relay.

Did you complete the replacement? —

Go to Step 11

—

10Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 11

—

111. Reconnect all previously disconnected fuse,

relay or harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Turn ON the ignition for 20 seconds while observing the DTC Information with a scan

tool.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 12

12 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1758 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-141

Circuit/ System Testing DTC P0232

StepAction Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Replace the fuel pump relay with the head light relay or replace with a known good relay.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail? —

Go to Step 4 Go to Step 5

4 1. Test the control circuit between the ECM (pin

54 of C-58) and the relay (pin 5 of X-13) for a

short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

5 Replace the fuel pump relay.

Did you complete the replacement? —

Go to Step 7

—

6Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 7

—

71. Reconnect all previously disconnected relay

or harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 8

8 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1768 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-151

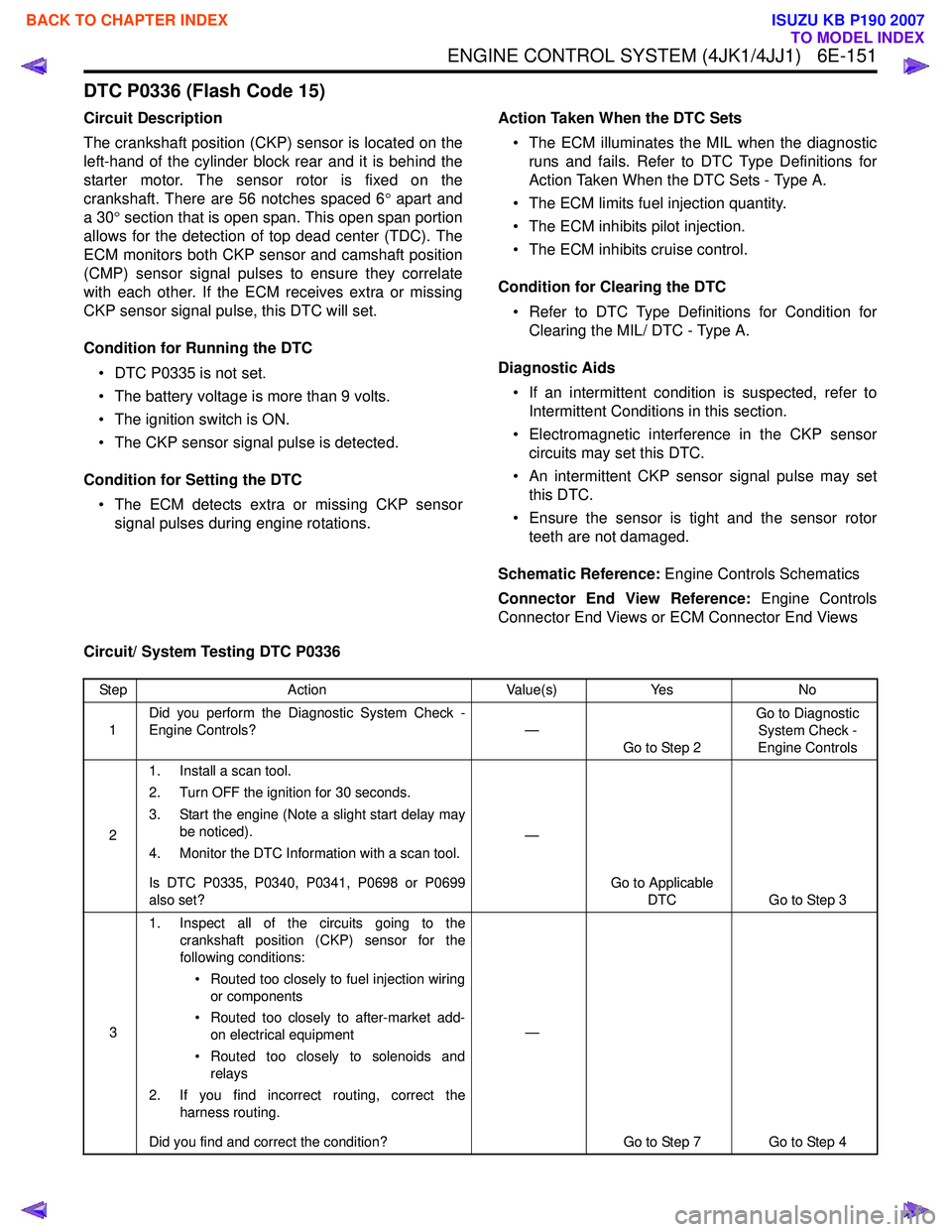

DTC P0336 (Flash Code 15)

Circuit Description

The crankshaft position (CKP) sensor is located on the

left-hand of the cylinder block rear and it is behind the

starter motor. The sensor rotor is fixed on the

crankshaft. There are 56 notches spaced 6 ° apart and

a 30 ° section that is open span. This open span portion

allows for the detection of top dead center (TDC). The

ECM monitors both CKP sensor and camshaft position

(CMP) sensor signal pulses to ensure they correlate

with each other. If the ECM receives extra or missing

CKP sensor signal pulse, this DTC will set.

Condition for Running the DTC • DTC P0335 is not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CKP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects extra or missing CKP sensor signal pulses during engine rotations. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CKP sensor circuits may set this DTC.

• An intermittent CKP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the sensor rotor teeth are not damaged.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0336

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine (Note a slight start delay may be noticed).

4. Monitor the DTC Information with a scan tool.

Is DTC P0335, P0340, P0341, P0698 or P0699

also set? —

Go to Applicable DTC Go to Step 3

3 1. Inspect all of the circuits going to the

crankshaft position (CKP) sensor for the

following conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids and relays

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 7 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1773 of 6020

6E-156 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0341 (Flash Code 14)

Circuit Description

The camshaft position (CMP) sensor is installed on the

timing chain sprocket cover at the front of the camshaft

idle gear. The CMP sensor detects total of five

projections per one engine cycle (four projections

arranged equally every 90 ° and one reference

projection on the timing chain sprocket surface). The

ECM monitors both crankshaft position (CKP) sensor

and CMP sensor signal pulses to ensure they correlate

with each other. If the ECM receives extra or missing

CMP sensor signal pulse, this DTC will set.

Condition for Running the DTC • DTCs P0016 and P0340 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CMP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects extra or missing CMP sensor signal pulses during engine rotations.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CMP sensor circuits may set this DTC.

• An intermittent CMP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the timing chain sprocket is not damaged.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0341

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

4. Monitor the DTC Information with a scan tool.

Is DTC P0340, P0652 or P0653 also set? —

Go to Applicable DTC Go to Step 3

3 1. Inspect all of the circuits going to the camshaft

position (CMP) sensor for the following

conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids and relays

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 7 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1775 of 6020

6E-158 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0380 (Flash Code 66)

Circuit Description

The ECM controls the glow relay which supplies power

to the glow plugs based on engine coolant

temperature. In the after glow phase, the glow indicator

light is not illuminated but glow plugs remain active for

a certain period. If the ECM detects an open circuit or

short circuit on the relay control circuit, this DTC will

set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The ECM detects a low voltage condition on the glow relay control circuit for longer than 3 second

when the relay is commanded OFF.

• The ECM detects a high voltage condition on the glow relay control circuit for longer than 3 second

when the relay is commanded ON.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Test Description

The numbers below refers to the step number on the

Circuit/ System Testing.

2. Listen for an audible click when the glow relay

operates. Command both the ON and OFF states.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0380

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Perform the Glow Relay Control with a scan tool.

3. Command the relay ON and OFF.

Does the glow relay click with each command? —

Go to Step 3 Go to Step 4

3 1. Turn OFF the ignition for 30 seconds.

2. Disconnect the engine coolant temperature (ECT) sensor harness connector in order to

gain glow ON time long enough.

3. Turn ON the ignition for 30 seconds while observing the DTC Information with a scan

tool.

Does the DTC P0380 fail this ignition? —

Go to Step 11 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1776 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-159

41. Turn OFF the ignition.

2. Replace the glow relay with the starter relay or replace with a known good relay.

3. Perform the Glow Relay Control with a scan tool.

4. Command the relay ON and OFF.

Does the glow relay click with each command? —

Go to Step 8 Go to Step 5

5 1. Turn OFF the ignition.

2. Remove the glow relay.

3. Turn ON the ignition, with the engine OFF.

4. Probe the ignition voltage feed circuit of the relay coil side (pin 2 of X-5) with a test lamp

that is connected to a known good ground.

Does the test lamp illuminate? —

Go to Step 6 Go to Step 7

6 1. Test the control circuit between the ECM (pin

37 of C-58) and the relay (pin 3 of X-5) for the

following conditions:

• An open circuit

• A short to ground

• A short to battery or ignition voltage

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 9

7 Repair the open circuit or high resistance between

the Engine (10A) fuse and the glow relay coil side

(pin 2 of X-5). Check the Engine (10A) fuse first.

Did you complete the repair? —

Go to Step 12

—

81. Remove the glow relay.

2. Inspect for an intermittent and for a poor connection on each relay terminal.

3. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 10

9 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

ECM (pin 37 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 11

10 Replace the glow relay.

Did you complete the replacement? —

Go to Step 12

—

11Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 12

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1777 of 6020

6E-160 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

121. Reconnect all previously disconnected fuse,

relay or harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Disconnect the ECT sensor harness connector in order to gain glow ON time long

enough.

5. Turn ON the ignition for 30 seconds while observing the DTC Information with a scan

tool.

Did the DTC P0380 fail this ignition? —

Go to Step 2 Go to Step 13

13 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1778 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-161

DTC P0401 (Flash Code 93)

Circuit Description

The ECM controls the EGR valve opening based on the

engine running condition and by controlling the EGR

solenoid. The EGR valve position is detected by the

position sensor, and relayed to the ECM. When the

proper enabling conditions are met, the ECM will open

the EGR valve while monitoring the mass air flow

(MAF) signal. An expected MAF difference should be

detected between the closed and open positions. If the

ECM detects the MAF difference less than expected,

this DTC will set. This DTC will only run once per

ignition cycle within the enabling conditions.

Condition for Running the DTC • DTCs P0101, P0102, P0103, P0112, P0113, P0116, P0117, P0118, P0122, P0123, P0403,

P0404, P0405, P0406, P0500, P0501, P0652,

P0653, P0698, P0699, P2100, P2101, P2102,

P2103, P2227, P2228 and P2229 are not set.

• The battery voltage is between 10 to 16 volts.

• The ignition switch is ON. Condition for Setting the DTC

• The ECM detects that the MAF amount is not within the calculated range during the EGR flow

test. This indicates insufficient amount of EGR

flow.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• A sticking or intermittently sticking the EGR valve may set this DTC.

Circuit/ System Testing DTC P0401

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and warm up as necessary (allow engine coolant temperature to reach at

least 60 °C [140 °F]).

4. Perform the EGR Solenoid Control with a scan tool.

5. Command the Desired EGR Position Increase or Decrease while observing the Mass Air

Flow (MAF) Sensor parameter with a scan

tool.

Does the MAF Sensor parameter decrease by at

least 0.5 volts when the Desired EGR Position is

commanded from 0 to 90%? —

Go to Diagnostic Aids Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1780 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-163

DTC P0403 (Flash Code 37)

Circuit Description

The ECM controls the EGR valve opening based on the

engine running condition and by controlling the EGR

solenoid. The EGR valve position is detected by the

position sensor, and relayed to the ECM. If the ECM

detects an open circuit or short circuit on the solenoid

circuits, this DTC will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The ECM detects an open circuit on the EGR solenoid circuits.

• The ECM detects a short to ground on the EGR solenoid circuits.

• The ECM detects a short to voltage circuit on the EGR solenoid circuits. Action Taken When the DTC Sets

• The ECM illuminates the MIL on the second consecutive driving cycle when the diagnostic runs

and fails. Refer to DTC Type Definitions for Action

Taken When the DTC Sets - Type B. (Euro 4

Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM inhibits EGR control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type B (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0403

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the EGR valve harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a DMM between the drive voltage circuit (pin 4 of E-71) and a known good

ground.

5. Connect a DMM between the low side circuit (pin 6 of E-71) and a known good ground.

Are both voltage readings within the specified

value? 1.4 - 1.8 volts

Go to Step 5 Go to Step 4

4 Is the DMM voltage more than the specified value

at Step 3? —

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007