relay ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2130 of 6020

6C-12 ENGINE FUEL (C24SE)

Fuel Pump Relay

General Description

In order to control the fuel pump and sender assembly

(FPAS) operation, the FPAS relay is provided. W hen

the starter switch is turned to “ON" position, the FPAS

relay operates the FPAS for 2 seconds.

W hen it is turned to “START" position, the Engine

Control Module receives the reference pulse from the

Ignition Control Module and it operates the relay, again

causing the FPAS to feed fuel.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2150 of 6020

6D3-2 STARTING AND CHARGING SYSTEM

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion shaft.

W hen the starter switch is turned on, the contacts of magnetic

switch are closed, and the armature rotates. At the same time,

the plunger is attracted, and the pinion is pushed forward by

the shift lever to mesh with the ring gear.

Then, the ring gear runs to start the engine. W hen the engine

starts and the starter switch is turned off, the plunger returns,

the pinion is disengaged from the ring gear, and the armature

stops rotation. W hen the engine speed is higher than the

pinion, the pinion idles, so that the armature is not driven.

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

Diagnosis

Condition Possible cause Correction

Starter does not run Charging failure Repair charging system

Battery Failure Replace Battery

Terminal connection failure Repair or replace terminal connector

and/or wiring harness

Starter switch failure Repair or replace starter switch

Starter failure Repair or replace starter

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2171 of 6020

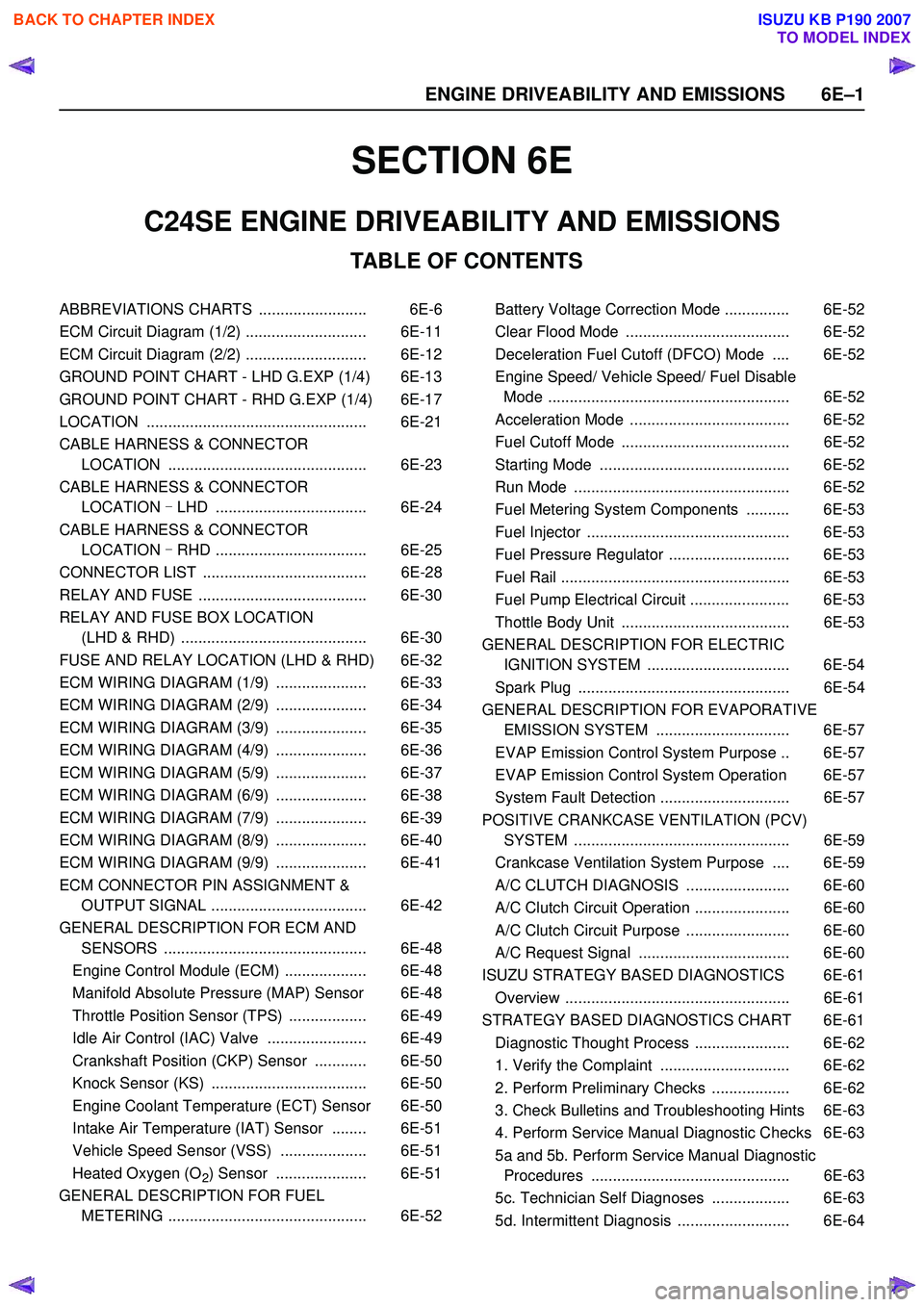

SECTION 6E

TABLE OF CONTENTS

C24SE ENGINE DRIVEABILITY AND EMISSIONS

ABBREVIATIONS CHARTS ......................... 6E-6

ECM Circuit Diagram (1/2) ............................ 6E-11

ECM Circuit Diagram (2/2) ............................ 6E-12

GROUND POINT CHART - LHD G.EXP (1/4) 6E-13

GROUND POINT CHART - RHD G.EXP (1/4) 6E-17

LOCATION ................................................... 6E-21

CABLE HARNESS & CONNECTOR LOCATION .............................................. 6E-23

CABLE HARNESS & CONNECTOR LOCATION - LHD ................................... 6E-24

CABLE HARNESS & CONNECTOR LOCATION - RHD ................................... 6E-25

CONNECTOR LIST ...................................... 6E-28

RELAY AND FUSE ....................................... 6E-30

RELAY AND FUSE BOX LOCATION (LHD & RHD) ........................................... 6E-30

FUSE AND RELAY LOCATION (LHD & RHD) 6E-32

ECM WIRING DIAGRAM (1/9) ..................... 6E-33

ECM WIRING DIAGRAM (2/9) ..................... 6E-34

ECM WIRING DIAGRAM (3/9) ..................... 6E-35

ECM WIRING DIAGRAM (4/9) ..................... 6E-36

ECM WIRING DIAGRAM (5/9) ..................... 6E-37

ECM WIRING DIAGRAM (6/9) ..................... 6E-38

ECM WIRING DIAGRAM (7/9) ..................... 6E-39

ECM WIRING DIAGRAM (8/9) ..................... 6E-40

ECM WIRING DIAGRAM (9/9) ..................... 6E-41

ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL .................................... 6E-42

GENERAL DESCRIPTION FOR ECM AND SENSORS ............................................... 6E-48

Engine Control Module (ECM) ................... 6E-48

Manifold Absolute Pressure (MAP) Sensor 6E-48

Throttle Position Sensor (TPS) .................. 6E-49

Idle Air Control (IAC) Valve ....................... 6E-49

Crankshaft Position (CKP) Sensor ............ 6E-50

Knock Sensor (KS) .................................... 6E-50

Engine Coolant Temperature (ECT) Sensor 6E-50

Intake Air Temperature (IAT) Sensor ........ 6E-51

Vehicle Speed Sensor (VSS) .................... 6E-51

Heated Oxygen (O

2) Sensor ..................... 6E-51

GENERAL DESCRIPTION FOR FUEL METERING .............................................. 6E-52 Battery Voltage Correction Mode ............... 6E-52

Clear Flood Mode ...................................... 6E-52

Deceleration Fuel Cutoff (DFCO) Mode .... 6E-52

Engine Speed/ Vehicle Speed/ Fuel Disable Mode ........................................................ 6E-52

Acceleration Mode ..................................... 6E-52

Fuel Cutoff Mode ....................................... 6E-52

Starting Mode ............................................ 6E-52

Run Mode .................................................. 6E-52

Fuel Metering System Components .......... 6E-53

Fuel Injector ............................................... 6E-53

Fuel Pressure Regulator ............................ 6E-53

Fuel Rail ..................................................... 6E-53

Fuel Pump Electrical Circuit ....................... 6E-53

Thottle Body Unit ....................................... 6E-53

GENERAL DESCRIPTION FOR ELECTRIC IGNITION SYSTEM ................................. 6E-54

Spark Plug ................................................. 6E-54

GENERAL DESCRIPTION FOR EVAPORATIVE EMISSION SYSTEM ............................... 6E-57

EVAP Emission Control System Purpose .. 6E-57

EVAP Emission Control System Operation 6E-57

System Fault Detection .............................. 6E-57

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM .................................................. 6E-59

Crankcase Ventilation System Purpose .... 6E-59

A/C CLUTCH DIAGNOSIS ........................ 6E-60

A/C Clutch Circuit Operation ...................... 6E-60

A/C Clutch Circuit Purpose ........................ 6E-60

A/C Request Signal ................................... 6E-60

ISUZU STRATEGY BASED DIAGNOSTICS 6E-61

Overview .................................................... 6E-61

STRATEGY BASED DIAGNOSTICS CHART 6E-61 Diagnostic Thought Process ...................... 6E-62

1. Verify the Complaint .............................. 6E-62

2. Perform Preliminary Checks .................. 6E-62

3. Check Bulletins and Troubleshooting Hints 6E-63

4. Perform Service Manual Diagnostic Checks 6E-63

5a and 5b. Perform Service Manual Diagnostic Procedures .............................................. 6E-63

5c. Technician Self Diagnoses .................. 6E-63

5d. Intermittent Diagnosis .......................... 6E-64

6 E –1

E N GINE DRIV EABILITY AND E M IS SIONS

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2199 of 6020

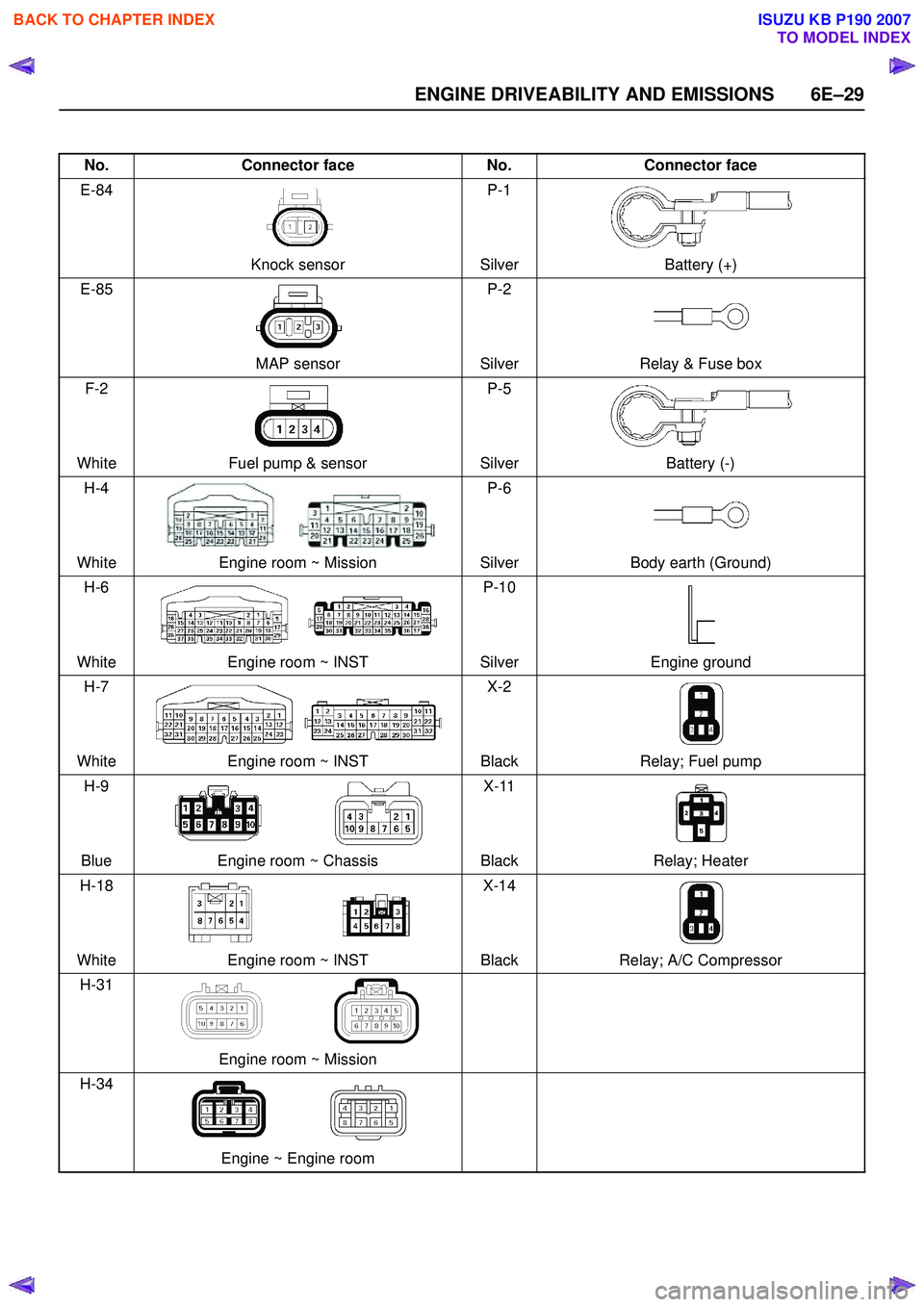

ENGINE DRIVEABILITY AND EMISSIONS 6E–29

No.Connector face No.Connector face

E-84

Knock sensor P-1

Silver Battery (+)

E-85

MAP sensor P-2

Silver Relay & Fuse box

F-2

White Fuel pump & sensor P-5

Silver Battery (-)

H-4

White Engine room ~ Mission P-6

Silver Body earth (Ground)

H-6

White Engine room ~ INST P-10

Silver Engine ground

H-7

White Engine room ~ INST X-2

Black Relay; Fuel pump

H-9

Blue Engine room ~ Chassis X-11

Black Relay; Heater

H-18

White Engine room ~ INST X-14

Black Relay; A/C Compressor

H-31

Engine room ~ Mission

H-34

Engine ~ Engine room

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2200 of 6020

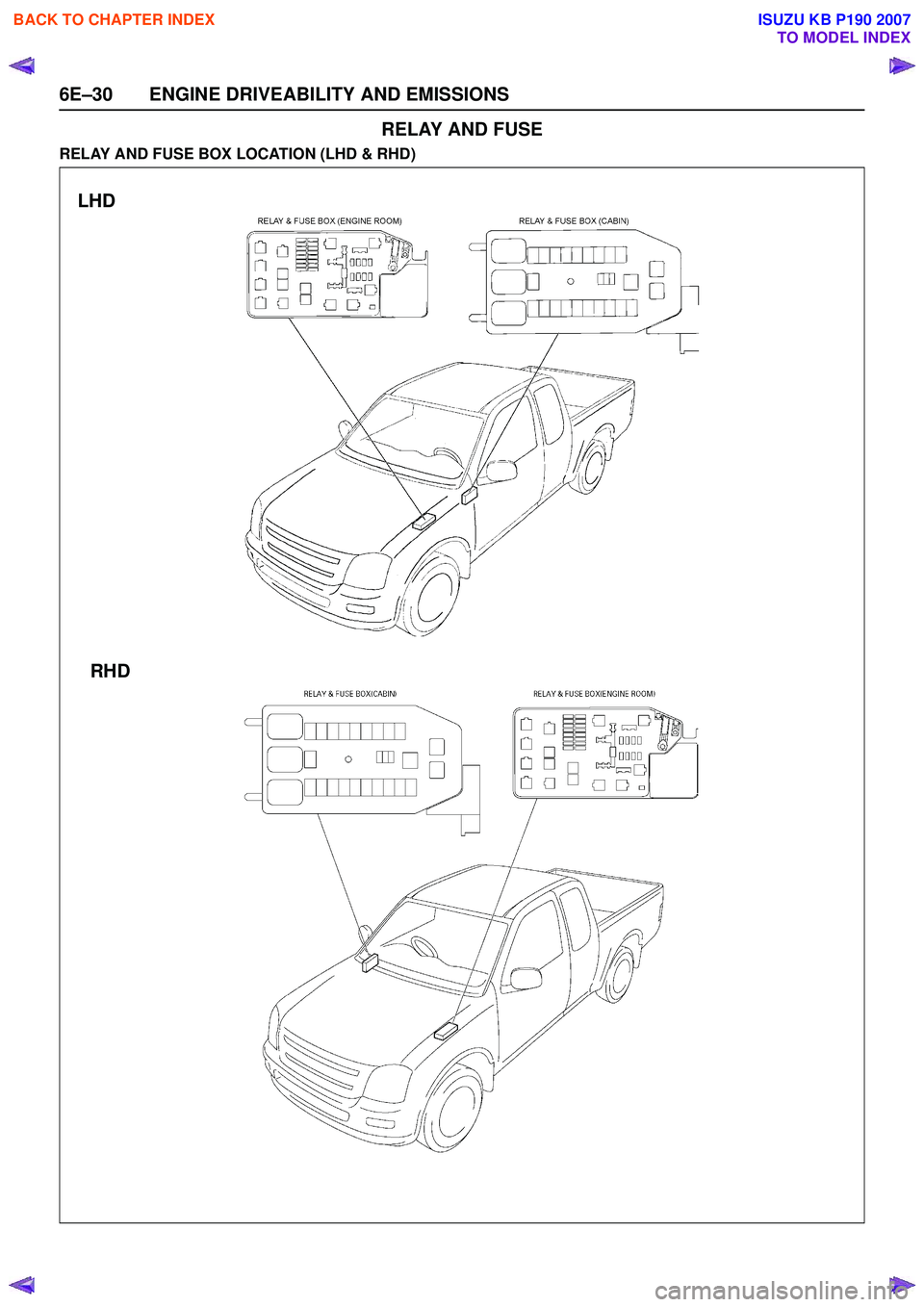

6E–30 ENGINE DRIVEABILITY AND EMISSIONS

RELAY AND FUSE

RELAY AND FUSE BOX LOCATION (LHD & RHD)

LHDRHD

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2201 of 6020

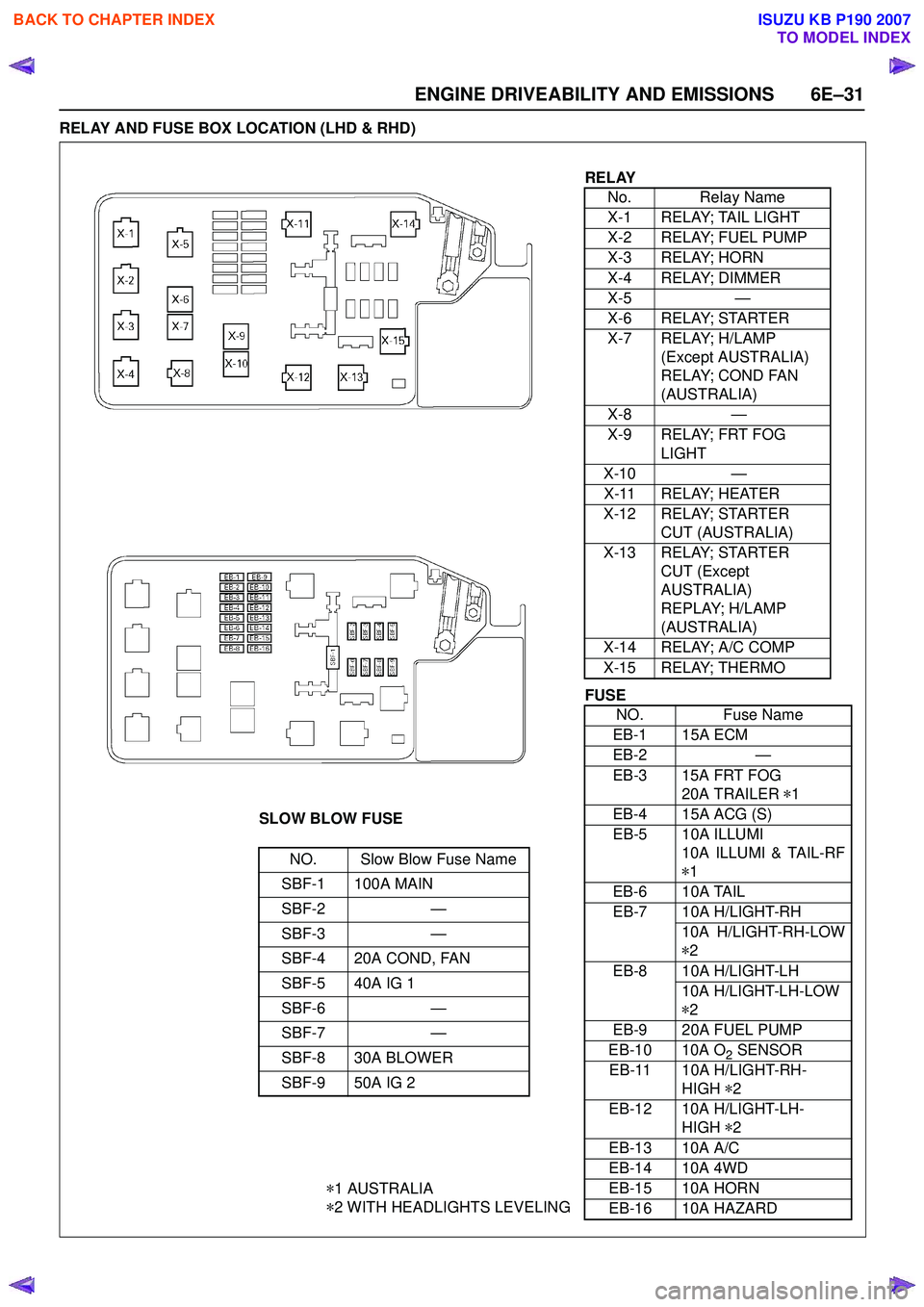

ENGINE DRIVEABILITY AND EMISSIONS 6E–31

RELAY AND FUSE BOX LOCATION (LHD & RHD)

RELAYNo. Relay Name

X-1 RELAY; TAIL LIGHT

X-2 RELAY; FUEL PUMP

X-3 RELAY; HORN

X-4 RELAY; DIMMER

X-5 —

X-6 RELAY; STARTER

X-7 RELAY; H/LAMP (Except AUSTRALIA)

RELAY; COND FAN

(AUSTRALIA)

X-8 —

X-9 RELAY; FRT FOG LIGHT

X-10 —

X-11 RELAY; HEATER

X-12 RELAY; STARTER CUT (AUSTRALIA)

X-13 RELAY; STARTER CUT (Except

AUSTRALIA)

REPLAY; H/LAMP

(AUSTRALIA)

X-14 RELAY; A/C COMP

X-15 RELAY; THERMO

SLOW BLOW FUSE

NO. Slow Blow Fuse Name

SBF-1 100A MAIN

SBF-2 —

SBF-3 —

SBF-4 20A COND, FAN

SBF-5 40A IG 1

SBF-6 —

SBF-7 —

SBF-8 30A BLOWER

SBF-9 50A IG 2

* 1 AUSTRALIA

* 2 WITH HEADLIGHTS LEVELING

FUSE

NO. Fuse Name

EB-1 15A ECM

EB-2 —

EB-3 15A FRT FOG 20A TRAILER *1

EB-4 15A ACG (S)

EB-5 10A ILLUMI 10A ILLUMI & TAIL-RF

* 1

EB-6 10A TAIL

EB-7 10A H/LIGHT-RH 10A H/LIGHT-RH-LOW

* 2

EB-8 10A H/LIGHT-LH 10A H/LIGHT-LH-LOW

* 2

EB-9 20A FUEL PUMP

EB-10 10A O

2 SENSOR

EB-11 10A H/LIGHT-RH- HIGH *2

EB-12 10A H/LIGHT-LH- HIGH *2

EB-13 10A A/C

EB-14 10A 4WD

EB-15 10A HORN

EB-16 10A HAZARD

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2202 of 6020

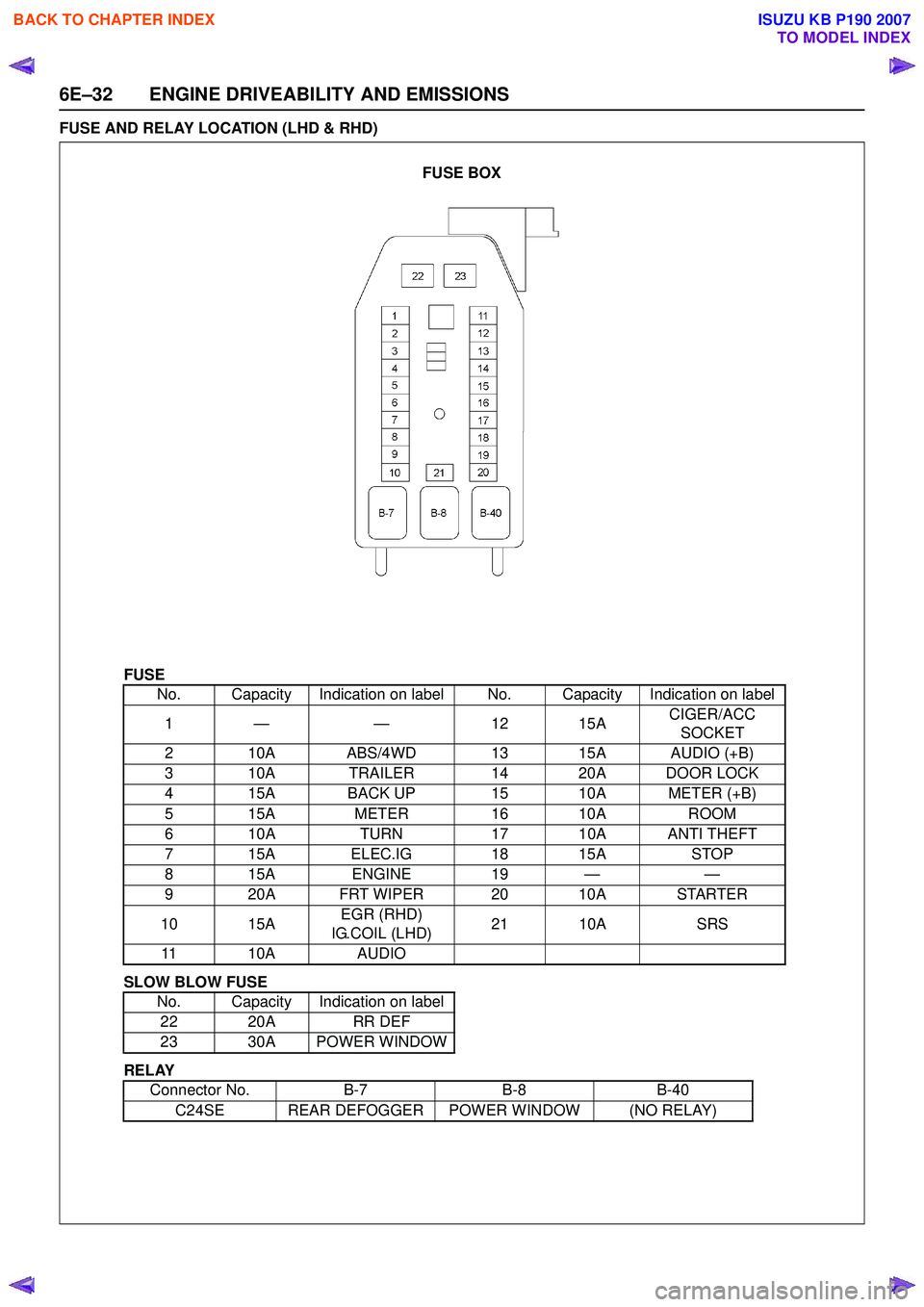

6E–32 ENGINE DRIVEABILITY AND EMISSIONS

FUSE AND RELAY LOCATION (LHD & RHD)

FUSE

SLOW BLOW FUSE

RELAY No. Capacity Indication on label No. Capacity Indication on label

1— — 1 215A CIGER/ACC

SOCKET

2 10A ABS/4WD 13 15A AUDIO (+B)

3 10A TRAILER 14 20A DOOR LOCK

4 15A BACK UP 15 10A METER (+B)

5 15A METER16 10A ROOM

6 10A TURN17 10A ANTI THEFT

7 15A ELEC.IG 18 15ASTOP

815A ENGINE 19 — —

9 20A FRT WIPER 20 10A STARTER

10 15A EGR (RHD)

IG.COIL (LHD) 21 10A

SRS

11 10A AUDIO

No. Capacity Indication on label 22 20A RR DEF

23 30A POWER WINDOW

Connector No. B-7B-8B-40

C24SE REAR DEFOGGER POWER WINDOW (NO RELAY)

FUSE BOX

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2214 of 6020

6E–44 ENGINE DRIVEABILITY AND EMISSIONS

Connector J2 Port: View Looking Into ECM Case

1

17 16

32

PIN32

PIN1

PIN17

PIN16

Pin

No. B/

Box No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

J2-1 J2-1 Intake Air Temp. (IAT) Sensor Ground GRN Continuity

with

ground -

- - Disconnect ΩJ2-1 GND

J2-2 J2-2 Battery Power Supply RED/ WHT10-14V

Connect DC V J2-2 GND

J2-3 J2-3 Ignition Power Supply BLU/ YELLess than

1V 10-14V

Connect DC V J2-3 GND

J2-4 J2-4 To Data Link Connector No. 6 BLU -

-- - -- - -

J2-5 J2-5 No Connection -- - - - -- - -

J2-6 J2-6 Oxygen Sensor (Ground) PNK Continuity

with

ground -

- - Connect ΩJ2-6 GND

J2-7 J2-7 No Connection -- - - - -- - -

J2-8 J2-8 No Connection -- - - - -- - -

J2-9 J2-9 No Connection -- - - - -- - -

J2-10 J2-10 CO Adjust Signal (W/O Catalystic

Converter) YEL -

-- - -- - -

J2-11 J2-11 Fuel Pump Relay GRN/ WHT10-14V

While relay

is activated; 10-14V

Relay is not

activated;

Less than 1V10-14V Connect DC V J2-11 GND

J2-12 J2-12 No Connection -- - - - -- - -

J2-13 J2-13 A/C Compressor Relay GRY/

RED Less than

1V A/C comp. is operated: Less than 1V

A/C comp. is not operated: 10-14V Connect DC V J2-13 GND

J2-14 J2-14 No Connection -- - - - -- - -

J2-15 J2-15 No Connection -- - - - -- - -

J2-16 J2-16 No Connection -- - - - -- - -

J2-17 J2-17 CO Adjust (W/O Catalystic Converter) RED -

-- - -- - -

J2-18 J2-18 Battery Power Supply RED/ WHT10-14V

Connect DC V J2-18 GND

J2-19 J2-19 No Connection -- - - - -- - -

J2-20 J2-20 Power Steering Pressure Switch GRN/

YEL Less than

1V

Pressure switch is turned on: Less than 1VPressure switch is turned off: 10-14VConnect DC V J2-20 GND

J2-21 J2-21 Oxygen Sensor BLU Less than 1VApprox.

0.4V Wave form D or 0.1 -

0.9V Connect DC V J2-21 J2-6

J2-22 J2-22 Intake Air Temp. (IAT) Sensor (Signal) YEL/

GRN Less than

1V

20℃: Approx. 2.9V / 40 ℃: Approx. 1.8V V

/ 60 ℃: Approx. 1.1V / 80 ℃: Approx. 0.6VConnect DC V J2-22 33

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2215 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–45

J2-23 J2-23 Vehicle Speed Sensor (VSS) Signal

(Immobilizer Control

Unit Terminal B8) WHT -

- Wave form C or Approx.

6.5V at 20km/h Connect AC V J2-23 GND

J2-24 J2-24 No Connection -- - - - -- - -

J2-25 J2-25 Tachometer Output Signal BLK/

RED -

- Wave form Wave form

B or

Approx.

4.5V Connect AC V J2-25 GND

J2-26 J2-26 Thermo Relay GRN/

BLK Less than

1V

A/C request is activated: 10-14V

A/C request is not activated: Less than 1VConnect DC V J2-26 GND

J2-27 J2-27 No Connection - - - - - - - - -

J2-28 J2-28 No Connection - - - - - - - - -

J2-29 J2-29 No Connection -- - - - -- - -

J2-30 J2-30 To Data Link Connector No. 2 GRN -

-- - -- - -

J2-31 J2-31 Oxygen Sensor Heater BLU/ WHTContinuity

with

ground - Wave

Form Wave

Form D Connect

ΩJ2-31 GND

J2-32 J2-32 Check Engine Lamp (Immobilizer Control

Unit Terminal B7) BRN/

YEL Less than

1V Less than

1V Lamp is turned on: Less

than 1V

Lamp is turned off: 10-

14V Connect DC V J2-32 GND

Pin

No. B/

Box No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2222 of 6020

6E–52 ENGINE DRIVEABILITY AND EMISSIONS

GENERAL DESCRIPTION FOR FUEL

METERING

The fuel metering system starts with the fuel in the fuel

tank. An electric fuel pump, located in the fuel tank,

pumps fuel to the fuel rail through an in-line fuel filter.

The pump is designed to provide fuel at a pressure

above the pressure needed by the injectors.

A fuel pressure regulator in the fuel rail keeps fuel

available to the fuel injectors at a constant pressure.

A return line delivers unused fuel back to the fuel tank.

The basic function of the air/fuel metering system is to

control the air/fuel delivery to the engine. Fuel is

delivered to the engine by individual fuel injectors

mounted in the intake manifold.

The main control sensor is the heated oxygen sensor

located in the exhaust system. The heated oxygen

sensor reports to the ECM how much oxygen is in the

exhaust gas. The ECM changes the air/fuel ratio to the

engine by controlling the amount of time that fuel

injector is “On”.

The best mixture to minimize exhaust emissions is 14.7

parts of air to 1 part of gasoline by weight, which allows

the catalytic converter to operate most efficiently.

Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a “closed

loop” system.

The ECM monitors signals from several sensors in

order to determine the fuel needs of the engine. Fuel is

delivered under one of several conditions called “mode”.

All modes are controlled by the ECM.

Battery Voltage Correction Mode

When battery voltage is low, the ECM will compensate

for the weak spark by increasing the following:

• The amount of fuel delivered.

• The idle RPM.

Clear Flood Mode

Clear a flooded engine by pushing the accelerator pedal

down all the way. The ECM then de-energizes the fuel

injectors. The ECM holds the fuel injectors de-energized

as long as the throttle remains above 75% and the

engine speed is below 800 RPM. If the throttle position

becomes less than 75%, the ECM again begins to pulse

the injectors ON and OFF, allowing fuel into the

cylinders.

Deceleration Fuel Cutoff (DFCO) Mode

The ECM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air

flow. When deceleration is very fast, the ECM may cut

off fuel completely. Until enable conditions meet the

engine revolution less 1000 rpm or manifold absolute

pressure less than 10 kPa.

Engine Speed/ Vehicle Speed/ Fuel Disable

Mode

The ECM monitors engine speed. It turns off the fuel

injectors when the engine speed increases above 6000

RPM. The fuel injectors are turned back on when

engine speed decreases below 3500 RPM.

Acceleration Mode

The ECM provides extra fuel when it detects a rapid

increase in the throttle position and the air flow.

Fuel Cutoff Mode

No fuel is delivered by the fuel injectors when the

ignition is OFF. This prevents engine run-on. In addition,

the ECM suspends fuel delivery if no reference pulses

are detected (engine not running) to prevent engine

flooding.

Starting Mode

When the ignition is first turned ON, the ECM energizes

the fuel pump relay for two seconds to allow the fuel

pump to build up pressure. The ECM then checks the

engine coolant temperature (ECT) sensor and the

throttle position sensor to determine the proper air/fuel

ratio for starting.

The ECM controls the amount of fuel delivered in the

starting mode by adjusting how long the fuel injectors

are energized by pulsing the injectors for very short

times.

Run Mode

The run mode has the following two conditions:

• Open loop

• Closed loop

When the engine is first started, the system is in “open

loop” operation. In “Open Loop,” the ECM ignores the

signal from the heated oxygen sensor (HO2S). It

calculates the air/fuel ratio based on inputs from the TP,

ECT, and MAP sensors.

The system remains in “Open Loop” until the following

conditions are met:

• The HO2S has a varying voltage output showing that it is hot enough to operate properly (this depends on

temperature).

• The ECT has reached a specified temperature.

• A specific amount of time has elapsed since starting the engine.

• Engine speed has been greater than a specified RPM since start-up.

The specific values for the above conditions vary with

different engines and are stored in the programmable

read only memory (PROM). When these conditions are

met, the system enters “closed loop” operation. In

“closed loop,” the ECM calculates the air/fuel ratio

(injector on-time) based on the signal from the HO2S.

This allows the air/fuel ratio to stay very close to 14.7:1.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007