relay ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1862 of 6020

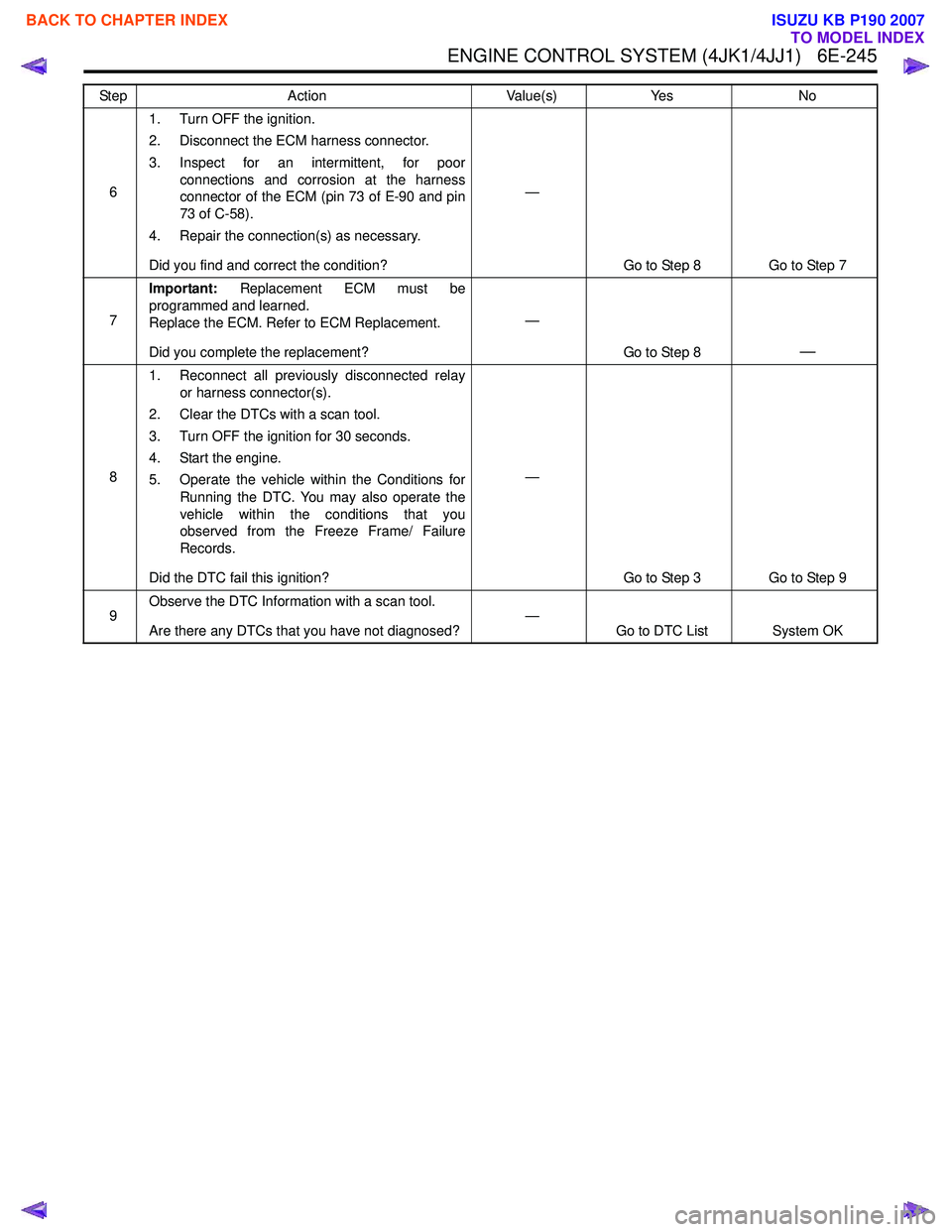

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-245

61. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pin 73 of E-90 and pin

73 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 7

7 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 8

—

81. Reconnect all previously disconnected relay

or harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 9

9 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1863 of 6020

6E-246 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P1404 (Flash Code 45)

Circuit Description

The ECM controls the EGR valve opening based on the

engine running condition and by controlling the EGR

solenoid. The EGR valve position is detected by the

position sensor, and relayed to the ECM.

If the ECM detects that the actual EGR position is

higher than certain amount, this DTC will set. (Closed

Position Error DTC)

If the ECM detects a variance between the learned

closed position and actual closed position, this DTC will

also set. (Learned Position Error DTC)

Condition for Running the DTC

Closed Position Error DTC • DTCs P0112, P0113, P0116, P0117, P0118, P0404 P0405, P0406, P0652, P0653, P2227,

P2228 and P2229 are not set.

• The battery voltage is between 10 to 16 volts.

• The ignition switch is ON.

• The engine coolant temperature is between 20 to 11 0 °C (68 to 230 °F).

• The intake air temperature is between 0 to 110 °C

(32 to 230 °F).

• The barometric pressure is between 60 to 120 kPa (8.7 to 17.4 psi)

Learned Position Error DTC

• DTCs P0404, P0405 and P0406 are not set.

Condition for Setting the DTC

Closed Position Error DTC • The ECM detects that the actual EGR position is

more than 20% for 5 seconds when the EGR

control is commanded OFF.

Learned Position Error DTC

• The ECM detects that the EGR learned minimum position is more than 10% or less than -10% when

the ignition switch is OFF.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits EGR control. (Closed Position Error DTC)

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• A sticking or intermittently sticking EGR valve may set this DTC.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P1404

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0403, P0405 or P0406 also set? —

Go to Applicable DTC Go to Step 3

3 1. Remove the EGR valve assembly from the

engine.

2. Inspect the EGR valve for the following conditions:

• Restricted EGR valve by foreign materials

• Excessive deposits at valve

• Bent valve shaft

3. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1865 of 6020

6E-248 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P1411, P1412 or P1413 (Flash Code 445)

Circuit Description

The ECM controls the EGR valve opening based on the

engine running condition and by controlling the EGR

solenoid. The EGR valve position is detected by the

position sensor, and relayed to the ECM. If the ECM

detects an excessively high temperature condition in its

internal EGR solenoid drive circuit for certain length of

time, DTC P1411, P1412 or P1413 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects an excessively high temperature in its internal EGR solenoid drive circuit for longer

than 30 seconds. (DTC P1411)

• The ECM detects an excessively high temperature in its internal EGR solenoid drive circuit for longer

than 60 seconds in accumulation time during same

ignition cycle. (DTC P1412) • The ECM detects an excessively high temperature

in its internal EGR solenoid drive circuit for longer

than 120 seconds in accumulation time exceeding

ignition cycle. (DTC P1413)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• A sticking or intermittently sticking EGR valve may set this DTC.

Circuit/ System Testing DTC P1411, P1412 or P1413

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0404 or P1404 also set? —

Go to Applicable DTC Go to Step 3

3 1. Perform the EGR Solenoid Control with a scan

tool several times.

2. Command the Desired EGR Position Increase and Decrease while observing the EGR

Position.

Does the EGR Position parameter follow within the

specified value quick enough (compare with a

similar unit if available)? ±

5%

Go to Diagnostic Aids Go to Step 4

4 1. Remove the EGR valve assembly from the

engine.

2. Inspect the EGR valve for the following conditions:

• Restricted EGR valve by foreign materials

• Excessive deposits at valve

• Bent valve shaft

3. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1867 of 6020

6E-250 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P156A or P156B (Flash Code 135)

Circuit Description

The ECM monitors the battery voltage on the ECM

main relay voltage feed terminal to make sure that the

voltage stays within the proper range. If the ECM

detects an excessively low or high battery voltage, DTC

P156A or P156B will set.

Condition for Running the DTC • The ignition voltage is more than 9 volts. (DTC P156B)

Condition for Setting the DTC • The ECM detects that the battery voltage feed circuit is less than 8 volts for 20 seconds. (DTC

P156A)

• The ECM detects that the battery voltage feed circuit is more than 16 volts for 5 seconds. (DTC

P156B)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity. (DTC P156B)

• The ECM inhibits pilot injection. (DTC P156B)

• The ECM inhibits cruise control. (DTC P156B)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • A charging system problem may set this DTC.

• The weakened battery may set DTC P156A.

• Jump starting the vehicle or a battery charger may have set DTC P156B.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P156A

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle.

4. Load the electrical system by turning ON the headlights, A/C, etc. while observing the

Battery Voltage parameter with a scan tool.

Does the scan tool indicate more than the specified

value? 10.0 volts

Go to Diagnostic Aids Go to Step 3

3 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 4 Go to Step 5

4 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1877 of 6020

6E-260 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P2100, P2101 or P2103 (Flash Code 446)

Circuit Description

The ECM controls the intake throttle valve opening

based on the engine running condition and by

controlling the intake throttle solenoid. The intake

throttle valve position is detected by the position

sensor, and relayed to the ECM. If the ECM detects an

open circuit or short circuit on the solenoid circuits,

DTC P2100, P2101 or P2103 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects an open circuit on the intake throttle solenoid circuits. (DTC P2100)

• The ECM detects a short to ground on the intake throttle solenoid circuits. (DTC P2101)

• The ECM detects a short to voltage circuit on the intake throttle solenoid circuits. (DTC P2103)

Action Taken When the DTC Sets • The ECM illuminates the MIL on the second consecutive driving cycle when the diagnostic runs

and fails. Refer to DTC Type Definitions for Action

Taken When the DTC Sets - Type B. (Euro 4

Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM inhibits EGR control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type B (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2100, P2101 or P2103

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the intake throttle valve harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a DMM between the drive voltage circuit (pin 2 of E-38) and a known good

ground.

5. Connect a DMM between the low side circuit (pin 1 of E-38) and a known good ground.

Are both voltage readings within the specified

value? 1.4 to 1.8 volts

Go to Step 5 Go to Step 4

4 Is the DMM voltage more than the specified value

at Step 3? —

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1923 of 6020

6E-306 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

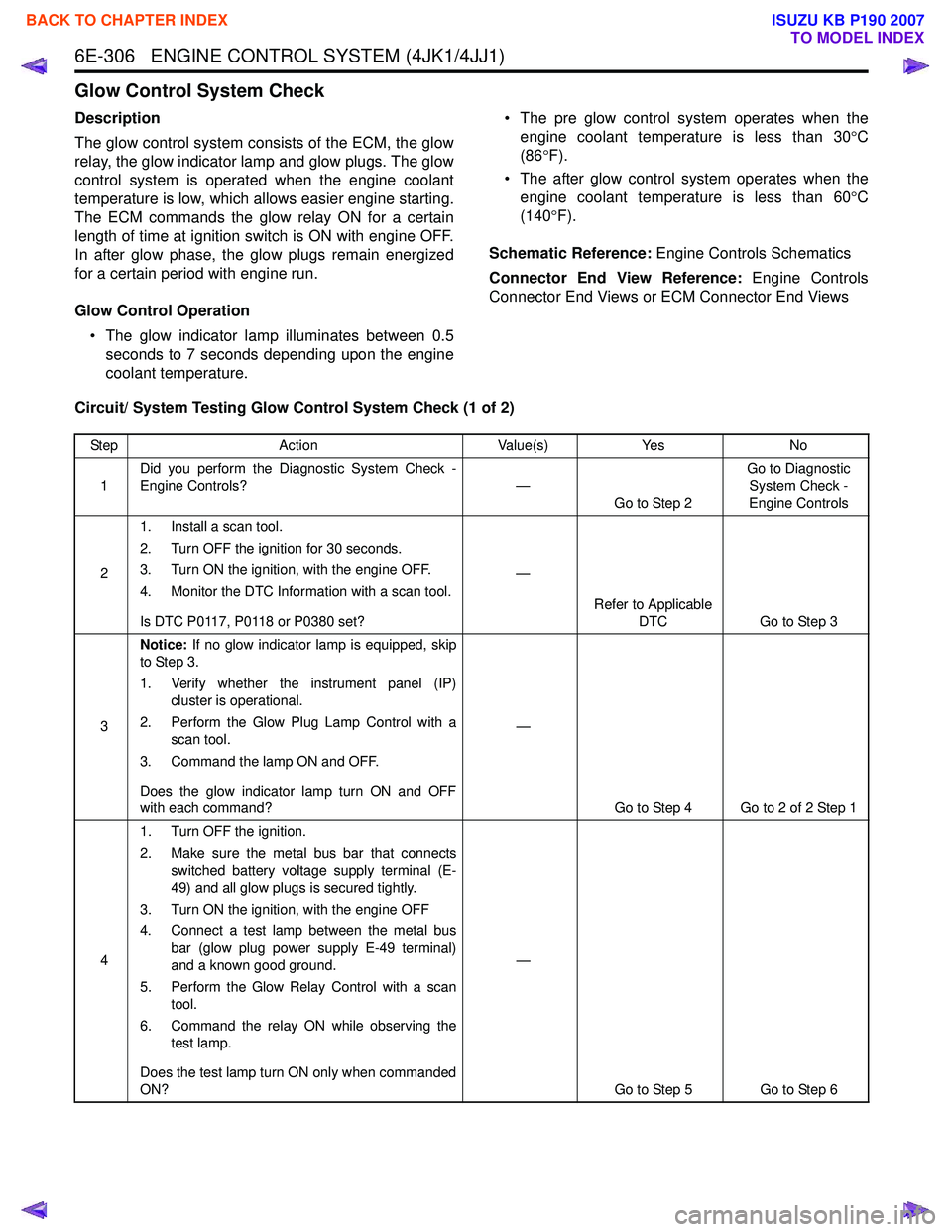

Glow Control System Check

Description

The glow control system consists of the ECM, the glow

relay, the glow indicator lamp and glow plugs. The glow

control system is operated when the engine coolant

temperature is low, which allows easier engine starting.

The ECM commands the glow relay ON for a certain

length of time at ignition switch is ON with engine OFF.

In after glow phase, the glow plugs remain energized

for a certain period with engine run.

Glow Control Operation • The glow indicator lamp illuminates between 0.5 seconds to 7 seconds depending upon the engine

coolant temperature. • The pre glow control system operates when the

engine coolant temperature is less than 30 °C

(86 °F).

• The after glow control system operates when the engine coolant temperature is less than 60 °C

(140 °F).

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Glow Control System Check (1 of 2)

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC P0117, P0118 or P0380 set? —

Refer to Applicable DTC Go to Step 3

3 Notice:

If no glow indicator lamp is equipped, skip

to Step 3.

1. Verify whether the instrument panel (IP) cluster is operational.

2. Perform the Glow Plug Lamp Control with a scan tool.

3. Command the lamp ON and OFF.

Does the glow indicator lamp turn ON and OFF

with each command? —

Go to Step 4 Go to 2 of 2 Step 1

4 1. Turn OFF the ignition.

2. Make sure the metal bus bar that connects switched battery voltage supply terminal (E-

49) and all glow plugs is secured tightly.

3. Turn ON the ignition, with the engine OFF

4. Connect a test lamp between the metal bus bar (glow plug power supply E-49 terminal)

and a known good ground.

5. Perform the Glow Relay Control with a scan tool.

6. Command the relay ON while observing the test lamp.

Does the test lamp turn ON only when commanded

ON? —

Go to Step 5 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1924 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-307

51. Turn OFF the ignition.

2. Remove the metal bus bar from the glow plugs.

3. Measure resistance of each glow plug between the glow plug terminals and a known

good ground. Make sure to record all

measurements and take them quickly as to

not allow engine temperature changes

between measurements.

Are the resistances within the specified value each

other? 1

Ω

System OK Go to Step 16

6 1. Turn OFF the ignition.

2. Replace the glow relay with the starter relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

4. Connect a test lamp between the metal bus bar (glow plug power supply E-49 connector)

and a known good ground.

5. Perform the Glow Relay Control with a scan tool.

6. Command the relay ON while observing the test lamp.

Does the test lamp turn ON only when commanded

ON? —

Go to Step 14 Go to Step 7

7 Inspect the Glow (60A) slow blow fuse in the

engine room fuse block.

Is the Glow (60A) slow blow fuse open? —

Go to Step 8 Go to Step 9

8 Replace the Glow (60A) slow blow fuse. If the slow

blow fuse continues to open, repair the short to

ground on a circuit fed by the slow blow fuse or

check for a shorted attached component.

Did you complete the repair? —

Go to Step 17

—

91. Turn OFF the ignition.

2. Remove the glow relay.

3. Probe the battery voltage feed circuit of the relay (pin 4 of X-5) with a test lamp that is

connected to a known good ground.

Does the test lamp illuminate? —

Go to Step 10 Go to Step 11

10 1. Probe the voltage supply circuit of glow plugs

(pin 1 of X-5) with a test lamp that is

connected to a known good ground.

2. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 13 Go to Step 12

11 Repair the open circuit or high resistance between

the Glow (60A) slow blow fuse and the glow relay

(pin 4 of X-5).

Did you complete the repair? —

Go to Step 17

—

12Repair the open circuit or high resistance between

the glow relay (pin 1 of X-5) and the glow plugs (E-

49 terminal).

Did you complete the repair? —

Go to Step 17

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1925 of 6020

6E-308 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Circuit/ System Testing Glow Control System Check (2 of 2)

13Important

: The glow plugs may be burnt out if the

battery voltage supply circuit is shorted to a voltage

source.

Repair the short to battery or ignition voltage

between the glow relay (pin 1 of X-5) and the glow

plugs (E-49 terminal).

Did you complete the repair? —

Go to Step 17

—

141. Remove the glow relay.

2. Inspect for an intermittent and for poor connection on each glow relay terminal.

3. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 17 Go to Step 15

15 Replace the glow relay.

Did you complete the replacement? —

Go to Step 17

—

16Replace the appropriate glow plug.

Did you complete the replacement? —

Go to Step 17—

171. Reconnect all previously disconnected

components, relay, fuse or harness

connector(s).

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Connect a test lamp between the metal bus bar (glow plug power supply E-49 connector)

and a known good ground.

5. Perform the Glow Relay Control with a scan tool.

6. Command the relay ON while observing the test lamp.

Does the test lamp turn ON only when commanded

ON? —

Go to Step 5 Go to Step 2

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 1. Turn OFF the ignition.

2. Inspect the Meter (10A) fuse in cabin fuse block.

Is the Meter (10A) fuse open? —

Go to Step 2 Go to Step 3

2 Replace the Meter (10A) fuse. If the fuse continues

to open, repair the short to ground on one of the

circuits that is fed by the Meter (10A) fuse or

replace the shorted attached component.

Did you complete the repair? —

Go to Step 14

—

31. Turn OFF the ignition.

2. Disconnect the ECM J-2 (C-58) harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the glow indicator lamp OFF? —

Go to Step 4 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1928 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-311

In-Tank Fuel Pump System Check

Description

The ECM controls the fuel pump relay, which supplies

power to the fuel pump in the fuel tank. The ECM

commands the fuel pump relay ON for a certain length

of time at ignition switch is ON with the engine OFF.

During the engine is running it is continuity commanded

ON.

In-tank Fuel Pump Control Operation • The battery voltage is more than 9 volts. • The ignition switch is ON.

• The fuel pump is commanded ON for 12 seconds at ignition switch is ON with the engine OFF.

• The fuel pump is continuously ON while engine is running.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing In-Tank Fuel Pump System Check

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition for 20 seconds, then start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0231 or P0232 set? —

Refer to Applicable DTC Go to Step 3

3 1. Turn OFF the ignition for 30 seconds.

2. Remove the fuel filler cap.

3. Turn ON the ignition, with the engine OFF.

Is the fuel pump operating sound heard from the

fuel filler? —

Go to Step 4 Go to Step 7

4 Does the fuel pump operating sound stop after

approximately 12 seconds passed? —

Go to Step 21 Go to Step 5

5 1. Turn OFF the ignition for 30 seconds.

2. Replace the fuel pump relay with the head light relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

Does the fuel pump operating sound stop after

approximately 12 seconds passed? —

Go to Step 20 Go to Step 6

6 Repair the short to battery or ignition voltage

between the fuel pump relay (pin 2 of X-13) and the

fuel pump (pin 1 of F-2).

Did you complete the repair? —

Go to Step 25

—

71. Turn OFF the ignition for 30 seconds.

2. Replace the fuel pump relay with the head light relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

Is the fuel pump operating sound heard from the

fuel filler? —

Go to Step 17 Go to Step 8

8 Inspect the Fuel Pump (10A) fuse in the engine

room fuse block.

Is the Fuel Pump (10A) fuse open? —

Go to Step 9 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1929 of 6020

6E-312 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

9Replace the Fuel Pump (10A) fuse. If the fuse

continues to open, repair the short to ground on a

circuit fed by the fuse or check for a shorted

attached component.

Did you complete the repair? —

Go to Step 25

—

101. Turn OFF the ignition.

2. Remove the fuel pump relay.

3. Probe the battery voltage feed circuit of the relay (pin 1 of X-13) with a test lamp that is

connected to a known good ground.

Does the test lamp illuminate? —

Go to Step 12 Go to Step 11

11 Repair the open circuit or high resistance between

the Fuel Pump (10A) fuse and the fuel pump relay

(pin 1 of X-13).

Did you complete the repair? —

Go to Step 25

—

121. Reconnect the fuel pump relay.

2. Disconnect the fuel pump resistor harness connector.

3. Measure the resistance across the fuel pump resistor.

Is the resistance within the specified value? 2.2 to 2.7

Ω

Go to Step 13 Go to Step 23

13 1. Connect a test lamp between the fuel pump

side voltage feed circuit on the resistor

harness (pin 1 of C-157) and a known good

ground.

2. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate for approximately 12

seconds then go out? —

Go to Step 14 Go to Step 15

14 Connect a test lamp between the ground circuit on

the resistor harness (pin 2 of C-157) and battery

voltage.

Does the test lamp illuminate? —

Go to Step 18 Go to Step 16

15 1. Test the fuel pump circuit between the fuel

pump (pins 1 and 4 of F-2) and the fuel pump

relay (pin 2 of X-13) or the fuel pump resistor

(pin 1 of C-157) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 25 Go to Step 19

16 Repair the open circuit or high resistance between

the fuel pump resistor (pin 2 of C-57) and the body

ground terminal (C-109). Clean or tighten ground

as necessary.

Did you complete the repair? —

Go to Step 25

—

171. Remove the fuel pump relay.

2. Inspect for an intermittent and for poor connection on each relay terminal.

3. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 25 Go to Step 20

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007