ABS ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3195 of 6020

Engine Cooling – V6 Engine Page 6B1–60

Transmission Oil Cooler Leak Test

If the transmission oil cooler is suspected of leaking oil, test it before the radiator is replaced, as follows:

1 Disconnect oil cooler pipes at the flexible hose connections. Refer to 3.14 Flexible Transmission Cooler Hose, in this Section.

2 Plug one of the connections, using a blocked pipe fitting and attach an air supply to the other flexible hose.

3 Remove coolant filler cap and check that the coolant is filled to the coolant filler cap filler neck.

4 Apply air pressure gradually, increasing up to an absolute maximum of 110 kPa. If bubbles appear in radiator neck, the oil cooler is leaking and the radiator assembly must be replaced.

Transmission Oil Cooler Seal Replacement.

It is strongly recommended that the transmission oil cooler connector fittings to the right-hand side radiator header tank,

not be disturbed. If coolant is found to leak from either of these two areas, then the radiator should be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3211 of 6020

Fuel System – V6 Page 6C – 9

A small amount of fuel may be released when

connecting the fuel pressure gauge to the fuel

pressure test point. Cover the fittings with a

shop towel to absorb any fuel spillage before

connecting the fuel pressure gauge. After the

fuel pressure test procedure, place the soiled

towel in an approved container for disposal.

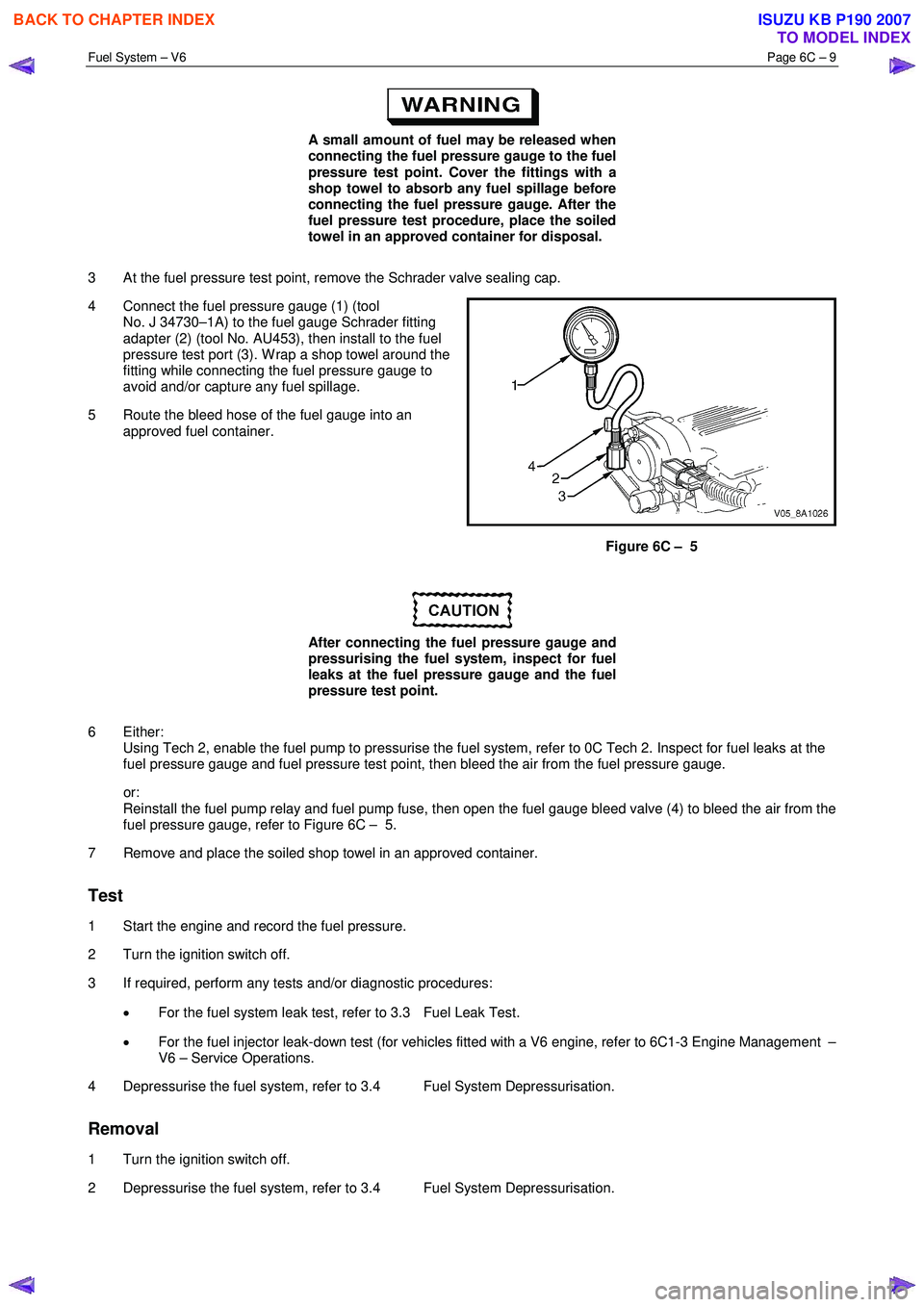

3 At the fuel pressure test point, remove the Schrader valve sealing cap.

4 Connect the fuel pressure gauge (1) (tool No. J 34730–1A) to the fuel gauge Schrader fitting

adapter (2) (tool No. AU453), then install to the fuel

pressure test port (3). W rap a shop towel around the

fitting while connecting the fuel pressure gauge to

avoid and/or capture any fuel spillage.

5 Route the bleed hose of the fuel gauge into an approved fuel container.

Figure 6C – 5

After connecting the fuel pressure gauge and

pressurising the fuel system, inspect for fuel

leaks at the fuel pressure gauge and the fuel

pressure test point.

6 Either: Using Tech 2, enable the fuel pump to pressurise the fuel system, refer to 0C Tech 2. Inspect for fuel leaks at the

fuel pressure gauge and fuel pressure test point, then bleed the air from the fuel pressure gauge.

or: Reinstall the fuel pump relay and fuel pump fuse, then open the fuel gauge bleed valve (4) to bleed the air from the

fuel pressure gauge, refer to Figure 6C – 5.

7 Remove and place the soiled shop towel in an approved container.

Test

1 Start the engine and record the fuel pressure.

2 Turn the ignition switch off.

3 If required, perform any tests and/or diagnostic procedures:

• For the fuel system leak test, refer to 3.3 Fuel Leak Test.

• For the fuel injector leak-down test (for vehicles fitted with a V6 engine, refer to 6C1-3 Engine Management –

V6 – Service Operations.

4 Depressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

Removal

1 Turn the ignition switch off.

2 Depressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3212 of 6020

Fuel System – V6 Page 6C – 10

After relieving the fuel system pressure, a

small amount of fuel may be released when

servicing the fuel lines or connections. Cover

the fittings with a shop towel before

disconnecting. This catches any leaking fuel.

Place the soiled towel in an approved

container when disconnection is completed.

3 W rap a shop towel around the fuel pressure test point to absorb any fuel spillage.

4 Remove the fuel pressure gauge and drain any fuel remaining in the fuel pressure gauge into an approved fuel container.

5 Remove the soiled shop towel and place in an approved container.

6 Repressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

7 Road-test the vehicle and check for correct operation.

3.3 Fuel Leak Test

After installing any fuel system component

and before starting the engine, check the fuel

system for leaks.

NOTE

For the fuel injector leak-down test (for vehicles

fitted with a V6 engine), refer to 6C1-3 Engine

Management – V6 – Service Operations.

1 Turn the ignition switch on for two seconds.

2 Turn the ignition switch off for 10 seconds.

3 Turn the ignition switch on.

4 Check for fuel leaks, particularly at points marked �z (that is, quick-connect fittings, fuel rails, fuel injectors,

Schrader valve and evaporative emission control canister purge solenoid, refer to Figure 6C – 6.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3214 of 6020

Fuel System – V6 Page 6C – 12

A small amount of fuel may be released when

pressing on the Schrader valve. Cover the

fitting with a shop towel to absorb any fuel

spillage before removing the Schrader valve

sealing cap. Place the soiled towel in an

approved container for disposal.

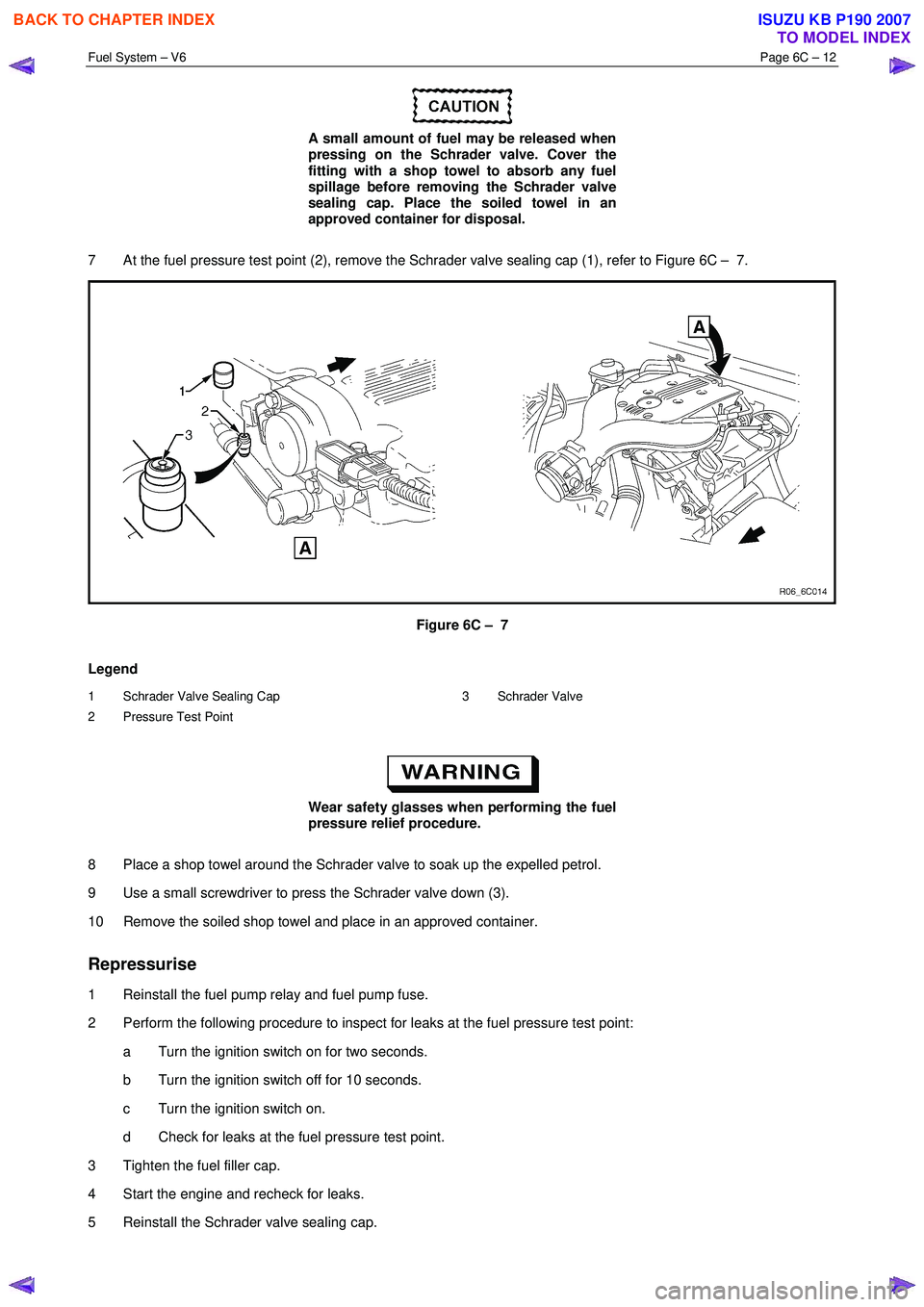

7 At the fuel pressure test point (2), remove the Schrader valve sealing cap (1), refer to Figure 6C – 7.

Figure 6C – 7

Legend

1 Schrader Valve Sealing Cap

2 Pressure Test Point 3 Schrader Valve

Wear safety glasses when performing the fuel

pressure relief procedure.

8 Place a shop towel around the Schrader valve to soak up the expelled petrol.

9 Use a small screwdriver to press the Schrader valve down (3).

10 Remove the soiled shop towel and place in an approved container.

Repressurise

1 Reinstall the fuel pump relay and fuel pump fuse.

2 Perform the following procedure to inspect for leaks at the fuel pressure test point: a Turn the ignition switch on for two seconds.

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Check for leaks at the fuel pressure test point.

3 Tighten the fuel filler cap.

4 Start the engine and recheck for leaks.

5 Reinstall the Schrader valve sealing cap.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3229 of 6020

Fuel System – V6 Page 6C – 27

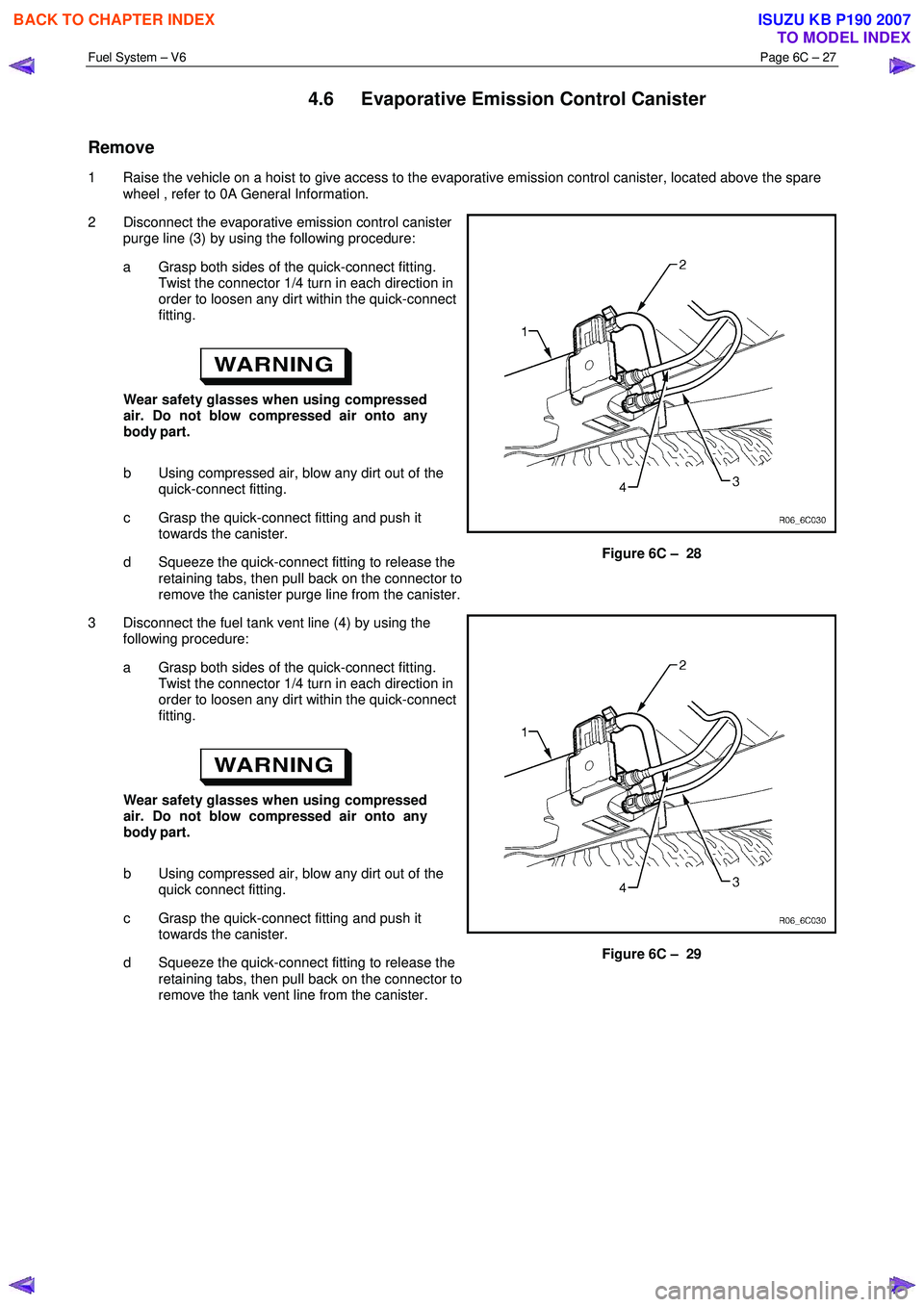

4.6 Evaporative Emission Control Canister

Remove

1 Raise the vehicle on a hoist to give access to the evaporative emission control canister, located above the spare

wheel , refer to 0A General Information.

2 Disconnect the evaporative emission control canister purge line (3) by using the following procedure:

a Grasp both sides of the quick-connect fitting. Twist the connector 1/4 turn in each direction in

order to loosen any dirt within the quick-connect

fitting.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

b Using compressed air, blow any dirt out of the quick-connect fitting.

c Grasp the quick-connect fitting and push it towards the canister.

d Squeeze the quick-connect fitting to release the retaining tabs, then pull back on the connector to

remove the canister purge line from the canister.

Figure 6C – 28

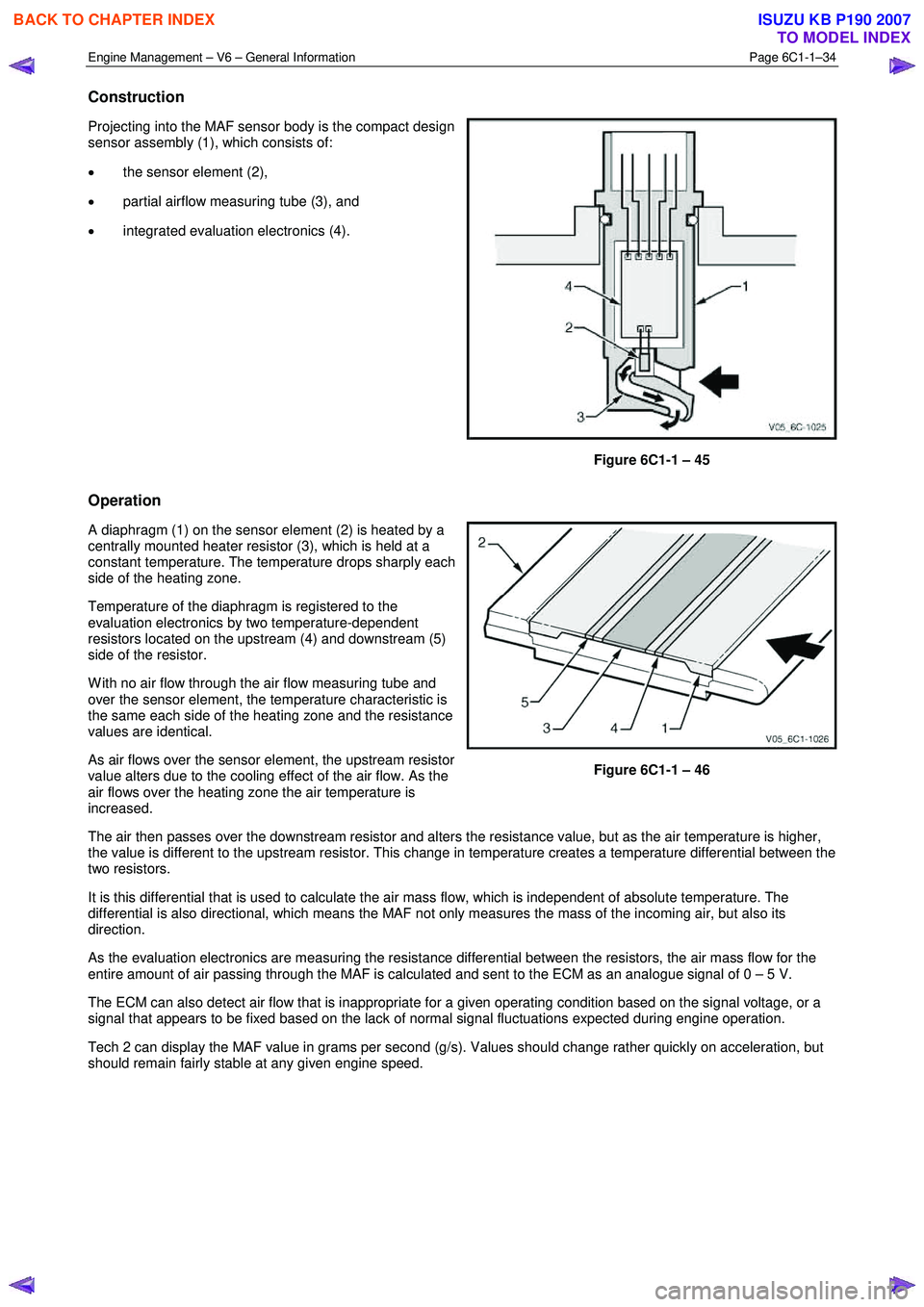

3 Disconnect the fuel tank vent line (4) by using the following procedure:

a Grasp both sides of the quick-connect fitting. Twist the connector 1/4 turn in each direction in

order to loosen any dirt within the quick-connect

fitting.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

b Using compressed air, blow any dirt out of the quick connect fitting.

c Grasp the quick-connect fitting and push it towards the canister.

d Squeeze the quick-connect fitting to release the retaining tabs, then pull back on the connector to

remove the tank vent line from the canister.

Figure 6C – 29

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3276 of 6020

Engine Management – V6 – General Information Page 6C1-1–34

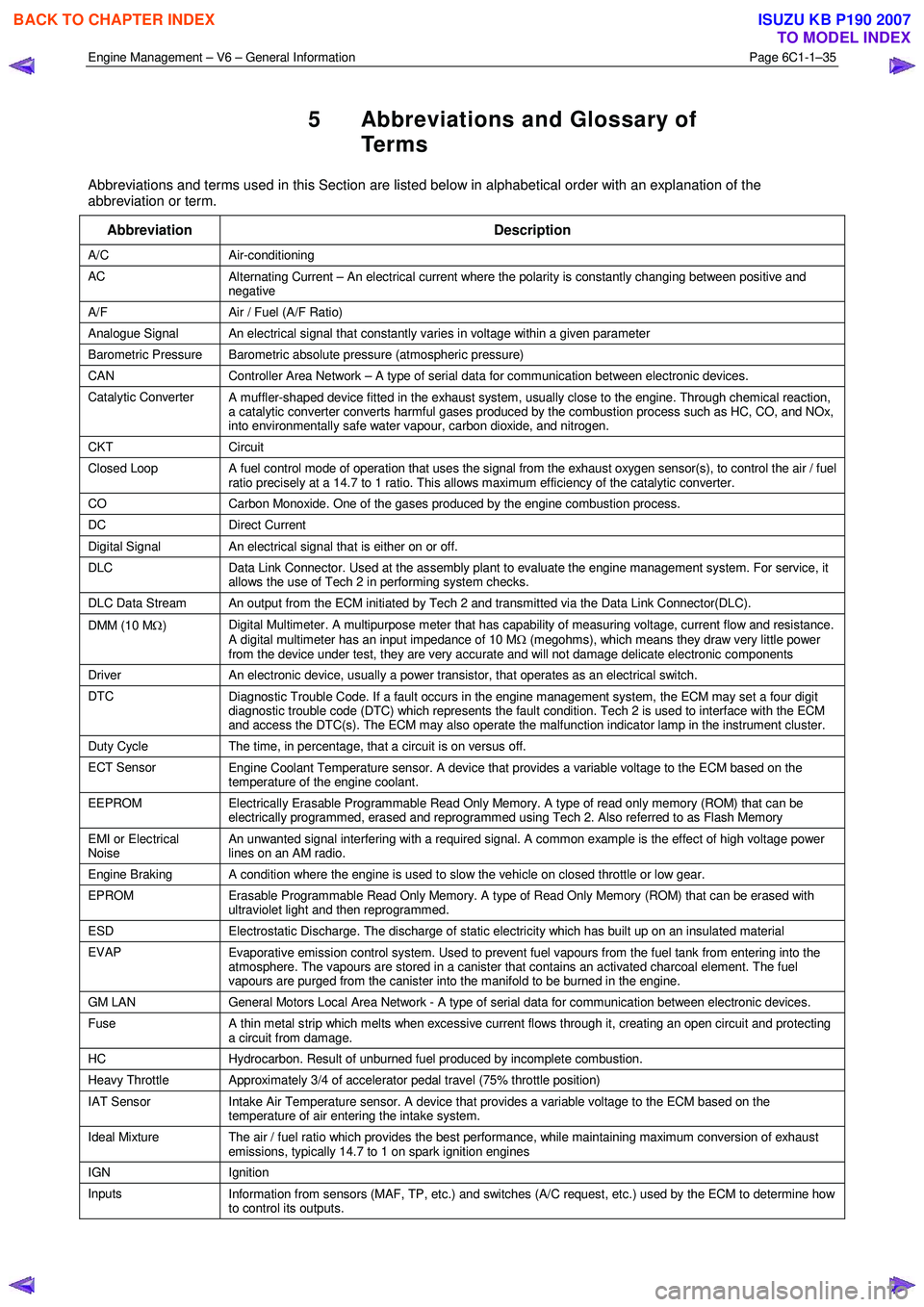

Construction

Projecting into the MAF sensor body is the compact design

sensor assembly (1), which consists of:

• the sensor element (2),

• partial airflow measuring tube (3), and

• integrated evaluation electronics (4).

Figure 6C1-1 – 45

Operation

A diaphragm (1) on the sensor element (2) is heated by a

centrally mounted heater resistor (3), which is held at a

constant temperature. The temperature drops sharply each

side of the heating zone.

Temperature of the diaphragm is registered to the

evaluation electronics by two temperature-dependent

resistors located on the upstream (4) and downstream (5)

side of the resistor.

W ith no air flow through the air flow measuring tube and

over the sensor element, the temperature characteristic is

the same each side of the heating zone and the resistance

values are identical.

As air flows over the sensor element, the upstream resistor

value alters due to the cooling effect of the air flow. As the

air flows over the heating zone the air temperature is

increased.

Figure 6C1-1 – 46

The air then passes over the downstream resistor and alters the resistance value, but as the air temperature is higher,

the value is different to the upstream resistor. This change in temperature creates a temperature differential between the

two resistors.

It is this differential that is used to calculate the air mass flow, which is independent of absolute temperature. The

differential is also directional, which means the MAF not only measures the mass of the incoming air, but also its

direction.

As the evaluation electronics are measuring the resistance differential between the resistors, the air mass flow for the

entire amount of air passing through the MAF is calculated and sent to the ECM as an analogue signal of 0 – 5 V.

The ECM can also detect air flow that is inappropriate for a given operating condition based on the signal voltage, or a

signal that appears to be fixed based on the lack of normal signal fluctuations expected during engine operation.

Tech 2 can display the MAF value in grams per second (g/s). Values should change rather quickly on acceleration, but

should remain fairly stable at any given engine speed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3277 of 6020

Engine Management – V6 – General Information Page 6C1-1–35

5 Abbreviations and Glossary of

Te r m s

Abbreviations and terms used in this Section are listed below in alphabetical order with an explanation of the

abbreviation or term.

Abbreviation Description

A/C Air-conditioning

AC Alternating Current – An electrical current where the polarity is constantly changing between positive and

negative

A/F Air / Fuel (A/F Ratio)

Analogue Signal An electrical signal that constantly varies in voltage within a given parameter

Barometric Pressure Barometric absolute pressure (atmospheric pressure)

CAN Controller Area Network – A type of serial data for communication between electronic devices.

Catalytic Converter

A muffler-shaped device fitted in the exhaust system, usually close to the engine. Through chemical reaction,

a catalytic converter converts harmful gases produced by the combustion process such as HC, CO, and NOx,

into environmentally safe water vapour, carbon dioxide, and nitrogen.

CKT Circuit

Closed Loop A fuel control mode of operation that uses the signal from the exhaust oxygen sensor(s), to control the air / fuel

ratio precisely at a 14.7 to 1 ratio. This allows maximum efficiency of the catalytic converter.

CO Carbon Monoxide. One of the gases produced by the engine combustion process.

DC Direct Current

Digital Signal An electrical signal that is either on or off.

DLC

Data Link Connector. Used at the assembly plant to evaluate the engine management system. For service, it

allows the use of Tech 2 in performing system checks.

DLC Data Stream An output from the ECM initiated by Tech 2 and transmitted via the Data Link Connector(DLC).

DMM (10 M Ω) Digital Multimeter. A multipurpose meter that has capability of measuring voltage, current flow and resistance.

A digital multimeter has an input impedance of 10 M Ω (megohms), which means they draw very little power

from the device under test, they are very accurate and will not damage delicate electronic components

Driver An electronic device, usually a power transistor, that operates as an electrical switch.

DTC

Diagnostic Trouble Code. If a fault occurs in the engine management system, the ECM may set a four digit

diagnostic trouble code (DTC) which represents the fault condition. Tech 2 is used to interface with the ECM

and access the DTC(s). The ECM may also operate the malfunction indicator lamp in the instrument cluster.

Duty Cycle The time, in percentage, that a circuit is on versus off.

ECT Sensor

Engine Coolant Temperature sensor. A device that provides a variable voltage to the ECM based on the

temperature of the engine coolant.

EEPROM Electrically Erasable Programmable Read Only Memory. A type of read only memory (ROM) that can be

electrically programmed, erased and reprogrammed using Tech 2. Also referred to as Flash Memory

EMI or Electrical

Noise An unwanted signal interfering with a required signal. A common example is the effect of high voltage power

lines on an AM radio.

Engine Braking A condition where the engine is used to slow the vehicle on closed throttle or low gear.

EPROM Erasable Programmable Read Only Memory. A type of Read Only Memory (ROM) that can be erased with

ultraviolet light and then reprogrammed.

ESD Electrostatic Discharge. The discharge of static electricity which has built up on an insulated material

EVAP

Evaporative emission control system. Used to prevent fuel vapours from the fuel tank from entering into the

atmosphere. The vapours are stored in a canister that contains an activated charcoal element. The fuel

vapours are purged from the canister into the manifold to be burned in the engine.

GM LAN General Motors Local Area Network - A type of serial data for communication between electronic devices.

Fuse

A thin metal strip which melts when excessive current flows through it, creating an open circuit and protecting

a circuit from damage.

HC Hydrocarbon. Result of unburned fuel produced by incomplete combustion.

Heavy Throttle Approximately 3/4 of accelerator pedal travel (75% throttle position)

IAT Sensor

Intake Air Temperature sensor. A device that provides a variable voltage to the ECM based on the

temperature of air entering the intake system.

Ideal Mixture The air / fuel ratio which provides the best performance, while maintaining maximum conversion of exhaust

emissions, typically 14.7 to 1 on spark ignition engines

IGN Ignition

Inputs Information from sensors (MAF, TP, etc.) and switches (A/C request, etc.) used by the ECM to determine how

to control its outputs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3521 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–243

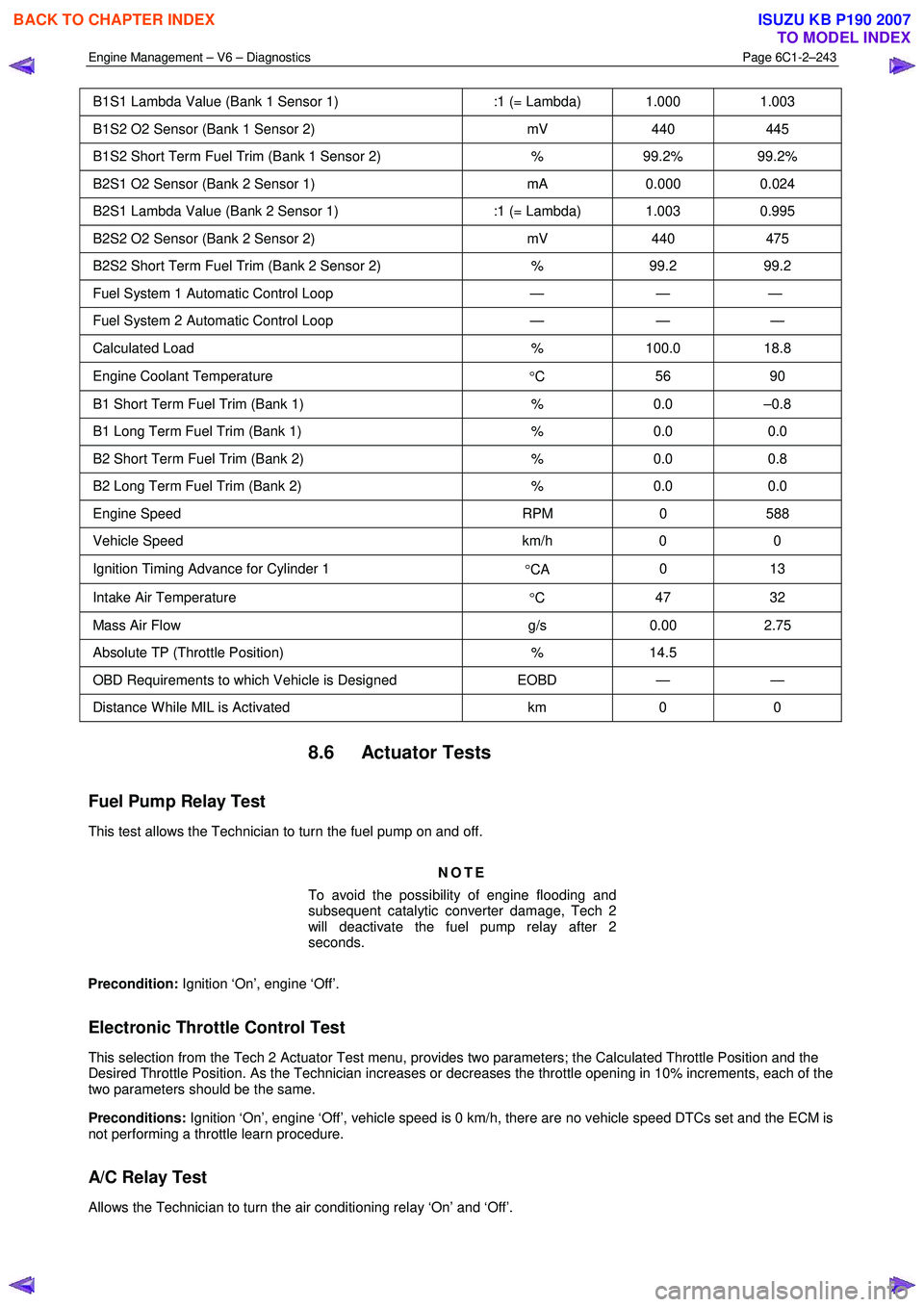

B1S1 Lambda Value (Bank 1 Sensor 1) :1 (= Lambda) 1.000 1.003

B1S2 O2 Sensor (Bank 1 Sensor 2) mV 440 445

B1S2 Short Term Fuel Trim (Bank 1 Sensor 2) % 99.2% 99.2%

B2S1 O2 Sensor (Bank 2 Sensor 1) mA 0.000 0.024

B2S1 Lambda Value (Bank 2 Sensor 1) :1 (= Lambda) 1.003 0.995

B2S2 O2 Sensor (Bank 2 Sensor 2) mV 440 475

B2S2 Short Term Fuel Trim (Bank 2 Sensor 2) % 99.2 99.2

Fuel System 1 Automatic Control Loop — — —

Fuel System 2 Automatic Control Loop — — —

Calculated Load % 100.0 18.8

Engine Coolant Temperature

°C 56 90

B1 Short Term Fuel Trim (Bank 1)

% 0.0 –0.8

B1 Long Term Fuel Trim (Bank 1) % 0.0 0.0

B2 Short Term Fuel Trim (Bank 2) % 0.0 0.8

B2 Long Term Fuel Trim (Bank 2) % 0.0 0.0

Engine Speed RPM 0 588

Vehicle Speed km/h 0 0

Ignition Timing Advance for Cylinder 1

°CA 0 13

Intake Air Temperature

°C 47 32

Mass Air Flow

g/s 0.00 2.75

Absolute TP (Throttle Position) % 14.5

OBD Requirements to which Vehicle is Designed EOBD — —

Distance W hile MIL is Activated km 0 0

8.6 Actuator Tests

Fuel Pump Relay Test

This test allows the Technician to turn the fuel pump on and off.

NOTE

To avoid the possibility of engine flooding and

subsequent catalytic converter damage, Tech 2

will deactivate the fuel pump relay after 2

seconds.

Precondition: Ignition ‘On’, engine ‘Off’.

Electronic Throttle Control Test

This selection from the Tech 2 Actuator Test menu, provides two parameters; the Calculated Throttle Position and the

Desired Throttle Position. As the Technician increases or decreases the throttle opening in 10% increments, each of the

two parameters should be the same.

Preconditions: Ignition ‘On’, engine ‘Off’, vehicle speed is 0 km/h, there are no vehicle speed DTCs set and the ECM is

not performing a throttle learn procedure.

A/C Relay Test

Allows the Technician to turn the air conditioning relay ‘On’ and ‘Off’.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3529 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–5

• Ensure the correct procedure for disconnecting and connecting engine management system wiring connectors is

always followed.

• Ensure that all wiring connectors are fitted correctly.

• The engine management system wiring connectors are designed to fit only one way; there are indexing tabs and

slots on both halves of the connector. Forcing the connector into place is not necessary if it is being installed with

the correct orientation. Failure to take care to match the indexing tabs and slots correctly can cause damage to the

connector, the module, or other vehicle components or systems.

• Never touch the connector pins of any electronic component, such as an ECM, as electrostatic discharge (ESD)

damage may result.

• W hen steam or pressure cleaning engines, do not direct the cleaning nozzle at engine management system

components.

• Never subject the ECM to temperatures less than -40 ° C and greater than 125 ° C.

• Prior to disconnection or removal of any components associated with the fuel system, clean the area around any

connection points to avoid possible contamination of the fuel system.

• A depressurised fuel system contains fuel in the fuel system and fuel lines that can be spilled during service

operations. To reduce the chance of personal injury, cover the fittings with a shop towel to absorb any fuel spillage

prior to performing the service operation. Once the service operation has been completed, place the towel in an

approved container for disposal.

• To avoid accidental fuel discharge, it is advisable to disconnect the battery and remove the fuel pump relay if the

fuel line between the fuel pump and the fuel rail is to be disconnected / open for an indefinite period.

• Always tighten fasteners to the correct tightening torque, and where indicated in the service procedure, follow the

correct tightening sequence, precautions and recommendations to prevent premature failure of the fastener or

component.

• After removing components, such as the upper or lower intake manifold, front engine pipe, heated oxygen sensor,

etc. always plug any openings to prevent dirt and other contaminants from entering.

• Do not use silicone based assembly lubricants as damage to the heated oxygen sensors may result.

Use of incorrect electrical test equipment

when performing engine management service

procedures could result in incorrect results or

component damage.

• Use only the test equipment specified in the diagnostic tables. Use of other test equipment may either give

incorrect results or damage serviceable components, refer to, 6C1-2 Engine Management – V6 – Diagnostics.

• After completing the required service operations, road test the vehicle to ensure correct engine management

system operation.

Service Requirements

Basic Knowledge Required

A lack of basic understanding of electronics,

electrical wiring circuits and use of electrical

circuit testing tools when performing certain

service procedures could result in incorrect

results or damage to components.

In addition, a general understanding of the engine management system and its component operation is essential to

prevent misdiagnosis and component damage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3548 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–24

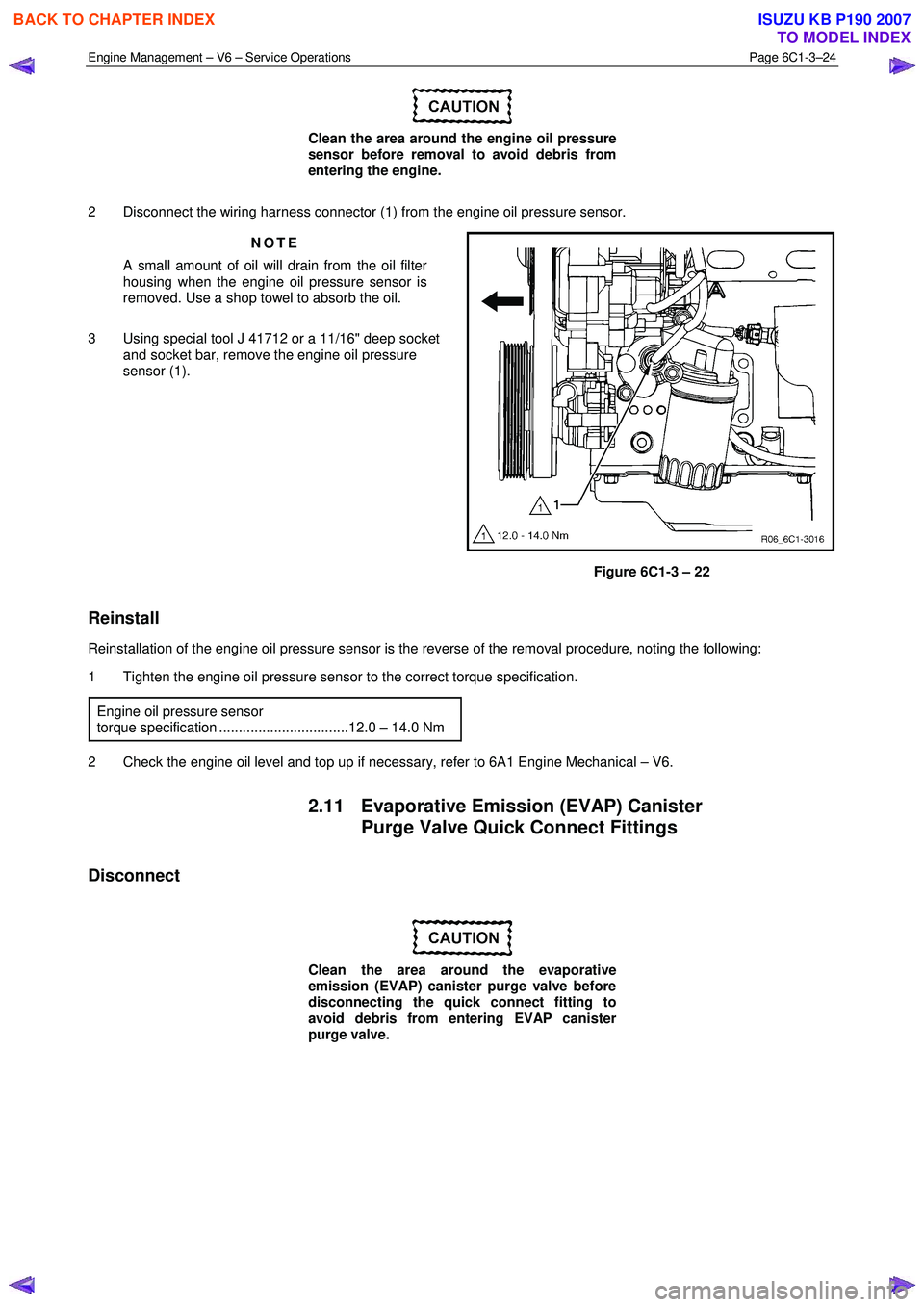

Clean the area around the engine oil pressure

sensor before removal to avoid debris from

entering the engine.

2 Disconnect the wiring harness connector (1) from the engine oil pressure sensor. NOTE

A small amount of oil will drain from the oil filter

housing when the engine oil pressure sensor is

removed. Use a shop towel to absorb the oil.

3 Using special tool J 41712 or a 11/16" deep socket and socket bar, remove the engine oil pressure

sensor (1).

Figure 6C1-3 – 22

Reinstall

Reinstallation of the engine oil pressure sensor is the reverse of the removal procedure, noting the following:

1 Tighten the engine oil pressure sensor to the correct torque specification.

Engine oil pressure sensor

torque specification .................................12.0 – 14.0 Nm

2 Check the engine oil level and top up if necessary, refer to 6A1 Engine Mechanical – V6.

2.11 Evaporative Emission (EVAP) Canister Purge Valve Quick Connect Fittings

Disconnect

Clean the area around the evaporative

emission (EVAP) canister purge valve before

disconnecting the quick connect fitting to

avoid debris from entering EVAP canister

purge valve.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007