ABS ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3571 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–47

2.21 Schrader Valve – Fuel Pressure Gauge

Connection Point

If the Schrader valve is to be removed but not

replaced immediately, it is advisable to

disconnect the battery to avoid possible fuel

discharge if an accidental attempt is made to

start the engine.

Disconnection of the battery affects vehicle

electronic systems. Refer to 6D1-3 Battery –

V6 before disconnecting the battery.

Remove

1 Depressurise the fuel system, refer to 6C Fuel System - V6.

2 Turn the ignition off.

A small amount of fuel may be released when

servicing the fuel pressure test point. To

reduce the chance of personal injury, cover

the fuel pressure test point with a shop towel

to absorb any fuel spillage when the Schrader

valve sealing cap and Schrader valve are

removed. After the procedure, place the towel

in an approved container for disposal.

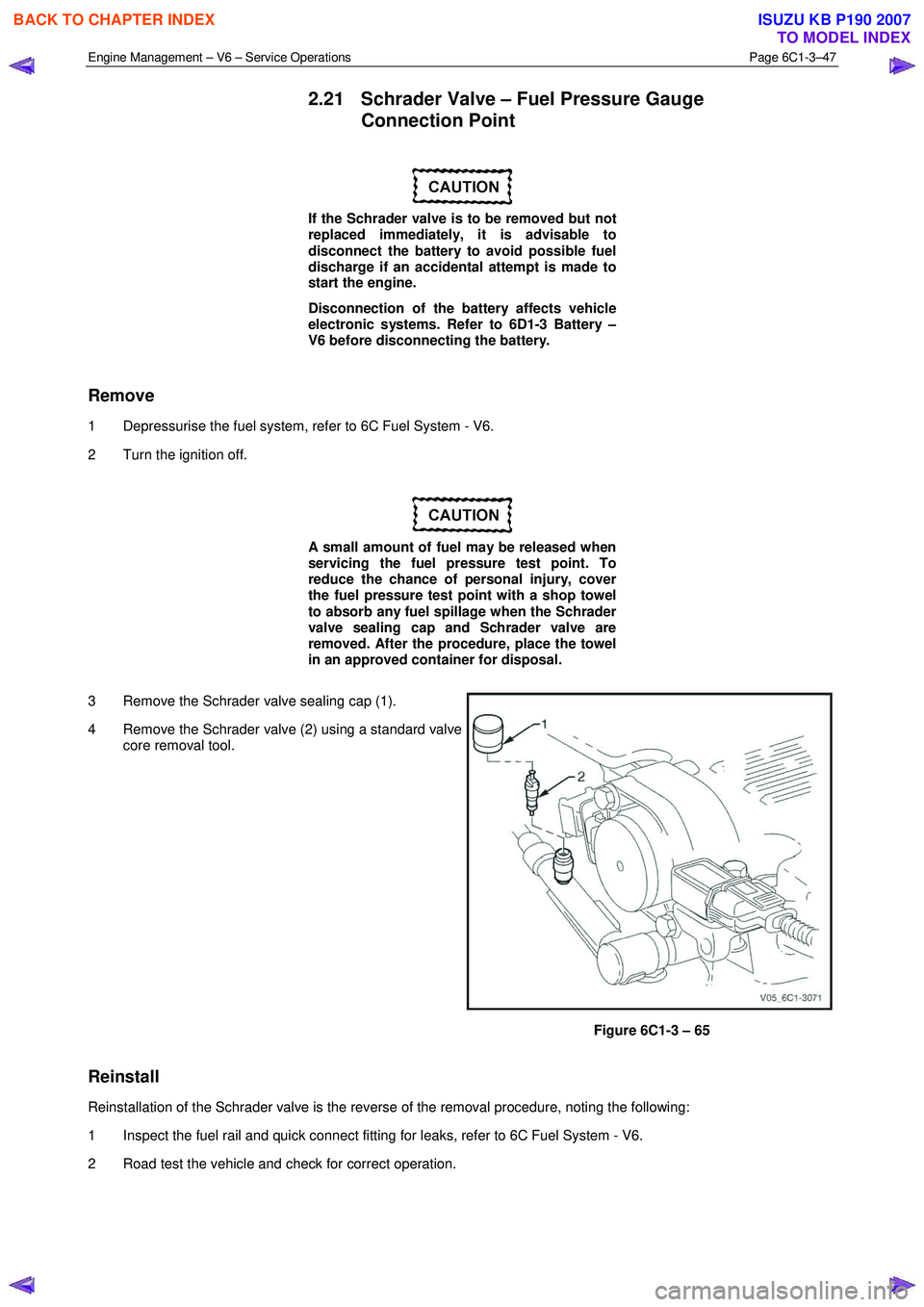

3 Remove the Schrader valve sealing cap (1).

4 Remove the Schrader valve (2) using a standard valve core removal tool.

Figure 6C1-3 – 65

Reinstall

Reinstallation of the Schrader valve is the reverse of the removal procedure, noting the following:

1 Inspect the fuel rail and quick connect fitting for leaks, refer to 6C Fuel System - V6.

2 Road test the vehicle and check for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3611 of 6020

Starting System – V6 Page 6D1-2–3

1 General Information

All HFV6 engines are fitted with a Mitsubishi starter motor. This consists of a solenoid switch on a DC motor. The motor

has permanent magnet excitation, which has the advantage of low weight a with high output torque and is visually

identifiable by the absence of pole-shoe retaining screws.

The starter motor does not have field coil windings or pole shoes. These parts have been replaced by six permanent

magnets that are held in the pole housing by clips. The positive brushes are now part of the brush plate assembly.

The solenoid switch is the only component of the starter motor assembly that is serviced separately. If any other parts

require replacement, the starter motor must be replaced.

1.1 WARNING, CAUTION and NOTES

This Section contains various W ARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. W ARNINGS, CAUTION and NOTE statements are not exhaustive.

HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific W ARNING, CAUTION and NOTE

statements. HOLDEN LTD is dedicated to the presentation of service information that helps the technician to diagnose

and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard to the

technician if they are not followed in the recommended manner. W ARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

WARNING defined

A W ARNING statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in death or injury. A W ARNING statement alerts you to take necessary action or not to take a

prohibited action. If a W ARNING statement is ignored, the following consequences may occur:

• Death or injury to the technician or other personnel working on the vehicle,

• Death or injury to other people in or near the workplace area, and / or

• Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destruction of equipment, or corruption of data. If a CAUTION statement is ignored,

the following consequences may occur:

• Damage to the vehicle,

• Unnecessary vehicle repairs or component replacement,

• Faulty operation or performance of any system or component being repaired,

• Damage to any system or components which depend on the proper operation of the system or component being

repaired,

• Faulty operation or performance of any systems or components which depend on the proper operation or

performance of the system or component under repair,

• Damage to fasteners, basic tools or special tools and / or

• Leakage of coolant, lubricant or other vital fluids.

NOTE defined

A NOTE statement immediately precedes or follows an operating procedure, maintenance practice or condition that

requires highlighting. A NOTE statement also emphasises necessary characteristics of a diagnostic or repair procedure.

A NOTE statement is designed to:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3612 of 6020

Starting System – V6 Page 6D1-2–4

• Clarify a procedure,

• Present additional information for accomplishing a procedure,

• Give insight into the reasons for performing a procedure in the recommended manner, and / or

Present information that gives the technician the benefit of past experience in accomplishing a procedure with greater

ease.

1.2 Components

Starting System Components

The main components of the starting system are:

• battery,

• wiring,

• ignition switch,

• theft deterrent engine crank inhibitor (a function of the theft deterrent system),

• park / neutral and back-up switch (on vehicles with 4 speed automatic transmission),

• engine control module (ECM),

• start relay,

• solenoid switch, and

• starter motor.

Starter Motor and Solenoid Switch Components

Solenoid Switch

The solenoid switch is used to activate the DC motor and has two windings; the pull-in winding and the hold-in winding.

The pull-in winding has heavier wire and is grounded through the DC motor winding and brushes. The hold-in winding is

grounded through the solenoid casing.

Planetary Drive Train

The planetary drive train consists of an internally toothed ring gear and three planetary gear wheels, which rotate on

sleeve bearings on the planetary drive shaft. The ring gear is keyed into the drive-end housing and is made from

high-grade polyamide with mineral additives.

W hen the starter motor operates, the armature turns the planetary gears inside the fixed planetary ring gear. This drives

the planetary shaft at a reduced speed ratio which turns the drive assembly. A fork lever in the drive-end housing forces

the drive assembly forward to engage with the flexplate / flywheel ring gear on the engine and transmit cranking torque.

An internal clutch allows the drive assembly pinion gear to rotate freely when the engine starts. This prevents the

armature from being driven at excessive speed by the engine.

Armature

The armature shaft is supported at each end by oil absorbent, sintered metal bushes; one in the commutator end shield

and one in the planetary drive shaft. The front end of the armature has a gear profile. This meshes with the three

planetary gear wheels. These in turn, mesh with the internal teeth of the ring gear.

Brushes

A brush plate supports four commutator brushes. This plate is fixed to the commutator end shield with two retaining

screws. Two negative brushes are grounded to the pole housing. The two positive brushes are insulated from the pole

housing and connected to the solenoid switch M terminal, refer to Figure 6D1-2 – 1.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3769 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–9

3 Transmission Control Module

Operation Overview

3.1 Transmission Control Module

W ith the introduction of the new HFV6 engine, the powertrain architecture has been redesigned to accommodate this

introduction. W ith this design, a new bus architecture and protocol has also been introduced. The new bus connects the

following modules:

• engine control module (ECM),

• transmission control module (TCM),

• powertrain interface module (PIM) and

• ABS module.

The protocol used to communicate between these modules is called General Motors Local Area Network (GM LAN)

which is based on Controller Area Network (CAN) communication protocol. For further information on GM LAN protocol

and data bus structure, refer to 6E1 Powertrain Interface Module – V6.

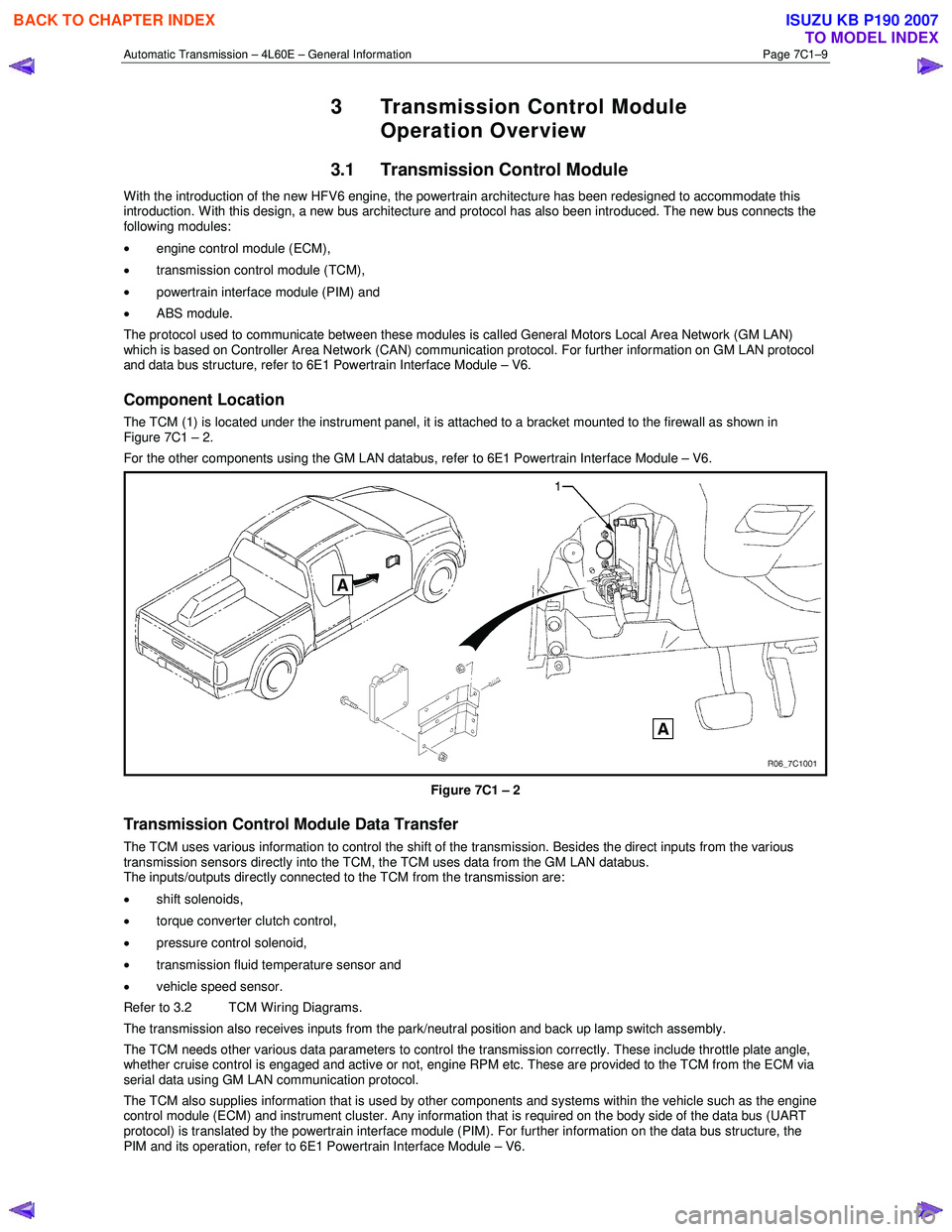

Component Location

The TCM (1) is located under the instrument panel, it is attached to a bracket mounted to the firewall as shown in

Figure 7C1 – 2.

For the other components using the GM LAN databus, refer to 6E1 Powertrain Interface Module – V6.

Figure 7C1 – 2

Transmission Control Module Data Transfer

The TCM uses various information to control the shift of the transmission. Besides the direct inputs from the various

transmission sensors directly into the TCM, the TCM uses data from the GM LAN databus.

The inputs/outputs directly connected to the TCM from the transmission are:

• shift solenoids,

• torque converter clutch control,

• pressure control solenoid,

• transmission fluid temperature sensor and

• vehicle speed sensor.

Refer to 3.2 TCM Wiring Diagrams.

The transmission also receives inputs from the park/neutral position and back up lamp switch assembly.

The TCM needs other various data parameters to control the transmission correctly. These include throttle plate angle,

whether cruise control is engaged and active or not, engine RPM etc. These are provided to the TCM from the ECM via

serial data using GM LAN communication protocol.

The TCM also supplies information that is used by other components and systems within the vehicle such as the engine

control module (ECM) and instrument cluster. Any information that is required on the body side of the data bus (UART

protocol) is translated by the powertrain interface module (PIM). For further information on the data bus structure, the

PIM and its operation, refer to 6E1 Powertrain Interface Module – V6.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3771 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–11

4 Transmission Definitions and

Abbreviations

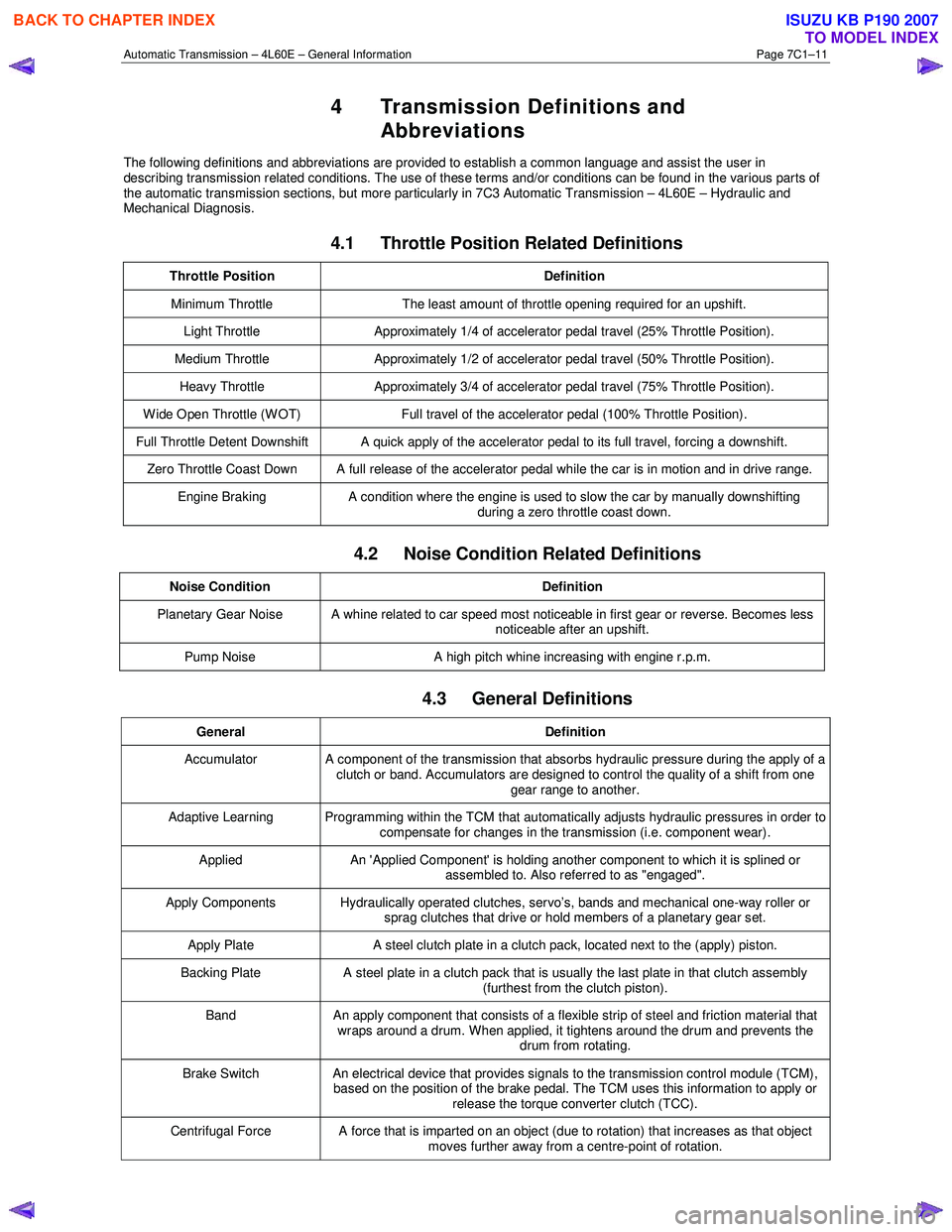

The following definitions and abbreviations are provided to establish a common language and assist the user in

describing transmission related conditions. The use of these terms and/or conditions can be found in the various parts of

the automatic transmission sections, but more particularly in 7C3 Automatic Transmission – 4L60E – Hydraulic and

Mechanical Diagnosis.

4.1 Throttle Position Related Definitions

Throttle Position Definition

Minimum Throttle The least amount of throttle opening required for an upshift.

Light Throttle Approximately 1/4 of accelerator pedal travel (25% Throttle Position).

Medium Throttle Approximately 1/2 of accelerator pedal travel (50% Throttle Position).

Heavy Throttle Approximately 3/4 of accelerator pedal travel (75% Throttle Position).

Wide Open Throttle (WOT) Full travel of the accelerator pedal (100% Throttle Position).

Full Throttle Detent Downshift A quick apply of the accelerator pedal to its full travel, forcing a downshift.

Zero Throttle Coast Down A full release of the accelerator pedal while the car is in motion and in drive range.

Engine Braking A condition where the engine is used to slow the car by manually downshifting

during a zero throttle coast down.

4.2 Noise Condition Related Definitions

Noise Condition Definition

Planetary Gear Noise A whine related to car speed most noticeable in first gear or reverse. Becomes less

noticeable after an upshift.

Pump Noise A high pitch whine increasing with engine r.p.m.

4.3 General Definitions

General Definition

Accumulator A component of the transmission that absorbs hydraulic pressure during the apply of a

clutch or band. Accumulators are designed to control the quality of a shift from one gear range to another.

Adaptive Learning Programming within the TCM that automatically adjusts hydraulic pressures in order to compensate for changes in the transmission (i.e. component wear).

Applied An 'Applied Component' is holding another component to which it is splined or

assembled to. Also referred to as "engaged".

Apply Components Hydraulically operated clutches, servo’s, bands and mechanical one-way roller or

sprag clutches that drive or hold members of a planetary gear set.

Apply Plate A steel clutch plate in a clutch pack, located next to the (apply) piston.

Backing Plate A steel plate in a clutch pack that is usually the last plate in that clutch assembly

(furthest from the clutch piston).

Band An apply component that consists of a flexible strip of steel and friction material that

wraps around a drum. When applied, it tightens around the drum and prevents the drum from rotating.

Brake Switch An electrical device that provides signals to the transmission control module (TCM),

based on the position of the brake pedal. The TCM uses this information to apply or

release the torque converter clutch (TCC).

Centrifugal Force A force that is imparted on an object (due to rotation) that increases as that object moves further away from a centre-point of rotation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3920 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–7

NOTE

This will also flush the cooler hose/line

assemblies and cooler with transmission fluid.

7 If the flow rate is satisfactory, reconnect the cooler inlet line to the transmission, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

8 Lower the vehicle, check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

Flow Rate Test

Do not run the engine any longer than

absolutely necessary, as a fluid level too low

can cause aeration and foaming.

1 Ensure the transmission fluid is at the recommended level or slightly above, refer to 2.1 Transmission Fluid.

2 Disconnect the cooler inlet line at the transmission quick-connect fitting, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

3 Place a suitable size container underneath the disconnected cooler inlet line.

4 W ith the selector lever in the P position, start the engine and observe the fluid flow into the container after all the air bubbles have ceased and a steady flow is evident. Measure the flow rate over 20 seconds and ensure it is within

the specification.

Transmission fluid flow rate specification per 20 Seconds:

Temperature: Ambient ............................................................ 0.7 Litres 86° – 93° C ...................................................... 1.2 Litres

5 If the flow rate is less than the specification, the cause of the low flow rate must be located and rectified. Possible cause could include:

• restricted cooler within the radiator tank,

• kinked or damaged transmission cooler hose/line assemblies, or

• internal transmission fault such as a faulty pump.

6 Reinstall the cooler inlet line to the transmission quick-connect fitting, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4000 of 6020

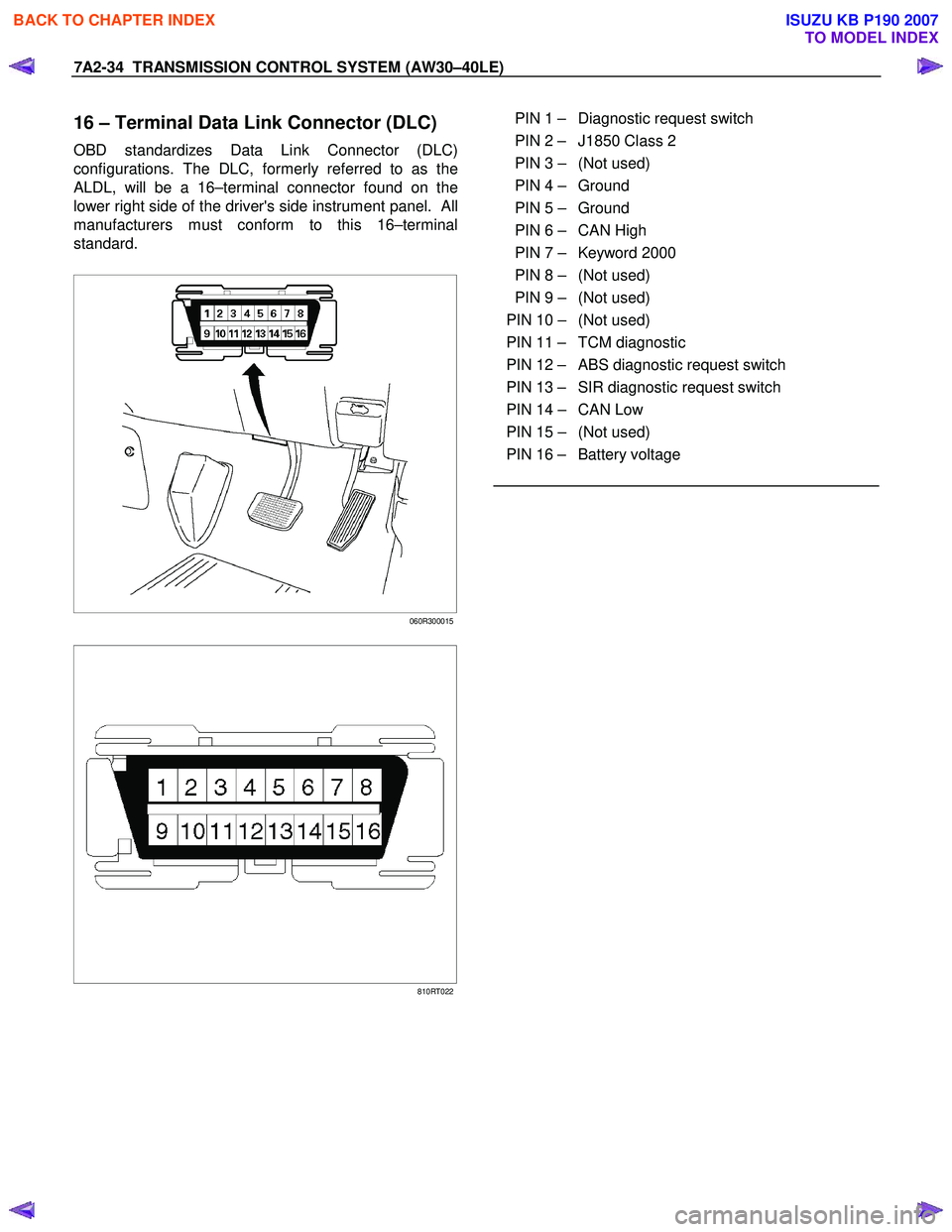

7A2-34 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

16 – Terminal Data Link Connector (DLC)

OBD standardizes Data Link Connector (DLC)

configurations. The DLC, formerly referred to as the

ALDL, will be a 16–terminal connector found on the

lower right side of the driver's side instrument panel. All

manufacturers must conform to this 16–terminal

standard.

060R300015

810RT022

PIN 1 – Diagnostic request switch

PIN 2 – J1850 Class 2

PIN 3 – (Not used)

PIN 4 – Ground

PIN 5 – Ground

PIN 6 – CAN High

PIN 7 – Keyword 2000

PIN 8 – (Not used)

PIN 9 – (Not used)

PIN 10 – (Not used)

PIN 11 – TCM diagnostic

PIN 12 – ABS diagnostic request switch

PIN 13 – SIR diagnostic request switch

PIN 14 – CAN Low

PIN 15 – (Not used)

PIN 16 – Battery voltage

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4139 of 6020

7A4–4 UNIT REPAIR (AW30–40LE)

Components (1)

Reassembly

1. Install a new gasket and the extension housing(4×2) to the transmission case.

Torque: 36 N·m (3.7 kgf·m/27 Ib ·ft)

2. Install the speedometer driven gear, plate, and speedometer sensor (4 ×2).

Torque:

Plate bolt – 15 N·m (1.5 kgf·m/11 Ib ·ft)

Speedometer sensor – 25 N·m (2.5 kgf·m/18 Ib ·ft)

3. Install the adapter housing (4 ×4).

Remove any gasket material on the contacting

surfaces of the adapter housing and transmission

case.

241RY00020

Apply liquid gasket (TB1281 –B or its equivalent)

(1) and install the apply gaskets (2) to the adapter

housing as shown in the figure.

Install the adapter housing to the transmission

case.

Torque: 36 N·m (3.7 kgf·m/27 Ib ·ft)

4. Install the neutral start switch. Using the transmission select lever, fully turn the

manual valve lever shaft back and return two

notches.

It is now in neutral.

Insert the neutral start switch onto the manual

valve lever shaft and temporarily tighten the

adjusting bolt.

Install the lock washer and nut.

Torque: 7 N·m (0.7 kgf·m/61 Ib ·in)

Align the neutral standard line and the switch

groove and tighten the adjusting bolt.

Torque: 13 N·m (1.3 kgf·m/113 Ib ·in)

Bend the tabs of the lock washer.

NOTE: Bend at least two of the lock washer tabs.

RUW17ASH013601

5. Install the oil temperature sensor to the transmission case.

Torque: 15 N·m (1.5 kgf·m/11 Ib ·ft)

RTW77ASH003501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4302 of 6020

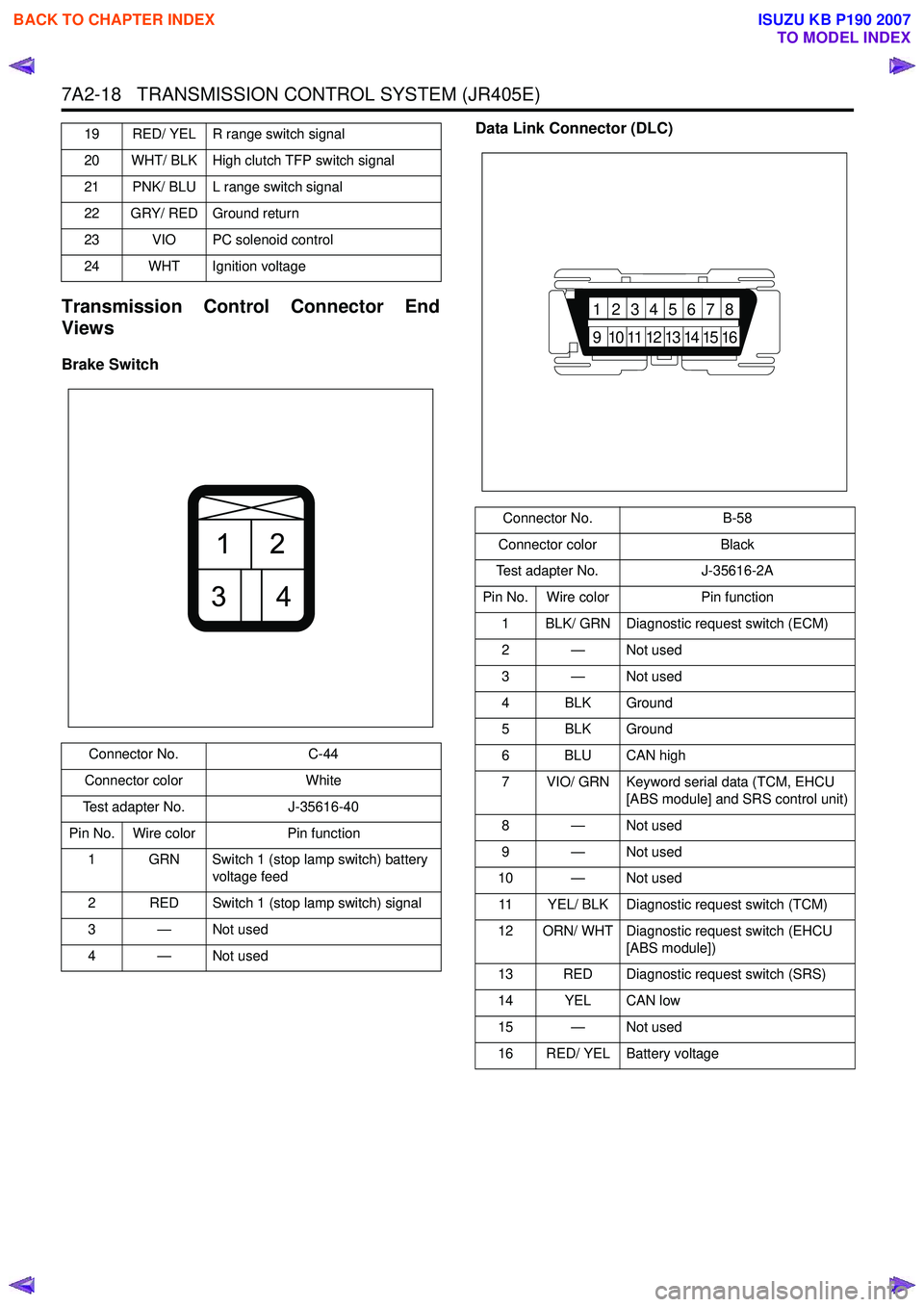

7A2-18 TRANSMISSION CONTROL SYSTEM (JR405E)

Transmission Control Connector End

Views

Brake Switch Data Link Connector (DLC)

19 RED/ YEL R range switch signal

20 WHT/ BLK High clutch TFP switch signal

21 PNK/ BLU L range switch signal

22 GRY/ RED Ground return

23 VIO PC solenoid control

24 WHT Ignition voltage

Connector No. C-44

Connector color White

Test adapter No. J-35616-40

Pin No. Wire color Pin function

1 GRN Switch 1 (stop lamp switch) battery voltage feed

2 RED Switch 1 (stop lamp switch) signal

3—Not used

4—Not used

21

34

Connector No. B-58

Connector color Black

Test adapter No. J-35616-2A

Pin No. Wire color Pin function

1 BLK/ GRN Diagnostic request switch (ECM)

2 — Not used

3 — Not used

4 BLK Ground

5 BLK Ground

6 BLU CAN high

7 VIO/ GRN Keyword serial data (TCM, EHCU [ABS module] and SRS control unit)

8 — Not used

9 — Not used

10 — Not used

11 YEL/ BLK Diagnostic request switch (TCM)

12 ORN/ WHT Diagnostic request switch (EHCU [ABS module])

13 RED Diagnostic request switch (SRS)

14 YEL CAN low

15 — Not used

16 RED/ YEL Battery voltage

87654321

16151413121110

9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4306 of 6020

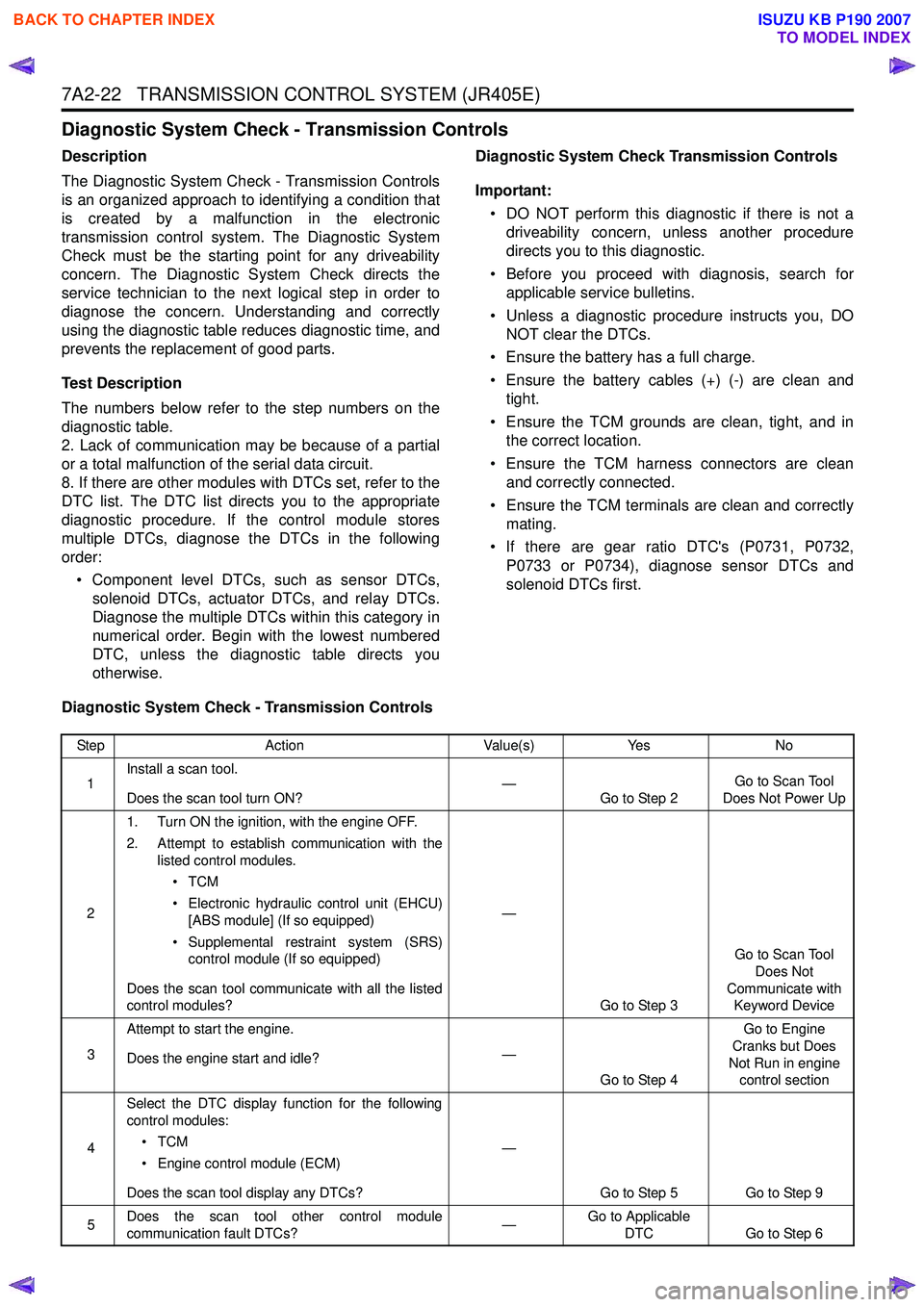

7A2-22 TRANSMISSION CONTROL SYSTEM (JR405E)

Diagnostic System Check - Transmission Controls

Description

The Diagnostic System Check - Transmission Controls

is an organized approach to identifying a condition that

is created by a malfunction in the electronic

transmission control system. The Diagnostic System

Check must be the starting point for any driveability

concern. The Diagnostic System Check directs the

service technician to the next logical step in order to

diagnose the concern. Understanding and correctly

using the diagnostic table reduces diagnostic time, and

prevents the replacement of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the serial data circuit.

8. If there are other modules with DTCs set, refer to the

DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order:

• Component level DTCs, such as sensor DTCs, solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise. Diagnostic System Check Transmission Controls

Important: • DO NOT perform this diagnostic if there is not a driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search for applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO NOT clear the DTCs.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and tight.

• Ensure the TCM grounds are clean, tight, and in the correct location.

• Ensure the TCM harness connectors are clean and correctly connected.

• Ensure the TCM terminals are clean and correctly mating.

• If there are gear ratio DTC's (P0731, P0732, P0733 or P0734), diagnose sensor DTCs and

solenoid DTCs first.

Diagnostic System Check - Transmission Controls

Step Action Value(s)Yes No

1 Install a scan tool.

Does the scan tool turn ON? —

Go to Step 2 Go to Scan Tool

Does Not Power Up

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules.

•TCM

• Electronic hydraulic control unit (EHCU) [ABS module] (If so equipped)

• Supplemental restraint system (SRS) control module (If so equipped)

Does the scan tool communicate with all the listed

control modules? —

Go to Step 3 Go to Scan Tool

Does Not

Communicate with Keyword Device

3 Attempt to start the engine.

Does the engine start and idle? —

Go to Step 4 Go to Engine

Cranks but Does

Not Run in engine control section

4 Select the DTC display function for the following

control modules:

•TCM

• Engine control module (ECM)

Does the scan tool display any DTCs? —

Go to Step 5 Go to Step 9

5 Does the scan tool other control module

communication fault DTCs? —Go to Applicable

DTC Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007