engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2725 of 6020

Engine Mechanical – V6 Page 6A1–246

General Thread Repair

NOTE

The use of a cutting type fluid such as WD 40® or

equivalent is recommended when performing the

drilling, counter boring and tapping procedures

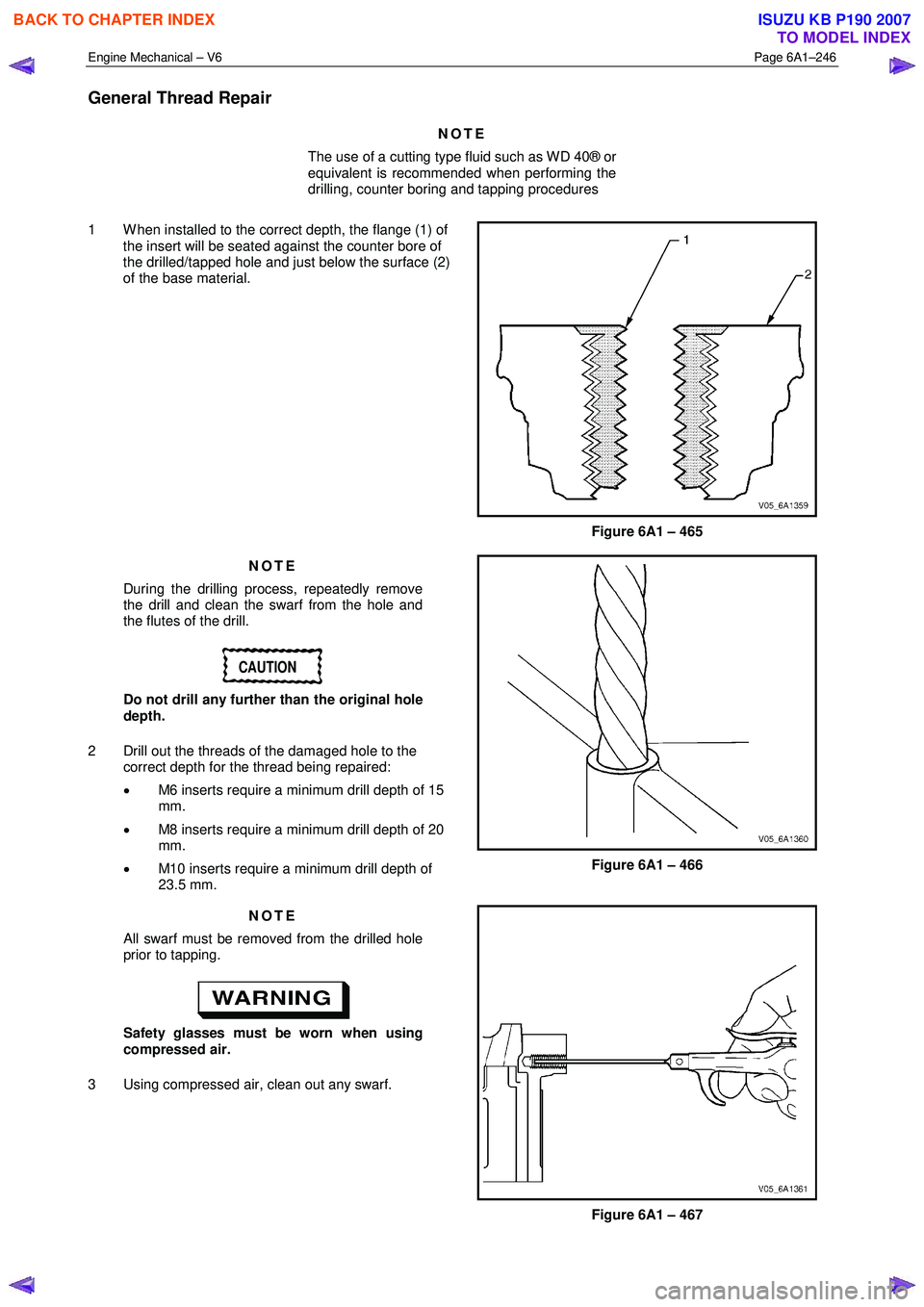

1 W hen installed to the correct depth, the flange (1) of the insert will be seated against the counter bore of

the drilled/tapped hole and just below the surface (2)

of the base material.

Figure 6A1 – 465

NOTE

During the drilling process, repeatedly remove

the drill and clean the swarf from the hole and

the flutes of the drill.

CAUTION

Do not drill any further than the original hole

depth.

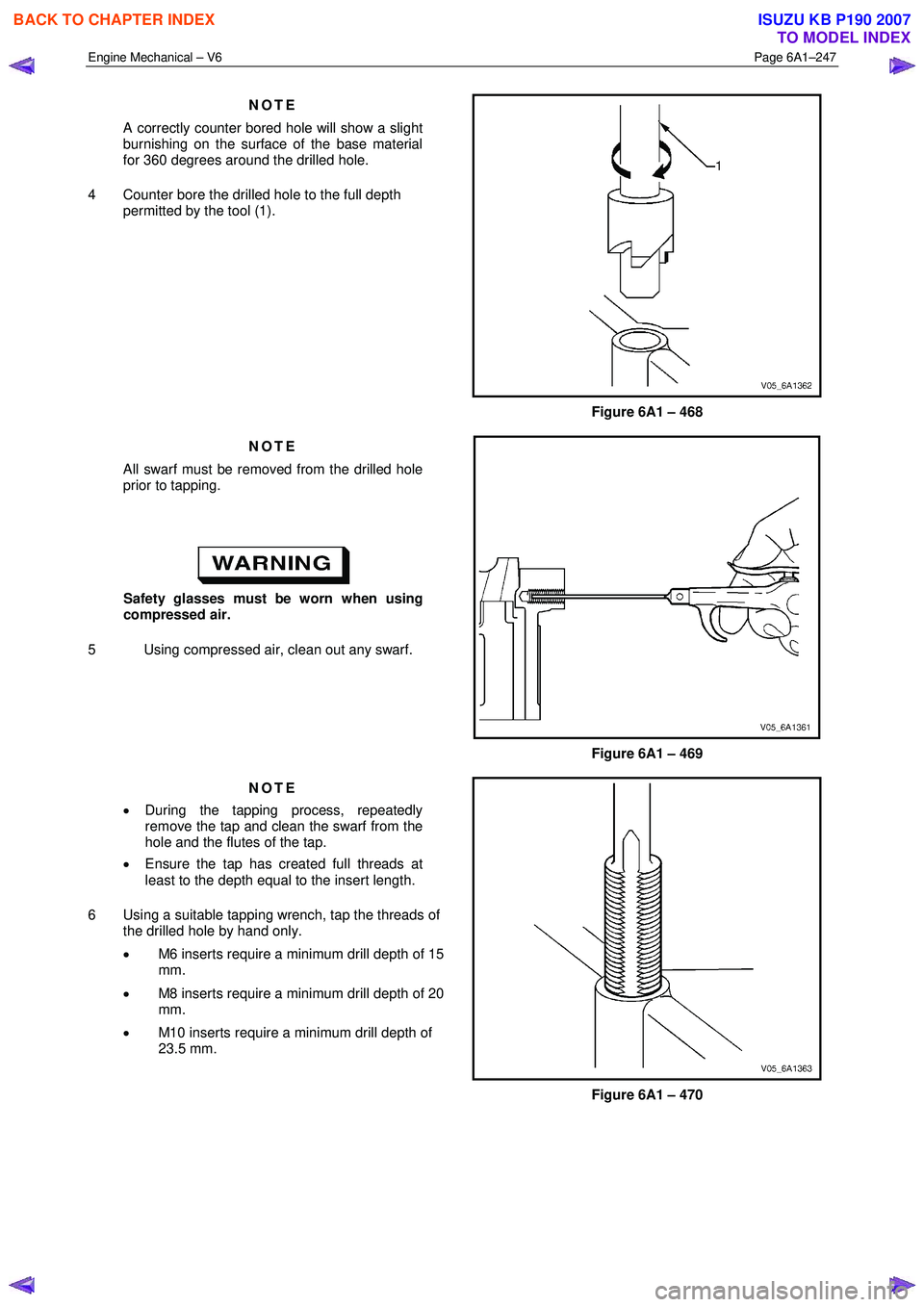

2 Drill out the threads of the damaged hole to the correct depth for the thread being repaired:

• M6 inserts require a minimum drill depth of 15

mm.

• M8 inserts require a minimum drill depth of 20

mm.

• M10 inserts require a minimum drill depth of

23.5 mm.

Figure 6A1 – 466

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

3 Using compressed air, clean out any swarf.

Figure 6A1 – 467

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2726 of 6020

Engine Mechanical – V6 Page 6A1–247

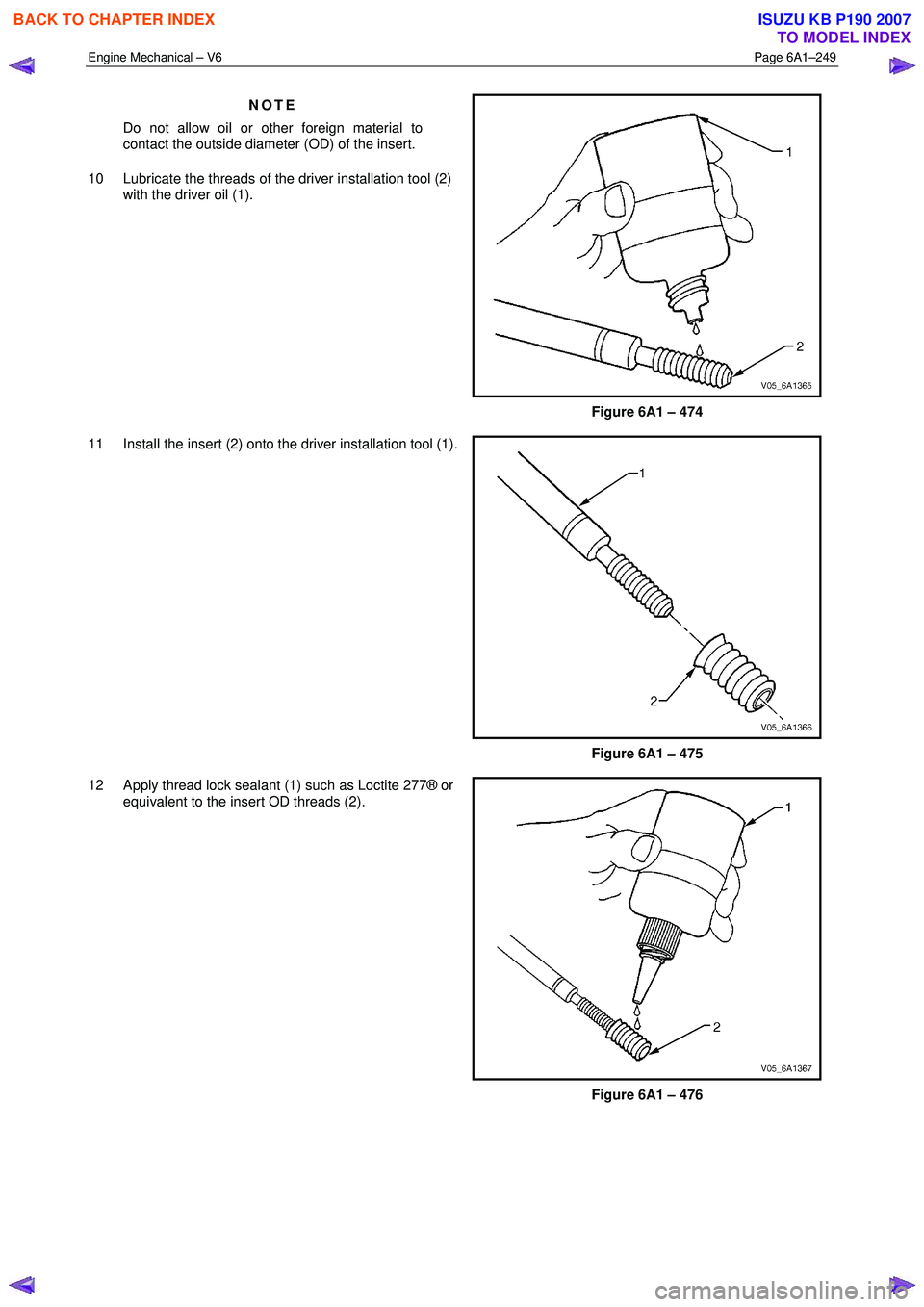

NOTE

A correctly counter bored hole will show a slight

burnishing on the surface of the base material

for 360 degrees around the drilled hole.

4 Counter bore the drilled hole to the full depth permitted by the tool (1).

Figure 6A1 – 468

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

5 Using compressed air, clean out any swarf.

Figure 6A1 – 469

NOTE

• During the tapping process, repeatedly

remove the tap and clean the swarf from the

hole and the flutes of the tap.

• Ensure the tap has created full threads at

least to the depth equal to the insert length.

6 Using a suitable tapping wrench, tap the threads of the drilled hole by hand only.

• M6 inserts require a minimum drill depth of 15

mm.

• M8 inserts require a minimum drill depth of 20

mm.

• M10 inserts require a minimum drill depth of

23.5 mm.

Figure 6A1 – 470

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2727 of 6020

Engine Mechanical – V6 Page 6A1–248

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

7 Using compressed air, clean out any swarf.

Figure 6A1 – 471

8 Spray a commercially available thread cleaner into the tapped hole.

Figure 6A1 – 472

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

9 Using compressed air, clean out any swarf.

Figure 6A1 – 473

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2728 of 6020

Engine Mechanical – V6 Page 6A1–249

NOTE

Do not allow oil or other foreign material to

contact the outside diameter (OD) of the insert.

10 Lubricate the threads of the driver installation tool (2) with the driver oil (1).

Figure 6A1 – 474

11 Install the insert (2) onto the driver installation tool (1).

Figure 6A1 – 475

12 Apply thread lock sealant (1) such as Loctite 277® or equivalent to the insert OD threads (2).

Figure 6A1 – 476

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2729 of 6020

Engine Mechanical – V6 Page 6A1–250

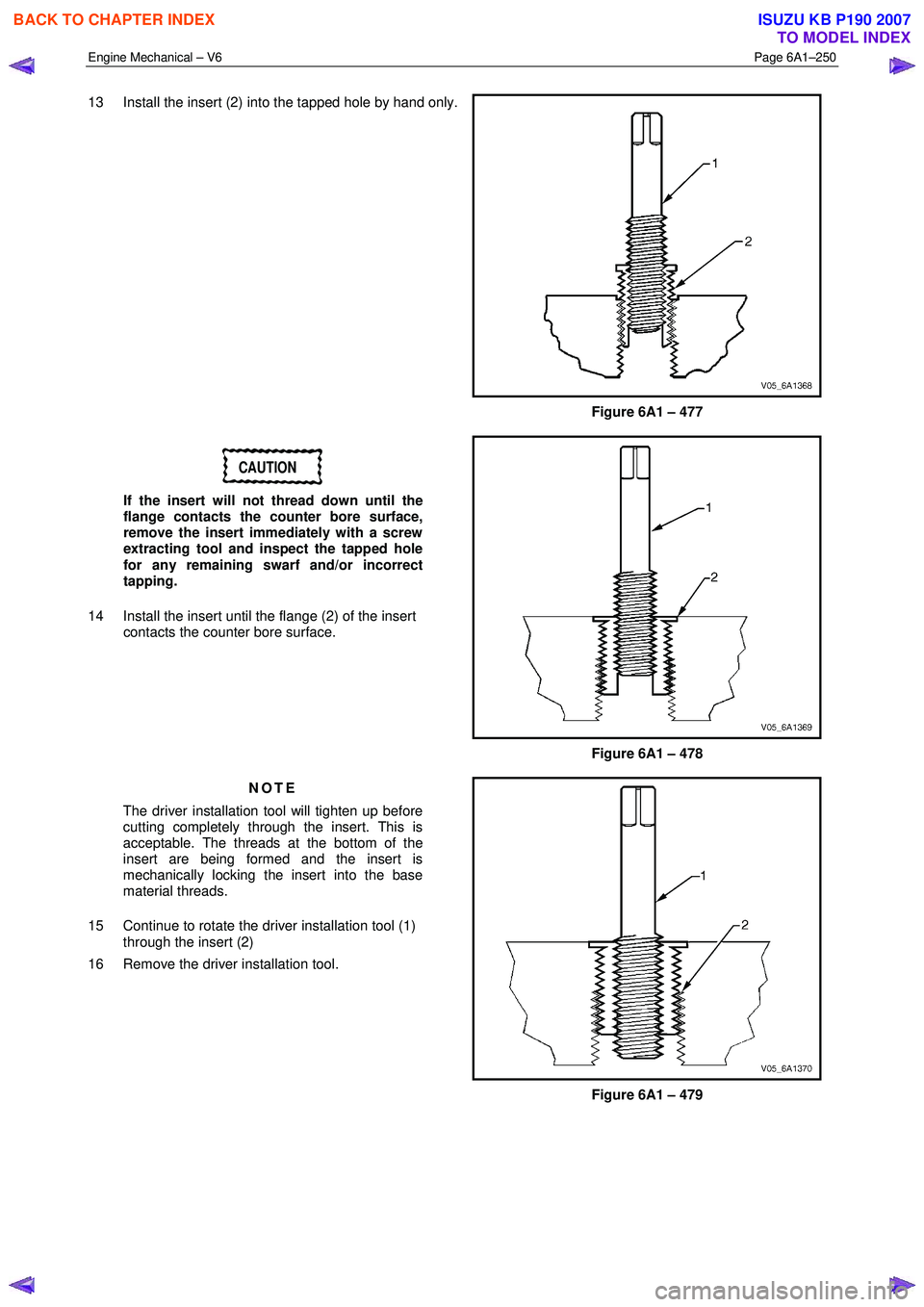

13 Install the insert (2) into the tapped hole by hand only.

Figure 6A1 – 477

CAUTION

If the insert will not thread down until the

flange contacts the counter bore surface,

remove the insert immediately with a screw

extracting tool and inspect the tapped hole

for any remaining swarf and/or incorrect

tapping.

14 Install the insert until the flange (2) of the insert contacts the counter bore surface.

Figure 6A1 – 478

NOTE

The driver installation tool will tighten up before

cutting completely through the insert. This is

acceptable. The threads at the bottom of the

insert are being formed and the insert is

mechanically locking the insert into the base

material threads.

15 Continue to rotate the driver installation tool (1) through the insert (2)

16 Remove the driver installation tool.

Figure 6A1 – 479

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2730 of 6020

Engine Mechanical – V6 Page 6A1–251

17 Inspect the insert for correct installation into the

tapped hole. A correctly installed insert (1) will be

either flush or slightly below flush with the surface of

the base material (2).

Figure 6A1 – 480

18 Any installed insert that restricts or blocks an oil or engine coolant passage (3) will need to have the oil or

engine coolant passage drilled out (4) to the original

size of the oil or engine coolant passage. After drilling

the restriction or blockage, clean out any swarf and

thread the installation driver tool through the insert

again to remove any burrs caused by the drilling of

the oil or engine coolant passage.

Figure 6A1 – 481

Main Bearing Cap Bolt Hole Thread Repair

The crankshaft main bearing bolt hole thread repair tools

are in Tool No. J 42385-2000 and J 42385-700 which

consist of the following:

• Drill (1) for outboard holes J 42385-702

• Tap (2) for outboard holes J 42385-703

• Installation driver (3) for outboard holes J 42385-704

• Bushing (4) for outboard holes J 42385-726

• Alignment pin (5) for outboard holes J 42385-727

• Bolts (6) for outboard holes J 42385-728

• Drill (7) for inboard holes J 42385-720

• Tap (8) for inboard holes J 42385-721

• Installation driver (9) for inboard holes J 42385-722

• Bushing (10) J 42385-713

• Alignment pin (11) J 42385-308

• Bolts (12) J 42385-734

• Fixture plate (13) J 42385-712

Figure 6A1 – 482

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2731 of 6020

Engine Mechanical – V6 Page 6A1–252

NOTE

• Ensure the fixture plate is installed during the

machining and installation processes of the

insert.

• The use of a cutting type fluid such as

WD 40® or equivalent is recommended when

performing the drilling, counter boring and

tapping procedures.

• When installed to the correct depth, the flange

of the insert will be seated against the counter

bore of the drilled/tapped hole.

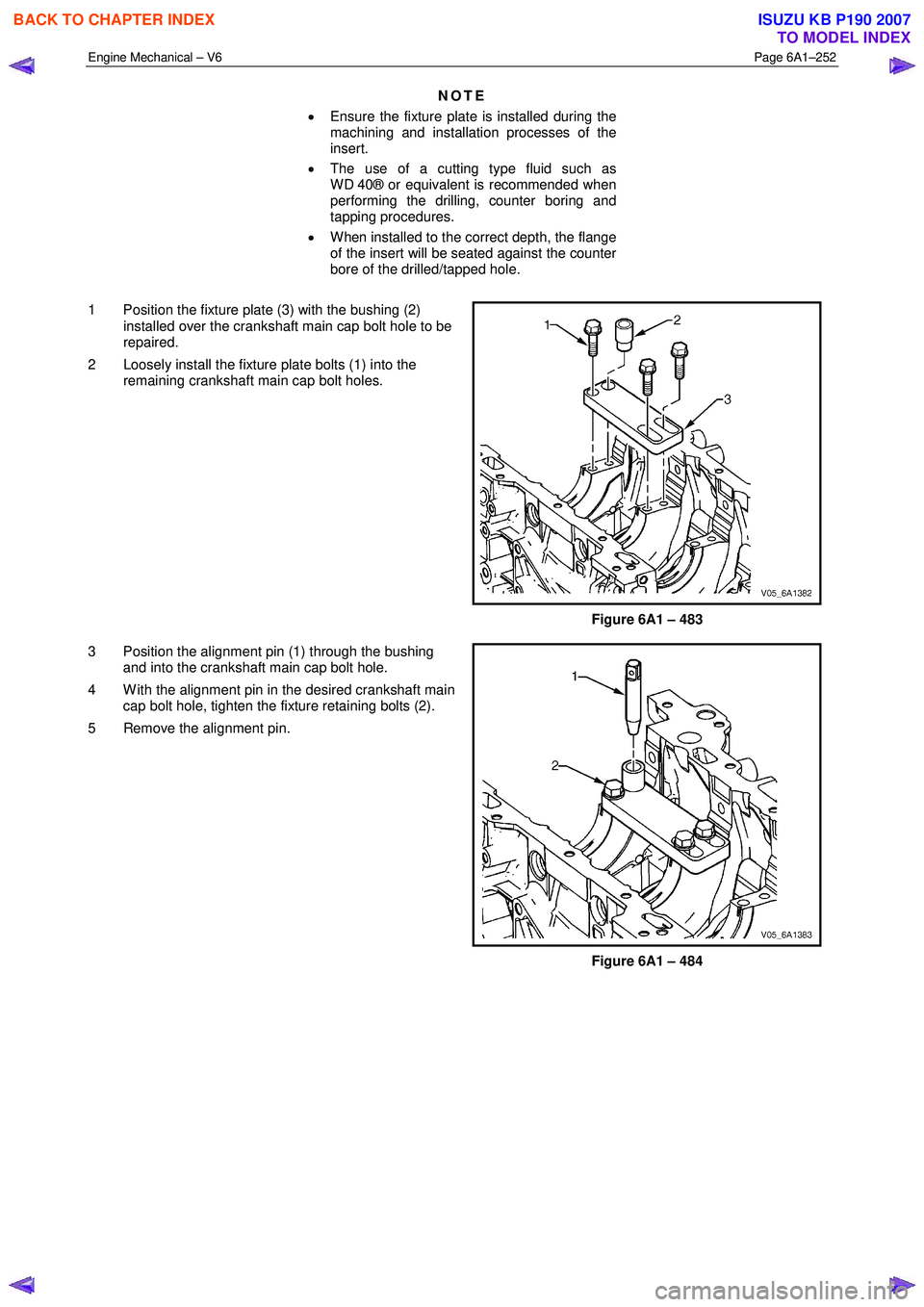

1 Position the fixture plate (3) with the bushing (2) installed over the crankshaft main cap bolt hole to be

repaired.

2 Loosely install the fixture plate bolts (1) into the remaining crankshaft main cap bolt holes.

Figure 6A1 – 483

3 Position the alignment pin (1) through the bushing and into the crankshaft main cap bolt hole.

4 W ith the alignment pin in the desired crankshaft main cap bolt hole, tighten the fixture retaining bolts (2).

5 Remove the alignment pin.

Figure 6A1 – 484

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2732 of 6020

Engine Mechanical – V6 Page 6A1–253

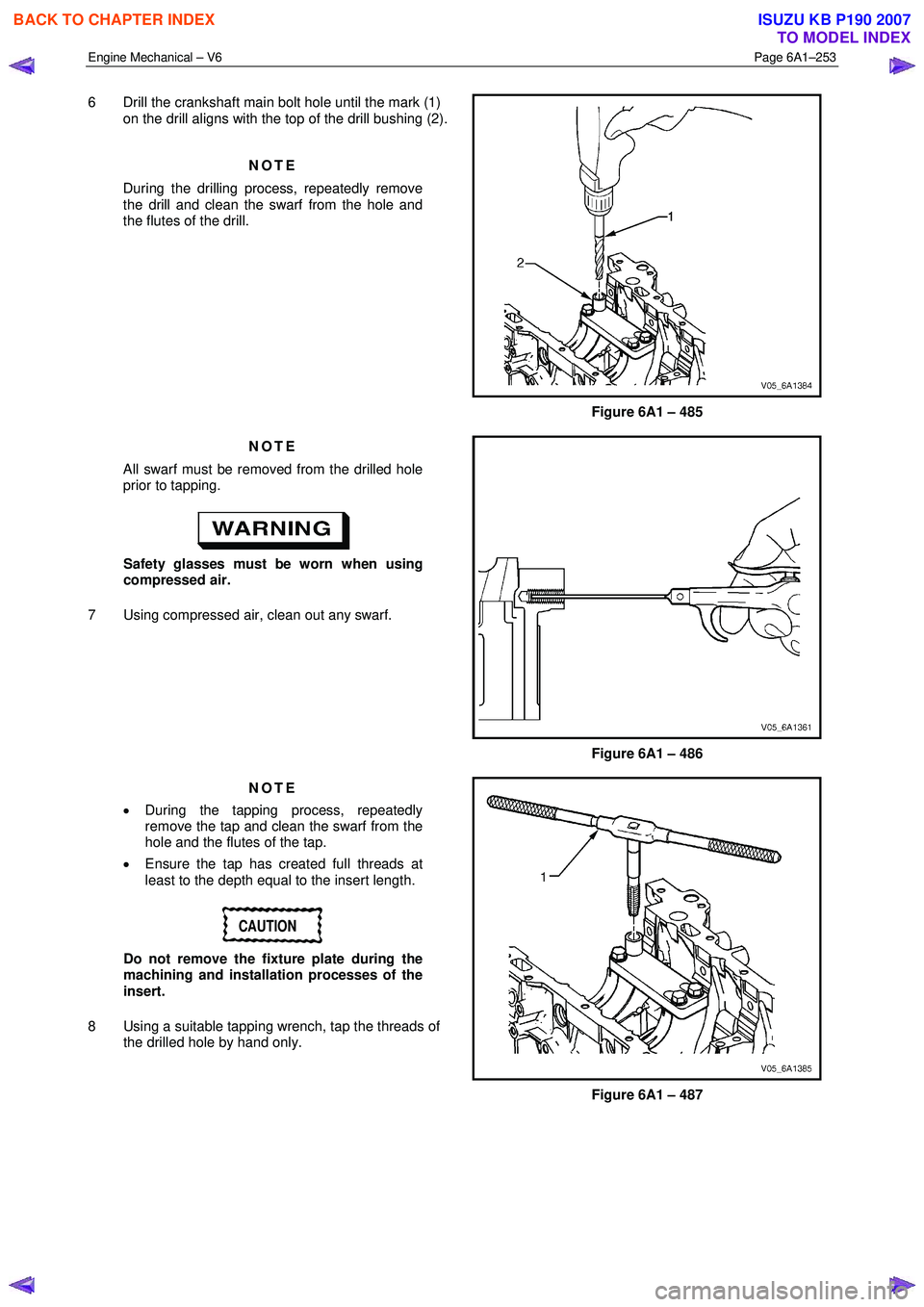

6 Drill the crankshaft main bolt hole until the mark (1)

on the drill aligns with the top of the drill bushing (2).

NOTE

During the drilling process, repeatedly remove

the drill and clean the swarf from the hole and

the flutes of the drill.

Figure 6A1 – 485

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

7 Using compressed air, clean out any swarf.

Figure 6A1 – 486

NOTE

• During the tapping process, repeatedly

remove the tap and clean the swarf from the

hole and the flutes of the tap.

• Ensure the tap has created full threads at

least to the depth equal to the insert length.

CAUTION

Do not remove the fixture plate during the

machining and installation processes of the

insert.

8 Using a suitable tapping wrench, tap the threads of the drilled hole by hand only.

Figure 6A1 – 487

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2733 of 6020

Engine Mechanical – V6 Page 6A1–254

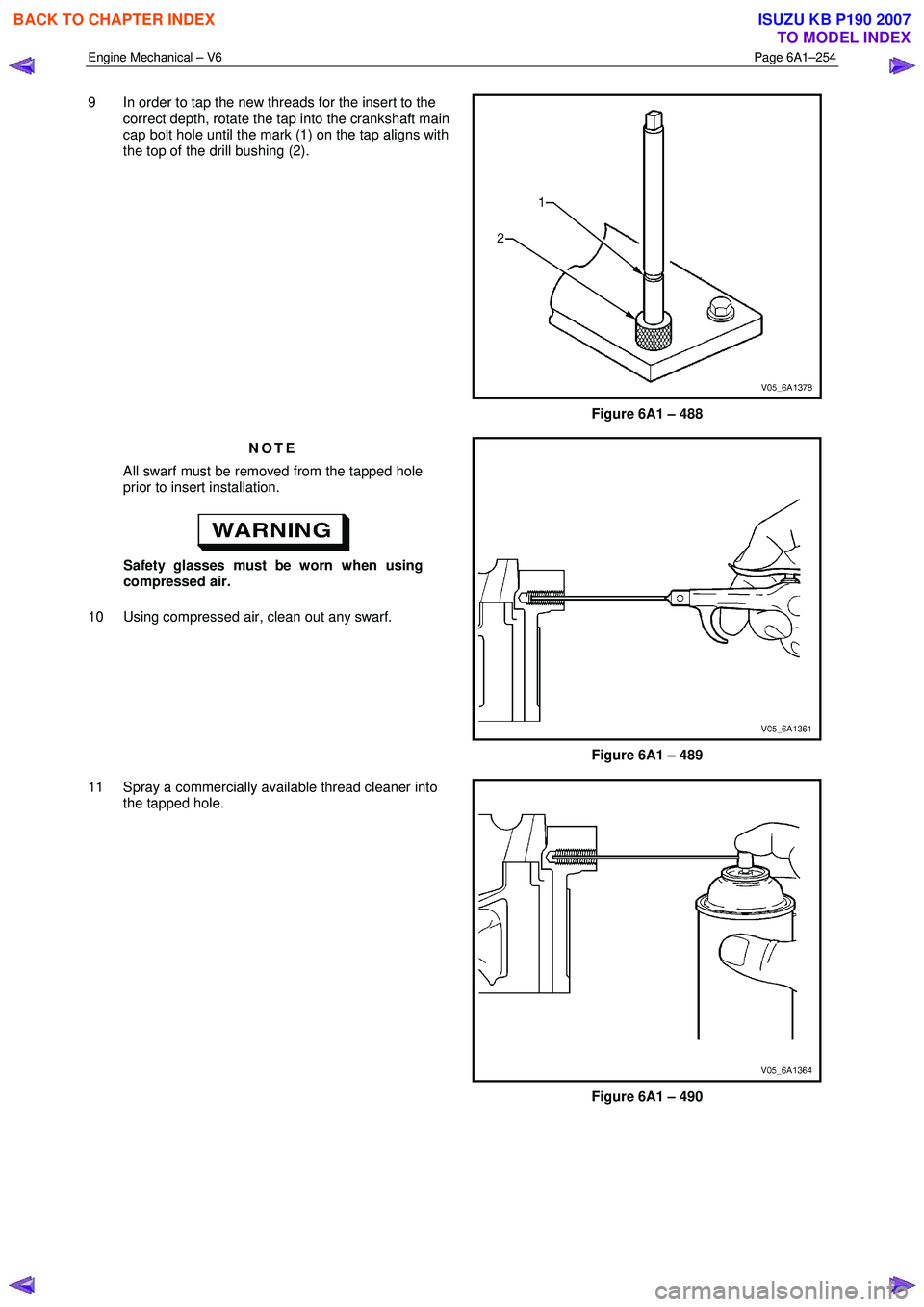

9 In order to tap the new threads for the insert to the

correct depth, rotate the tap into the crankshaft main

cap bolt hole until the mark (1) on the tap aligns with

the top of the drill bushing (2).

Figure 6A1 – 488

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

10 Using compressed air, clean out any swarf.

Figure 6A1 – 489

11 Spray a commercially available thread cleaner into the tapped hole.

Figure 6A1 – 490

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2734 of 6020

Engine Mechanical – V6 Page 6A1–255

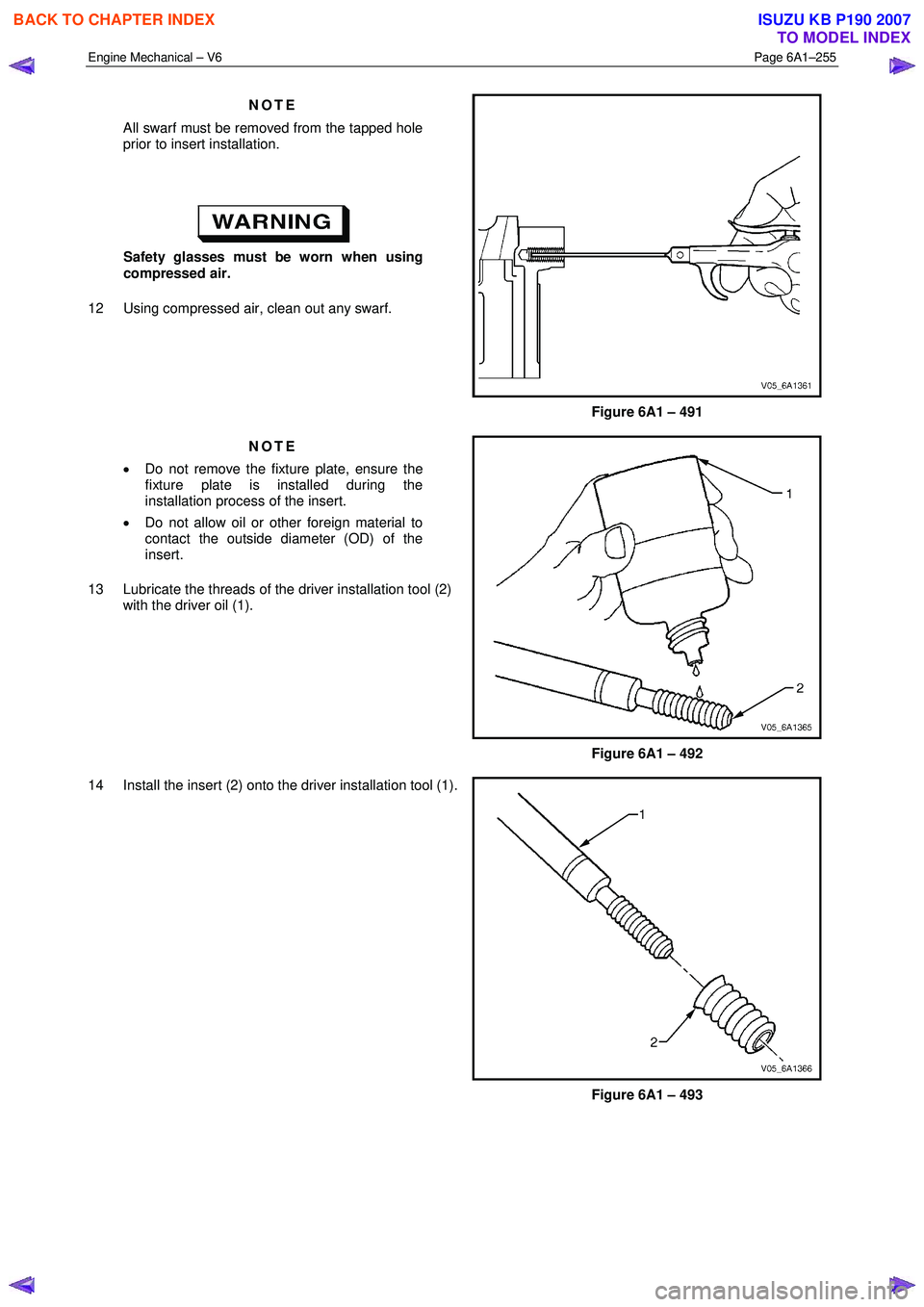

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

12 Using compressed air, clean out any swarf.

Figure 6A1 – 491

NOTE

• Do not remove the fixture plate, ensure the

fixture plate is installed during the

installation process of the insert.

• Do not allow oil or other foreign material to

contact the outside diameter (OD) of the

insert.

13 Lubricate the threads of the driver installation tool (2) with the driver oil (1).

Figure 6A1 – 492

14 Install the insert (2) onto the driver installation tool (1).

Figure 6A1 – 493

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007