ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1981 of 6020

6E-364 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Fuel Injection System Description

Fuel Injection Quantity Control

This control determines the fuel injection quantity by

adding coolant temperature, fuel temperature, intake

air temperature, barometric pressure, mass air flow and

some switch inputs information corrections to the basic

injection quantity is calculated by the ECM based on

the engine operating conditions (engine speed,

accelerator pedal pressing amount and boost pressure

sensor). More fuel rate indicates if the engine load is

increased as the accelerator pedal is stepped on at

constant engine speed.

Combined with high pressure injection of atomized fuel,

this control improves exhaust gas and ensures proper

fuel consumption. Compared with conventional

mechanical governors, an electronic control system

provides higher degree of freedom of fuel injection

quantity control, thereby presenting high accelerator

response (acceleration feeling and pressing feeling).

Starting Injection Quantity Control

At the engine starting (after the key switch is turned to

the START position to start the engine, up to return of

key switch to the ON position), optimum fuel injection

quantity is controlled based on the information on the

engine speed and coolant temperature. At low

temperature, the fuel injection quantity increases.

When the engine started completely, this boosted

quantity mode at the starting is cancelled and normal

running mode is restored.

Idle Speed Control

A control is made so as to achieve stable idling speed

at all time regardless of engine secular changes or

engine condition variations. The ECM sets target idling

speed and controls the fuel injection quantity according

to the engine conditions (actual engine speed, coolant

temperature and engine load) to follow actual engine

speed to the target idling speed so as to ensure stable

idling speed.

Idle Vibration Control

A control is made so as to reduce the engine vibration

caused by torque variations between cylinders due to

variations in fuel injection quantity of each cylinder or

injector performance. The ECM corrects the injection

quantity between cylinders based on the revolution

signals from the crankshaft position (CKP) sensor.

Normal range of correction quantity between cylinders

is within ±5 mm

3.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1982 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-365

Exhaust Gas Recirculation (EGR) System Description

Legend1. EGR cooler

2. Engine coolant outlet

3. Engine coolant inlet

4. EGR valve 5. ECM

6. MAF sensor

7. Intake throttle valve

The EGR system recirculates a part of exhaust gas

back into the intake manifold, which results in reducing

nitrogen oxide (NOx) emissions. The EGR control

system uses an electronic control system to ensure

both driveability and low emission. A control current

from the ECM operates a solenoid to control the lift

amount of EGR valve. Also, an EGR position sensor is

provided at the rear of the motor to feed actual valve lift

amount back to the ECM for more precision control of

the EGR amount.

The EGR control starts when the conditions for engine

speed, engine coolant temperature, intake air

temperature and barometric pressure are satisfied.

Then, the valve opening is calculated according to the

engine speed, and target fuel injection quantity. Based

on this valve opening, the drive duty of the solenoid is

determined and the valve is driven accordingly. The

intake throttle valve is provided to adequate intake

manifold depression to ensure EGR gas flow. EGR Valve

RTW56EMF001701

1

4

7 5

6

23

RTW56ESH000801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1983 of 6020

6E-366 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

The EGR valve is mounted on the intake manifold. The

ECM controls the EGR valve opening based on the

engine running condition. The ECM controls the EGR

valve by controlling the solenoid. The solenoid is

controlled based on pulse width modulation (PWM)

signal sent from the ECM. A duty ratio change 0% to

appropriate percentage is EGR valve lift control. To

open the valve, duty ratio is increased. To close the

valve, duty ratio becomes small.

The EGR valve position is detected by the position

sensor, and relayed to the ECM. The position sensor

provides a signal to the ECM on the signal circuit,

which is relative to the position changes of the EGR

valve. The ECM should detect a low signal voltage at a

small lift amount or closed position. The ECM should

detect high signal voltage at a large lift amount.

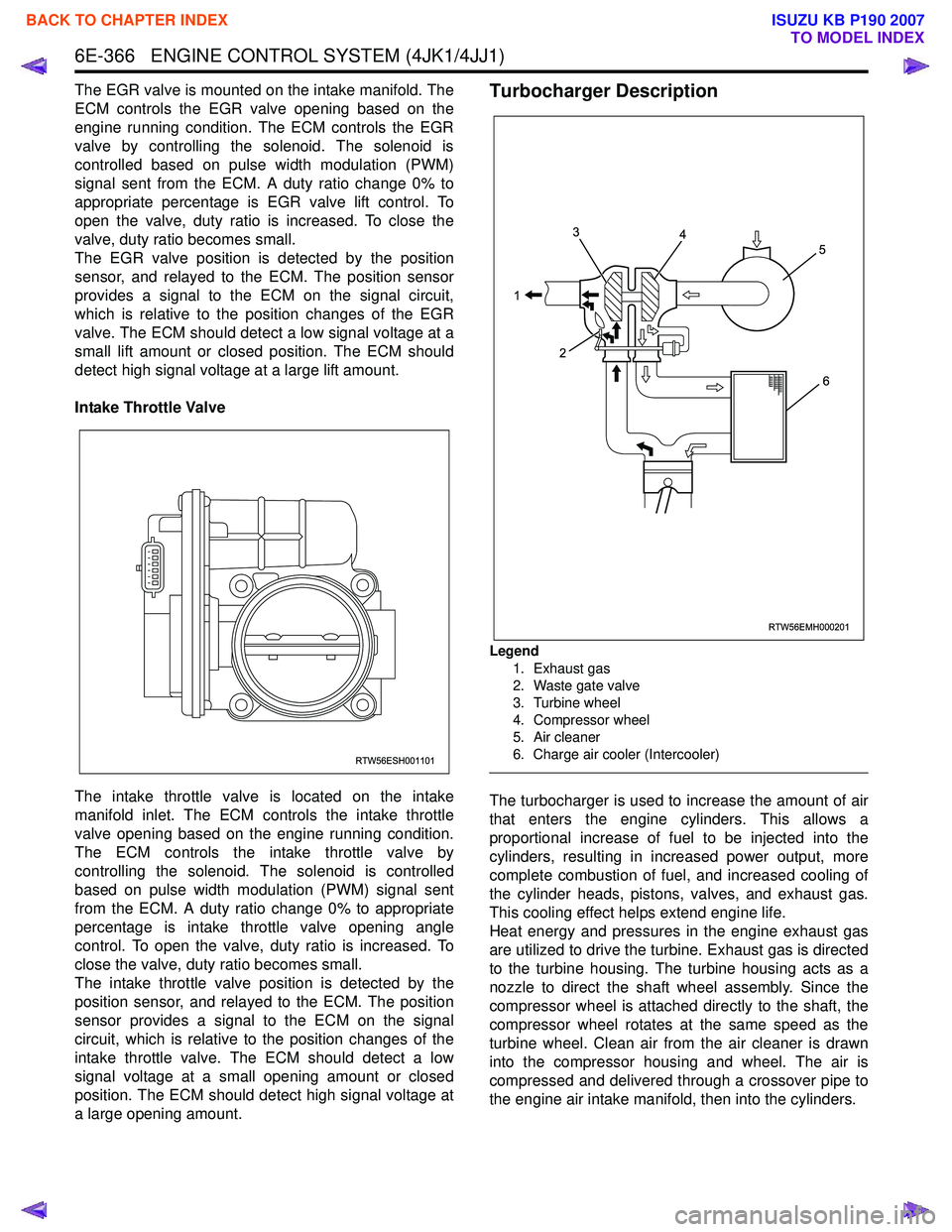

Intake Throttle Valve

The intake throttle valve is located on the intake

manifold inlet. The ECM controls the intake throttle

valve opening based on the engine running condition.

The ECM controls the intake throttle valve by

controlling the solenoid. The solenoid is controlled

based on pulse width modulation (PWM) signal sent

from the ECM. A duty ratio change 0% to appropriate

percentage is intake throttle valve opening angle

control. To open the valve, duty ratio is increased. To

close the valve, duty ratio becomes small.

The intake throttle valve position is detected by the

position sensor, and relayed to the ECM. The position

sensor provides a signal to the ECM on the signal

circuit, which is relative to the position changes of the

intake throttle valve. The ECM should detect a low

signal voltage at a small opening amount or closed

position. The ECM should detect high signal voltage at

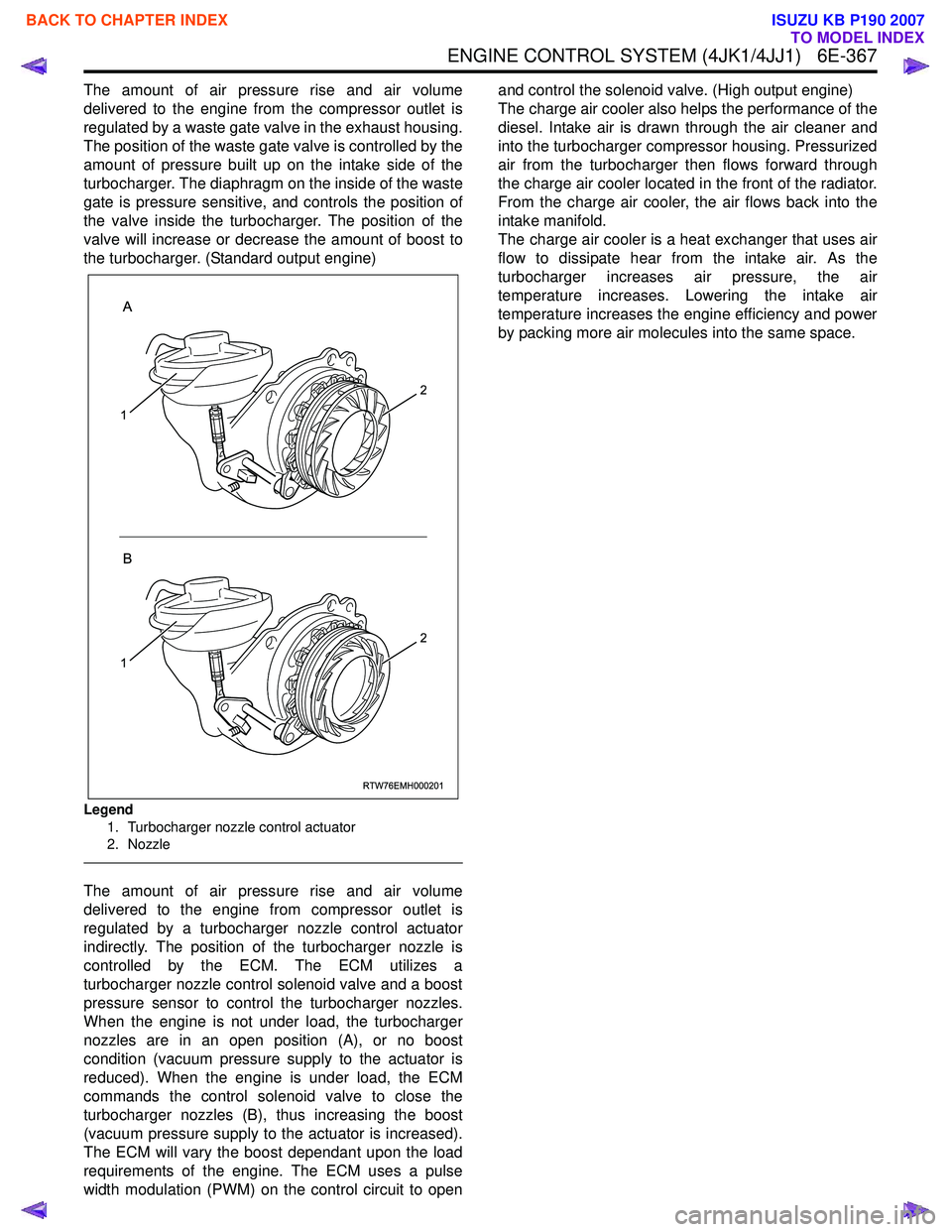

a large opening amount.Turbocharger Description

Legend

1. Exhaust gas

2. Waste gate valve

3. Turbine wheel

4. Compressor wheel

5. Air cleaner

6. Charge air cooler (Intercooler)

The turbocharger is used to increase the amount of air

that enters the engine cylinders. This allows a

proportional increase of fuel to be injected into the

cylinders, resulting in increased power output, more

complete combustion of fuel, and increased cooling of

the cylinder heads, pistons, valves, and exhaust gas.

This cooling effect helps extend engine life.

Heat energy and pressures in the engine exhaust gas

are utilized to drive the turbine. Exhaust gas is directed

to the turbine housing. The turbine housing acts as a

nozzle to direct the shaft wheel assembly. Since the

compressor wheel is attached directly to the shaft, the

compressor wheel rotates at the same speed as the

turbine wheel. Clean air from the air cleaner is drawn

into the compressor housing and wheel. The air is

compressed and delivered through a crossover pipe to

the engine air intake manifold, then into the cylinders.

RTW56ESH001101

RTW56EMH000201

1 3

2 4

5

6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1984 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-367

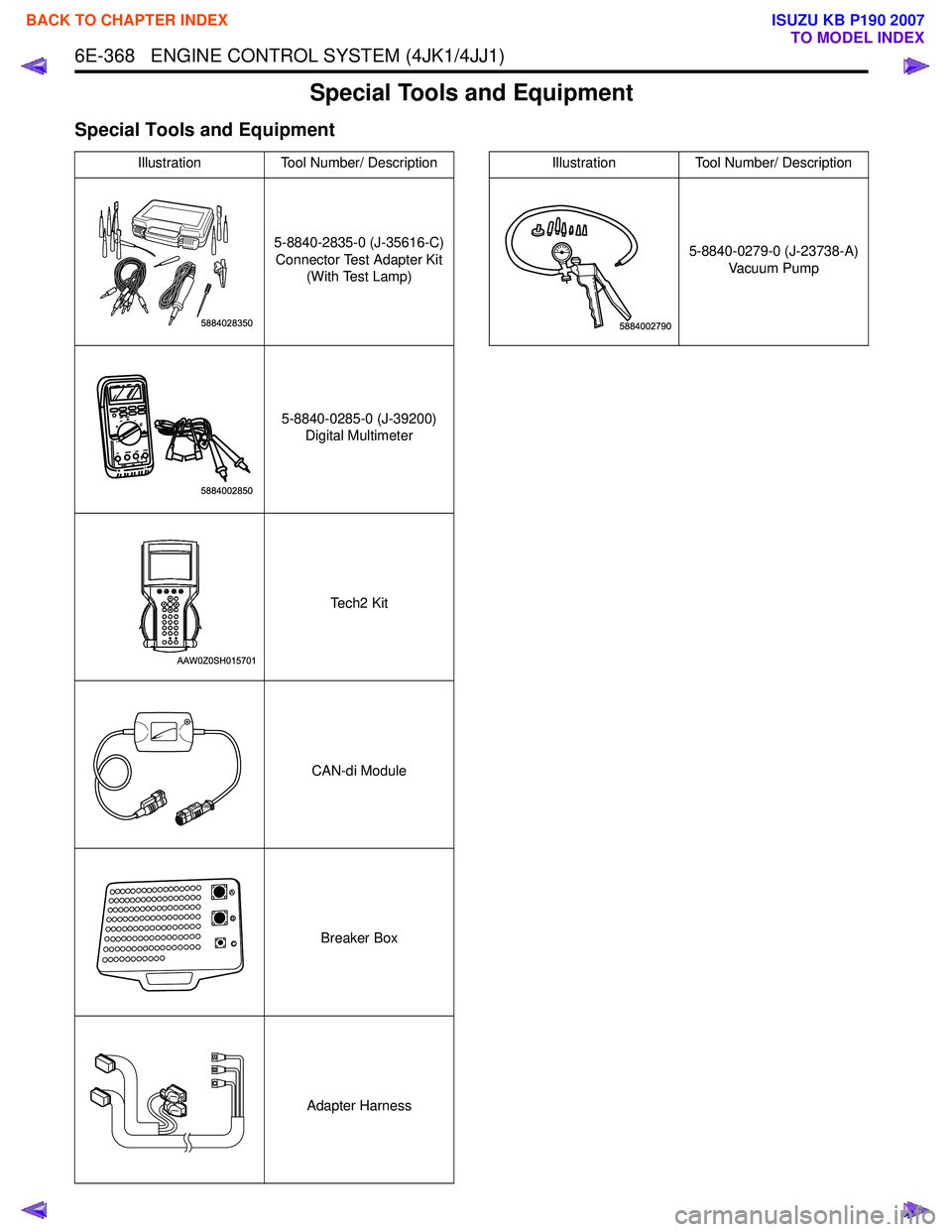

The amount of air pressure rise and air volume

delivered to the engine from the compressor outlet is

regulated by a waste gate valve in the exhaust housing.

The position of the waste gate valve is controlled by the

amount of pressure built up on the intake side of the

turbocharger. The diaphragm on the inside of the waste

gate is pressure sensitive, and controls the position of

the valve inside the turbocharger. The position of the

valve will increase or decrease the amount of boost to

the turbocharger. (Standard output engine)

Legend

1. Turbocharger nozzle control actuator

2. Nozzle

The amount of air pressure rise and air volume

delivered to the engine from compressor outlet is

regulated by a turbocharger nozzle control actuator

indirectly. The position of the turbocharger nozzle is

controlled by the ECM. The ECM utilizes a

turbocharger nozzle control solenoid valve and a boost

pressure sensor to control the turbocharger nozzles.

When the engine is not under load, the turbocharger

nozzles are in an open position (A), or no boost

condition (vacuum pressure supply to the actuator is

reduced). When the engine is under load, the ECM

commands the control solenoid valve to close the

turbocharger nozzles (B), thus increasing the boost

(vacuum pressure supply to the actuator is increased).

The ECM will vary the boost dependant upon the load

requirements of the engine. The ECM uses a pulse

width modulation (PWM) on the control circuit to open and control the solenoid valve. (High output engine)

The charge air cooler also helps the performance of the

diesel. Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressurized

air from the turbocharger then flows forward through

the charge air cooler located in the front of the radiator.

From the charge air cooler, the air flows back into the

intake manifold.

The charge air cooler is a heat exchanger that uses air

flow to dissipate hear from the intake air. As the

turbocharger increases air pressure, the air

temperature increases. Lowering the intake air

temperature increases the engine efficiency and power

by packing more air molecules into the same space.

RTW76EMH000201

A

B

1

2

1

2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1985 of 6020

6E-368 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

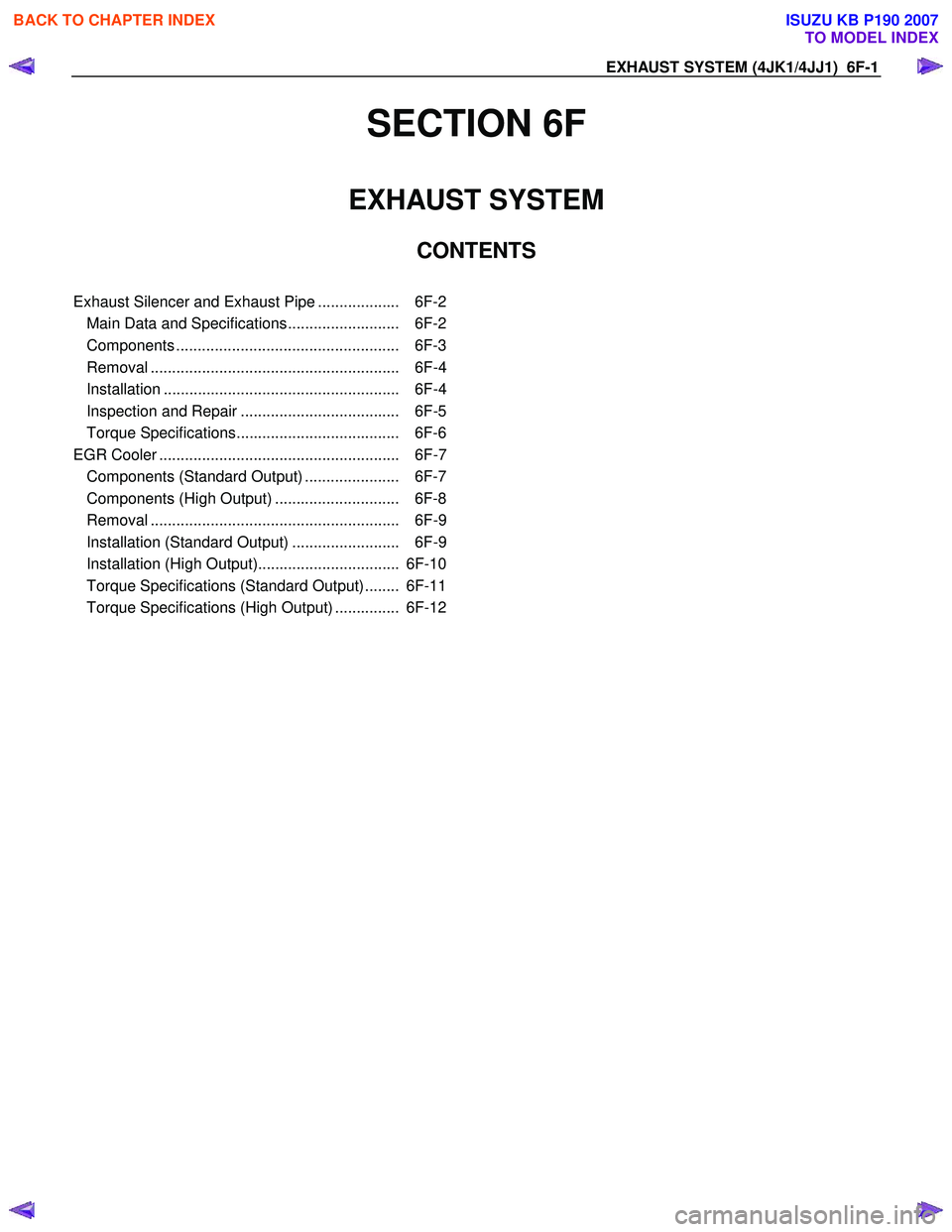

Special Tools and Equipment

Special Tools and Equipment

IllustrationTool Number/ Description

5-8840-2835-0 (J-35616-C) Connector Test Adapter Kit (With Test Lamp)

5-8840-0285-0 (J-39200) Digital Multimeter

Te c h 2 K i t

CAN-di Module Breaker Box

Adapter Harness

5884028350

5884002850

AAW0Z0SH015701

1851110030

A

B C

ABC

5-8840-0279-0 (J-23738-A) Vacuum Pump

Illustration Tool Number/ Description

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1986 of 6020

EXHAUST SYSTEM (4JK1/4JJ1) 6F-1

SECTION 6F

EXHAUST SYSTEM

CONTENTS

Exhaust Silencer and Exhaust Pipe ................... 6F-2

Main Data and Specifications .......................... 6F-2

Components .................................................... 6F-3

Removal .......................................................... 6F-4

Installation ....................................................... 6F-4

Inspection and Repair ..................................... 6F-5

Torque Specifications...................................... 6F-6

EGR Cooler ........................................................ 6F-7 Components (Standard Output) ...................... 6F-7

Components (High Output) ............................. 6F-8

Removal .......................................................... 6F-9

Installation (Standard Output) ......................... 6F-9

Installation (High Output)................................. 6F-10

Torque Specifications (Standard Output) ........ 6F-11

Torque Specifications (High Output) ............... 6F-12

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1987 of 6020

6F-2 EXHAUST SYSTEM (4JK1/4JJ1)

Exhaust Silencer and Exhaust Pipe

Main Data and Specifications

Front pipe

Pipe outside diameter × thickness mm (in)50.8 × 1.5 (2.0 × 0.059) and

60.5 × 1.5 (2.38 × 0.059)

Middle pipe

Pipe outside diameter × thickness mm (in)60.5 × 1.5 (2.38 × 0.059)

Silencer & tail pipe

Type Circular section-shell construction of double skin

and end plates, internal construction of baffles and perforated tubes.

Tail pipe outside diameter × thickness mm (in) Standard output: 60.5 × 1.6 (2.38 × 0.063)

High output: 63.5 × 1.6 (2.5 × 0.063)

Length mm (in)Approximately 1335 (52.6)

Mounting

Number of suspension points 4

Type Rubber

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1988 of 6020

EXHAUST SYSTEM (4JK1/4JJ1) 6F-3

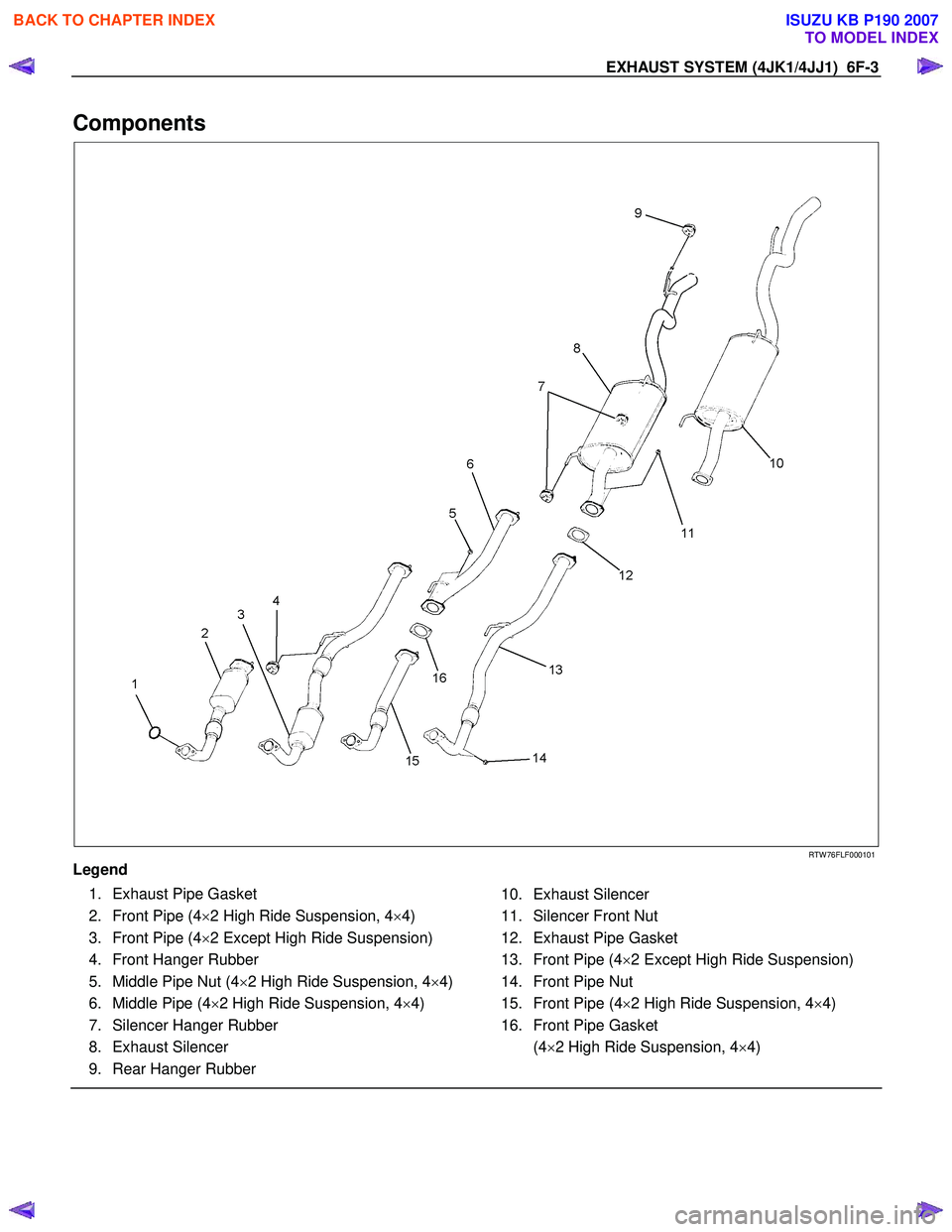

Components

RTW 76FLF000101

Legend

1. Exhaust Pipe Gasket

2. Front Pipe (4 ×2 High Ride Suspension, 4 ×4)

3. Front Pipe (4 ×2 Except High Ride Suspension)

4. Front Hanger Rubber

5. Middle Pipe Nut (4 ×2 High Ride Suspension, 4 ×4)

6. Middle Pipe (4 ×2 High Ride Suspension, 4 ×4)

7. Silencer Hanger Rubber

8. Exhaust Silencer

9. Rear Hanger Rubber

10. Exhaust Silencer

11. Silencer Front Nut

12. Exhaust Pipe Gasket

13. Front Pipe (4 ×2 Except High Ride Suspension)

14. Front Pipe Nut

15. Front Pipe (4 ×2 High Ride Suspension, 4 ×4)

16. Front Pipe Gasket

(4 ×2 High Ride Suspension, 4 ×4)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1989 of 6020

6F-4 EXHAUST SYSTEM (4JK1/4JJ1)

Removal

1. Rear hanger rubber

2. Silencer front nut

3. Exhaust silencer

4. Silencer hanger rubber

5. Front hanger rubber

6. Middle pipe nut (4 ×2 High Ride Suspension, 4 ×4)

7. Middle pipe (4 ×2 High Ride Suspension, 4 ×4)

8. Front pipe nut

9. Exhaust pipe gasket

Installation

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention

to the important points during the installation procedure.

1. Front Pipe Nut

Connect the exhaust pipe to the catalytic converter.

Torque: 67 N ⋅

⋅⋅

⋅

m (6.8 kg ⋅

⋅⋅

⋅

m / 49 lb ft)

2. Middle pipe Nut (4 ×2 High Ride Suspension,4 ×4)

Connect the middle pipe to the front pipe.

Torque: 43 N ⋅

⋅⋅

⋅

m (4.4 kg ⋅

⋅⋅

⋅

m / 32 lb ft)

3. Silencer Front Nut

Connect the silencer to the front or middle pipe.

Torque: 43 N ⋅

⋅⋅

⋅

m (4.4 kg ⋅

⋅⋅

⋅

m / 32 lb ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1990 of 6020

EXHAUST SYSTEM (4JK1/4JJ1) 6F-5

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Front Exhaust Pipe

Exhaust Silencer

Check the pipes for corrosion, cracking, damage o

r

misalignment and repair as required.

Check the rubber rings for deterioration or damage and

repair as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007