charging ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 125 of 6020

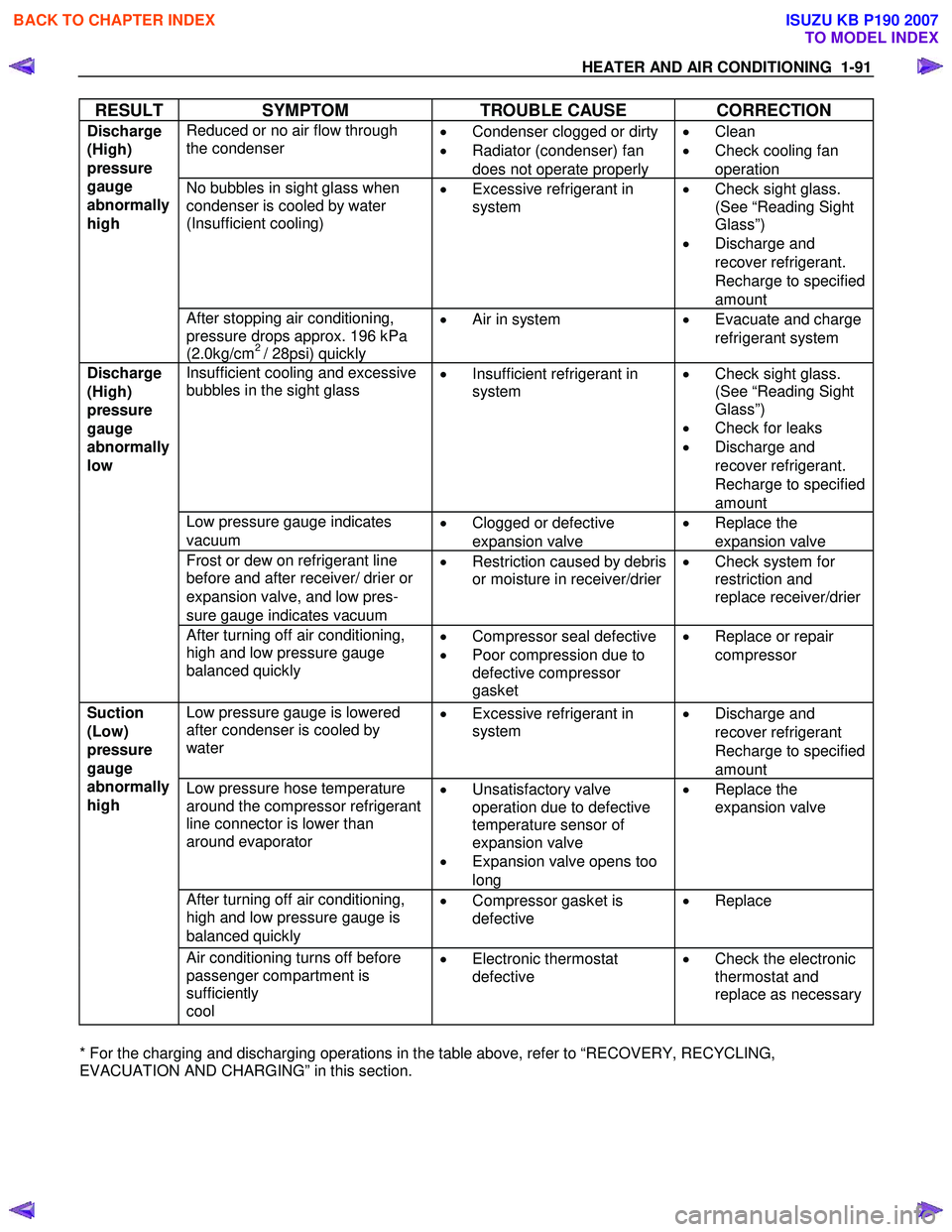

HEATER AND AIR CONDITIONING 1-91

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Reduced or no air flow through

the condenser

•

Condenser clogged or dirty

• Radiator (condenser) fan

does not operate properly •

Clean

• Check cooling fan

operation

No bubbles in sight glass when

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Discharge

(High)

pressure

gauge

abnormally

high

After stopping air conditioning,

pressure drops approx. 196 kPa

(2.0kg/cm

2 / 28psi) quickly •

Air in system

•

Evacuate and charge

refrigerant system

Insufficient cooling and excessive

bubbles in the sight glass

•

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Low pressure gauge indicates

vacuum •

Clogged or defective

expansion valve •

Replace the

expansion valve

Frost or dew on refrigerant line

before and after receiver/ drier or

expansion valve, and low pres-

sure gauge indicates vacuum •

Restriction caused by debris

or moisture in receiver/drier

•

Check system for

restriction and

replace receiver/drier

Discharge

(High)

pressure

gauge

abnormally

low

After turning off air conditioning,

high and low pressure gauge

balanced quickly

•

Compressor seal defective

• Poor compression due to

defective compressor

gasket •

Replace or repair

compressor

Low pressure gauge is lowered

after condenser is cooled by

water

•

Excessive refrigerant in

system

•

Discharge and

recover refrigerant

Recharge to specified

amount

Low pressure hose temperature

around the compressor refrigerant

line connector is lower than

around evaporator

•

Unsatisfactory valve

operation due to defective

temperature sensor of

expansion valve

• Expansion valve opens too

long •

Replace the

expansion valve

After turning off air conditioning,

high and low pressure gauge is

balanced quickly •

Compressor gasket is

defective

•

Replace

Suction

(Low)

pressure

gauge

abnormally

high

Air conditioning turns off before

passenger compartment is

sufficiently

cool •

Electronic thermostat

defective

•

Check the electronic

thermostat and

replace as necessary

* For the charging and discharging operations in the table above, refer to “RECOVERY, RECYCLING,

EVACUATION AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 786 of 6020

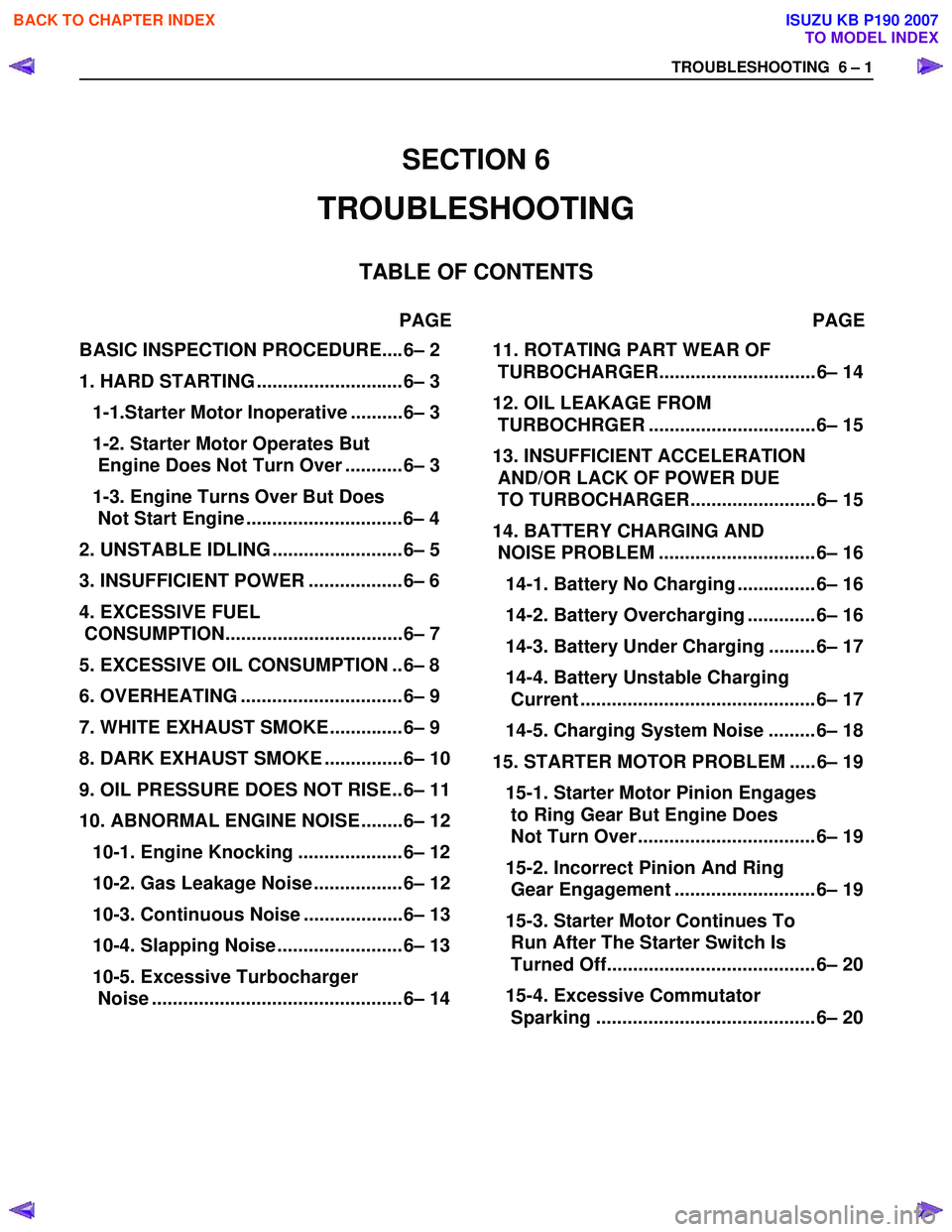

TROUBLESHOOTING 6 – 1

BASIC INSPECTION PROCEDURE....6– 2

1. HARD STARTING ............................6– 3

1-1.Starter Motor Inoperative ..........6– 3

1-2. Starter Motor Operates But

Engine Does Not Turn Over ...........6– 3

1-3. Engine Turns Over But Does

Not Start Engine ..............................6– 4

2. UNSTABLE IDLING .........................6– 5

3. INSUFFICIENT POWER ..................6– 6

4. EXCESSIVE FUEL

CONSUMPTION..................................6– 7

5. EXCESSIVE OIL CONSUMPTION ..6– 8

6. OVERHEATING ...............................6– 9

7. WHITE EXHAUST SMOKE..............6– 9

8. DARK EXHAUST SMOKE ...............6– 10

9. OIL PRESSURE DOES NOT RISE..6– 11

10. ABNORMAL ENGINE NOISE ........6– 12

10-1. Engine Knocking ....................6– 12

10-2. Gas Leakage Noise .................6– 12

10-3. Continuous Noise ...................6– 13

10-4. Slapping Noise ........................6– 13

10-5. Excessive Turbocharger

Noise ................................................6– 14

11. ROTATING PART WEAR OF

TURBOCHARGER.............................. 6– 14

12. OIL LEAKAGE FROM

TURBOCHRGER ................................ 6– 15

13. INSUFFICIENT ACCELERATION

AND/OR LACK OF POWER DUE

TO TURBOCHARGER........................ 6– 15

14. BATTERY CHARGING AND

NOISE PROBLEM .............................. 6– 16

14-1. Battery No Charging ............... 6– 16

14-2. Battery Overcharging ............. 6– 16

14-3. Battery Under Charging ......... 6– 17

14-4. Battery Unstable Charging

Current ............................................. 6– 17

14-5. Charging System Noise ......... 6– 18

15. STARTER MOTOR PROBLEM ..... 6– 19

15-1. Starter Motor Pinion Engages

to Ring Gear But Engine Does

Not Turn Over .................................. 6– 19

15-2. Incorrect Pinion And Ring

Gear Engagement ........................... 6– 19

15-3. Starter Motor Continues To

Run After The Starter Switch Is

Turned Off........................................ 6– 20

15-4. Excessive Commutator

Sparking .......................................... 6– 20

SECTION 6

TROUBLESHOOTING

TABLE OF CONTENTS

PAGE PAGE

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 801 of 6020

6 – 16 TROUBLESHOOTING

14. Battery Charging and Noise Problem

Visual/physical check the following items before diagnosis.

The drive belt tension.

The battery terminals connection condition.

The ground connection condition.

The generator and the battery fastener condition.

The battery fluid level and specific gravity.

14-1 Battery No Charging

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there poor contact between the brush and the

slip ring? —

Repair or

replace the

brush and/or the slip ring. Go to Step 3

3 Inspect the stator coil on the generator.

Was there an open circuit or the scorching on the

stator coil? —

Replace the stator coil. Go to Step 4

4 Inspect the rotor coil on the generator.

Was there an open circuit or the scorching on the

rotor coil? —

Replace the rotor coil. Go to Step 5

5 Inspect the rectifier on the generator.

Was the rectifier defective? —

Replace the

rectifier Go to Step 6

6 Inspect the IC regulator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Are any DTC stored? — Go to indicated

DTC. Solved

14-2 Battery Overcharging

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the terminal circuit.

Were the B and F terminals shorted? —

Repair the

short circuit. Go to Step 3

3 Check the regulating voltage.

Was the IC regulator voltage excessive? —

Replace the IC

regulator. Go to Step 4

4 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 802 of 6020

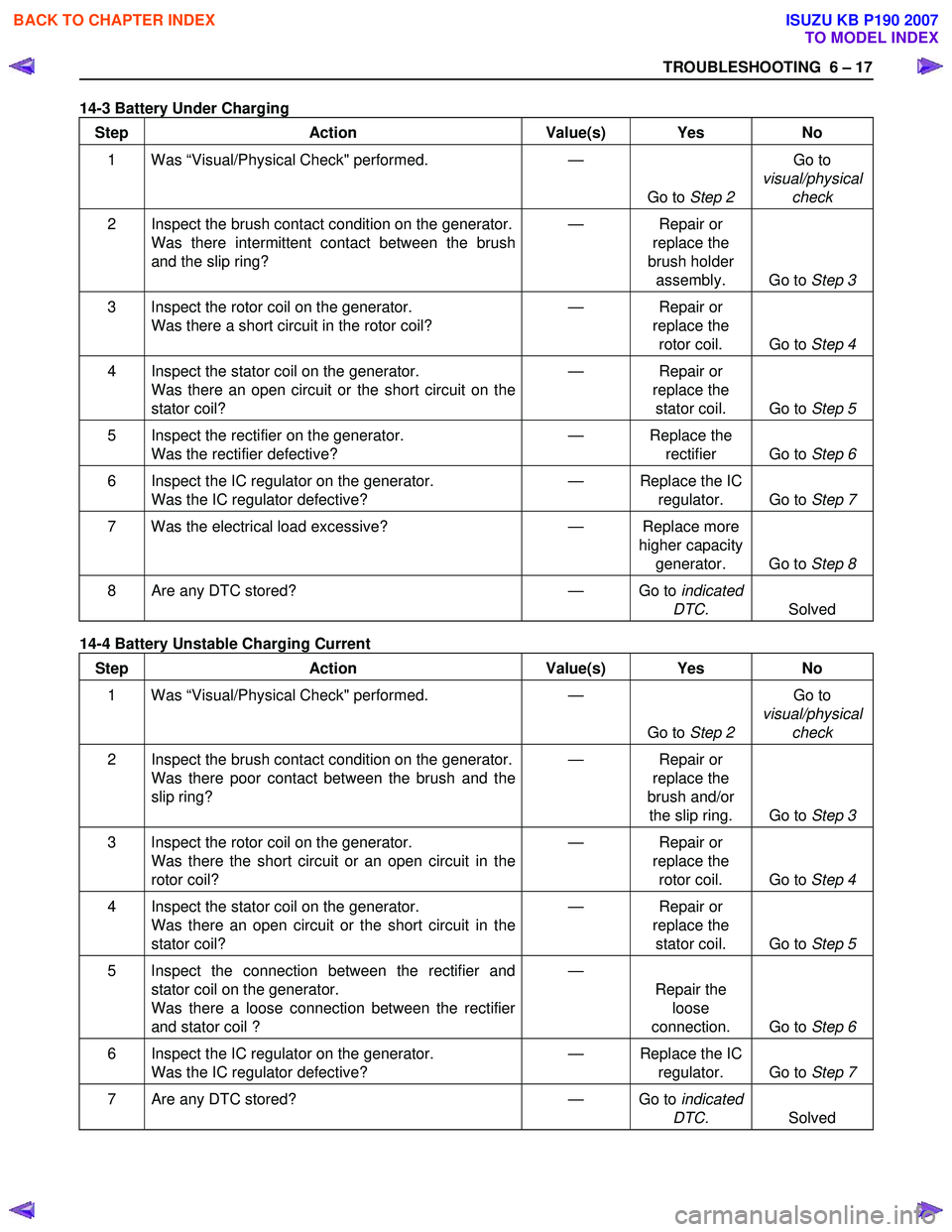

TROUBLESHOOTING 6 – 17

14-3 Battery Under Charging

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there intermittent contact between the brush

and the slip ring? —

Repair or

replace the

brush holder assembly. Go to Step 3

3 Inspect the rotor coil on the generator.

Was there a short circuit in the rotor coil? —

Repair or

replace the rotor coil. Go to Step 4

4 Inspect the stator coil on the generator.

Was there an open circuit or the short circuit on the

stator coil? —

Repair or

replace the stator coil. Go to Step 5

5 Inspect the rectifier on the generator.

Was the rectifier defective? —

Replace the

rectifier Go to Step 6

6 Inspect the IC regulator on the generator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Was the electrical load excessive? — Replace more

higher capacity generator. Go to Step 8

8 Are any DTC stored? — Go to indicated

DTC. Solved

14-4 Battery Unstable Charging Current

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there poor contact between the brush and the

slip ring? —

Repair or

replace the

brush and/or the slip ring. Go to Step 3

3 Inspect the rotor coil on the generator.

Was there the short circuit or an open circuit in the

rotor coil? —

Repair or

replace the rotor coil. Go to Step 4

4 Inspect the stator coil on the generator.

Was there an open circuit or the short circuit in the

stator coil? —

Repair or

replace the stator coil. Go to Step 5

5 Inspect the connection between the rectifier and

stator coil on the generator.

Was there a loose connection between the rectifier

and stator coil ? —

Repair the loose

connection. Go to Step 6

6 Inspect the IC regulator on the generator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 803 of 6020

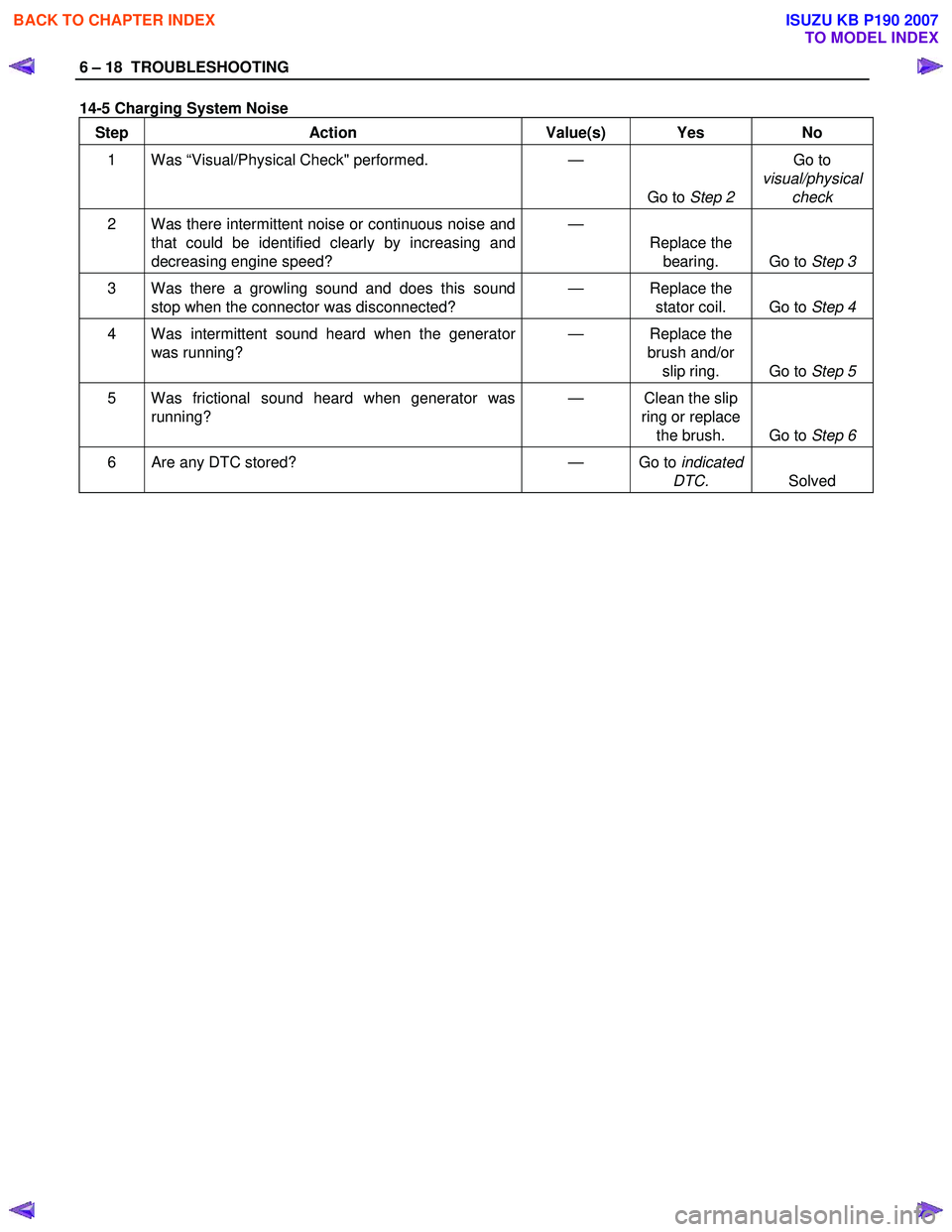

6 – 18 TROUBLESHOOTING

14-5 Charging System Noise Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Was there intermittent noise or continuous noise and

that could be identified clearly by increasing and

decreasing engine speed? —

Replace the bearing. Go to Step 3

3 Was there a growling sound and does this sound

stop when the connector was disconnected? —

Replace the

stator coil. Go to Step 4

4 Was intermittent sound heard when the generator

was running? —

Replace the

brush and/or slip ring. Go to Step 5

5 Was frictional sound heard when generator was

running? —

Clean the slip

ring or replace the brush. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1004 of 6020

ENGINE ELECTRICAL 6D – 3

GENERAL DESCRIPTION

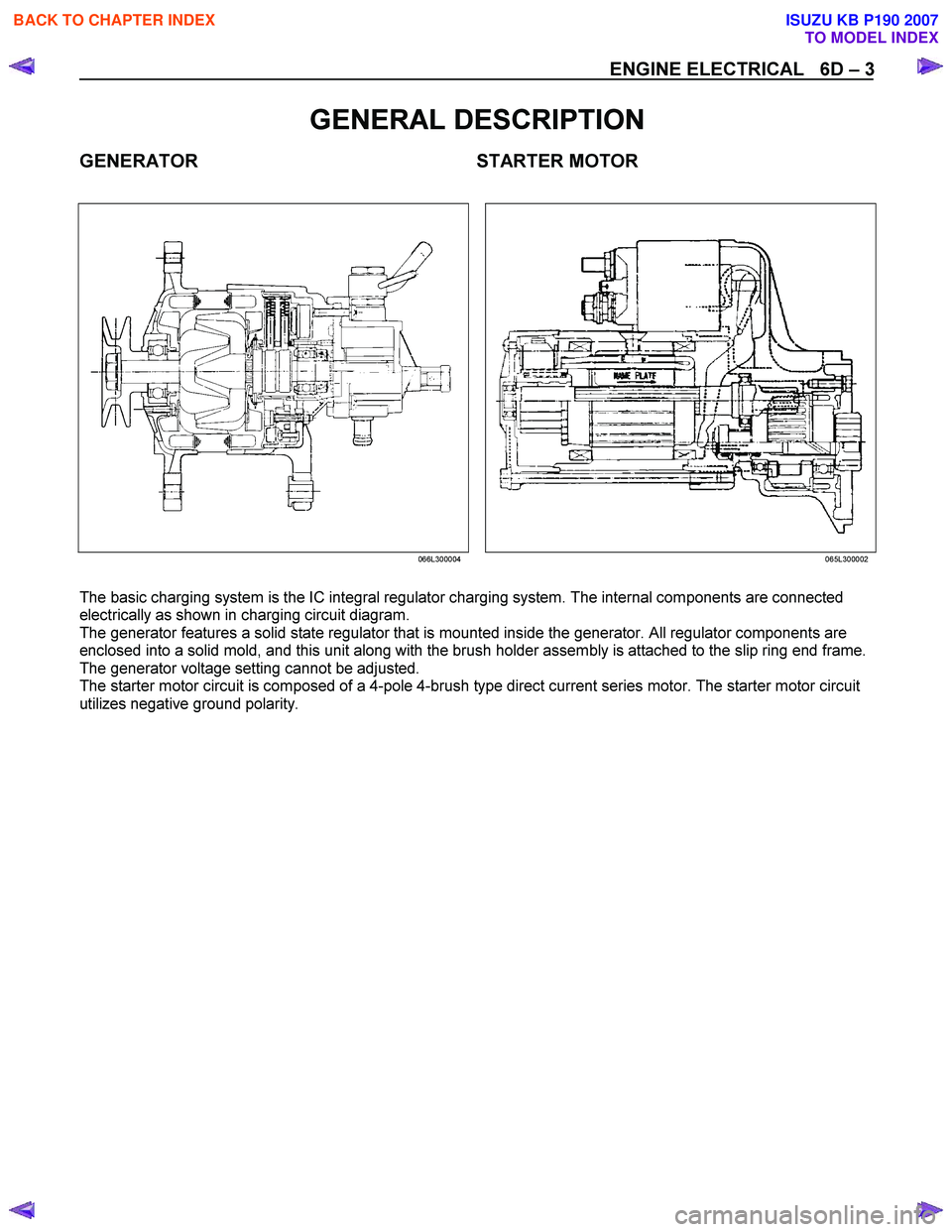

GENERATOR STARTER MOTOR

066L300004 065L300002

The basic charging system is the IC integral regulator charging system. The internal components are connected

electrically as shown in charging circuit diagram.

The generator features a solid state regulator that is mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brush holder assembly is attached to the slip ring end frame.

The generator voltage setting cannot be adjusted.

The starter motor circuit is composed of a 4-pole 4-brush type direct current series motor. The starter motor circuit

utilizes negative ground polarity.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1005 of 6020

6D – 4 ENGINE ELECTRICAL

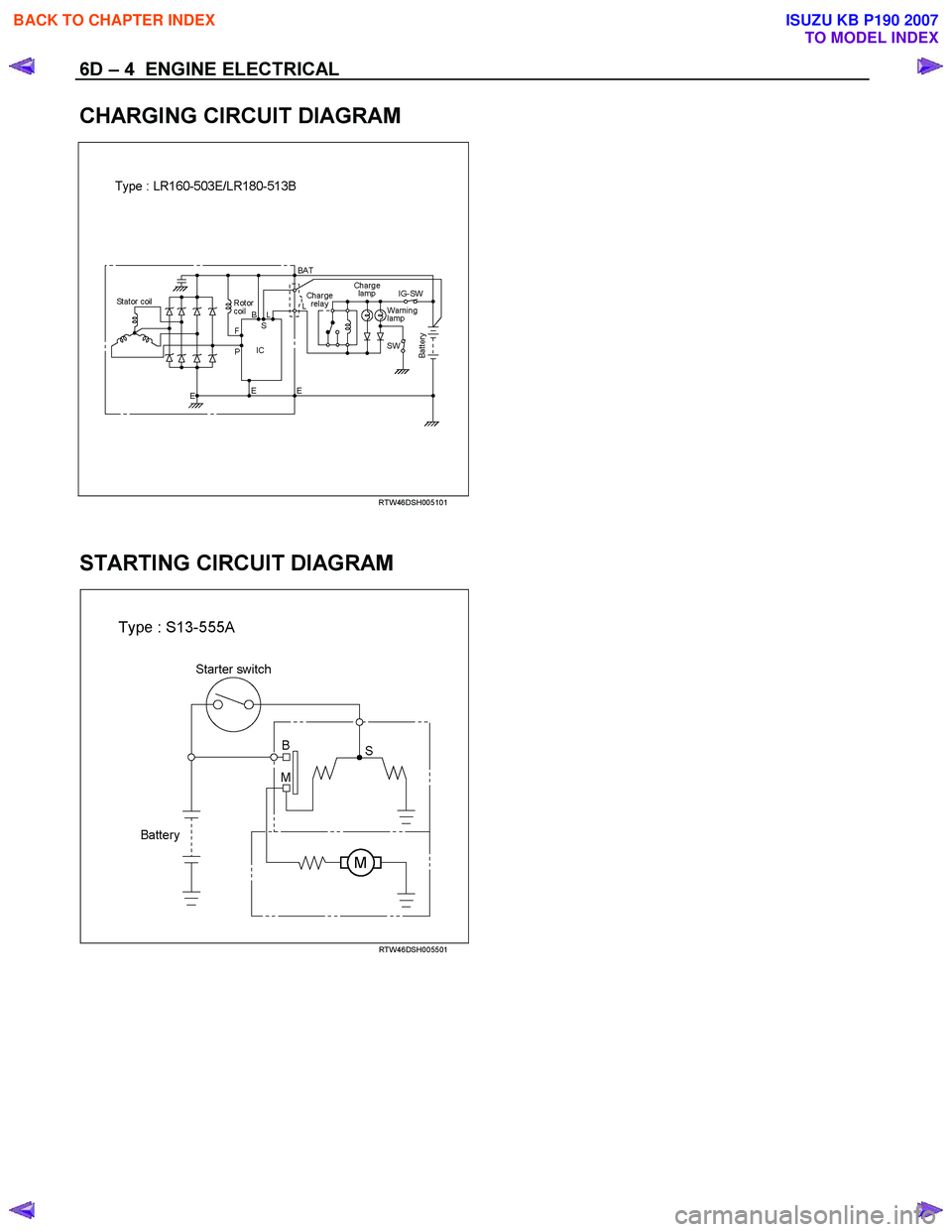

CHARGING CIRCUIT DIAGRAM

RTW46DSH005101

STARTING CIRCUIT DIAGRAM

RTW46DSH005501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1044 of 6020

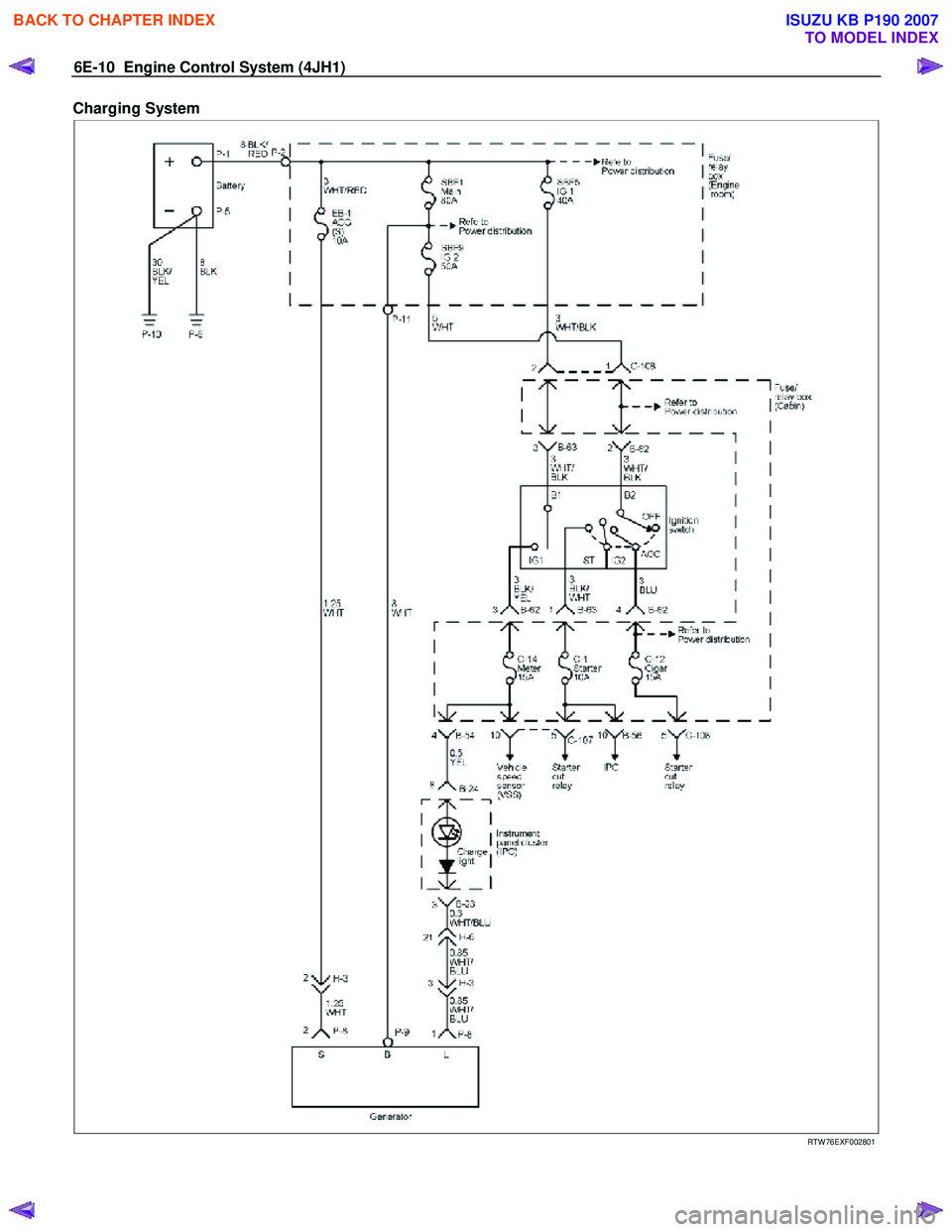

6E-10 Engine Control System (4JH1)

Charging System

RTW 76EXF002801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1092 of 6020

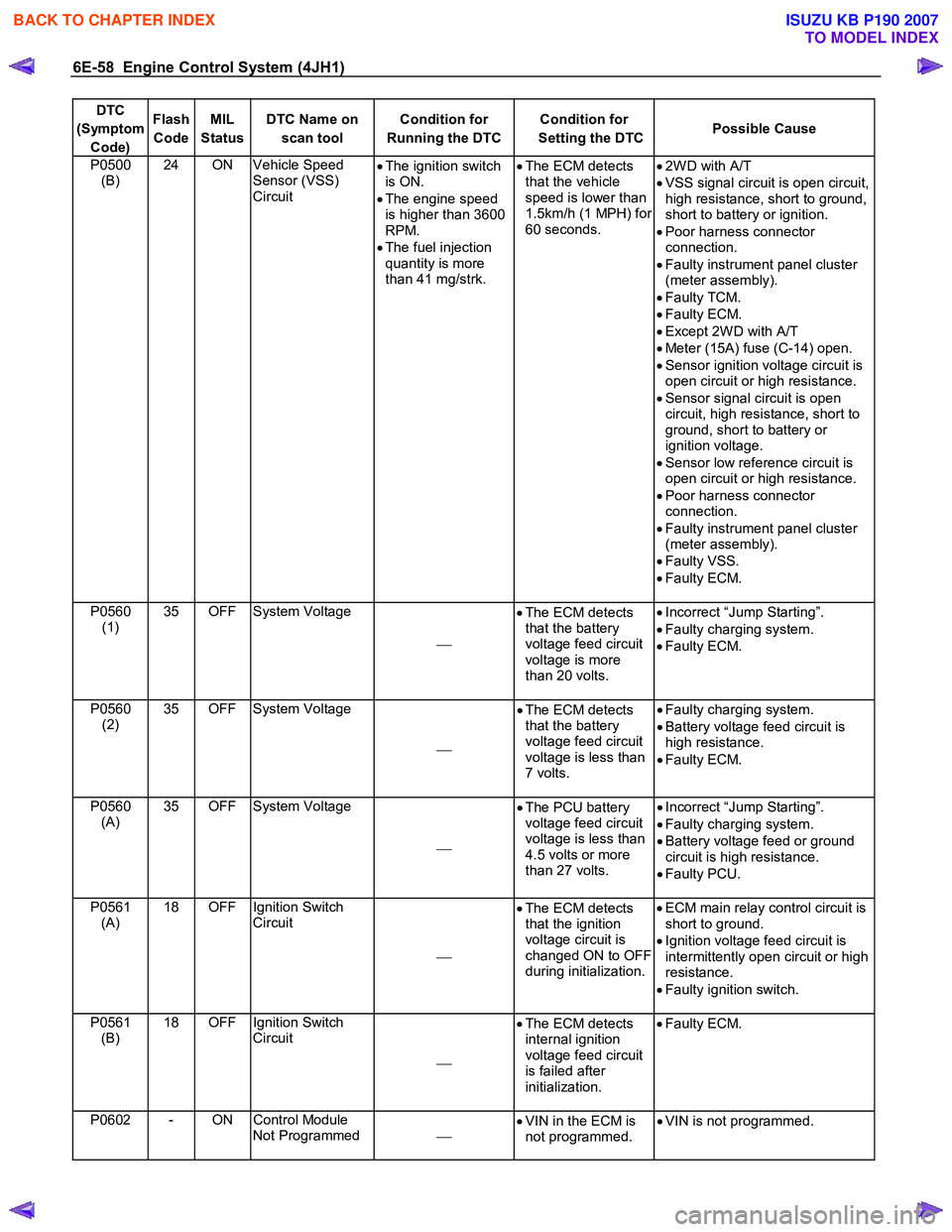

6E-58 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P0500

(B) 24 ON Vehicle Speed

Sensor (VSS)

Circuit

•

The ignition switch

is ON.

• The engine speed

is higher than 3600

RPM.

• The fuel injection

quantity is more

than 41 mg/strk.

•

The ECM detects

that the vehicle

speed is lower than

1.5km/h (1 MPH) for

60 seconds.

•

2W D with A/T

• VSS signal circuit is open circuit,

high resistance, short to ground,

short to battery or ignition.

• Poor harness connector

connection.

• Faulty instrument panel cluster

(meter assembly).

• Faulty TCM.

• Faulty ECM.

• Except 2W D with A/T

• Meter (15A) fuse (C-14) open.

• Sensor ignition voltage circuit is

open circuit or high resistance.

• Sensor signal circuit is open

circuit, high resistance, short to

ground, short to battery or

ignition voltage.

• Sensor low reference circuit is

open circuit or high resistance.

• Poor harness connector

connection.

• Faulty instrument panel cluster

(meter assembly).

• Faulty VSS.

• Faulty ECM.

P0560 (1) 35 OFF System Voltage

•

The ECM detects

that the battery

voltage feed circuit

voltage is more

than 20 volts.

•

Incorrect “Jump Starting”.

• Faulty charging system.

• Faulty ECM.

P0560 (2) 35 OFF System Voltage

•

The ECM detects

that the battery

voltage feed circuit

voltage is less than

7 volts.

•

Faulty charging system.

• Battery voltage feed circuit is

high resistance.

• Faulty ECM.

P0560 (A) 35 OFF System Voltage

•

The PCU battery

voltage feed circuit

voltage is less than

4.5 volts or more

than 27 volts.

•

Incorrect “Jump Starting”.

• Faulty charging system.

• Battery voltage feed or ground

circuit is high resistance.

• Faulty PCU.

P0561 (A) 18 OFF Ignition Switch

Circuit

•

The ECM detects

that the ignition

voltage circuit is

changed ON to OFF

during initialization.

•

ECM main relay control circuit is

short to ground.

• Ignition voltage feed circuit is

intermittently open circuit or high

resistance.

• Faulty ignition switch.

P0561 (B) 18 OFF Ignition Switch

Circuit

•

The ECM detects

internal ignition

voltage feed circuit

is failed after

initialization.

•

Faulty ECM.

P0602 - ON Control Module

Not Programmed

•

VIN in the ECM is

not programmed. •

VIN is not programmed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1200 of 6020

6E-166 Engine Control System (4JH1)

DTC P0560 (Symptom Code 1) (Flash Code 35)

Circuit Description

The engine control module (ECM) monitors the system

voltage on the ECM main relay load supply voltage

terminal to make sure that the voltage stays within the

proper range. If the ECM detects an excessively high

system voltage, this DTC will set.

Condition for Setting the DTC

• The ECM detects that the battery voltage feed

circuit voltage is more than 20 volts.

Action Taken When the DTC Sets

• The ECM does not illuminate the malfunction

indicator lamp (MIL) when the diagnostic runs and

fails.

Condition for Clearing the DTC • A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• A charging system problem may set this DTC.

• Jump starting the vehicle or a battery charger may

have set this DTC.

DTC P0560 (Symptom Code 1) (Flash Code 35)

Schematic Reference: Engine Controls Schematics &

Starting and Charging Schematics

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 W as the vehicle recently jump started from 24 volts system?

Go to Step 8 Go to Step 4

4 1. Start the engine and let idle for 30 seconds.

2. Observe the System Voltage parameter with the scan tool.

Is the System Voltage parameter less than the

specified value? 16 volts

Go to Diagnostic Aids Go to Step 5

5 Test the charging system. Refer to Diagnosis of The Charging System in the Charging System Section.

Did you find a charging system problem?

Go to Step 6 Go to Step 7

6 Repair the charging system. Refer to Diagnosis of The Charging System in the Charging System

Section.

Did you complete the repair?

Go to Step 8

7 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 8

8 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Observe the System Voltage parameter with the scan tool.

Is the System Voltage parameter less than the

specified value? 16 volts

Go to Step 9 Go to Step 5

9 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007