ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2101 of 6020

ENGINE MECHANICAL (C24SE) 6A-87

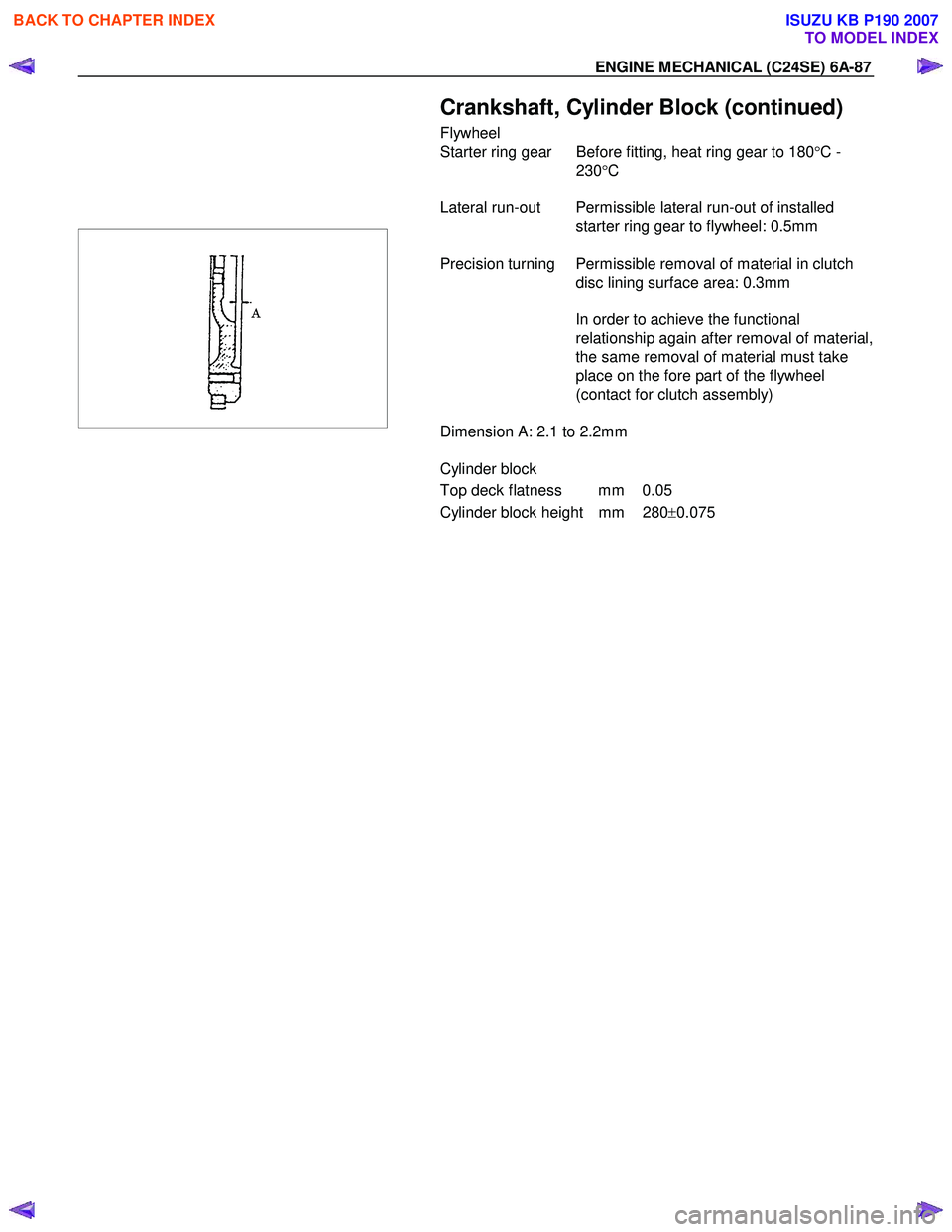

Crankshaft, Cylinder Block (continued)

Flywheel

Starter ring gear Before fitting, heat ring gear to 180 °C -

230 °C

Lateral run-out Permissible lateral run-out of installed

starter ring gear to flywheel: 0.5mm

Precision turning Permissible removal of material in clutch disc lining surface area: 0.3mm

In order to achieve the functional

relationship again after removal of material,

the same removal of material must take

place on the fore part of the flywheel

(contact for clutch assembly)

Dimension A: 2.1 to 2.2mm

Cylinder block

Top deck flatness mm 0.05

Cylinder block height mm 280 ±0.075

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2102 of 6020

6A-88 ENGINE MECHANICAL (C24SE)

Recommended Torque Values

N⋅m (kgf ⋅m)

Bearing cover to cylinder block ........................................................................................ 60

1) 6.1 +40 ° to 50 °

Bracket for alternator to cylinder block ............................................................................ 40 4.1

Bracket for engine damping block to transmission .......................................................... 60

2) 6.1

Bracket for engine damping block to engine block .......................................................... 60 6.1

Bracket for pump/compressor to engine block ................................................................ 35 3.6

Camshaft housing cover to housing ................................................................................ 8 0.8

Camshaft timing gear to camshaft ................................................................................... 50 5.1

Clamping bracket for alternator to intake manifold .......................................................... 25 2.5

Clamping bracket to alternator ......................................................................................... 25 2.5

Con-rod bearing cap to con-rod ....................................................................................... 35

1) 3.5 +45 ° to 60 °

Crankshaft pulley bolts ..................................................................................................... 2 0 2.0

Cylinder head to cylinder block ........................................................................................ 25

1)2) 2.5 +90 ° +90 °

+90 °

Engine damping block to engine bracket ......................................................................... 85 8.7

Engine damping block to side member ............................................................................ 52

1) 5.3

Exhaust manifold to cylinder head ................................................................................... 22 2.2

1) Use new bolts

2) Use new locking plates

Recommended Torque Values

N⋅m (kgf ⋅m)

Flywheel to crankshaft ..................................................................................................... 65

1) 6.6 +30° to 45 °

Front exhaust pipe to exhaust manifold ........................................................................... 25 2.5

Guide sleeve for pressure bearing to transmission ......................................................... 22 2.2

Intake manifold to cylinder head ...................................................................................... 22 2.2

Lower alternator bracket .................................................................................................. 25 2.5

Oil drain plug to oil pan .................................................................................................... 45 4.6

Oil intake pipe bracket to cylinder block ........................................................................... 6

2) 0.6

Oil intake pipe to oil pump ................................................................................................ 8 0.8

Oil pan to cylinder block ................................................................................................... 8

2)3) 0.8

Bearing bridge to cylinder block ....................................................................................... 8 2)3) 0.8

Oil pressure switch to oil pump ........................................................................................ 30 3.2

Pump for power steering (ribbed V-belt) to engine block ................................................. 30 3.2

Spark plugs in cylinder head ............................................................................................ 20 2. 3

Starter support to cylinder block ...................................................................................... 25 2.5

Starter to cylinder block - engine side .............................................................................. 45 4.6

Starter to cylinder block - transmission side .................................................................... 75 7.6

Thermostat housing to cylinder head ............................................................................... 15 1.5

Toothed belt drive gear to crankshaft .............................................................................. 130

1) 13.3

Toothed belt front cover ................................................................................................... 4 0.4

Toothed belt rear cover .................................................................................................... 6 0.6

Toothed belt tension roller to oil pump ............................................................................. 20 2.3 (M10) ............................................................................ 45 4.6

Transmission to engine block ......................................................................................... 76 7.7 (M12) ............................................................................ 60 6.1

W ater pump to cylinder block .......................................................................................... 17 1.7

1) Use new bolts

2) Use Locking Compound

3) Maximum installation time - 10 minutes

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2103 of 6020

ENGINE MECHANICAL (C24SE) 6A-89

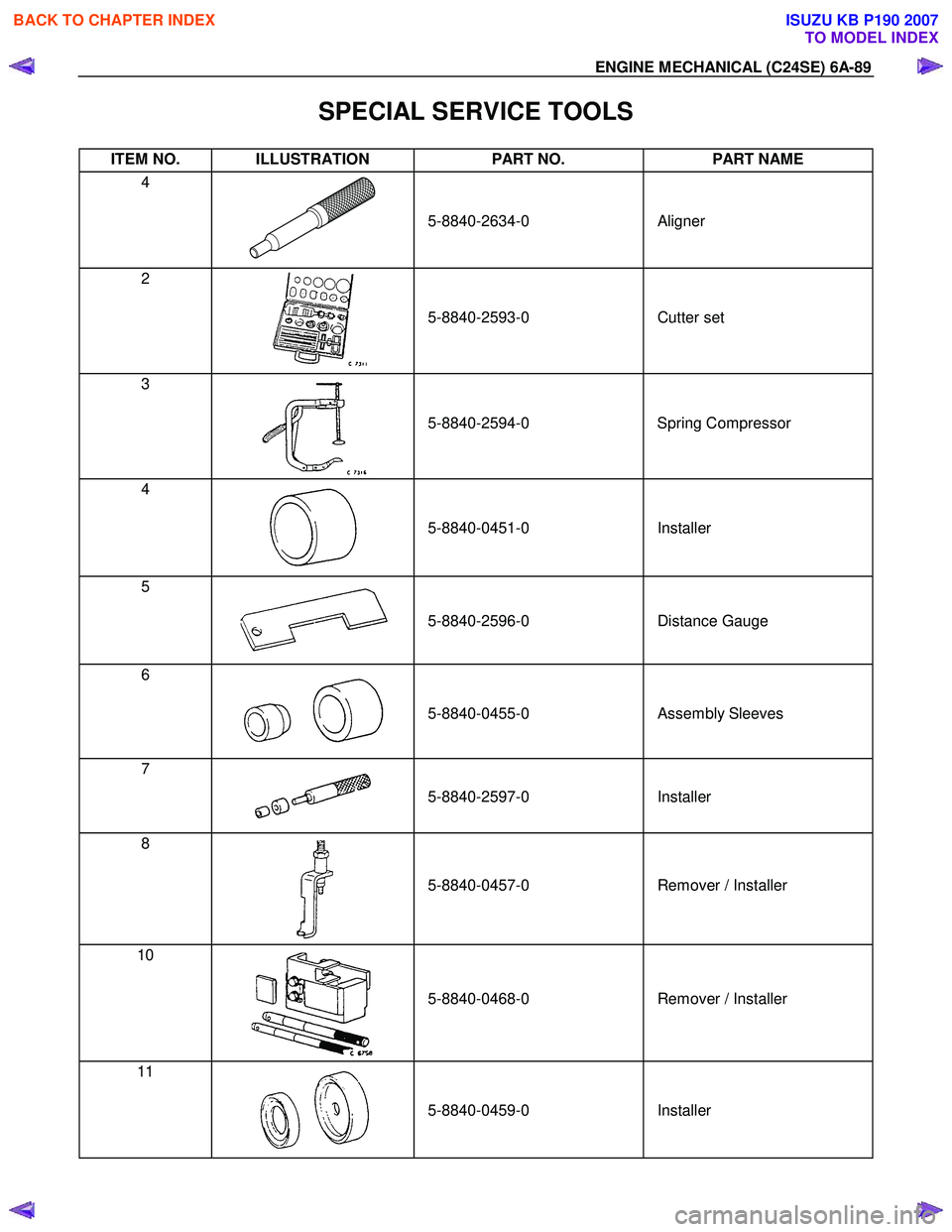

SPECIAL SERVICE TOOLS

ITEM NO. ILLUSTRATION PART NO. PART NAME

4

5-8840-2634-0

Aligner

2

5-8840-2593-0

Cutter set

3

5-8840-2594-0

Spring Compressor

4

5-8840-0451-0

Installer

5

5-8840-2596-0

Distance Gauge

6

5-8840-0455-0

Assembly Sleeves

7

5-8840-2597-0

Installer

8

5-8840-0457-0

Remover / Installer

10

5-8840-0468-0

Remover / Installer

11

5-8840-0459-0

Installer

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2104 of 6020

6A-90 ENGINE MECHANICAL (C24SE)

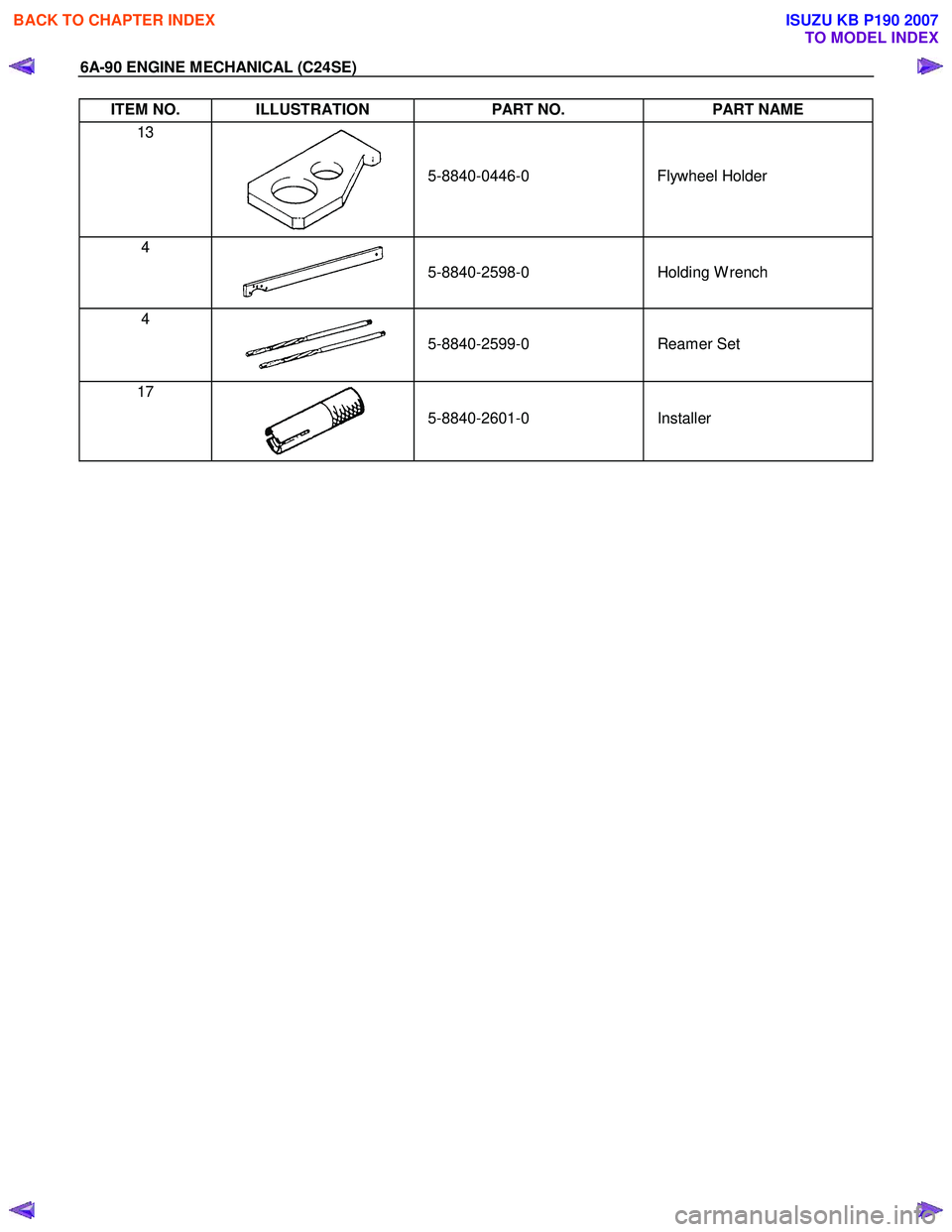

ITEM NO. ILLUSTRATION PART NO. PART NAME

13

5-8840-0446-0

Flywheel Holder

4

5-8840-2598-0

Holding W rench

4

5-8840-2599-0

Reamer Set

17

5-8840-2601-0

Installer

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2105 of 6020

ENGINE COOLING 6B-1

SECTION 6B

ENGINE COOLING

TABLE OF CONTENTS

PAGE

General Description ....................................................................................................... 6B- 2

Service Precaution ......................................................................................................... 6B- 3

Diagnosis ...................................................................................................................... .. 6B- 5

Draining and Refilling Cooling System ........................................................................ 6B- 6

Water Pump .................................................................................................................... 6B- 7

Water Pump and Associated Parts .......................................................................... 6B- 7

Removal ...................................................................................................................... 6 B- 7

Inspection ................................................................................................................... 6 B- 7

Installation .................................................................................................................. 6B- 8

Thermostat ..................................................................................................................... . 6B- 9

Removal ...................................................................................................................... 6 B- 9

Inspection ................................................................................................................... 6 B- 9

Installation .................................................................................................................. 6B- 9

Fan clutch with Cooling Fan.......................................................................................... 6B- 9 Inspection and Repair ............................................................................................... 6B- 9

Radiator ....................................................................................................................... .... 6B-11

Radiator and Associated Parts ................................................................................. 6B-11

Removal ...................................................................................................................... 6 B-11

Inspection ................................................................................................................... 6 B-12

Installation .................................................................................................................. 6B-13

Main Data and Specifications ........................................................................................ 6B-13

Special Service Tool....................................................................................................... 6B- 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2106 of 6020

6B-2 ENGINE COOLING

General Description

Legend

1 W ater Pump

2 Thermostat

3 Radiator

4 Reserve Tank 5 Coolant Distributor

6 Cylinder Block and Head

7 Throttle Body

8 Heater

The Cooling System is a pressurized type, where the water

pump, which is cambelt driven, forces the circulation of

the coolant through the cylinder block and head. The

thermostat regulates the flow of coolant between the

radiator and the bypass circuit. The heater is part of the

bypass circuit. The throttle body pre-heat is a separate

circuit which is not regulated by the thermostat. An oil

cooler may be fitted as part of this circuit.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2107 of 6020

ENGINE COOLING 6B-3

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

Water pump

The water pump is centrifugal type and is driven by timing belt.

Thermostat

The thermostat is a bypass type and is a wax pellet type with a

air hole.

110RS001

Radiator

The radiator is a flow type with corrugated fins.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2108 of 6020

6B-4 ENGINE COOLING

Antifreeze Solution

• Calculating mixing ratio

Mixing ratio

= Antifreeze solution (Lit/gal.)

Antifreeze solution (Lit/gal.) + W ater (Lit/gal.)

NOTE: Antifreeze solution + W ater = Total cooling system

capacity.

• Total Cooling System Capacity

8Lit

• Mixing ratio

Check the specific gravity of engine coolant in the cooling system temperature ranges from 0 °C to 50 °C using a

suction type hydrometer, then determine the density of the

engine coolant by referring to the table.

NOTE: The LLC is 50% at all environment in order to prevent

the corrosion of cooling system parts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2109 of 6020

ENGINE COOLING 6B-5

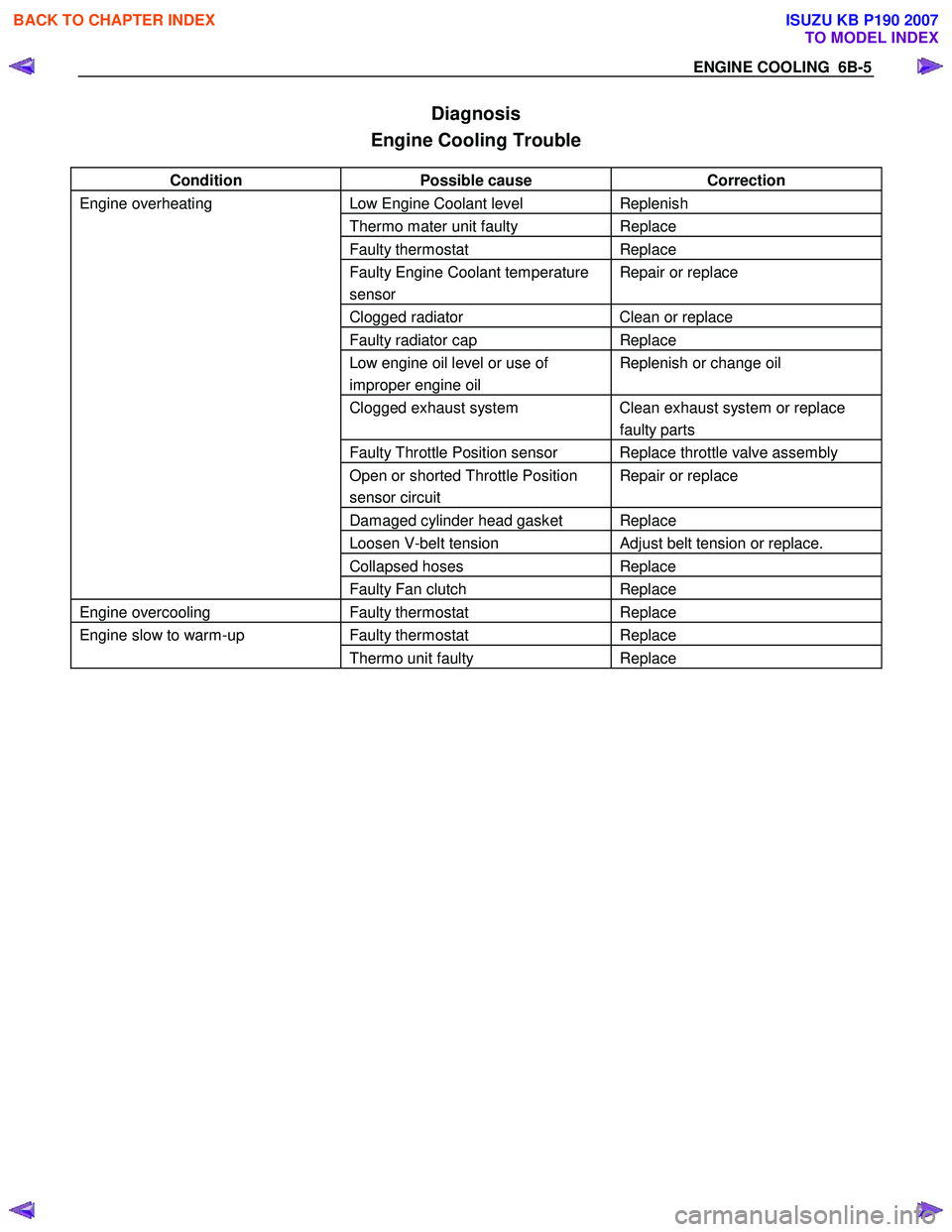

Diagnosis

Engine Cooling Trouble

Condition Possible cause Correction

Engine overheating Low Engine Coolant level Replenish

Thermo mater unit faulty Replace

Faulty thermostat Replace

Faulty Engine Coolant temperature

sensor Repair or replace

Clogged radiator Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of

improper engine oil Replenish or change oil

Clogged exhaust system Clean exhaust system or replace

faulty parts

Faulty Throttle Position sensor Replace throttle valve assembly

Open or shorted Throttle Position

sensor circuit Repair or replace

Damaged cylinder head gasket Replace

Loosen V-belt tension Adjust belt tension or replace.

Collapsed hoses Replace

Faulty Fan clutch Replace

Engine overcooling Faulty thermostat Replace

Engine slow to warm-up Faulty thermostat Replace

Thermo unit faulty Replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2110 of 6020

6B-6 ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system and

perform any necessary service to ensure that it is clean, does

not leak and is in proper working order. The engine coolant

level should be between the "MIN" and "MAX" lines of reserve

tank when the engine is cold. If low, check for leakage and add

engine coolant up to the "MAX" line. There should not be any

excessive deposit of rust or scales around the radiator cap or

radiator filler hole, and the engine coolant should also be free

from oil.

Replace the engine coolant if excessively dirty.

1. Completely drain the cooling system by opening the drain

plug at the bottom of the radiator.

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING BURNED,

DO NOT REMOVE THE CAP WHILE THE ENGINE AND

RADIATOR ARE STILL HOT. SCALDING FLUID AND

STEAM CAN BE BLOWN OUT UNDER PRESSURE.

3. Disconnect all hoses from the engine coolant reserve tank.

Scrub and clean the inside of the reserve tank with soap and water. Flush it well with clean water, then drain it. Install

the reserve tank and hoses.

4. Refill the cooling system with the engine coolant using a solution that is at least 50 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the engine coolant reserve tank to "MAX" line when the engine is cold.

6. Block the drive wheels and firmly apply the parking brake and place the shift lever in the "NEUTRAL" position.

7. Remove the radiator cap. Start the engine and warm it up at 2,500 - 3,000 rpm for about 30 minutes.

8. W hen the air comes out from the radiator filler neck and the engine coolant level has gone down, replenish with the

engine coolant. Repeat this procedure until the engine

coolant level does not go down. Then stop the engine and

install the radiator cap. Let the engine cool down.

9. After the engine has cooled, replenish with engine coolant up to the "MAX" line of the reserve tank.

10. Start the engine. W ith the engine running at 3,000 rpm, make sure there is no running water sound from the heate

r

core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to 10.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007