indicator ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4743 of 6020

7B1-24 Manual Transmission (MUX)

Clutch Hub Spline Play• Set a dial indicator to the clutch hub to be measured.

• Move the clutch hub as far as possible to both the right and the left.

Note the dial indicator reading.

If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Counter Gear Spline Play

Refer to Counter Shaft Assembly in this section.

Installation

1. Use a pair of snap ring pliers to hold the new input middle bearing snap ring open .

Install the input shaft assembly to the intermediate

plate.

• Never reinstall the used snap ring.

2. Install the input middle bearing snap ring.

3. Install the 5th input gear needle bearing. (2 piece type)

4. Install the 5th input gear assembly. • Apply engine oil to the gear internal surface.

5. Assemble the 5th synchronizer assembly by performing the following steps.

• Turn the clutch hub face (2) toward the sleeve groove (1) (rear side) on the outer

circumference. • Check that the inserts (3) fit snugly into the

clutch hub (6) ring insert grooves.

• Check that the inserts springs (4) are fitted to the inserts as shown in the figure.

• Check that the clutch hub (6) and the sleeve (5) slide smoothly.

• The insert springs (4) must be set in such a way that the opening of spring faces different

direction.

6. Install the 5th block ring and 5th synchronizer assembly.

7. Install the new 5th hub snap ring (1).

• Never reinstall the used snap ring.

• Choose the thickest snap ring among ones whitch can be assembled.

Snap Ring Availability

Standard

Limit

3rd - 4th 0.010 - 0.102 mm

(0.0004 - 0.0040 in) 0.15 mm

(0.0059 in)

5th 0.009 - 0.104 mm

(0.0004 - 0.0041 in) 0.15 mm

(0.0059 in)

LNW25CSH029101

Thickness Identification color

1.95 mm(0.077 in) No color

2.10 mm(0.083 in) Yellow

1

2

LNW25CSH025601

3 45

6

LNW25CSH025701

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4760 of 6020

Manual Transmission (MUX) 7B1-41

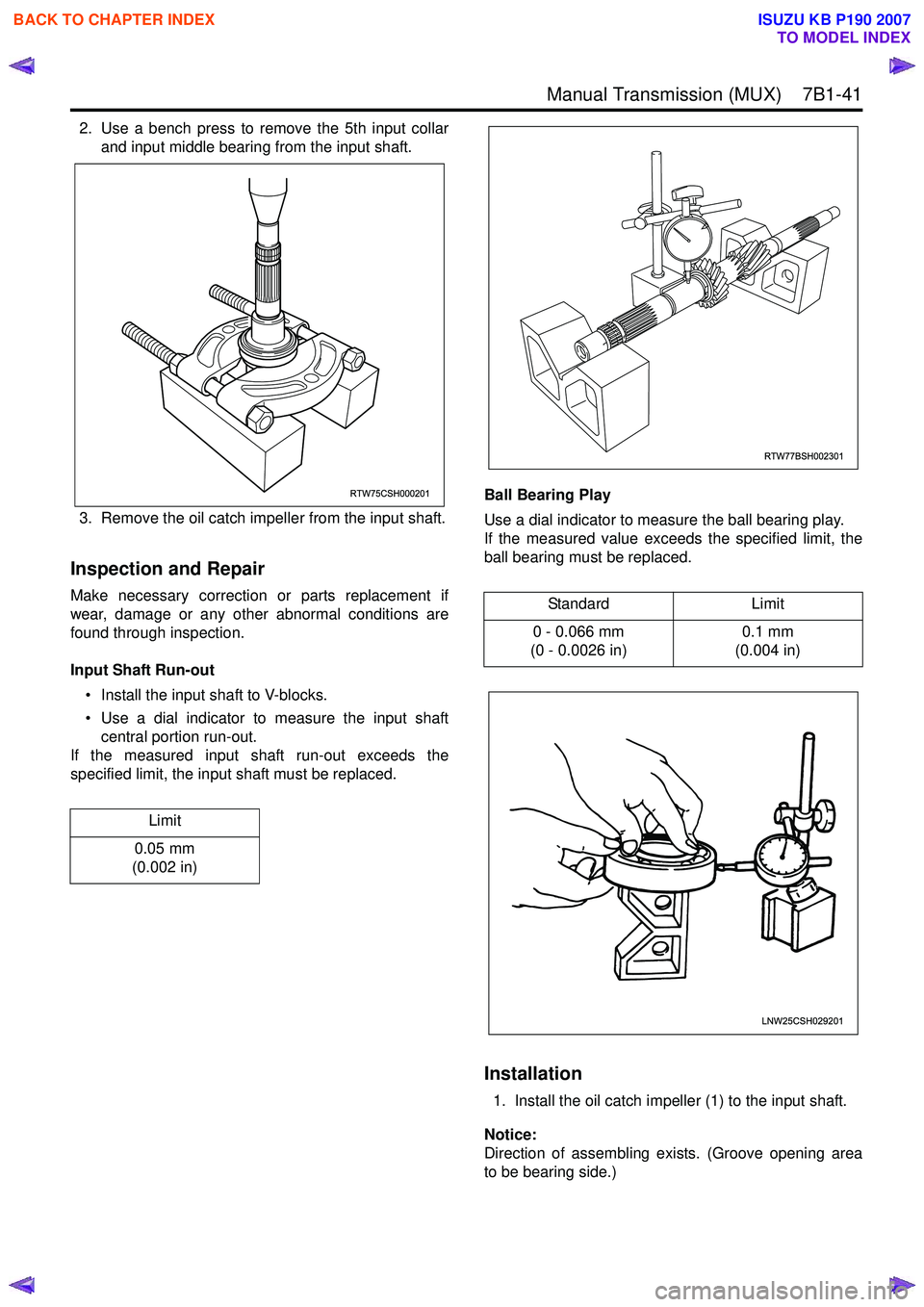

2. Use a bench press to remove the 5th input collarand input middle bearing from the input shaft.

3. Remove the oil catch impeller from the input shaft.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage or any other abnormal conditions are

found through inspection.

Input Shaft Run-out • Install the input shaft to V-blocks.

• Use a dial indicator to measure the input shaft central portion run-out.

If the measured input shaft run-out exceeds the

specified limit, the input shaft must be replaced. Ball Bearing Play

Use a dial indicator to measure the ball bearing play.

If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Installation

1. Install the oil catch impeller (1) to the input shaft.

Notice:

Direction of assembling exists. (Groove opening area

to be bearing side.)

Limit

0.05 mm

(0.002 in)

RTW75CSH000201

Standard Limit

0 - 0.066 mm

(0 - 0.0026 in) 0.1 mm

(0.004 in)

RTW77BSH002301

LNW25CSH029201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4764 of 6020

Manual Transmission (MUX) 7B1-45

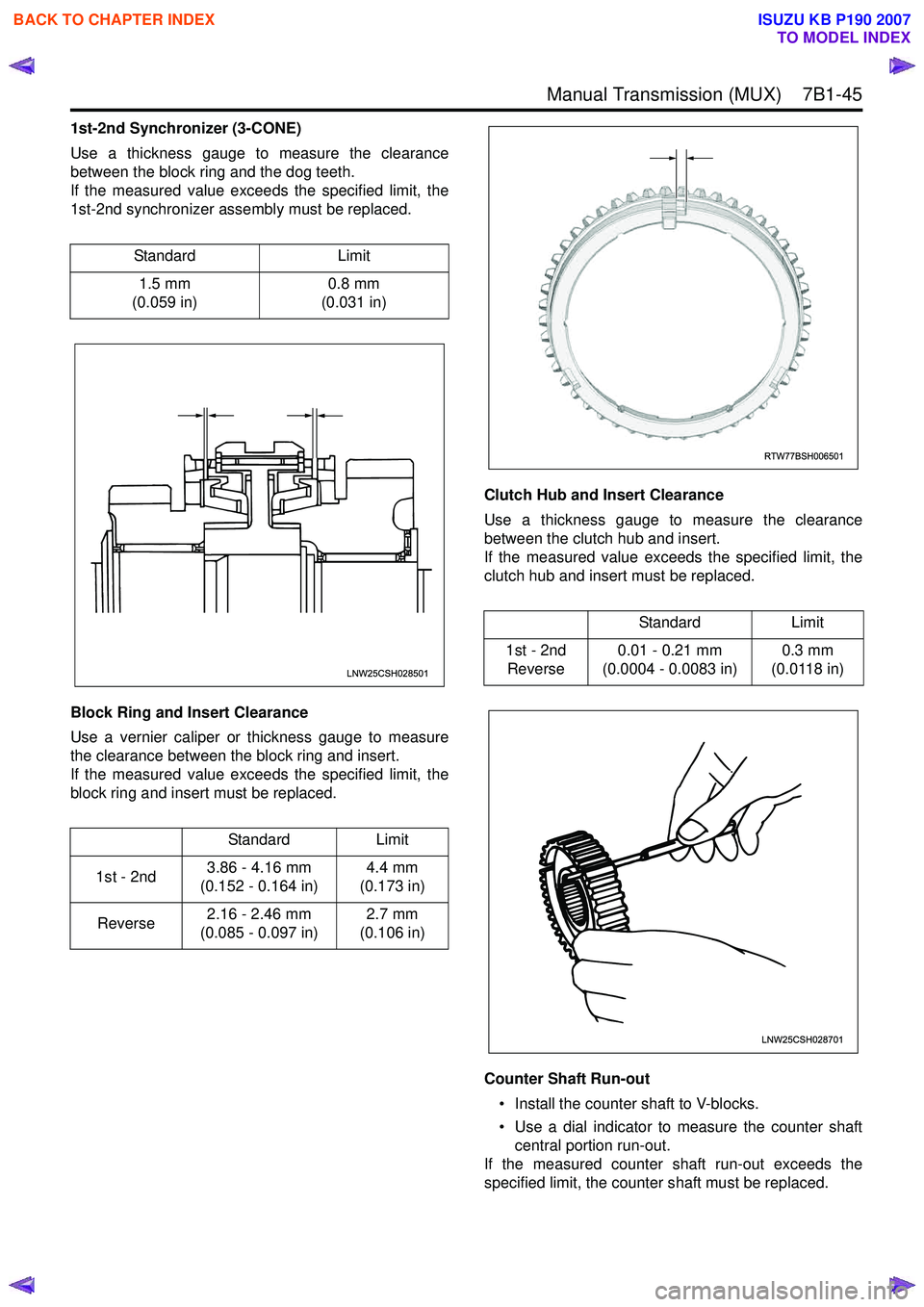

1st-2nd Synchronizer (3-CONE)

Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

If the measured value exceeds the specified limit, the

1st-2nd synchronizer assembly must be replaced.

Block Ring and Insert Clearance

Use a vernier caliper or thickness gauge to measure

the clearance between the block ring and insert.

If the measured value exceeds the specified limit, the

block ring and insert must be replaced. Clutch Hub and Insert Clearance

Use a thickness gauge to measure the clearance

between the clutch hub and insert.

If the measured value exceeds the specified limit, the

clutch hub and insert must be replaced.

Counter Shaft Run-out • Install the counter shaft to V-blocks.

• Use a dial indicator to measure the counter shaft central portion run-out.

If the measured counter shaft run-out exceeds the

specified limit, the counter shaft must be replaced.

Standard Limit

1.5 mm

(0.059 in) 0.8 mm

(0.031 in)

Standard Limit

1st - 2nd 3.86 - 4.16 mm

(0.152 - 0.164 in) 4.4 mm

(0.173 in)

Reverse 2.16 - 2.46 mm

(0.085 - 0.097 in) 2.7 mm

(0.106 in)

LNW25CSH028501

Standard Limit

1st - 2nd Reverse 0.01 - 0.21 mm

(0.0004 - 0.0083 in) 0.3 mm

(0.0118 in)

RTW77BSH006501

LNW25CSH028701

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4765 of 6020

7B1-46 Manual Transmission (MUX)

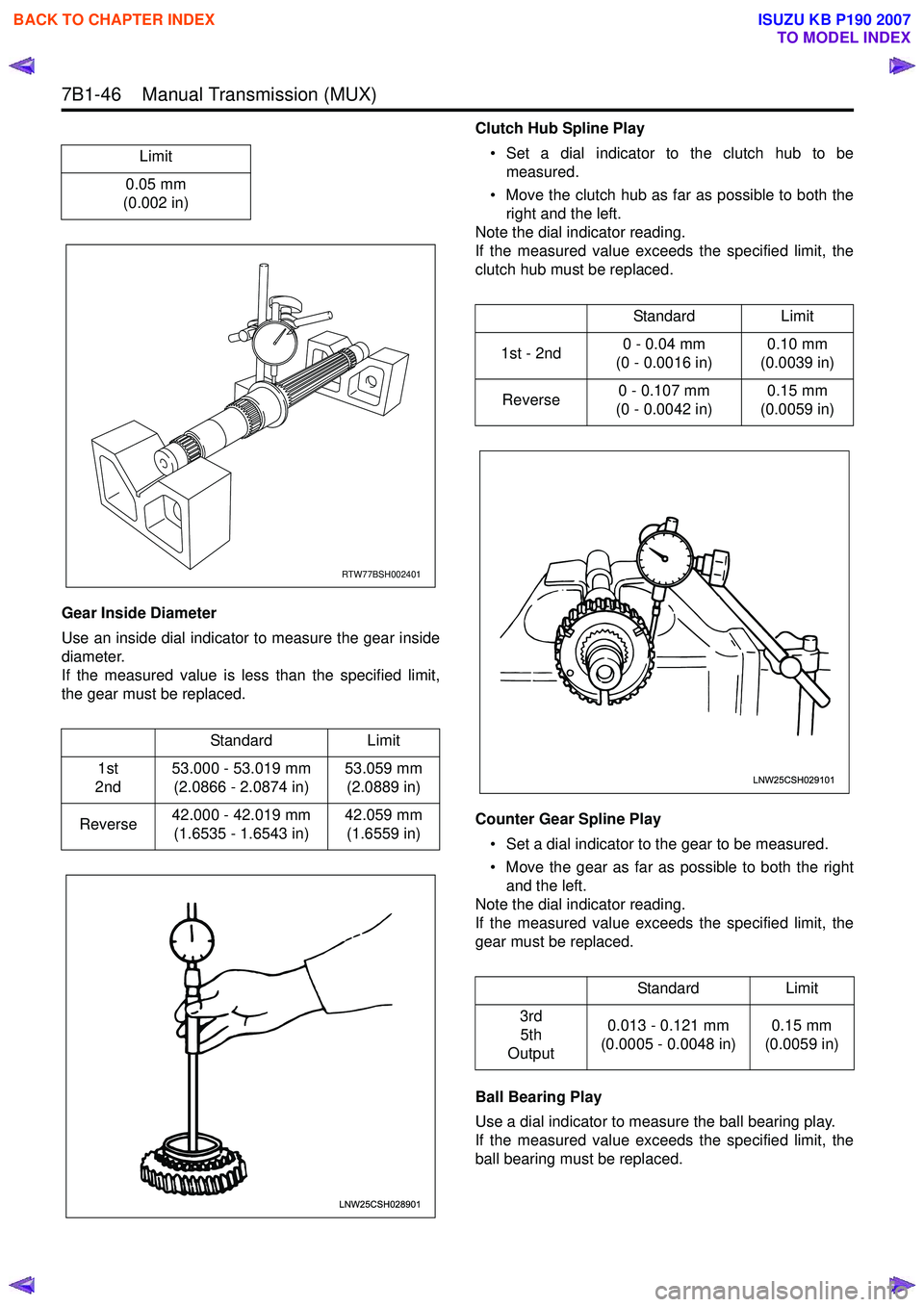

Gear Inside Diameter

Use an inside dial indicator to measure the gear inside

diameter.

If the measured value is less than the specified limit,

the gear must be replaced. Clutch Hub Spline Play

• Set a dial indicator to the clutch hub to be measured.

• Move the clutch hub as far as possible to both the right and the left.

Note the dial indicator reading.

If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Counter Gear Spline Play

• Set a dial indicator to the gear to be measured.

• Move the gear as far as possible to both the right and the left.

Note the dial indicator reading.

If the measured value exceeds the specified limit, the

gear must be replaced.

Ball Bearing Play

Use a dial indicator to measure the ball bearing play.

If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Limit

0.05 mm

(0.002 in)

Standard Limit

1st

2nd 53.000 - 53.019 mm

(2.0866 - 2.0874 in) 53.059 mm

(2.0889 in)

Reverse 42.000 - 42.019 mm

(1.6535 - 1.6543 in) 42.059 mm

(1.6559 in)

RTW77BSH002401

LNW25CSH028901

Standard Limit

1st - 2nd 0 - 0.04 mm

(0 - 0.0016 in) 0.10 mm

(0.0039 in)

Reverse 0 - 0.107 mm

(0 - 0.0042 in) 0.15 mm

(0.0059 in)

Standard Limit

3rd 5th

Output 0.013 - 0.121 mm

(0.0005 - 0.0048 in) 0.15 mm

(0.0059 in)

LNW25CSH029101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4809 of 6020

CLUTCH 7C-31

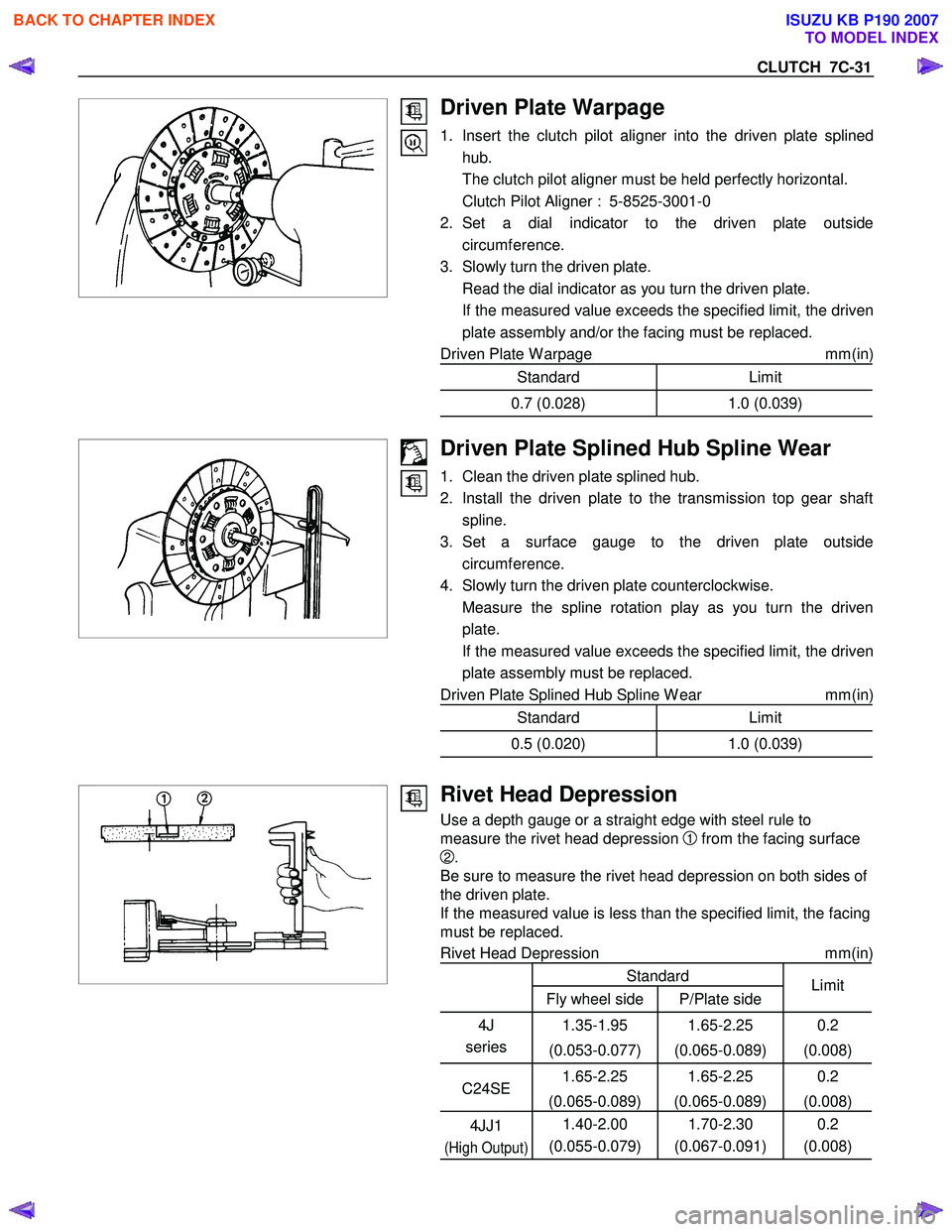

Driven Plate Warpage

1. Insert the clutch pilot aligner into the driven plate splinedhub.

The clutch pilot aligner must be held perfectly horizontal.

Clutch Pilot Aligner : 5-8525-3001-0

2. Set a dial indicator to the driven plate outside circumference.

3. Slowly turn the driven plate.

Read the dial indicator as you turn the driven plate.

If the measured value exceeds the specified limit, the driven plate assembly and/or the facing must be replaced.

Driven Plate W arpage mm(in)

Standard Limit

0.7 (0.028)1.0 (0.039)

Driven Plate Splined Hub Spline Wear

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear shaft spline.

3. Set a surface gauge to the driven plate outside circumference.

4. Slowly turn the driven plate counterclockwise.

Measure the spline rotation play as you turn the driven plate.

If the measured value exceeds the specified limit, the driven plate assembly must be replaced.

Driven Plate Splined Hub Spline W ear mm(in)

Standard Limit

0.5 (0.020)1.0 (0.039)

Rivet Head Depression

Use a depth gauge or a straight edge with steel rule to

measure the rivet head depression

1 from the facing surface

2.

Be sure to measure the rivet head depression on both sides of

the driven plate.

If the measured value is less than the specified limit, the facing

must be replaced.

Rivet Head Depression mm(in)

Standard

Fly wheel side P/Plate side Limit

4J

series 1.35-1.95

(0.053-0.077) 1.65-2.25

(0.065-0.089) 0.2

(0.008)

C24SE 1.65-2.25

(0.065-0.089) 1.65-2.25

(0.065-0.089) 0.2

(0.008)

4JJ1

(High Output)

1.40-2.00

(0.055-0.079) 1.70-2.30

(0.067-0.091) 0.2

(0.008)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4814 of 6020

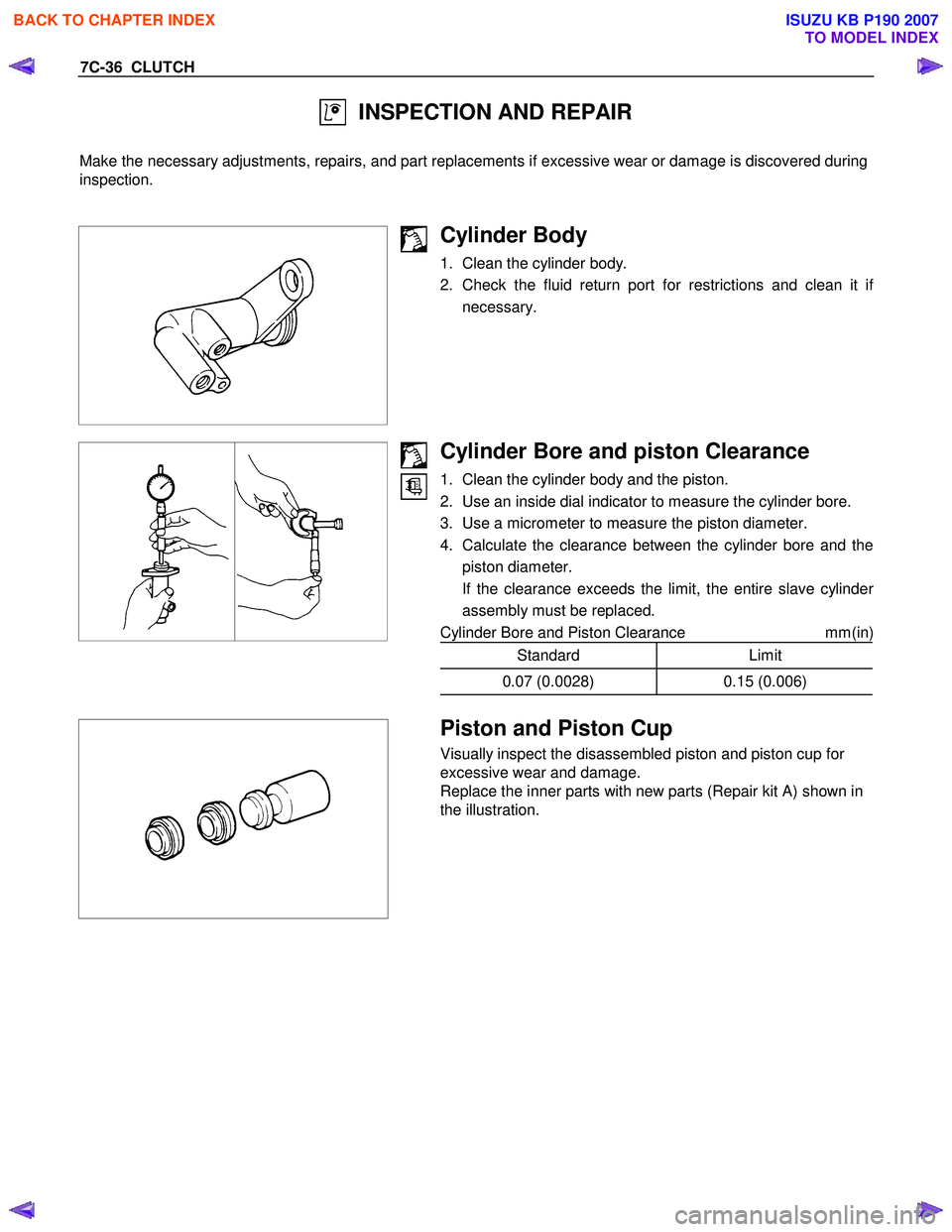

7C-36 CLUTCH

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Cylinder Body

1. Clean the cylinder body.

2. Check the fluid return port for restrictions and clean it i

f

necessary.

Cylinder Bore and piston Clearance

1. Clean the cylinder body and the piston.

2. Use an inside dial indicator to measure the cylinder bore.

3. Use a micrometer to measure the piston diameter.

4. Calculate the clearance between the cylinder bore and the piston diameter.

If the clearance exceeds the limit, the entire slave cylinde

r

assembly must be replaced.

Cylinder Bore and Piston Clearance mm(in)

Standard Limit

0.07 (0.0028)0.15 (0.006)

Piston and Piston Cup

Visually inspect the disassembled piston and piston cup for

excessive wear and damage.

Replace the inner parts with new parts (Repair kit A) shown in

the illustration.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4833 of 6020

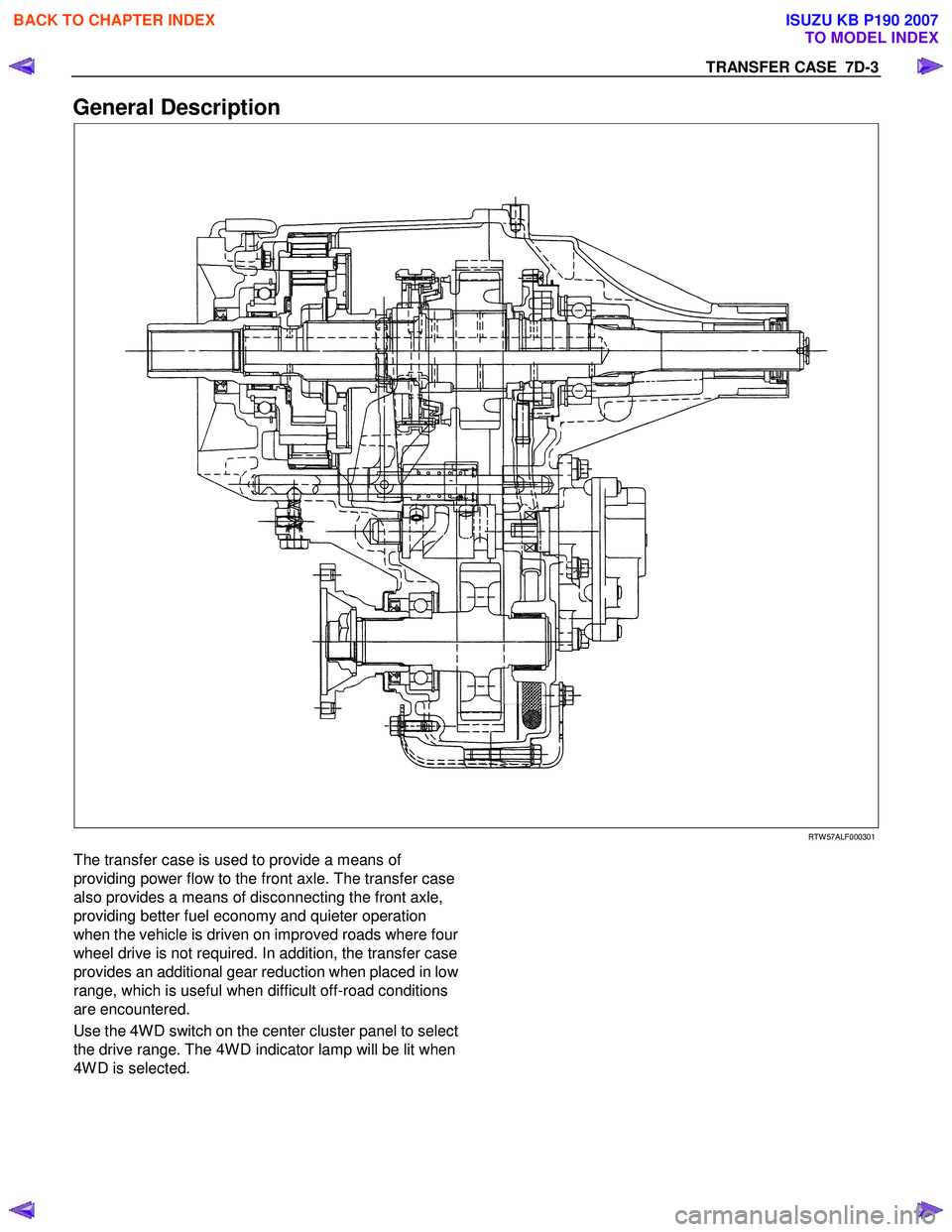

TRANSFER CASE 7D-3

General Description

RTW 57ALF000301

The transfer case is used to provide a means of

providing power flow to the front axle. The transfer case

also provides a means of disconnecting the front axle,

providing better fuel economy and quieter operation

when the vehicle is driven on improved roads where fou

r

wheel drive is not required. In addition, the transfer case

provides an additional gear reduction when placed in lo

w

range, which is useful when difficult off-road conditions

are encountered.

Use the 4W D switch on the center cluster panel to select

the drive range. The 4W D indicator lamp will be lit when

4W D is selected.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4842 of 6020

7D-12 TRANSFER CASE

Removal

NOTE: Before removing transmission and transfer

assembly from vehicle, change the transfer mode to

2W D using the 4W D push button switch on dash panel.

1. Disconnect battery ground cable.

2. Raise and support vehicle with suitable stands. Drain

transfer case fluid.

3. Remove rear propeller shaft and front propeller shaft.

NOTE: Apply alignment marks on the flange at both front

and rear sides.

4. Disconnect harness connectors and clip.

Connector: transfer switch, 2W D-4W D actuator,

speed sensor.

NOTE: Avoid turning the vehicle ignition switch to the ON

position when the 2W D-4W D connector is removed

(battery connected).

If the ignition switch must be turned to the ON position,

the controller must first be removed (memory must be

cleared because the CHECK 4W D INDICATOR will

light).

5. Remove transfer case assembly from the vehicle.

Installation

1. Apply a thin coat of molybdenum disulfide grease to

the input shaft spline as shown in the figure.

260R300001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4858 of 6020

7D-28 TRANSFER CASE

Oil Pump

• Remove foreign materials from the strainer. If the

strainer is damaged, replace it.

If the area into which the shaft is inserted is excessively

worn or damaged, replace the oil pump assembly.

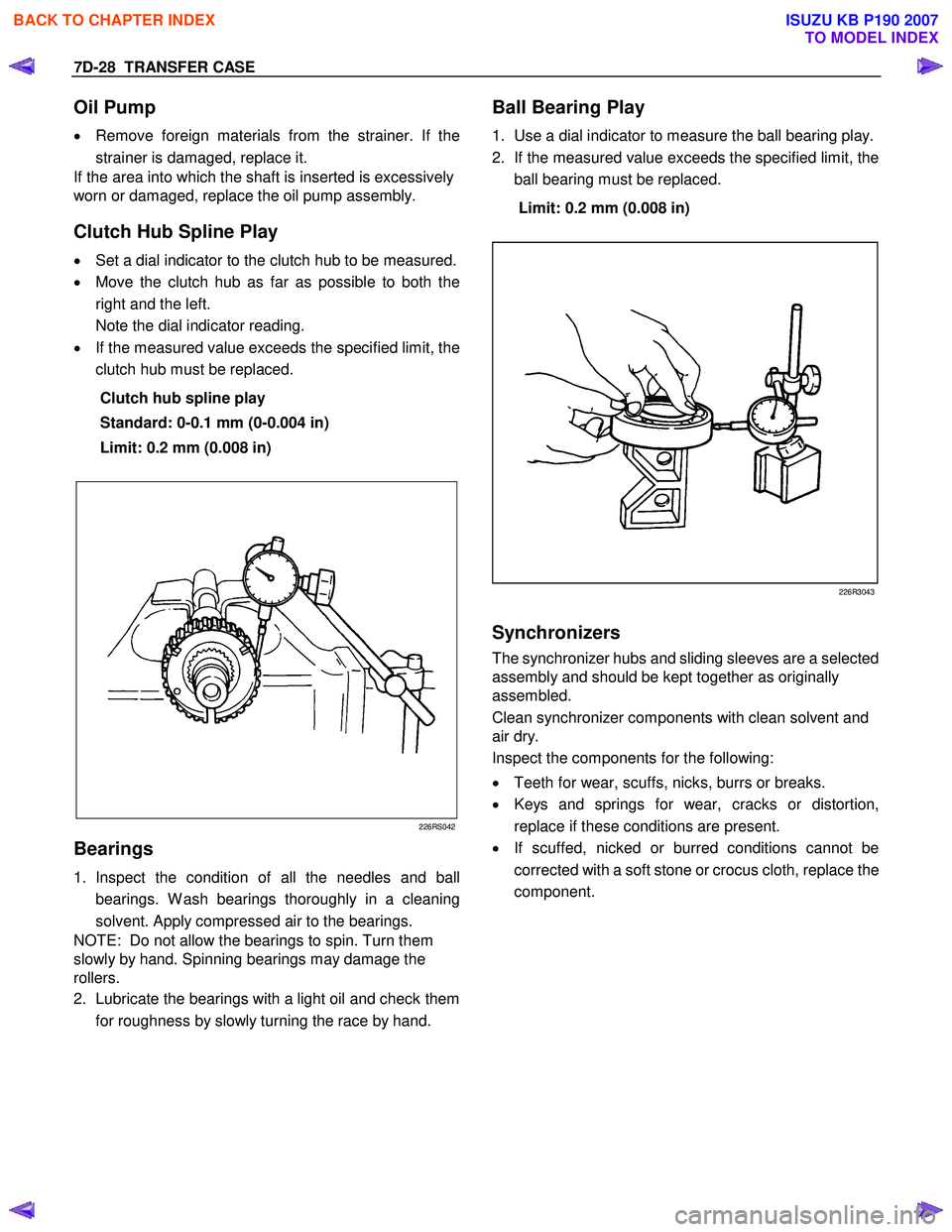

Clutch Hub Spline Play

• Set a dial indicator to the clutch hub to be measured.

• Move the clutch hub as far as possible to both the

right and the left.

Note the dial indicator reading.

• If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch hub spline play

Standard: 0-0.1 mm (0-0.004 in)

Limit: 0.2 mm (0.008 in)

226RS042

Bearings

1. Inspect the condition of all the needles and ball

bearings. W ash bearings thoroughly in a cleaning

solvent. Apply compressed air to the bearings.

NOTE: Do not allow the bearings to spin. Turn them

slowly by hand. Spinning bearings may damage the

rollers.

2. Lubricate the bearings with a light oil and check them

for roughness by slowly turning the race by hand.

Ball Bearing Play

1. Use a dial indicator to measure the ball bearing play.

2. If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Limit: 0.2 mm (0.008 in)

226R3043

Synchronizers

The synchronizer hubs and sliding sleeves are a selected

assembly and should be kept together as originally

assembled.

Clean synchronizer components with clean solvent and

air dry.

Inspect the components for the following:

• Teeth for wear, scuffs, nicks, burrs or breaks.

• Keys and springs for wear, cracks or distortion,

replace if these conditions are present.

• If scuffed, nicked or burred conditions cannot be

corrected with a soft stone or crocus cloth, replace the

component.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4875 of 6020

TRANSFER CONTROL SYSTEM 7D1-1

SECTION 7D1

TRANSFER CONTROL SYSTEM

TABLE OF CONTENTS

PAGE

Service Precaution ..................................................................................................... 7D1 - 2

General Description ................................................................................................... 7D1 - 3

System Components .................................................................................................. 7D1 - 5 Parts Location ....................................................................................................... 7D1 - 5

Functions of Switch and Indicator Lamp ................................................................. 7D1 - 12

Parts Location ............................................................................................................ 7D1 - 24

Circuit Diagram ........................................................................................................... 7D1 - 33

Connector List ............................................................................................................ 7D1 - 41

Diagnosis .................................................................................................................... 7D1 - 46

Before determining a trouble (Non-trouble mode) ............................................ 7D1 - 46

Memory erasing procedure ....................................................................................... 7D1 - 52

Diagnosis from symptom ........................................................................................... 7D1 - 54

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007