clock ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1003 of 6020

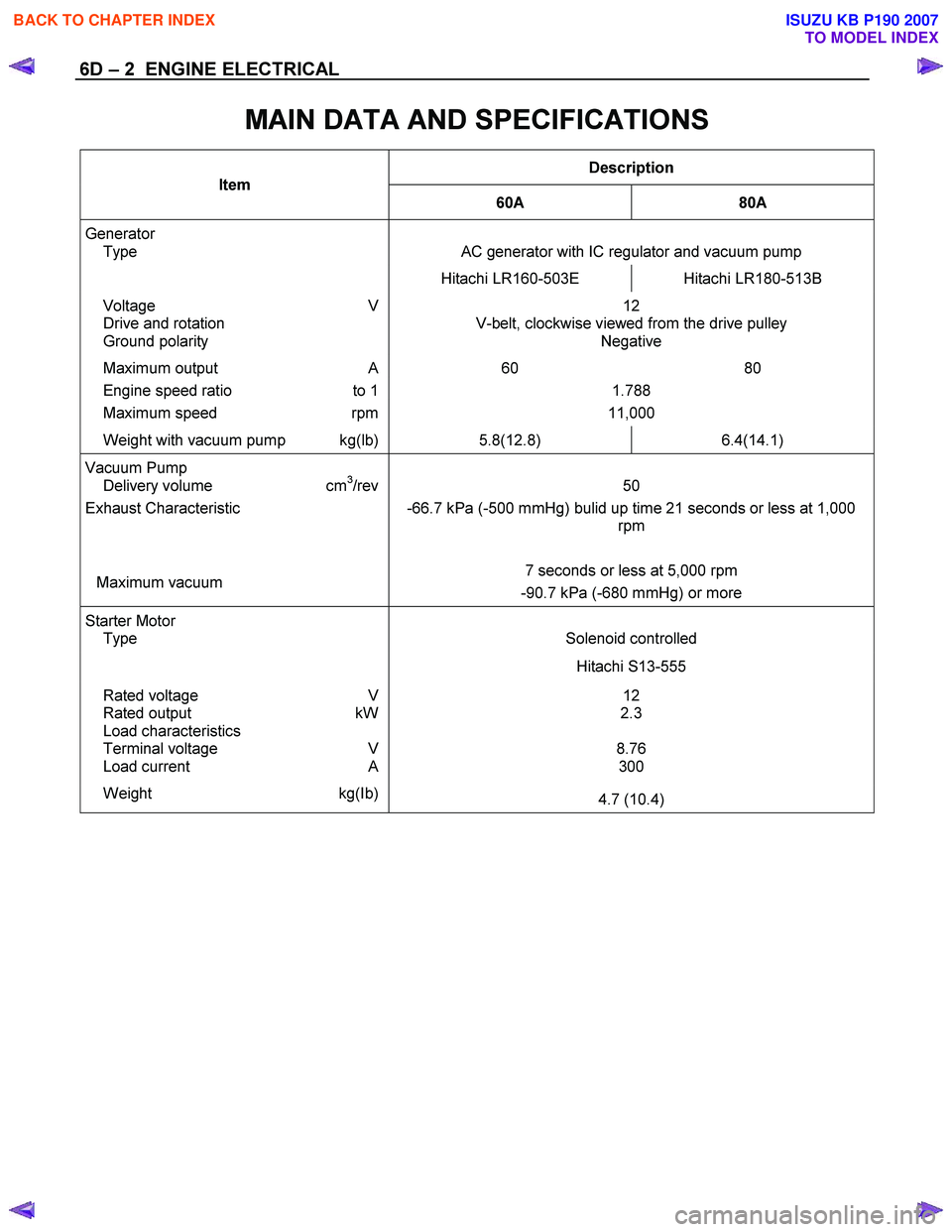

6D – 2 ENGINE ELECTRICAL

MAIN DATA AND SPECIFICATIONS

Description

Item

60A 80A

Generator

Type

AC generator with IC regulator and vacuum pump

Hitachi LR160-503E Hitachi LR180-513B

Voltage V

Drive and rotation

Ground polarity 12

V-belt, clockwise viewed from the drive pulley Negative

Maximum output A 60 80

Engine speed ratio to 1 1.788

Maximum speed rpm 11,000

Weight with vacuum pump kg(lb) 5.8(12.8) 6.4(14.1)

Vacuum Pump

Delivery volume cm3/rev

Exhaust Characteristic

Maximum vacuum

50

-66.7 kPa (-500 mmHg) bulid up time 21 seconds or less at 1,000 rpm

7 seconds or less at 5,000 rpm

-90.7 kPa (-680 mmHg) or more

Starter Motor

Type

Solenoid controlled

Hitachi S13-555

12

2.3

8.76 300 Rated voltage V

Rated output kW

Load characteristics

Terminal voltage V

Load current A

Weight kg(Ib) 4.7 (10.4)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1029 of 6020

6D – 28 ENGINE ELECTRICAL

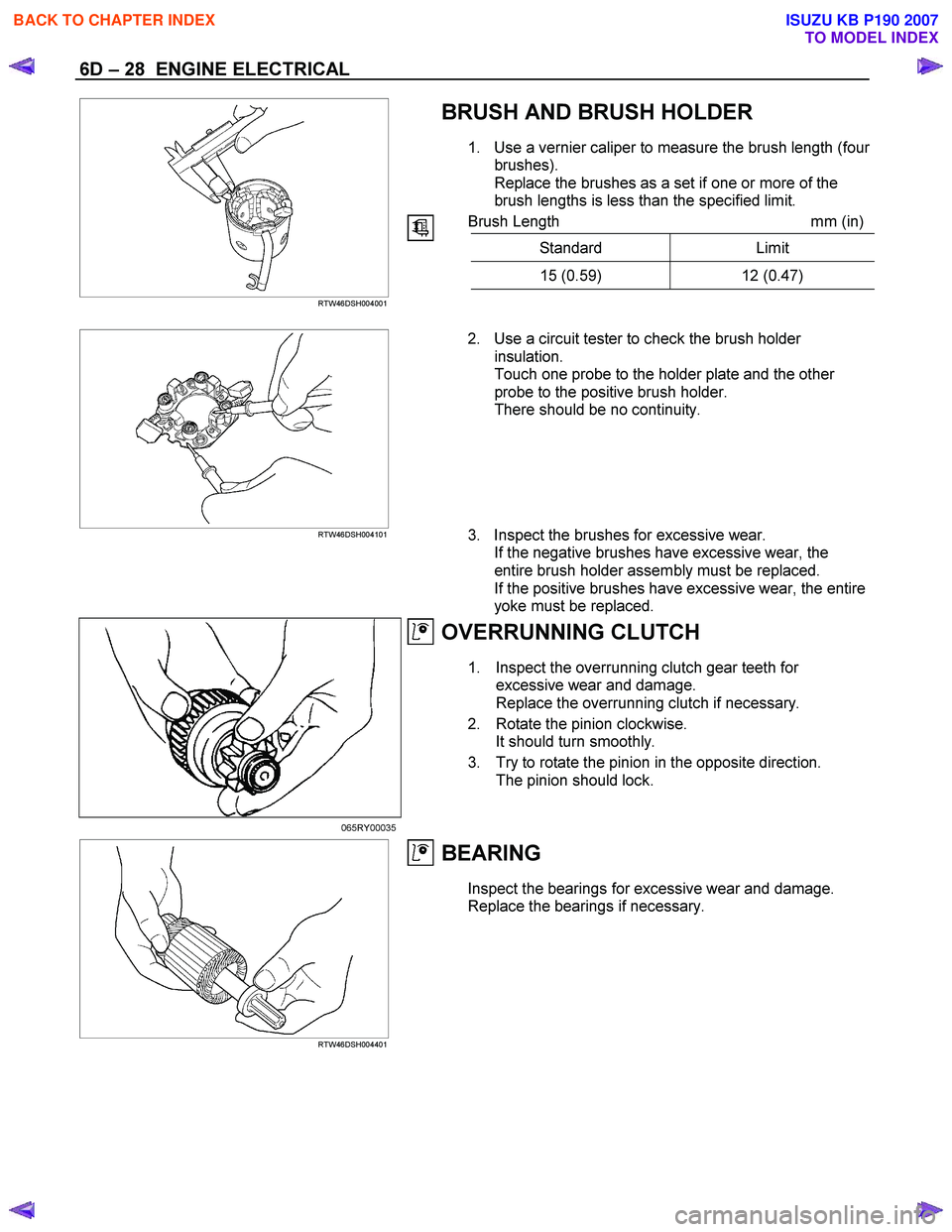

BRUSH AND BRUSH HOLDER

1. Use a vernier caliper to measure the brush length (four

brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW46DSH004001

RTW46DSH004101

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear. If the negative brushes have excessive wear, the

entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire

yoke must be replaced.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise. It should turn smoothly.

3. Try to rotate the pinion in the opposite direction. The pinion should lock.

065RY00035

RTW46DSH004401

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1507 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-147

Reassembly

1. Install the gasket on the element.

2. Install the element.

3. Tighten the element fixing nut using the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

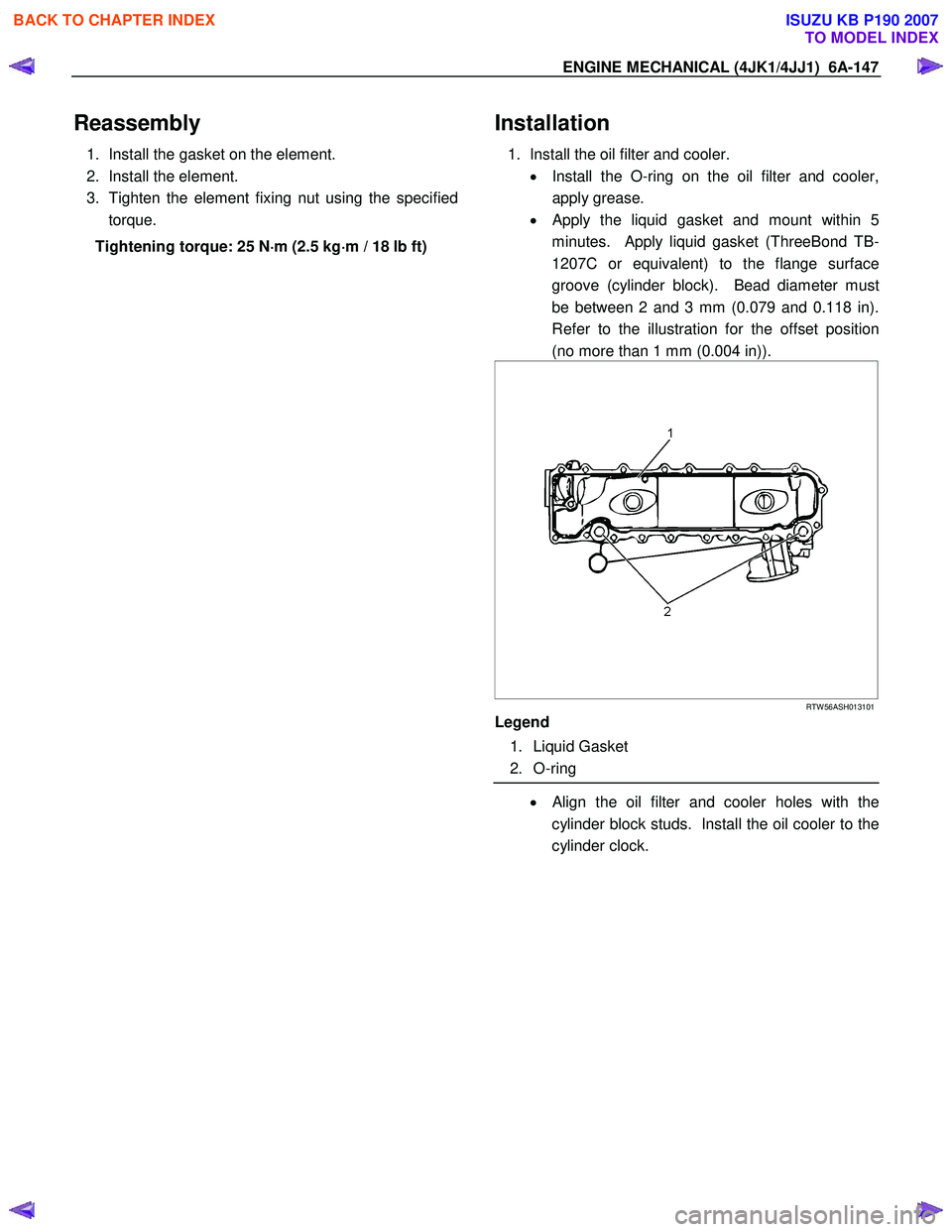

Installation

1. Install the oil filter and cooler.

• Install the O-ring on the oil filter and cooler,

apply grease.

•

Apply the liquid gasket and mount within 5

minutes. Apply liquid gasket (ThreeBond TB-

1207C or equivalent) to the flange surface

groove (cylinder block). Bead diameter must

be between 2 and 3 mm (0.079 and 0.118 in).

Refer to the illustration for the offset position

(no more than 1 mm (0.004 in)).

RTW 56ASH013101

Legend

1. Liquid Gasket

2. O-ring

• Align the oil filter and cooler holes with the

cylinder block studs. Install the oil cooler to the

cylinder clock.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1554 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-13

Fuel Filter Element

Removal

1. Detach the drain hose on the lower part of the fuel

filter or the drain plug, loosen the air bleed plug,

and drain the fuel from the fuel filter.

2. Detach the water-in-fuel switch harness.

3. Turn the element case counterclockwise to detach, and remove the filter element.

4. Replace the O-ring and confirm the snap-fit position, and fit a new filter element inside the

element case.

NOTE

It is strongly advisable to use the ISUZU/GM genuine

fuel filter for replacement.

RTW 76CSH000901

Legend

1. Element

2. O-ring

3. Sedimenter Sensor

Installation

1. Apply a light coat of new diesel oil to the O-ring

and gasket.

2. Turn the element case clockwise until it is completely seated against the upper cover. Then

check that the drain hose is in its correct position,

and then use a filter wrench and tighten to the

specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

3. Use a clip to fix the drain hose at the base of the fuel filter, and fit the water-in-fuel switch harness.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1596 of 6020

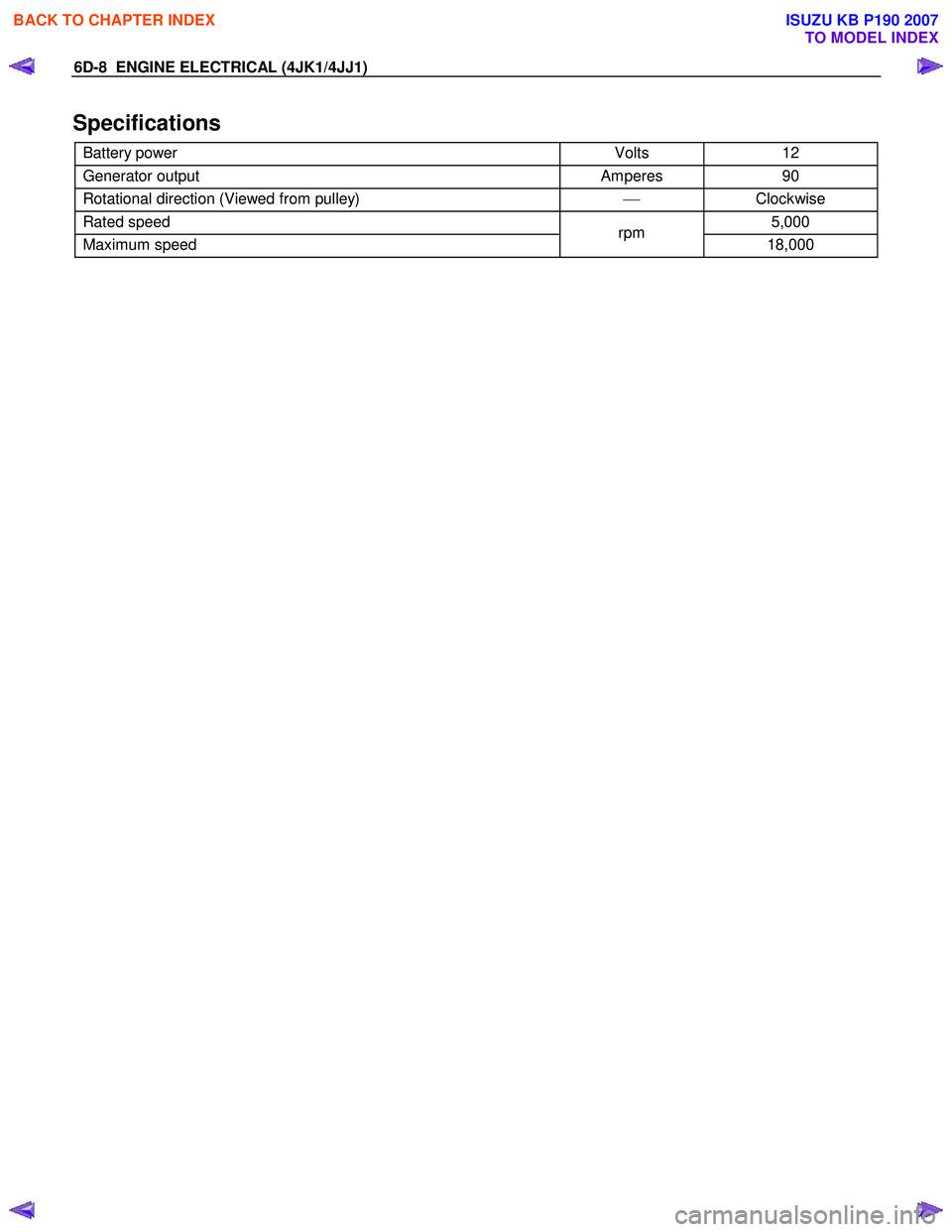

6D-8 ENGINE ELECTRICAL (4JK1/4JJ1)

Specifications

Battery power Volts 12

Generator output Amperes 90

Rotational direction (Viewed from pulley) Clockwise

Rated speed 5,000

Maximum speed rpm

18,000

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1610 of 6020

6D-22 ENGINE ELECTRICAL (4JK1/4JJ1)

RTW 46DSH003901

Brush and Brush Holder

1. Use a vernier caliper to measure the brush length

(four brushes).

Replace the brushes as a set if one or more of the brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW 46DSH004001

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the othe

r

probe to the positive brush holder.

There should be no continuity.

RTW 46DSH004101

3. Inspect the brushes for excessive wear.

If the negative brushes have excessive wear, the entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire yoke must be replaced.

Overrunning Clutch

1. Inspect the overrunning clutch gear teeth for

excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise.

It should turn smoothly.

3. Try to rotate the pinion in the opposite direction.

The pinion should lock.

065RY00035

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2037 of 6020

ENGINE MECHANICAL (C24SE) 6A-23

Toothed Belt Tension, Adjust

(Engines with toothed belt tension

roller)

Removal

Refer to 6A-21. Toothed Belt and Timing check and removal

steps.

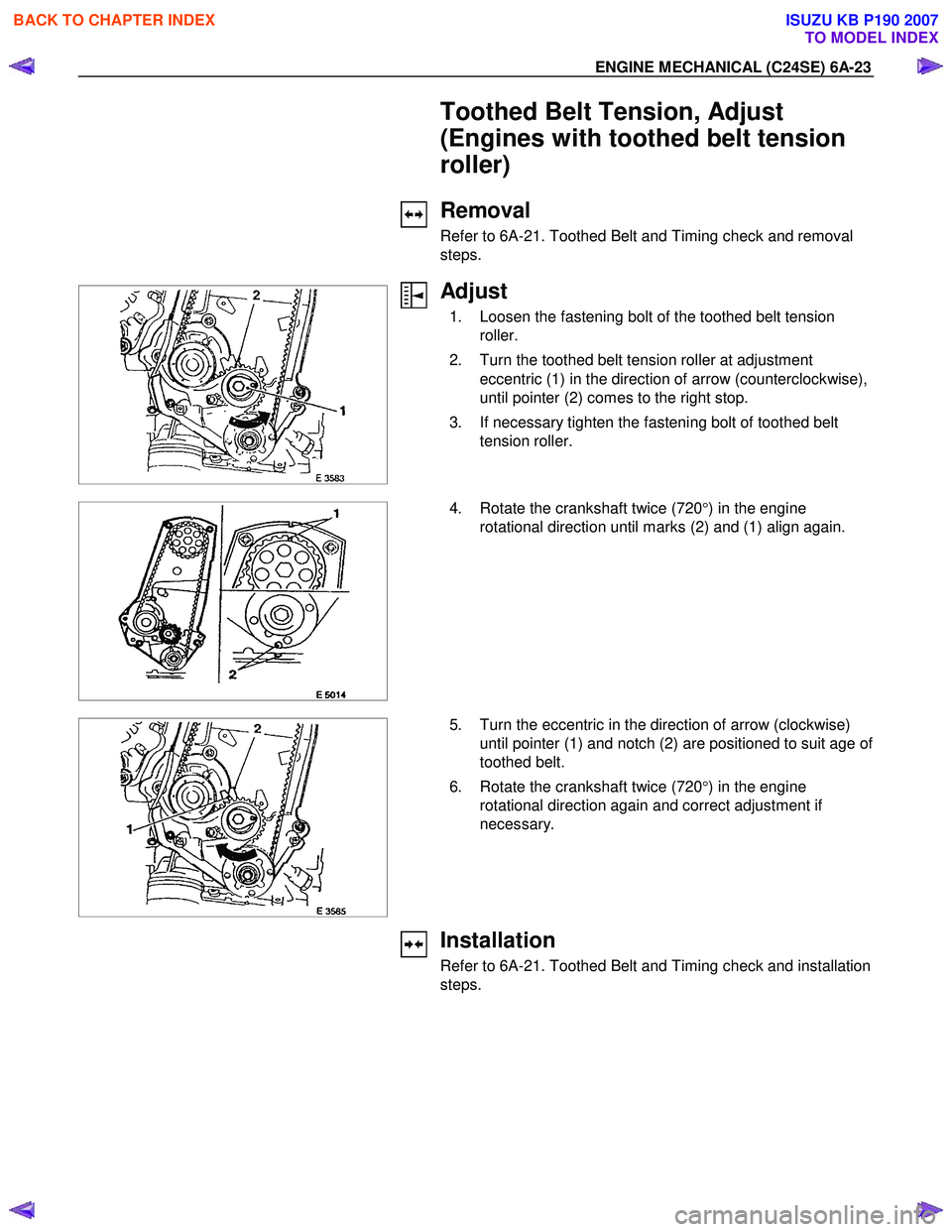

Adjust

1. Loosen the fastening bolt of the toothed belt tension roller.

2. Turn the toothed belt tension roller at adjustment eccentric (1) in the direction of arrow (counterclockwise),

until pointer (2) comes to the right stop.

3. If necessary tighten the fastening bolt of toothed belt tension roller.

4. Rotate the crankshaft twice (720

°) in the engine

rotational direction until marks (2) and (1) align again.

5. Turn the eccentric in the direction of arrow (clockwise)

until pointer (1) and notch (2) are positioned to suit age of

toothed belt.

6. Rotate the crankshaft twice (720 °) in the engine

rotational direction again and correct adjustment if

necessary.

Installation

Refer to 6A-21. Toothed Belt and Timing check and installation

steps.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2039 of 6020

ENGINE MECHANICAL (C24SE) 6A-25

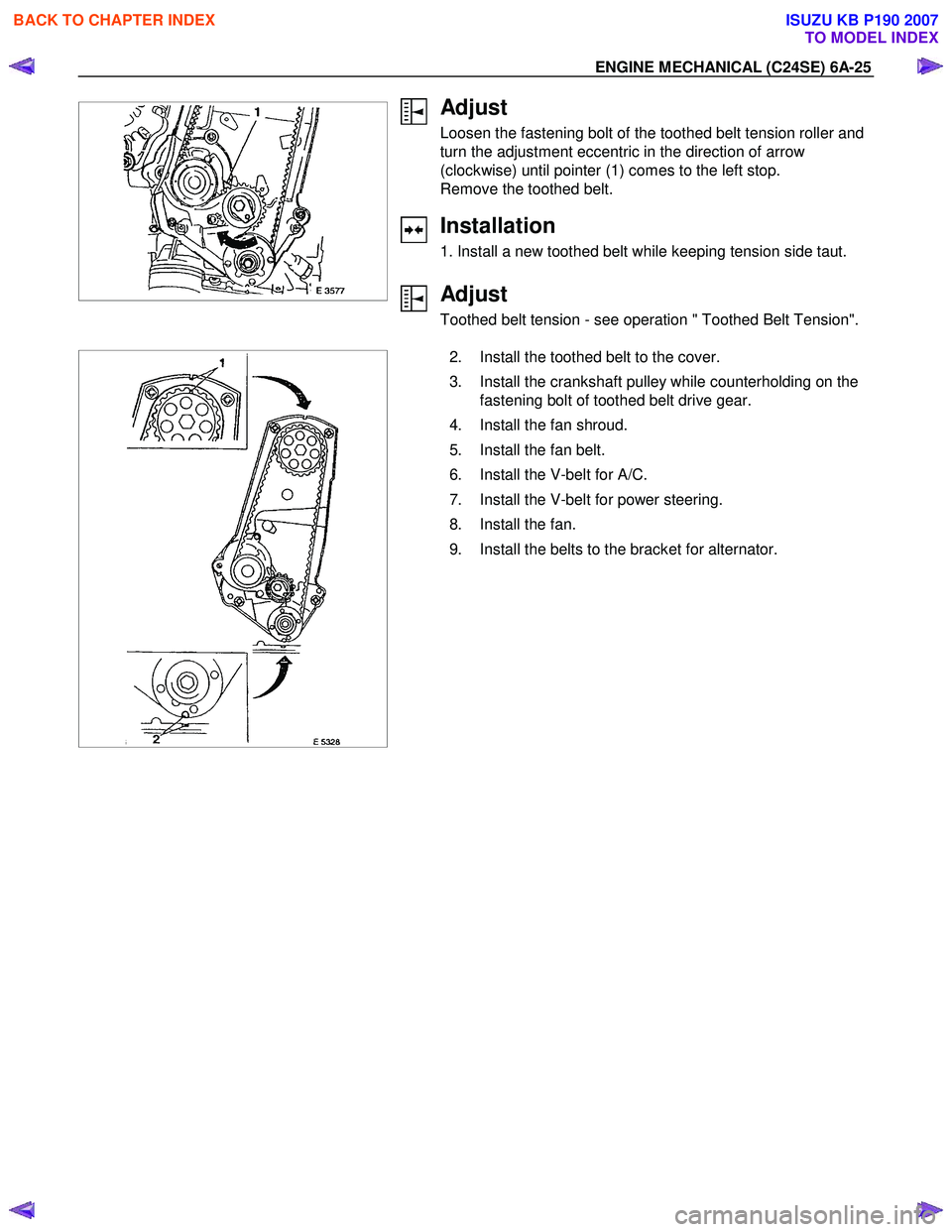

Adjust

Loosen the fastening bolt of the toothed belt tension roller and

turn the adjustment eccentric in the direction of arrow

(clockwise) until pointer (1) comes to the left stop.

Remove the toothed belt.

Installation

1. Install a new toothed belt while keeping tension side taut.

Adjust

Toothed belt tension - see operation " Toothed Belt Tension".

2. Install the toothed belt to the cover.

3. Install the crankshaft pulley while counterholding on the fastening bolt of toothed belt drive gear.

4. Install the fan shroud.

5. Install the fan belt.

6. Install the V-belt for A/C.

7. Install the V-belt for power steering.

8. Install the fan.

9. Install the belts to the bracket for alternator.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2158 of 6020

6D3-10 STARTING AND CHARGING SYSTEM

The generator has four external connections; the "B+" lead to

battery positive, "L" lead to the warning lamp circuit(max. 2

watts), "S" lead to battery positive terminal for battery sensing

and an earth connection.

Explanation of type inscripiton

Example:KC-A--> 14V 50-90A.

K = Code for Stator OD(126mm OD).

C = Compact Generator.

A = Ausland (countries other than Germany)

> = Direction of rotation(clockwise).

14V = Generator Operating Voltage.

50A = Stabilised output at 25 C at 1800 RPM./13.5

Volts.

90A = Stabilised output at 25 C at 1800 RPM./13.5

Volts.

Generator Connetions.

B+ : Battery Main Connection (battery positive)

S : Battery Sense Connection(battery positive)

L : W aring lamp(via warning lamp to Ignition switch)

BATT.SENSE

REGULATOR ASSEMBLYHYBR10 ALTERNATOR ASSEMBLY

12V BATT. 1GN.SW .

300a*

W ARN.LAMP

1.2 W ATT L

S 8+

SUPPRESSOR

CAPACITOR

0.5 µf

NOTE: * RESISTOR IS RECOMMENDED TO

ENSURE THAT THE GENERATOR

REMAINS FUNCTIONAL IN CASE OF

W ARNING LAMP FAILURE

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2538 of 6020

Engine Mechanical – V6 Page 6A1–59

3.5 Accessory Drive Belt

RWD Vehicle

Remove

1 Remove the air intake duct from between the air flow meter and the throttle body, refer to 6C1-3 Engine

Management – V6 – Service Operations.

2 Note the accessory drive belt (1) routing.

Figure 6A1 – 29

3 Using a suitable ½” drive socket bar (1), rotate the drive belt tensioner (2) clockwise, to reduce belt

tension.

4 W hile holding the tensioner in the reduced tension position, remove the accessory drive belt (3).

NOTE

If required use an assistant to maintain the tensioner in the required position.

CAUTION

If running the engine with the accessory

drive belt removed, the coolant pump will

not be operating and the engine may

overheat if left unsupervised even for a short

period.

Figure 6A1 – 30

Reinstall

1 Install the drive belt over the A/C compressor, idler pulley, power steering pump, coolant pump, generator and tensioner pulleys.

2 Using a suitable ½” drive socket bar (1), rotate the drive belt tensioner (2) clockwise, refer to Figure 6A1 – 30.

3 W ith an assistant holding the tensioner in the required position, feed the accessory drive belt (3) over the crankshaft pulley.

4 Slowly release the drive belt tensioner mechanism.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007