clock ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2672 of 6020

Engine Mechanical – V6 Page 6A1–193

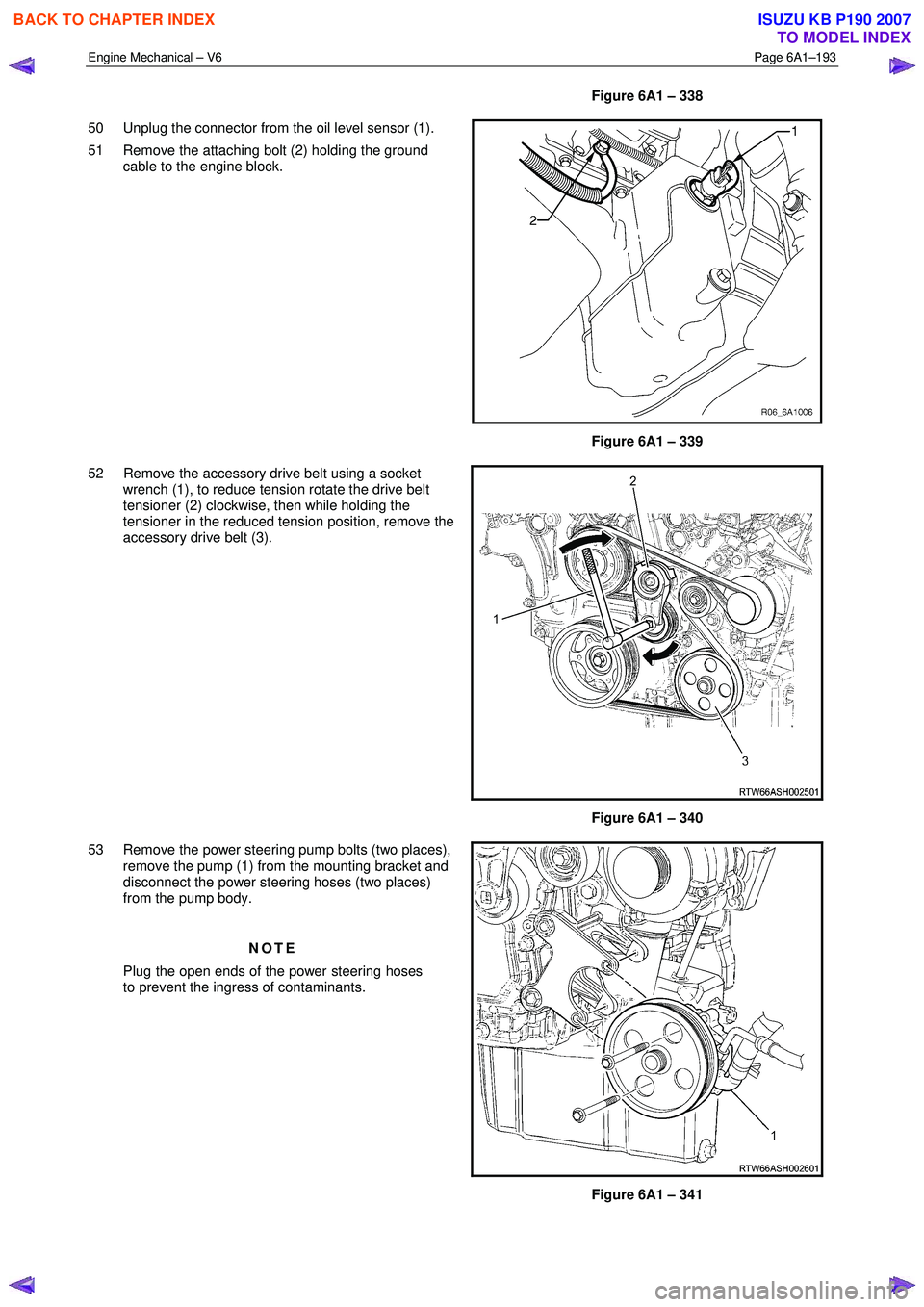

Figure 6A1 – 338

50 Unplug the connector from the oil level sensor (1).

51 Remove the attaching bolt (2) holding the ground cable to the engine block.

Figure 6A1 – 339

52 Remove the accessory drive belt using a socket wrench (1), to reduce tension rotate the drive belt

tensioner (2) clockwise, then while holding the

tensioner in the reduced tension position, remove the

accessory drive belt (3).

Figure 6A1 – 340

53 Remove the power steering pump bolts (two places), remove the pump (1) from the mounting bracket and

disconnect the power steering hoses (two places)

from the pump body.

NOTE

Plug the open ends of the power steering hoses

to prevent the ingress of contaminants.

Figure 6A1 – 341

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2849 of 6020

Engine Mechanical – V6 Page 6A1–72

Page 6A1–72

3.5 Accessory Drive Belt

RWD Vehicle

Remove

1 Remove the air intake duct from between the air flow meter and the throttle body, refer to

Section 6C1-3 Engine Management – V6 – Service Operations.

2 Note the accessory drive belt (1) routing.

Figure 6A1 – 29

3 Using a suitable ½” drive socket bar (1), rotate the drive belt tensioner (2) clockwise, to reduce belt

tension.

4 While holding the tensioner in the reduced tension

position, remove the accessory drive belt (3).

NOTE

If required use an assistant to maintain the tensioner in the required position.

CAUTION

If running the engine with the accessory

drive belt removed, the coolant pump will

not be operating and the engine may

overheat if left unsupervised even for a short

period.

Figure 6A1 – 30

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2850 of 6020

Engine Mechanical – V6 Page 6A1–73

Page 6A1–73

Reinstall

1 Install the drive belt over the A/C compressor, idler pulley, power steering pump, coolant pump, generator and

tensioner pulleys.

2 Using a suitable ½” drive socket bar (1), rotate the driv e belt tensioner (2) clockwise, refer to Figure 6A1 – 30.

3 With an assistant holding the tensi oner in the required position, feed the accessory drive belt (3) over the

crankshaft pulley.

4 Slowly release the drive belt tensioner mechanism.

NOTE

Ensure the drive belt ribs are correctly aligned

with the grooves in the accessory drive pulleys or

damage to the drive belt and accessory drive

components and pulleys may occur.

5 Reinstall the air intake duct to the ai r flow meter and the throttle body, refer to Section 6C1-3 Engine Management

– V6 – Service Operations .

6 Run the engine to ensure correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2891 of 6020

Engine Mechanical – V6 Page 6A1–114

Page 6A1–114

Remove

Right-hand Secondary Timing Chain

CAUTION

After removing the upper intake manifold, and

spark plugs, plug any openings to prevent dirt

and other contaminants from entering.

1 Remove the engine front cover assembly, refer to 3.15 Front Cover Assembly.

2 Remove the spark plugs to aid crankshaft/engine rotation, refer to Section 6C1-3 Engine Management – V6 –

Service Operations .

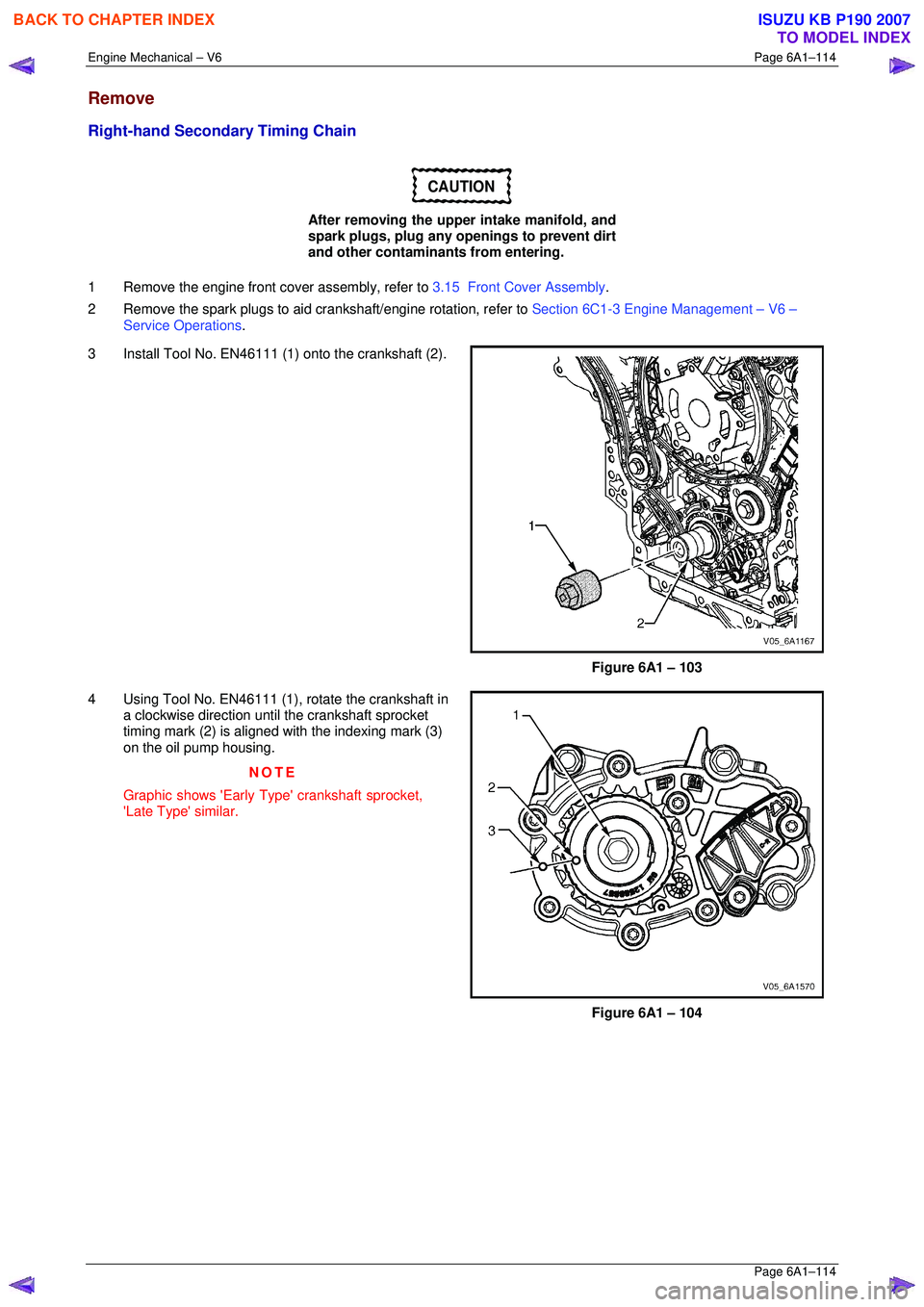

3 Install Tool No. EN46111 (1) onto the crankshaft (2).

Figure 6A1 – 103

4 Using Tool No. EN46111 (1), rotate the crankshaft in a clockwise direction until the crankshaft sprocket

timing mark (2) is aligned with the indexing mark (3)

on the oil pump housing.

NOTE

Graphic shows 'Early Type' crankshaft sprocket,

'Late Type' similar.

Figure 6A1 – 104

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2903 of 6020

Engine Mechanical – V6 Page 6A1–126

Page 6A1–126

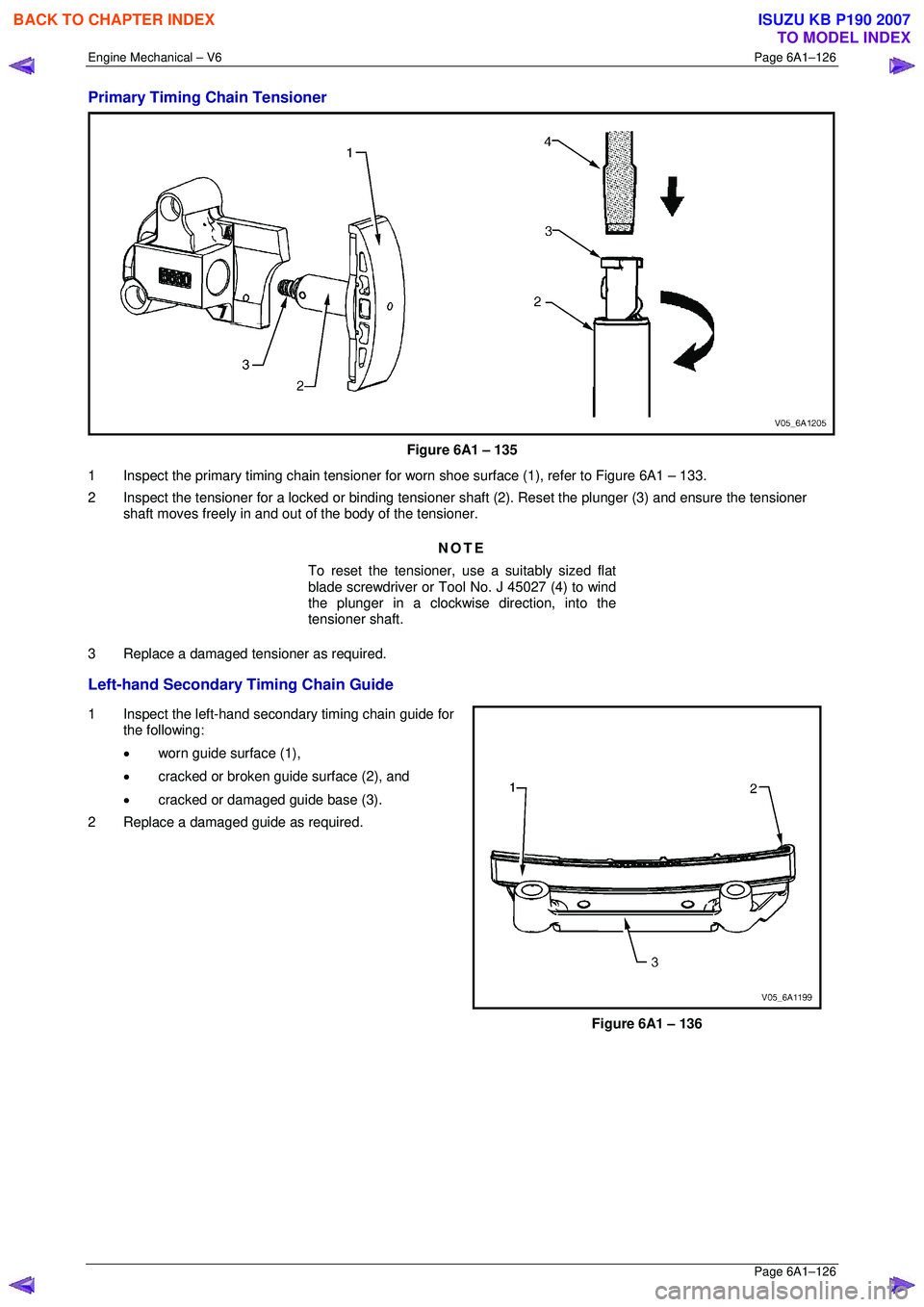

Primary Timing Chain Tensioner

Figure 6A1 – 135

1 Inspect the primary timing chain tensioner for wo rn shoe surface (1), refer to Figure 6A1 – 133.

2 Inspect the tensioner for a locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner

shaft moves freely in and out of the body of the tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

3 Replace a damaged tens ioner as required.

Left-hand Secondary Timing Chain Guide

1 Inspect the left-hand secondary timing chain guide for

the following:

• worn guide surface (1),

• cracked or broken guide surface (2), and

• cracked or damaged guide base (3).

2 Replace a damaged guide as required.

Figure 6A1 – 136

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2905 of 6020

Engine Mechanical – V6 Page 6A1–128

Page 6A1–128

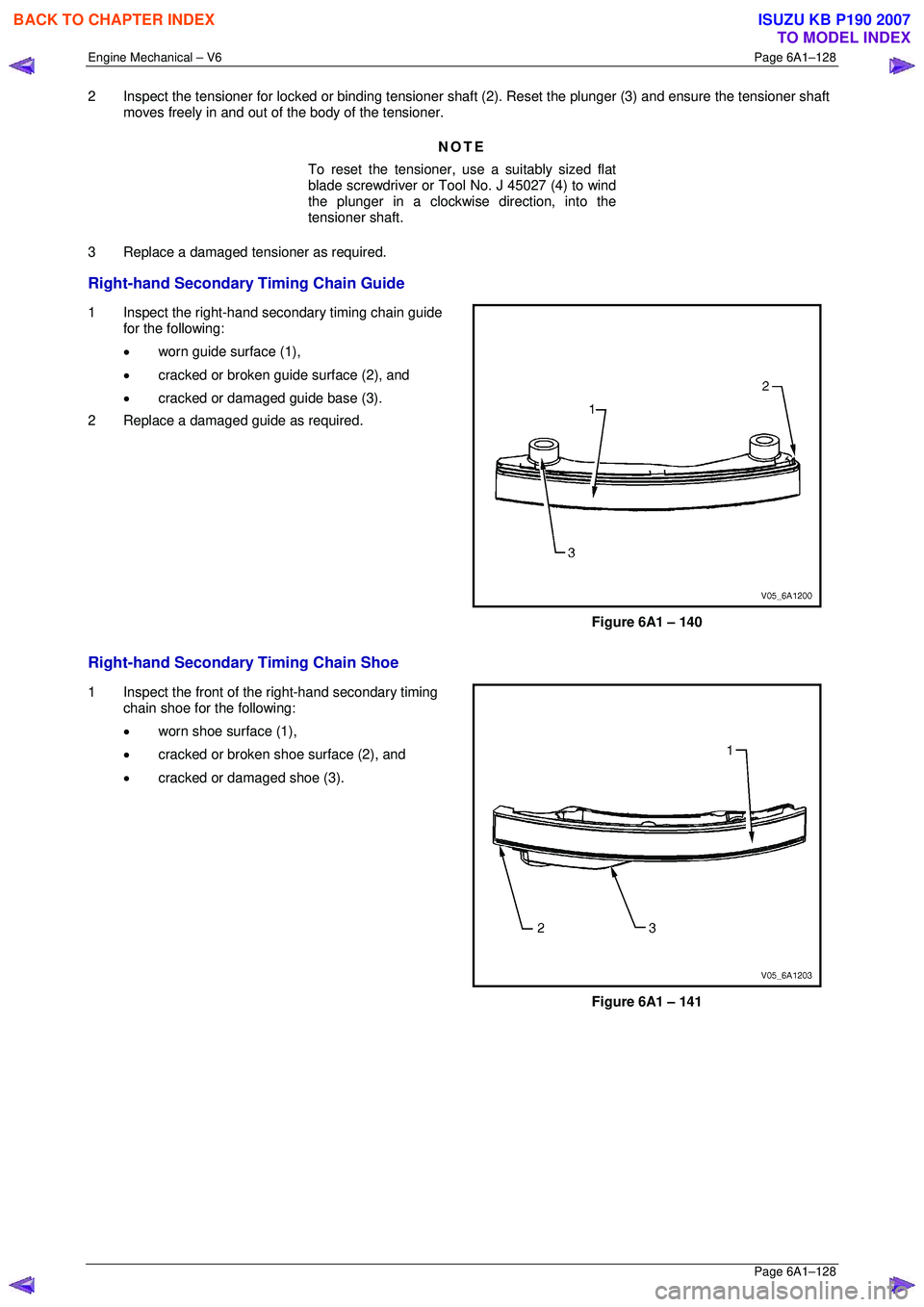

2 Inspect the tensioner for locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner shaft

moves freely in and out of the body of the tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

3 Replace a damaged tens ioner as required.

Right-hand Secondary Timing Chain Guide

1 Inspect the right-hand secondary timing chain guide

for the following:

• worn guide surface (1),

• cracked or broken guide surface (2), and

• cracked or damaged guide base (3).

2 Replace a damaged guide as required.

Figure 6A1 – 140

Right-hand Secondary Timing Chain Shoe

1 Inspect the front of t he right-hand secondary timing

chain shoe for the following:

• worn shoe surface (1),

• cracked or broken shoe surface (2), and

• cracked or damaged shoe (3).

Figure 6A1 – 141

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2906 of 6020

Engine Mechanical – V6 Page 6A1–129

Page 6A1–129

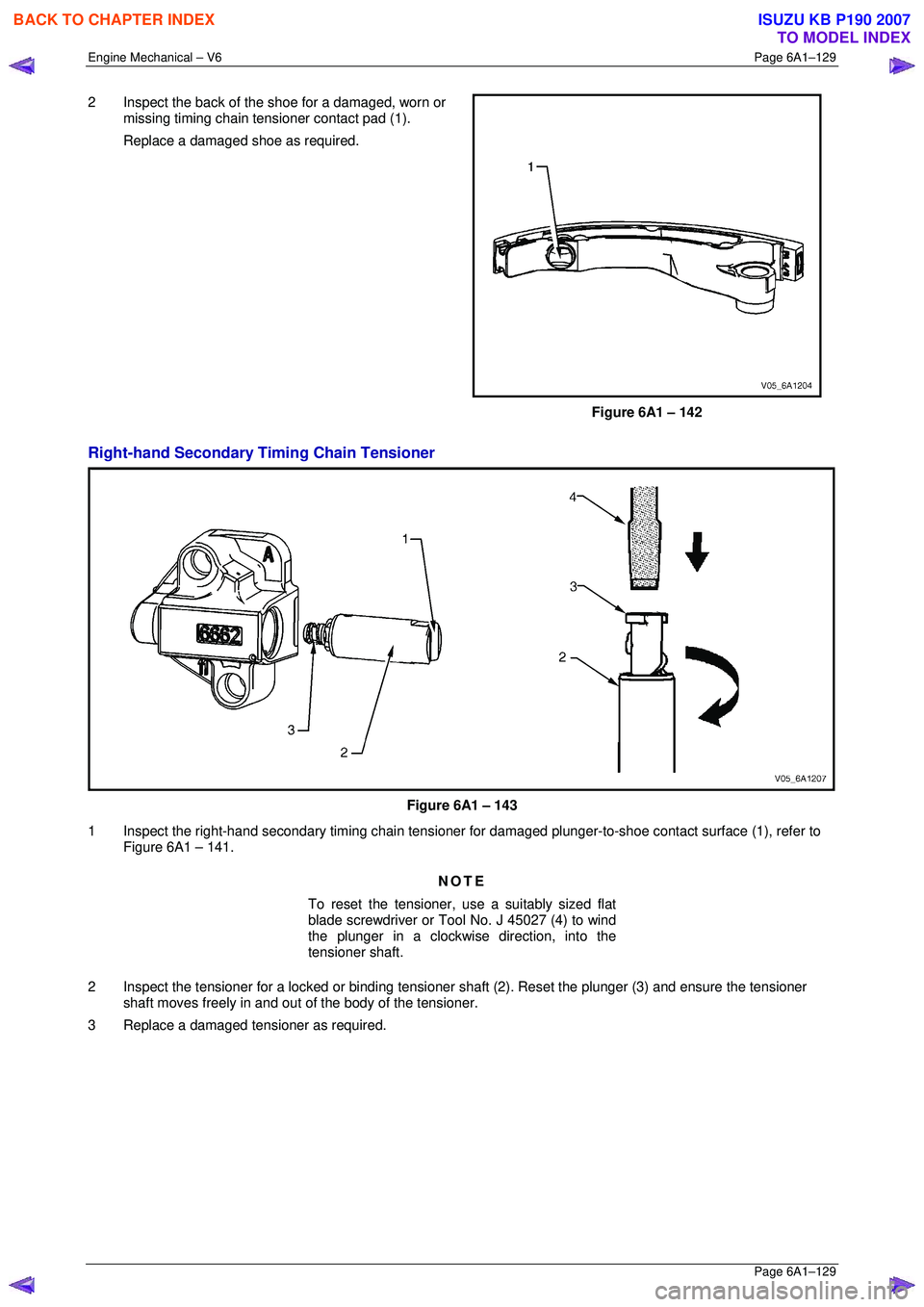

2 Inspect the back of the shoe for a damaged, worn or

missing timing chain tensioner contact pad (1).

Replace a damaged shoe as required.

Figure 6A1 – 142

Right-hand Secondary Timing Chain Tensioner

Figure 6A1 – 143

1 Inspect the right-hand secondary timing chain tensioner for damaged plunger-to-shoe contact surface (1), refer to

Figure 6A1 – 141.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

2 Inspect the tensioner for a locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner

shaft moves freely in and out of the body of the tensioner.

3 Replace a damaged tens ioner as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2907 of 6020

Engine Mechanical – V6 Page 6A1–130

Page 6A1–130

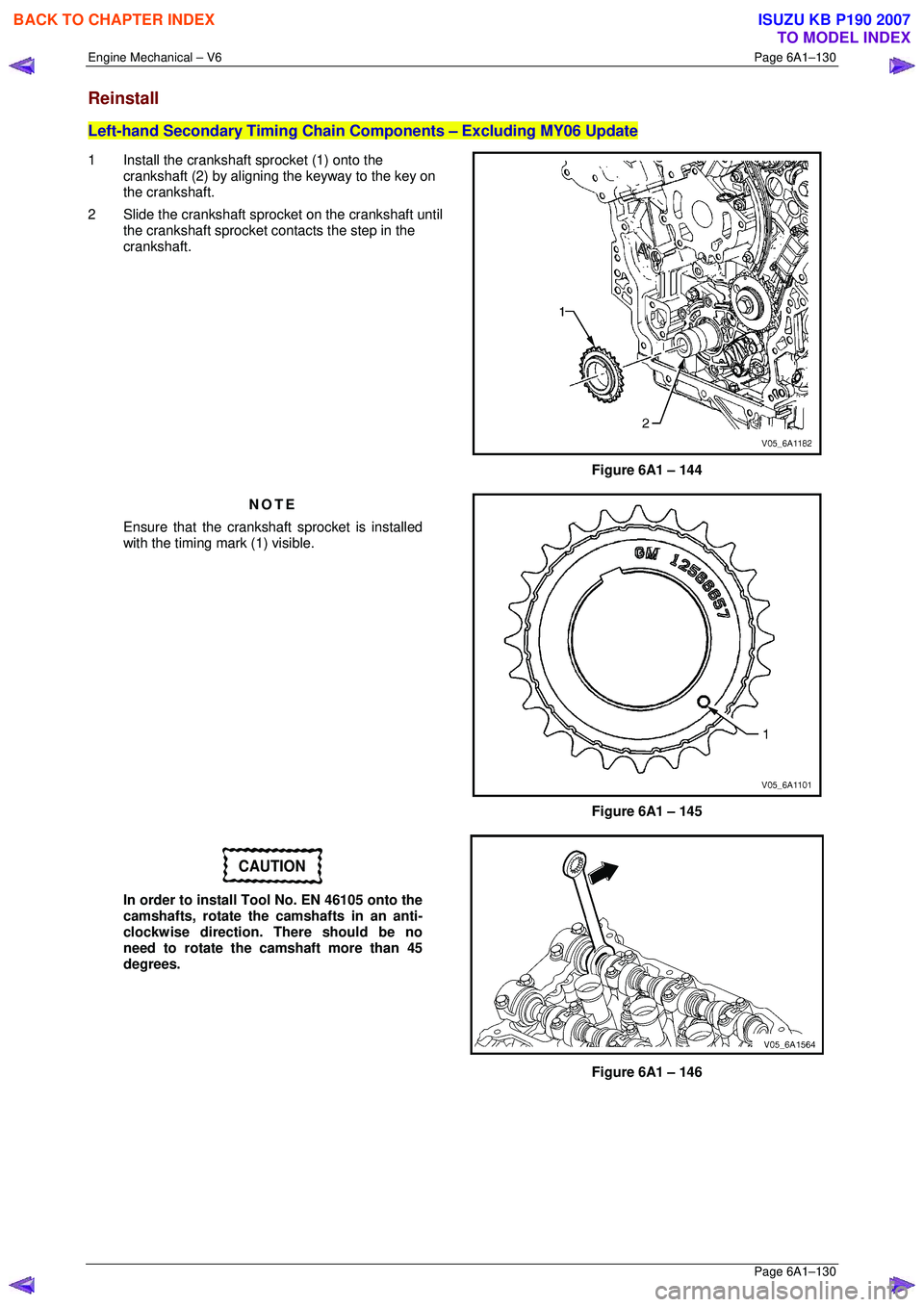

Reinstall

Left-hand Secondary Timing Chain Components – Excluding MY06 Update

1 Install the crankshaft sprocket (1) onto the

crankshaft (2) by aligning the keyway to the key on

the crankshaft.

2 Slide the crankshaft sprocket on the crankshaft until the crankshaft sprocket contacts the step in the

crankshaft.

Figure 6A1 – 144

NOTE

Ensure that the crankshaft sprocket is installed

with the timing mark (1) visible.

Figure 6A1 – 145

CAUTION

In order to install Tool No. EN 46105 onto the

camshafts, rotate the camshafts in an anti-

clockwise direction. There should be no

need to rotate the camshaft more than 45

degrees.

Figure 6A1 – 146

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2908 of 6020

Engine Mechanical – V6 Page 6A1–131

Page 6A1–131

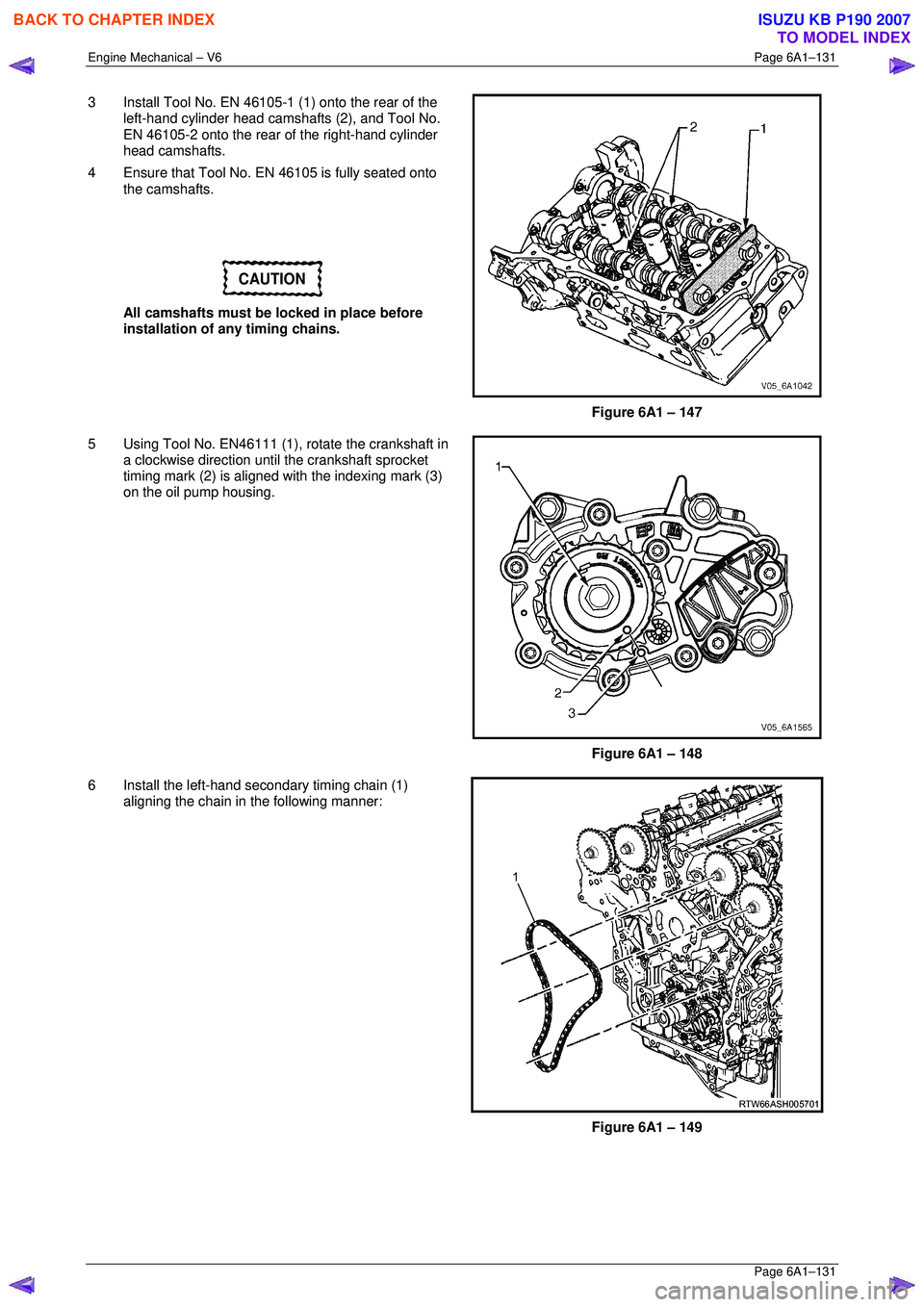

3 Install Tool No. EN 46105-1 (1) onto the rear of the

left-hand cylinder head camshafts (2), and Tool No.

EN 46105-2 onto the rear of the right-hand cylinder

head camshafts.

4 Ensure that Tool No. EN 46105 is fully seated onto the camshafts.

CAUTION

All camshafts must be locked in place before

installation of any timing chains.

Figure 6A1 – 147

5 Using Tool No. EN46111 (1), rotate the crankshaft in a clockwise direction until the crankshaft sprocket

timing mark (2) is aligned with the indexing mark (3)

on the oil pump housing.

Figure 6A1 – 148

6 Install the left-hand secondary timing chain (1) aligning the chain in the following manner:

Figure 6A1 – 149

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2913 of 6020

Engine Mechanical – V6 Page 6A1–136

Page 6A1–136

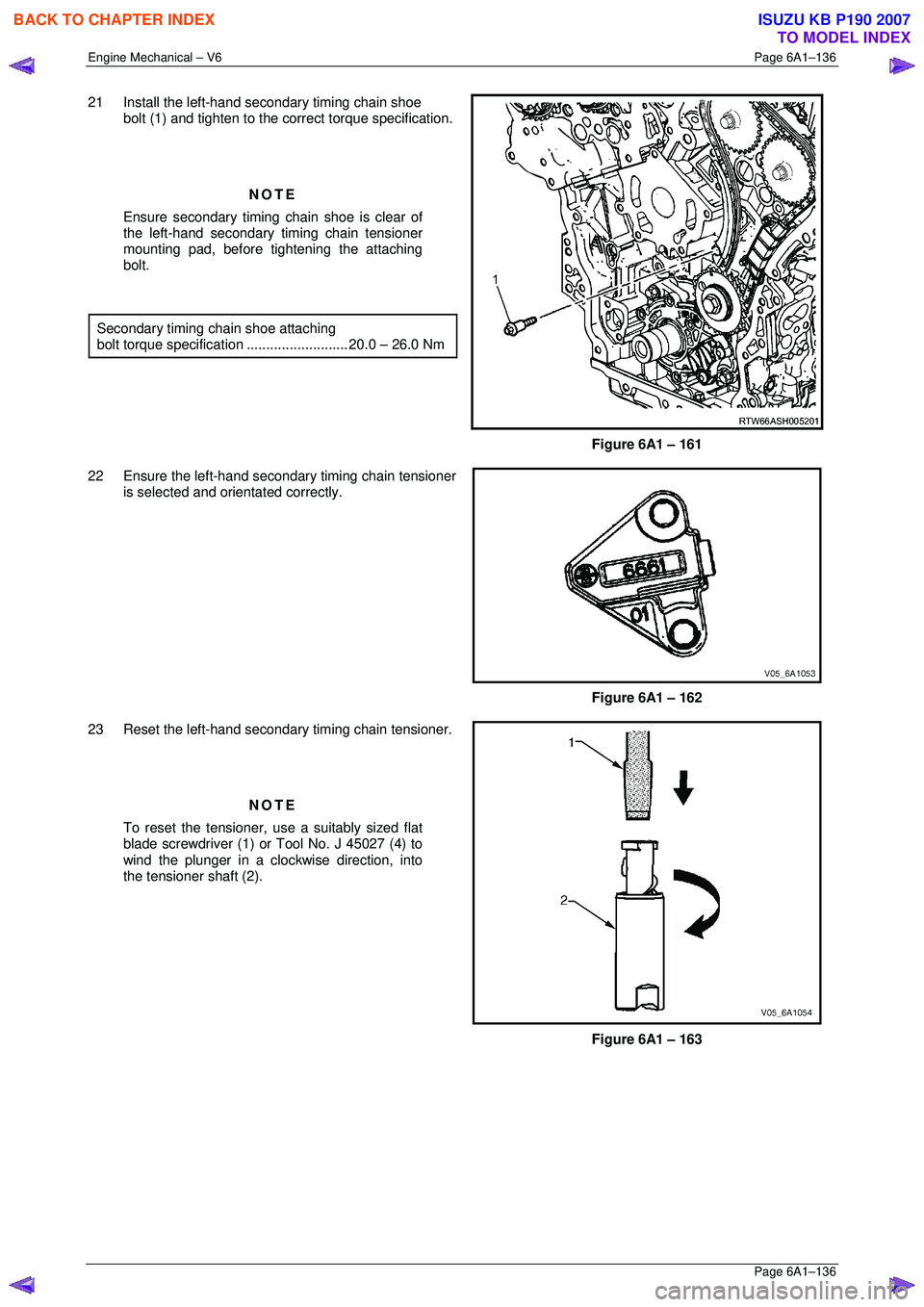

21 Install the left-hand secondary timing chain shoe

bolt (1) and tighten to the co rrect torque specification.

NOTE

Ensure secondary timing chain shoe is clear of

the left-hand secondary timing chain tensioner

mounting pad, before ti ghtening the attaching

bolt.

Secondary timing chain shoe attaching

bolt torque specificat ion .......................... 20.0 – 26.0 Nm

Figure 6A1 – 161

22 Ensure the left-hand secondary timing chain tensioner is selected and orientated correctly.

Figure 6A1 – 162

23 Reset the left-hand secondary timing chain tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver (1) or Tool No. J 45027 (4) to

wind the plunger in a clockwise direction, into

the tensioner shaft (2).

Figure 6A1 – 163

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007