front differential ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 541 of 6020

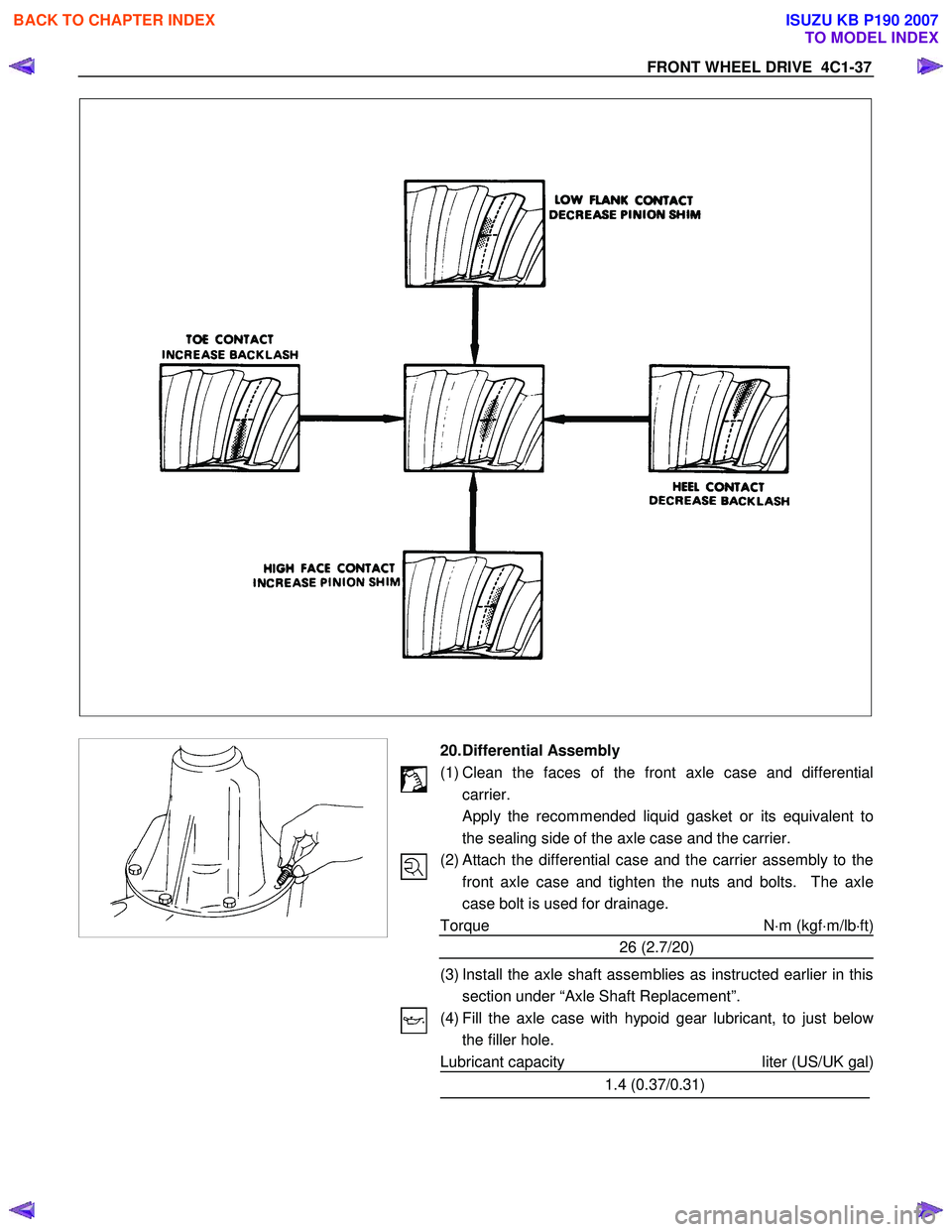

FRONT WHEEL DRIVE 4C1-37

20. Differential Assembly

(1) Clean the faces of the front axle case and differential carrier.

Apply the recommended liquid gasket or its equivalent to

the sealing side of the axle case and the carrier.

(2)

Attach the differential case and the carrier assembly to the

front axle case and tighten the nuts and bolts. The axle

case bolt is used for drainage.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

26 (2.7/20)

(3) Install the axle shaft assemblies as instructed earlier in this section under “Axle Shaft Replacement”.

(4) Fill the axle case with hypoid gear lubricant, to just belo

w

the filler hole.

Lubricant capacity liter (US/UK gal)

1.4 (0.37/0.31)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 571 of 6020

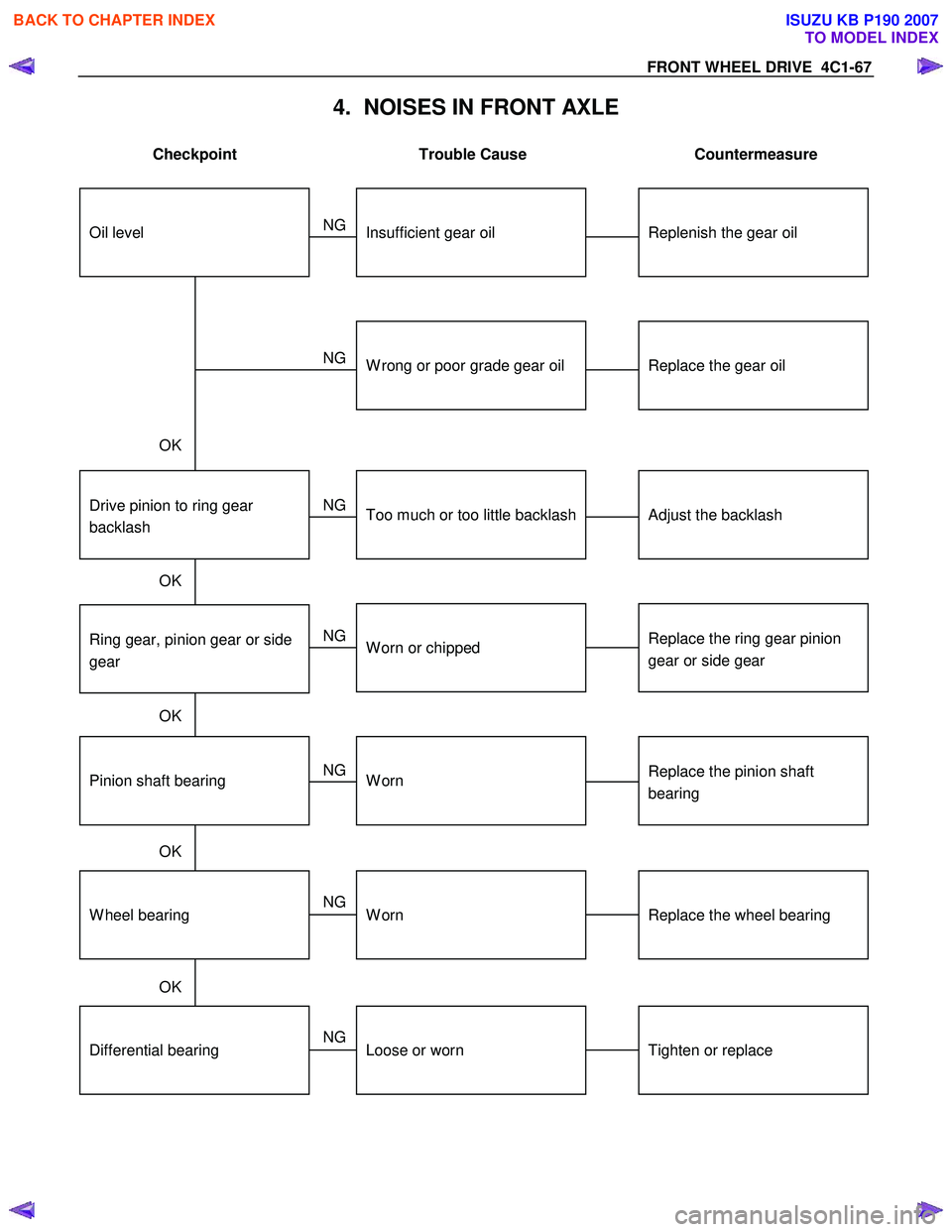

FRONT WHEEL DRIVE 4C1-67

4. NOISES IN FRONT AXLE

Checkpoint Trouble Cause Countermeasure

Replenish the gear oilInsufficient gear oil

NG

Replace the wheel bearing

Replace the pinion shaft

bearing

Replace the ring gear pinion

gear or side gear

Replace the gear oil

W heel bearingWorn

Pinion shaft bearingWorn

W orn or chipped

W rong or poor grade gear oil

Ring gear, pinion gear or side

gear

Adjust the backlashDrive pinion to ring gear

backlashToo much or too little backlash

NG

NG

NG

NG

NG

OK

OK

OK

OK

Oil level

Tighten or replaceDifferential bearingLoose or worn

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 588 of 6020

4C2-10 SHIFT ON THE FLY SYSTEM

412RS044

13. Inner Shaft Bearing

• Place a new snap ring in inner shaft.

• Force a new inner shaft bearing into the inner shaft.

Installer : 5-8840-2197-0

12. Snap Ring

NOTE;

Be careful not to damage the inner shaft.

11.inner Shaft • Clean the housing contact surface of the front axle

case.

• Insert inner shaft assembly into the front axle case.

NOTE:

Be careful not to damage oil seal.

412RW 017

10. Snap Ring

Install snap ring in the groove of front axle case.

NOTE:

Be sure to install the snap ring properly.

9. Clutch Gear Apply differential gear oil to clutch oil.

8. Sleeve Apply differential gear oil to sleeve.

412RW 023

7. Housing

• Clean contact surface with the front axle and actuato

r

mounting surface.

•

Apply liquid gasket to the contact surface on the front

axle case and install in the housing.

6. Bolt

Tighten bolts to specified tightening torque.

Housing Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

75 (7.6/55)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 589 of 6020

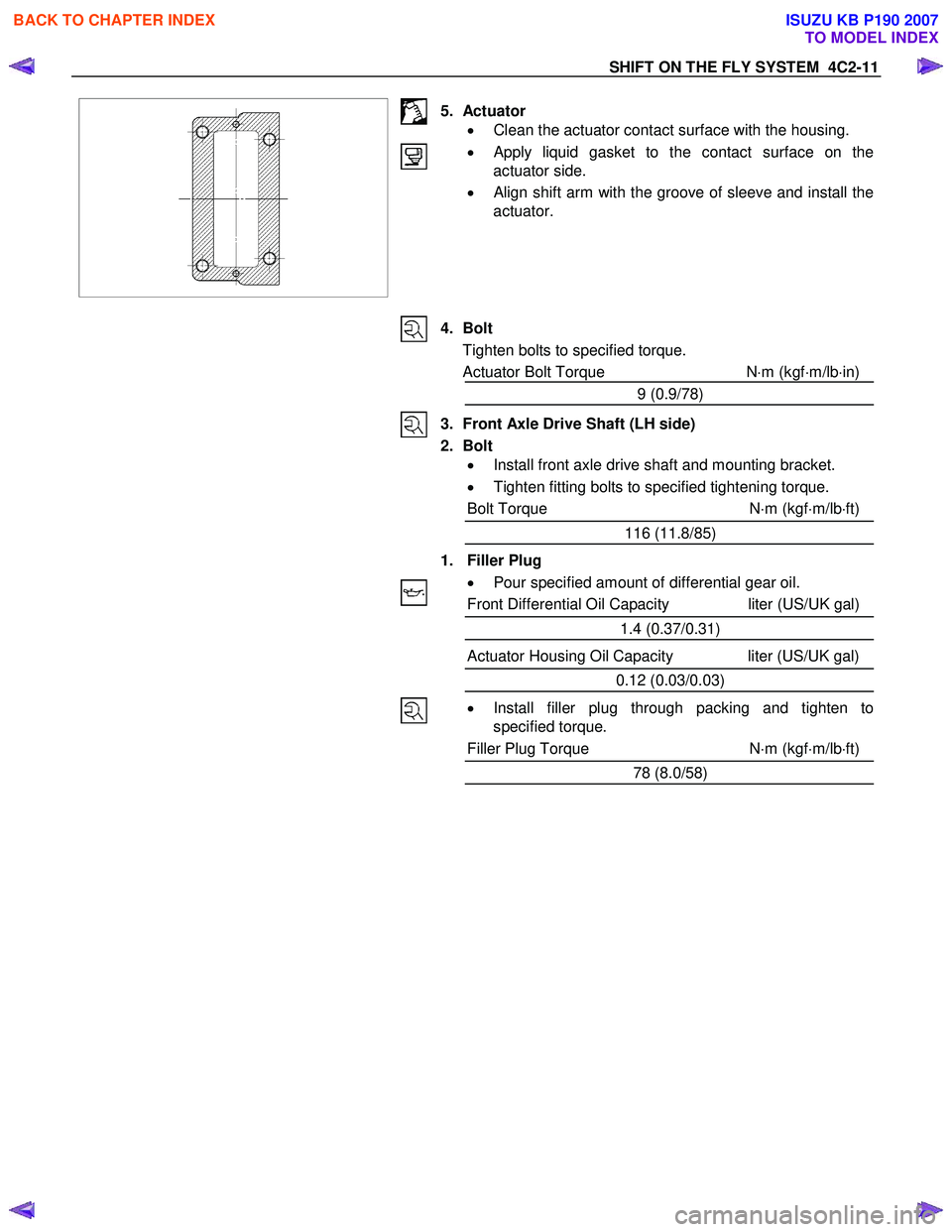

SHIFT ON THE FLY SYSTEM 4C2-11

5. Actuator • Clean the actuator contact surface with the housing.

•

Apply liquid gasket to the contact surface on the

actuator side.

• Align shift arm with the groove of sleeve and install the

actuator.

4. Bolt

Tighten bolts to specified torque.

Actuator Bolt Torque N⋅m (kgf ⋅m/lb ⋅in)

9 (0.9/78)

3. Front Axle Drive Shaft (LH side)

2. Bolt • Install front axle drive shaft and mounting bracket.

• Tighten fitting bolts to specified tightening torque.

Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

116 (11.8/85)

1. Filler Plug • Pour specified amount of differential gear oil.

Front Differential Oil Capacity liter (US/UK gal)

1.4 (0.37/0.31)

Actuator Housing Oil Capacity liter (US/UK gal) 0.12 (0.03/0.03)

• Install filler plug through packing and tighten to

specified torque.

Filler Plug Torque N⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0/58)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 657 of 6020

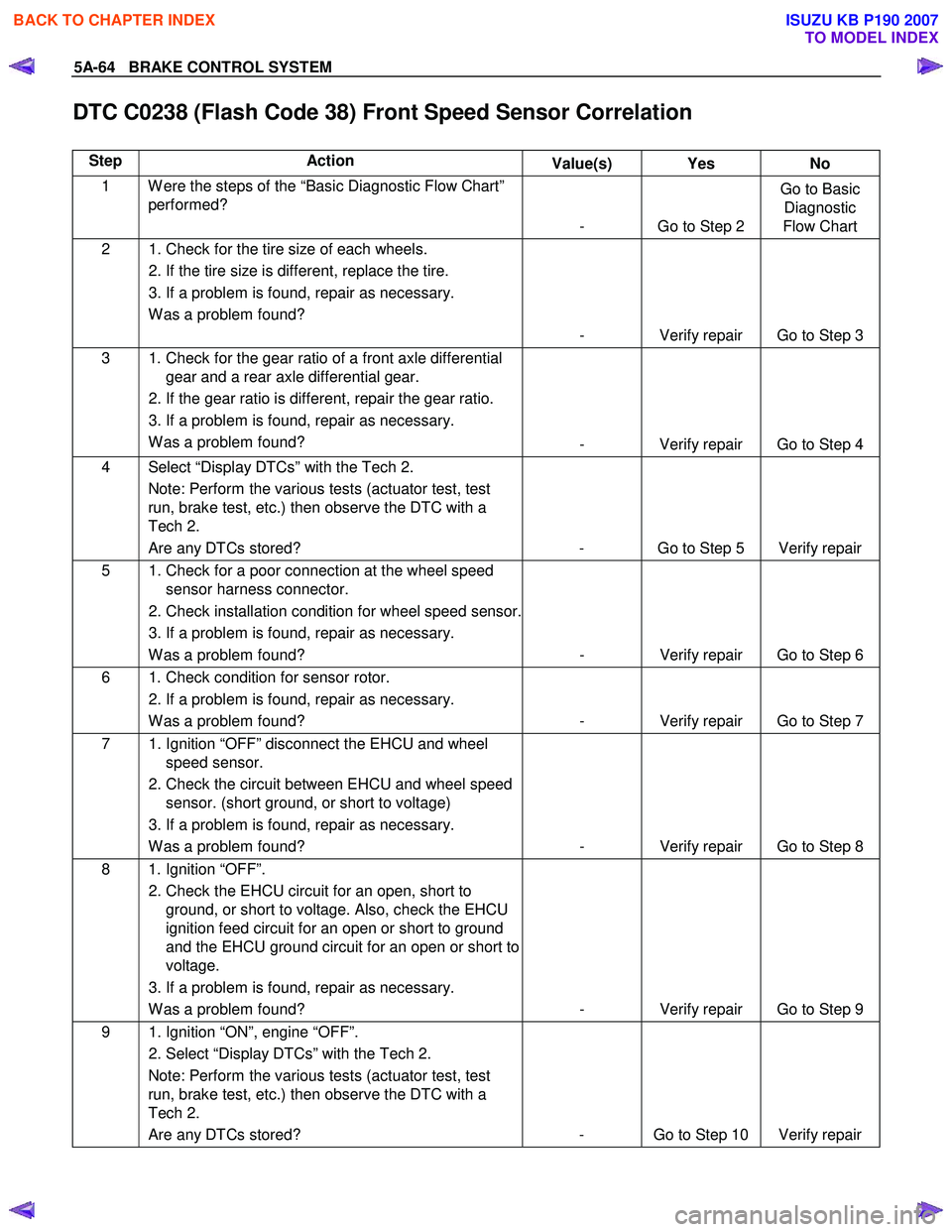

5A-64 BRAKE CONTROL SYSTEM

DTC C0238 (Flash Code 38) Front Speed Sensor Correlation

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Check for the tire size of each wheels.

2. If the tire size is different, replace the tire.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 3

3 1. Check for the gear ratio of a front axle differential gear and a rear axle differential gear.

2. If the gear ratio is different, repair the gear ratio.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 4

4 Select “Display DTCs” with the Tech 2.

Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 5 Verify repair

5 1. Check for a poor connection at the wheel speed sensor harness connector.

2. Check installation condition for wheel speed sensor.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 6

6 1. Check condition for sensor rotor.

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 7

7 1. Ignition “OFF” disconnect the EHCU and wheel

speed sensor.

2. Check the circuit between EHCU and wheel speed sensor. (short ground, or short to voltage)

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 8

8 1. Ignition “OFF”.

2. Check the EHCU circuit for an open, short to ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open or short to

voltage.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 9

9 1. Ignition “ON”, engine “OFF”.

2. Select “Display DTCs” with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 10 Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 842 of 6020

ENGINE MECHANICAL 6A – 37

REMOVAL AND INSTALLATION

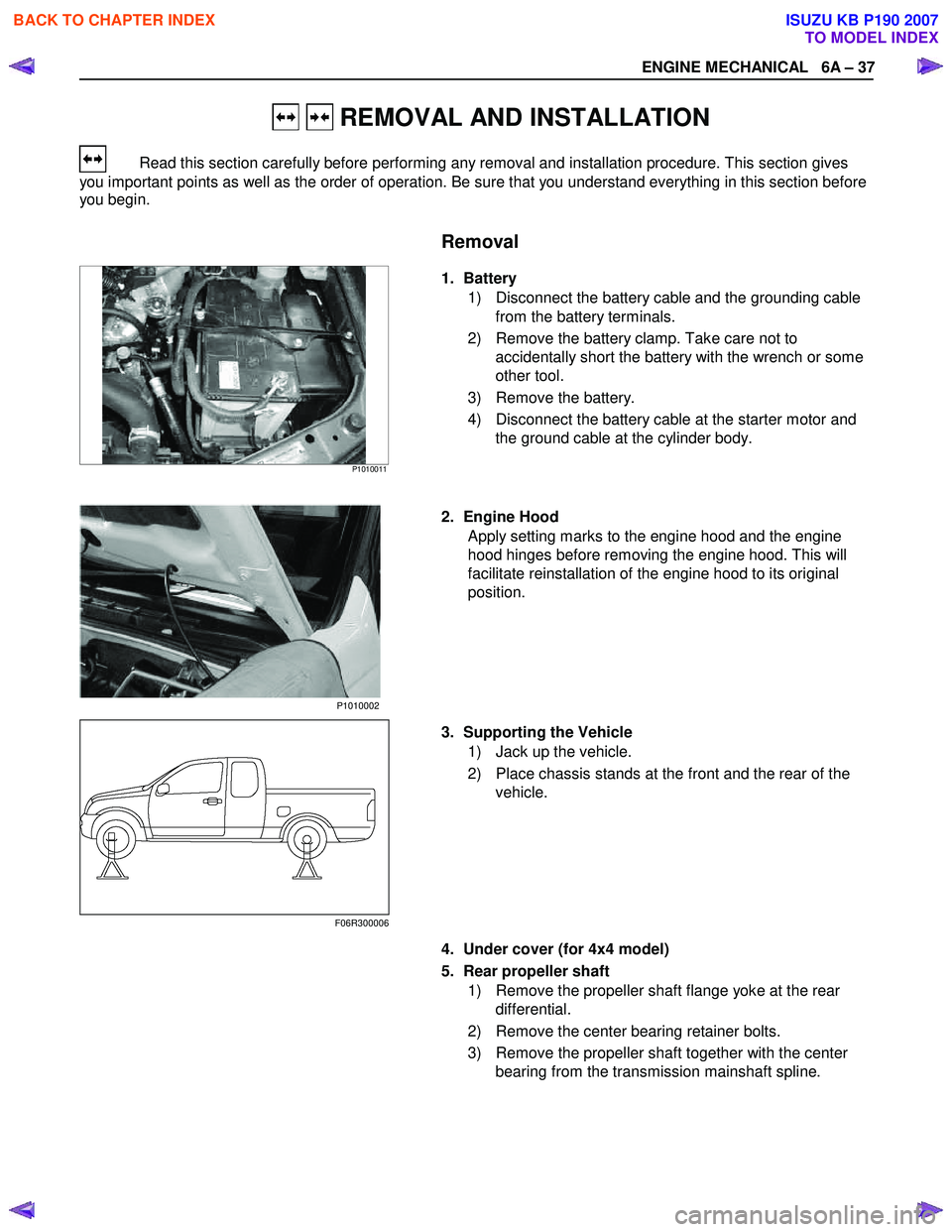

Read this section carefully before performing any removal and installation procedure. This section gives

you important points as well as the order of operation. Be sure that you understand everything in this section before

you begin.

Removal

P1010011

1. Battery

1) Disconnect the battery cable and the grounding cable from the battery terminals.

2) Remove the battery clamp. Take care not to accidentally short the battery with the wrench or some

other tool.

3) Remove the battery.

4) Disconnect the battery cable at the starter motor and the ground cable at the cylinder body.

2. Engine Hood Apply setting marks to the engine hood and the engine

hood hinges before removing the engine hood. This will

facilitate reinstallation of the engine hood to its original

position.

3. Supporting the Vehicle 1) Jack up the vehicle.

2) Place chassis stands at the front and the rear of the vehicle.

4. Under cover (for 4x4 model) 5. Rear propeller shaft 1) Remove the propeller shaft flange yoke at the rear differential.

2) Remove the center bearing retainer bolts.

3) Remove the propeller shaft together with the center bearing from the transmission mainshaft spline.

F06R300006 P1010002

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4125 of 6020

7A3-40 ON-VEHICLE SERVICE (AW30–40LE)

Removal

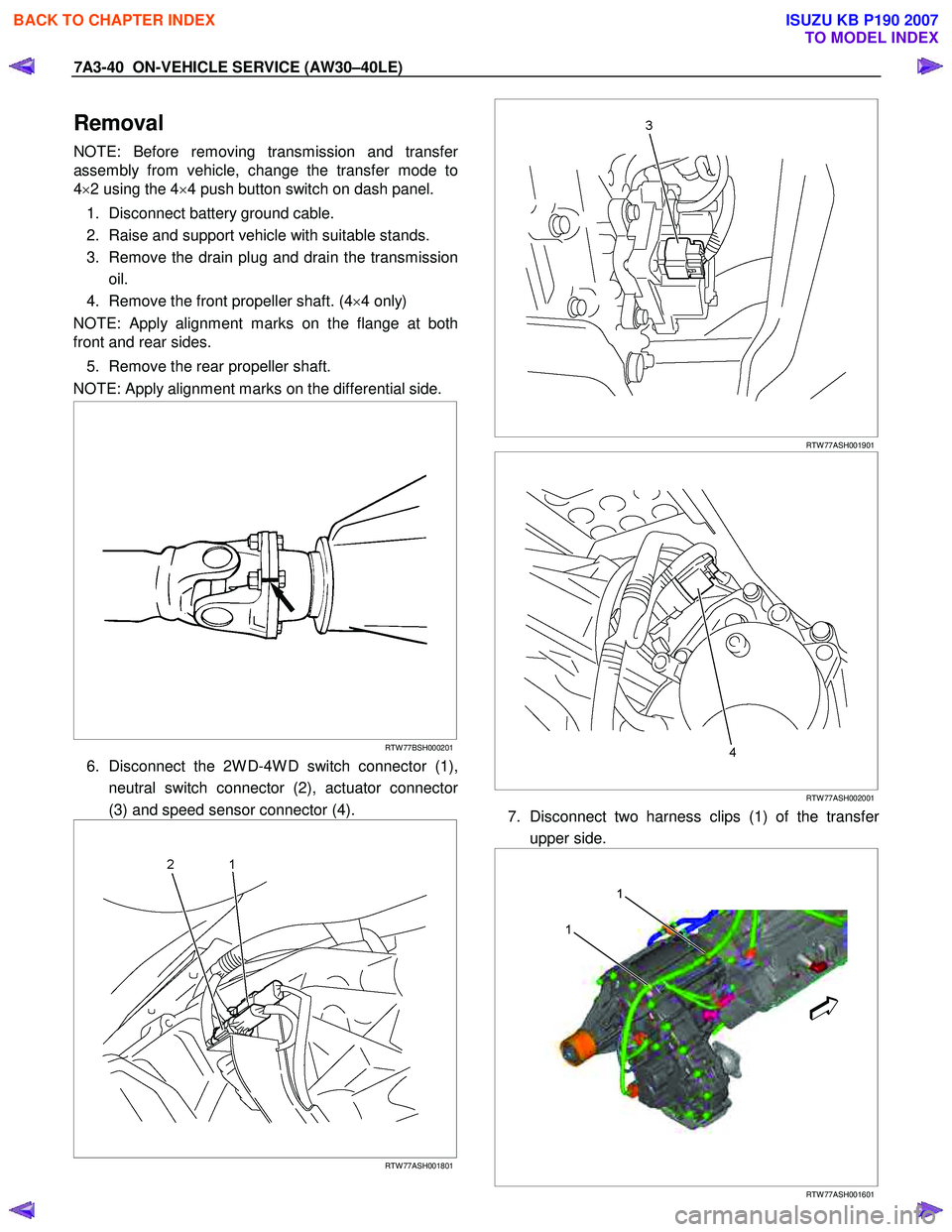

NOTE: Before removing transmission and transfer

assembly from vehicle, change the transfer mode to

4 ×2 using the 4 ×4 push button switch on dash panel.

1. Disconnect battery ground cable.

2. Raise and support vehicle with suitable stands.

3. Remove the drain plug and drain the transmission oil.

4. Remove the front propeller shaft. (4 ×4 only)

NOTE: Apply alignment marks on the flange at both

front and rear sides.

5. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the differential side.

RTW 77BSH000201

6. Disconnect the 2W D-4W D switch connector (1),

neutral switch connector (2), actuator connecto

r

(3) and speed sensor connector (4).

RTW 77ASH001801

RTW 77ASH001901

RTW 77ASH002001

7. Disconnect two harness clips (1) of the transfer

upper side.

1

1

RTW 77ASH001601

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4615 of 6020

MANUAL TRANSMISSION 7B1-9

6. Remove the gear control lever.

7. Raise and support the vehicle with suitable stands.

8. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the flange at the

differential side.

401RS023

9. Loosen the front exhaust pipe fixing nuts at the engine side but do not remove them. (Diesel engine

only)

RTW 67BSH000101

10. Disconnect the harness connectors and clips on the

transmission.

• Neutral Switch

• Back up Switch

• Car Speed Sensor

11. Remove the fuel pipe bracket with pipes from the transmission.

Diesel engine

220R300012

Legend

(1) Bolt

(2) Nut

(3) Fuel Pipe Assembly

C24SE

Scan-1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4669 of 6020

MANUAL TRANSMISSION 7B1-63

6. Remove the gear control lever.

7. Raise and support the vehicle with suitable stands.

8. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the flange at the

differential side.

9. Remove the front propeller shaft.

NOTE:

Apply alignment marks on the flange at both

front and rear sides.

401RS023

10. Loosen the front exhaust pipe fixing nuts at the engine side but do not remove them. (Diesel engine

only)

RTW 67BSH000101

11. Disconnect the harness connectors and clips on the

transmission and transfer.

• Neutral Switch: Transmission

• Back up Switch

• Actuator

• 2W D-4W D Switch

• Neutral Switch: Transfer

• Car Speed Sensor

810R300069

Legend

(1) Neutral Switch Connector: Transmission

(2) Back up Switch Connector

(3) Speed Sensor Connector

(4) Actuator Connector

(5) 2W D - 4W D Switch Connector

(6) Neutral Switch Connector: Transfer

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4728 of 6020

Manual Transmission (MUX) 7B1-9

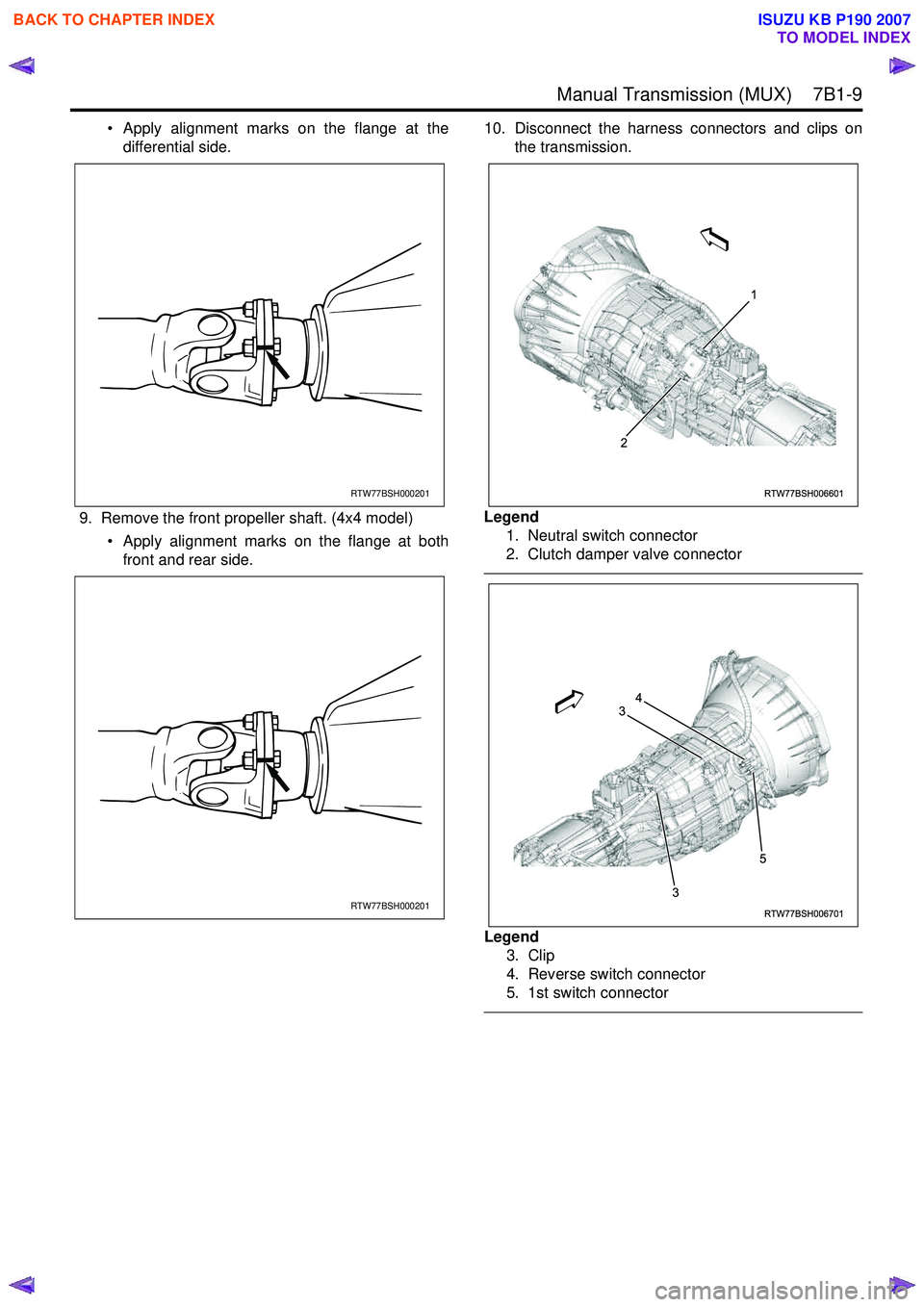

• Apply alignment marks on the flange at thedifferential side.

9. Remove the front propeller shaft. (4x4 model) • Apply alignment marks on the flange at bothfront and rear side. 10. Disconnect the harness connectors and clips on

the transmission.

Legend 1. Neutral switch connector

2. Clutch damper valve connector

Legend 3. Clip

4. Reverse switch connector

5. 1st switch connector

RTW77BSH000201

RTW77BSH000201

RTW77BSH006601

1

2

RTW77BSH006701

3

3 54

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007