spark plugs replace ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2446 of 6020

6E–276 ENGINE DRIVEABILITY AND EMISSIONS

• Oil in the combustion chamber.

• The spark plug gap is not set correctly.

If spark plug fouling is excessive, check the fuel and al

system for possible causes of trouble. If fuel and al

system are normal, install spark plugs of a higher heat

range which have the same physical dimensions as the

original equipment spark plugs.

The following symptoms are characteristics of spark

plugs that are running too hot:

• Fuel mixture is too lean.

• Heat range is incorrect.

If vehicle usage does not conform to normal driving

conditions, a more suitable spark plug may be

substituted.

If fuel and al system are normal, in most cases of this

sort, the problem can be corrected by using a colder

type spark plug with the same physical dimensions as

the original equipment spark plug.

3. Check the gaskets for damage and replace if necessary.

4. Measure the spark plug gap. The specification is 1.0 to 1.1mm (0.039 to 0.043").

5. Adjust the spark gap by bending the grounded electrode. Installation

1. Tighten the spark plug to the 25N·m (2.5kgf·m).

2. Push the spark plug cable in until it snaps in.

Installation Procedure 1. Install the spark plug to the cylinder head.

2. Tighten the spark plug with specified tightening torque.

Tightening Torque

• Bolt: 25N·m (2.5kgf·m) 3. Connect the spark plug cable to the spark plug.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify proper connection of spark plug cables for each

cylinders.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2509 of 6020

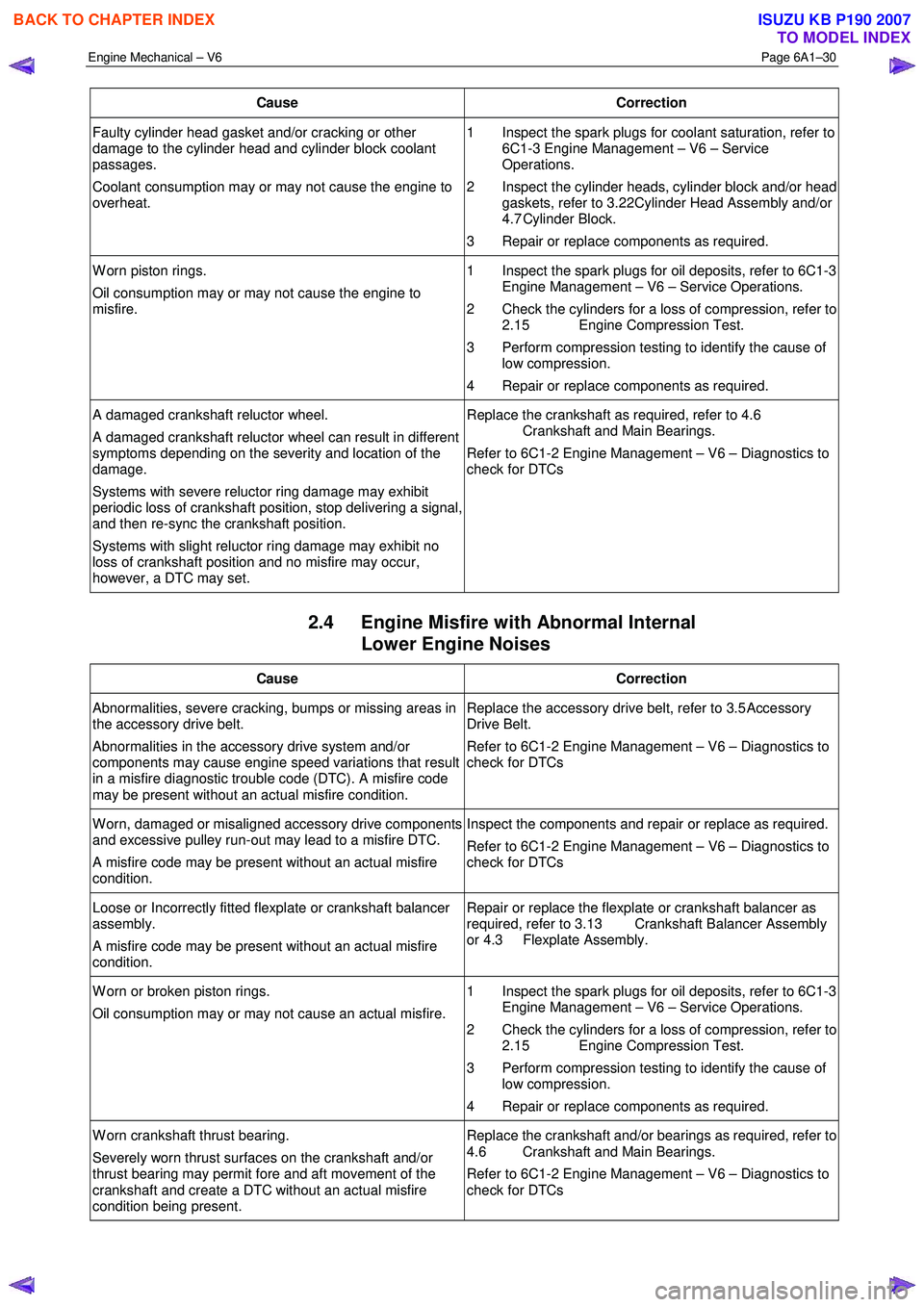

Engine Mechanical – V6 Page 6A1–30

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder head and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly and/or

4.7 Cylinder Block.

3 Repair or replace components as required.

W orn piston rings.

Oil consumption may or may not cause the engine to

misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of low compression.

4 Repair or replace components as required.

A damaged crankshaft reluctor wheel.

A damaged crankshaft reluctor wheel can result in different

symptoms depending on the severity and location of the

damage.

Systems with severe reluctor ring damage may exhibit

periodic loss of crankshaft position, stop delivering a signal,

and then re-sync the crankshaft position.

Systems with slight reluctor ring damage may exhibit no

loss of crankshaft position and no misfire may occur,

however, a DTC may set. Replace the crankshaft as required, refer to 4.6

Crankshaft and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

2.4 Engine Misfire with Abnormal Internal Lower Engine Noises

Cause Correction

Abnormalities, severe cracking, bumps or missing areas in

the accessory drive belt.

Abnormalities in the accessory drive system and/or

components may cause engine speed variations that result

in a misfire diagnostic trouble code (DTC). A misfire code

may be present without an actual misfire condition. Replace the accessory drive belt, refer to 3.5

Accessory

Drive Belt.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

W orn, damaged or misaligned accessory drive components

and excessive pulley run-out may lead to a misfire DTC.

A misfire code may be present without an actual misfire

condition. Inspect the components and repair or replace as required.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Loose or Incorrectly fitted flexplate or crankshaft balancer

assembly.

A misfire code may be present without an actual misfire

condition. Repair or replace the flexplate or crankshaft balancer as

required, refer to 3.13 Crankshaft Balancer Assembly

or 4.3 Flexplate Assembly.

W orn or broken piston rings.

Oil consumption may or may not cause an actual misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of low compression.

4 Repair or replace components as required.

W orn crankshaft thrust bearing.

Severely worn thrust surfaces on the crankshaft and/or

thrust bearing may permit fore and aft movement of the

crankshaft and create a DTC without an actual misfire

condition being present. Replace the crankshaft and/or bearings as required, refer to

4.6 Crankshaft and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2510 of 6020

Engine Mechanical – V6 Page 6A1–31

2.5 Engine Misfire with Abnormal Valve

Train Noise

Cause Correction

W orn or loose stationary hydraulic lash adjusters (SHLA)

and/or valve rocker arms.

The SHLAs, rocker arm and roller bearings should be intact

and in the correct position. Replace the SHLAs and/or rocker arms as required, refer to

3.21 Stationary Hydraulic Lash Adjuster or 3.20

Rocker Arm.

Stuck valves.

Carbon build up on the valve stems can result in the valves

not closing correctly. Repair or replace as required, refer to 3.22 Cylinder Head

Assembly.

Excessively worn or misaligned timing chain/s. Replace the timing chain/s and components as required,

refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

W orn camshaft lobes. Replace the camshaft/s and SHLAs as required, refer to

3.19 Camshaft or 3.21 Stationary Hydraulic Lash

Adjuster.

Sticking camshaft lash adjusters. Replace the lash adjusters as required, refer to 3.21

Stationary Hydraulic Lash Adjuster.

2.6 Engine Misfire with Coolant

Consumption

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder heads and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly and/or

4.7 Cylinder Block.

3 Repair or replace components as required.

2.7 Engine Misfire with Excessive Oil Consumption

Cause Correction

W orn valves, valve guides and/or valve stem oil seals. 1 Inspect the spark plugs for coolant saturation, refer to 6C1-3 Engine Management – V6 – Service

Operations.

2 Repair or replace components as required, refer to 3.22 Cylinder Head Assembly.

W orn or broken piston rings.

Oil consumption may or may not cause an actual misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of low compression.

4 Repair or replace components as required.

2.8 Engine Noise on Start-up, but only Lasting a Few Seconds

NOTE

A cold piston knock, which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when the specific cylinder’s

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2514 of 6020

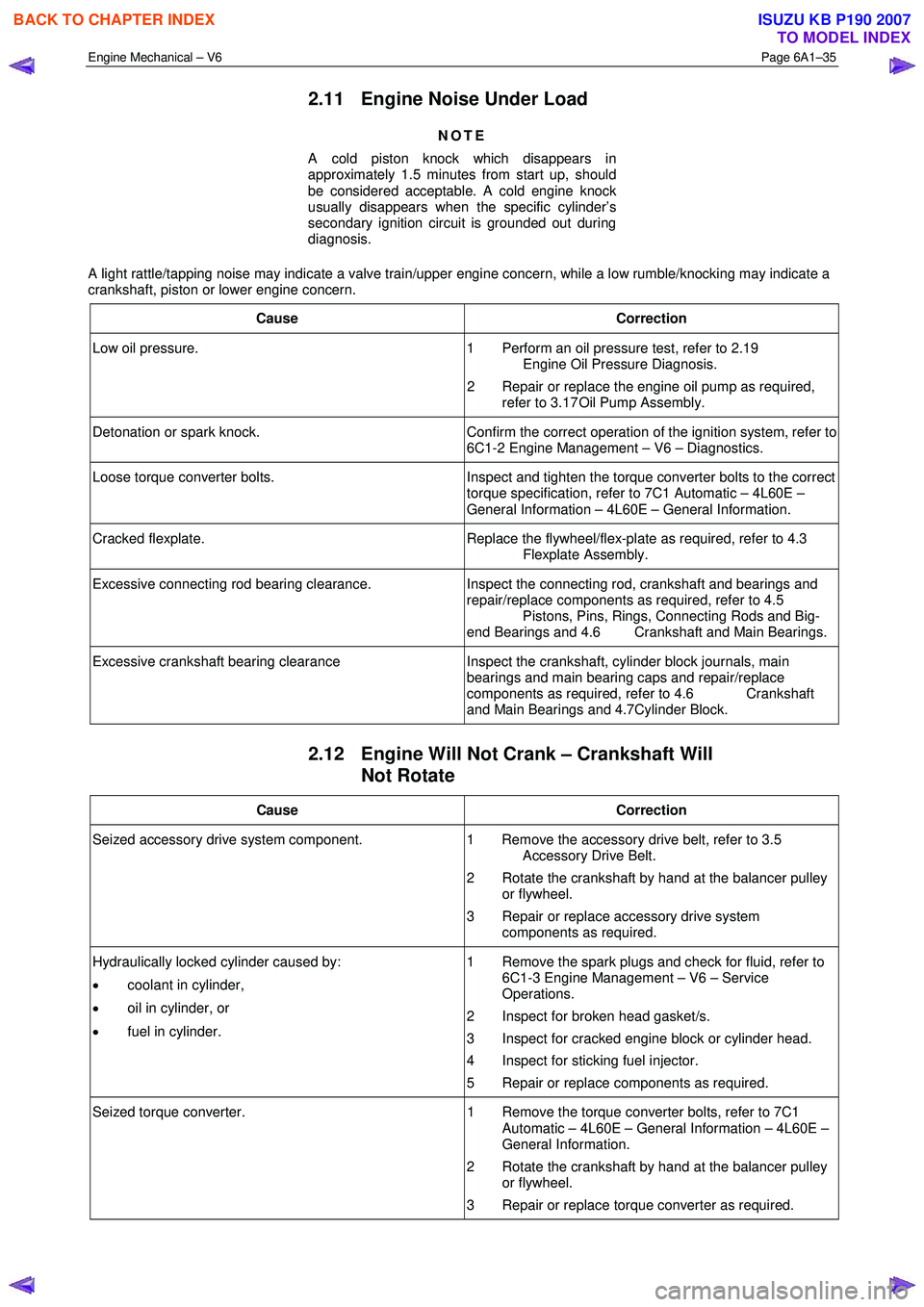

Engine Mechanical – V6 Page 6A1–35

2.11 Engine Noise Under Load

NOTE

A cold piston knock which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when the specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Low oil pressure. 1 Perform an oil pressure test, refer to 2.19

Engine Oil Pressure Diagnosis.

2 Repair or replace the engine oil pump as required, refer to 3.17 Oil Pump Assembly.

Detonation or spark knock. Confirm the correct operation of the ignition system, refer to

6C1-2 Engine Management – V6 – Diagnostics.

Loose torque converter bolts. Inspect and tighten the torque converter bolts to the correct

torque specification, refer to 7C1 Automatic – 4L60E –

General Information – 4L60E – General Information.

Cracked flexplate. Replace the flywheel/flex-plate as required, refer to 4.3

Flexplate Assembly.

Excessive connecting rod bearing clearance. Inspect the connecting rod, crankshaft and bearings and

repair/replace components as required, refer to 4.5

Pistons, Pins, Rings, Connecting Rods and Big-

end Bearings and 4.6 Crankshaft and Main Bearings.

Excessive crankshaft bearing clearance Inspect the crankshaft, cylinder block journals, main

bearings and main bearing caps and repair/replace

components as required, refer to 4.6 Crankshaft

and Main Bearings and 4.7Cylinder Block.

2.12 Engine Will Not Crank – Crankshaft Will Not Rotate

Cause Correction

Seized accessory drive system component. 1 Remove the accessory drive belt, refer to 3.5

Accessory Drive Belt.

2 Rotate the crankshaft by hand at the balancer pulley or flywheel.

3 Repair or replace accessory drive system components as required.

Hydraulically locked cylinder caused by:

• coolant in cylinder,

• oil in cylinder, or

• fuel in cylinder. 1 Remove the spark plugs and check for fluid, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect for broken head gasket/s.

3 Inspect for cracked engine block or cylinder head.

4 Inspect for sticking fuel injector.

5 Repair or replace components as required.

Seized torque converter. 1 Remove the torque converter bolts, refer to 7C1

Automatic – 4L60E – General Information – 4L60E –

General Information.

2 Rotate the crankshaft by hand at the balancer pulley or flywheel.

3 Repair or replace torque converter as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2516 of 6020

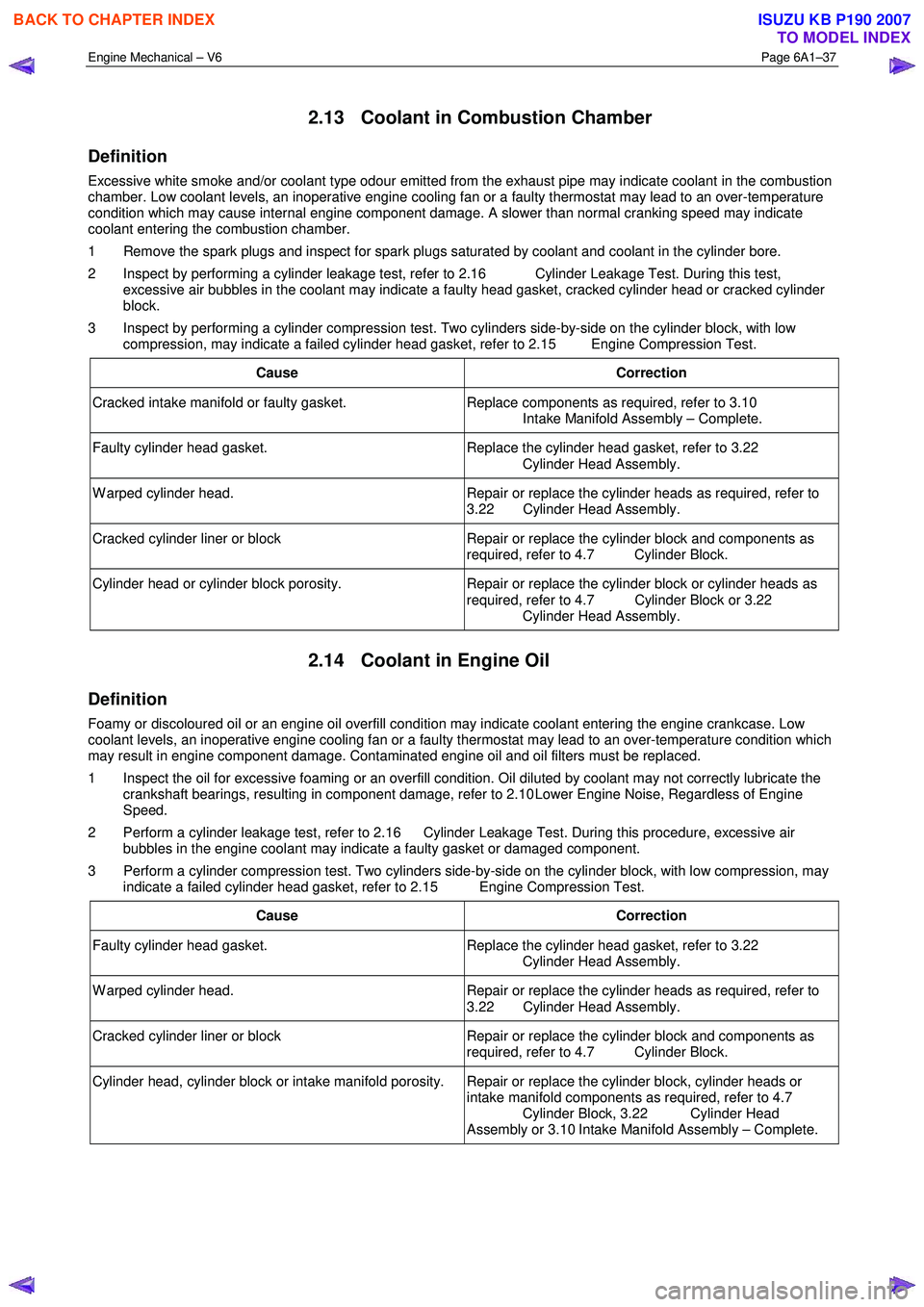

Engine Mechanical – V6 Page 6A1–37

2.13 Coolant in Combustion Chamber

Definition

Excessive white smoke and/or coolant type odour emitted from the exhaust pipe may indicate coolant in the combustion

chamber. Low coolant levels, an inoperative engine cooling fan or a faulty thermostat may lead to an over-temperature

condition which may cause internal engine component damage. A slower than normal cranking speed may indicate

coolant entering the combustion chamber.

1 Remove the spark plugs and inspect for spark plugs saturated by coolant and coolant in the cylinder bore.

2 Inspect by performing a cylinder leakage test, refer to 2.16 Cylinder Leakage Test. During this test, excessive air bubbles in the coolant may indicate a faulty head gasket, cracked cylinder head or cracked cylinder

block.

3 Inspect by performing a cylinder compression test. Two cylinders side-by-side on the cylinder block, with low compression, may indicate a failed cylinder head gasket, refer to 2.15 Engine Compression Test.

Cause Correction

Cracked intake manifold or faulty gasket. Replace components as required, refer to 3.10

Intake Manifold Assembly – Complete.

Faulty cylinder head gasket. Replace the cylinder head gasket, refer to 3.22

Cylinder Head Assembly.

W arped cylinder head. Repair or replace the cylinder heads as required, refer to

3.22 Cylinder Head Assembly.

Cracked cylinder liner or block Repair or replace the cylinder block and components as

required, refer to 4.7 Cylinder Block.

Cylinder head or cylinder block porosity. Repair or replace the cylinder block or cylinder heads as

required, refer to 4.7 Cylinder Block or 3.22

Cylinder Head Assembly.

2.14 Coolant in Engine Oil

Definition

Foamy or discoloured oil or an engine oil overfill condition may indicate coolant entering the engine crankcase. Low

coolant levels, an inoperative engine cooling fan or a faulty thermostat may lead to an over-temperature condition which

may result in engine component damage. Contaminated engine oil and oil filters must be replaced.

1 Inspect the oil for excessive foaming or an overfill condition. Oil diluted by coolant may not correctly lubricate the crankshaft bearings, resulting in component damage, refer to 2.10 Lower Engine Noise, Regardless of Engine

Speed.

2 Perform a cylinder leakage test, refer to 2.16 Cylinder Leakage Test. During this procedure, excessive air bubbles in the engine coolant may indicate a faulty gasket or damaged component.

3 Perform a cylinder compression test. Two cylinders side-by-side on the cylinder block, with low compression, may indicate a failed cylinder head gasket, refer to 2.15 Engine Compression Test.

Cause Correction

Faulty cylinder head gasket. Replace the cylinder head gasket, refer to 3.22

Cylinder Head Assembly.

W arped cylinder head. Repair or replace the cylinder heads as required, refer to

3.22 Cylinder Head Assembly.

Cracked cylinder liner or block Repair or replace the cylinder block and components as

required, refer to 4.7 Cylinder Block.

Cylinder head, cylinder block or intake manifold porosity. Repair or replace the cylinder block, cylinder heads or intake manifold components as required, refer to 4.7

Cylinder Block, 3.22 Cylinder Head

Assembly or 3.10 Intake Manifold Assembly – Complete.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2518 of 6020

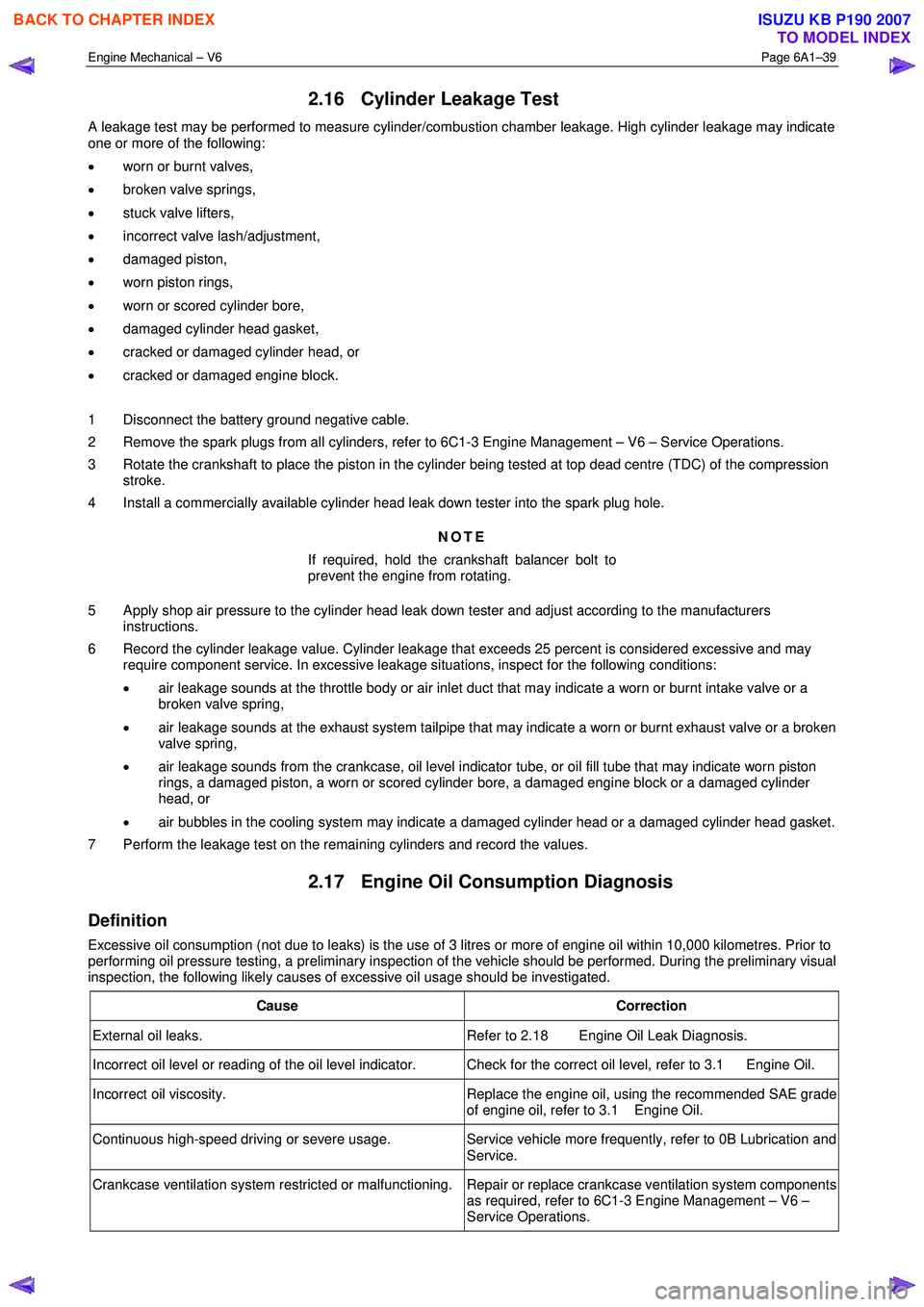

Engine Mechanical – V6 Page 6A1–39

2.16 Cylinder Leakage Test

A leakage test may be performed to measure cylinder/combustion chamber leakage. High cylinder leakage may indicate

one or more of the following:

• worn or burnt valves,

• broken valve springs,

• stuck valve lifters,

• incorrect valve lash/adjustment,

• damaged piston,

• worn piston rings,

• worn or scored cylinder bore,

• damaged cylinder head gasket,

• cracked or damaged cylinder head, or

• cracked or damaged engine block.

1 Disconnect the battery ground negative cable.

2 Remove the spark plugs from all cylinders, refer to 6C1-3 Engine Management – V6 – Service Operations.

3 Rotate the crankshaft to place the piston in the cylinder being tested at top dead centre (TDC) of the compression stroke.

4 Install a commercially available cylinder head leak down tester into the spark plug hole.

NOTE

If required, hold the crankshaft balancer bolt to

prevent the engine from rotating.

5 Apply shop air pressure to the cylinder head leak down tester and adjust according to the manufacturers instructions.

6 Record the cylinder leakage value. Cylinder leakage that exceeds 25 percent is considered excessive and may require component service. In excessive leakage situations, inspect for the following conditions:

• air leakage sounds at the throttle body or air inlet duct that may indicate a worn or burnt intake valve or a

broken valve spring,

• air leakage sounds at the exhaust system tailpipe that may indicate a worn or burnt exhaust valve or a broken

valve spring,

• air leakage sounds from the crankcase, oil level indicator tube, or oil fill tube that may indicate worn piston

rings, a damaged piston, a worn or scored cylinder bore, a damaged engine block or a damaged cylinder

head, or

• air bubbles in the cooling system may indicate a damaged cylinder head or a damaged cylinder head gasket.

7 Perform the leakage test on the remaining cylinders and record the values.

2.17 Engine Oil Consumption Diagnosis

Definition

Excessive oil consumption (not due to leaks) is the use of 3 litres or more of engine oil within 10,000 kilometres. Prior to

performing oil pressure testing, a preliminary inspection of the vehicle should be performed. During the preliminary visual

inspection, the following likely causes of excessive oil usage should be investigated.

Cause Correction

External oil leaks. Refer to 2.18 Engine Oil Leak Diagnosis.

Incorrect oil level or reading of the oil level indicator. Check for the correct oil level, refer to 3.1 Engine Oil.

Incorrect oil viscosity. Replace the engine oil, using the recommended SAE grade

of engine oil, refer to 3.1 Engine Oil.

Continuous high-speed driving or severe usage. Service vehicle more frequently, refer to 0B Lubrication and

Service.

Crankcase ventilation system restricted or malfunctioning. Repair or replace crankcase ventilation system components as required, refer to 6C1-3 Engine Management – V6 –

Service Operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2810 of 6020

Engine Mechanical – V6 Page 6A1–33

Page 6A1–33

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder head and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for

coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly

and/or 4.7 Cylinder Block.

3 Repair or replace components as required.

Worn piston rings.

Oil consumption may or ma y not cause the engine to

misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

A damaged crankshaft reluctor wheel.

A damaged crankshaft reluctor wheel can result in different

symptoms depending on the severity and location of the

damage.

Systems with severe relu ctor ring damage may exhibit

periodic loss of crankshaft posit ion, stop delivering a signal,

and then re-sync the crankshaft position.

Systems with slight reluctor ring damage may exhibit no

loss of crankshaft position and no misfire may occur,

however, a DTC may set. Replace the crankshaft as required, refer to 4.6 Crankshaft

and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2811 of 6020

Engine Mechanical – V6 Page 6A1–34

Page 6A1–34

2.4 Engine Misfire with Abnormal Internal

Lower Engine Noises

Cause Correction

Abnormalities, severe cracking, bumps or missing areas in

the accessory drive belt.

Abnormalities in the accessory drive system and/or

components may cause engine speed variations that result

in a misfire diagnostic trouble code (DTC). A misfire code

may be present without an ac tual misfire condition. Replace the accessory drive belt, refer to 3.5 Accessory

Drive Belt.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Worn, damaged or misaligned accessory drive components

and excessive pulley run-out may lead to a misfire DTC.

A misfire code may be present without an actual misfire

condition. Inspect the components and repair or replace as required.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Loose or Incorrectly fitted flexplate or crankshaft balancer

assembly.

A misfire code may be present without an actual misfire

condition. Repair or replace the flexplat

e or crankshaft balancer as

required, refer to 3.13 Crankshaft Balancer Assembly or

4.3 Flexplate Assembly.

Worn or broken piston rings.

Oil consumption may or may not cause an actual misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

Worn crankshaft thrust bearing.

Severely worn thrust surfaces on the crankshaft and/or

thrust bearing may permit fore and aft movement of the

crankshaft and create a DTC wi thout an actual misfire

condition being present. Replace the crankshaft and/or bear

ings as required, refer to

4.6 Crankshaft and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2813 of 6020

Engine Mechanical – V6 Page 6A1–36

Page 6A1–36

2.6 Engine Misfire with Coolant

Consumption

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder heads and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for

coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly

and/or 4.7 Cylinder Block.

3 Repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2814 of 6020

Engine Mechanical – V6 Page 6A1–37

Page 6A1–37

2.7 Engine Misfire with Excessive Oil

Consumption

Cause Correction

Worn valves, valve guides and/or valve stem oil seals. 1 Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Repair or replace components as required, refer to 3.22 Cylinder Head Assembly.

Worn or broken piston rings.

Oil consumption may or may not cause an actual misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007