sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1670 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-53

Cam/ Crank Sensor Signal/ Synchronization Status

This parameter displays the synchronization state of

the crankshaft position (CKP) sensor signal and

camshaft position (CMP) sensor signal. Asynchronous

indicates the CMP sensor signal is not detected or only

CKP sensor signal is detected. No Crank Signal

indicates CMP sensor signal is detected but CKP

sensor signal is not detected. Synchronous indicates

both sensor signals are detected correctly.

Engine Runtime

This parameter displays the time elapsed since the

engine start. The scan tool will display the time in

hours, minutes and seconds. The engine run time will

reset to zero as soon as the ignition switch is OFF.

Vehicle Speed

This parameter indicates the vehicle speed calculated

by the ECM using the signal from the vehicle speed

sensor (VSS). The scan tool will display a low value at

lower vehicle speeds, and a high value at higher

vehicle speeds.

Transmission Gear

This parameter displays the estimated transmission

gear position as calculated by the ECM based on

inputs from the vehicle speed and the engine speed.

Starter Switch

This parameter displays the input status of the starter

switch to the ECM. When the ignition switch is turned at

START position, the scan tool displays On.

Ignition Switch

This parameter displays the input status of the ignition

switch to the ECM. When the ignition switch is turned

ON position, the scan tool displays On.

Ignition Voltage

This parameter displays the ignition voltage measured

at the ignition feed circuit of the ECM. Voltage is

applied to the ECM when the ignition switch is ON

position.

Battery Voltage

This parameter displays the battery voltage measured

at the ECM main relay switched voltage feed circuit of

the ECM. Voltage is applied to the ECM when the ECM

main relay is energized.

Fuel Pump Relay Command

This parameter displays the commanded state of the

fuel pump relay control circuit. On indicates the fuel

pump relay control circuit is being grounded by the

ECM, allowing fuel pumping from the tank.

Swirl Control Solenoid Command

This parameter displays the commanded state of the

swirl control solenoid control circuit. On indicates the

swirl control solenoid control circuit is being grounded

by the ECM, allowing vacuum pressure to the swirl

control

actuator. Fuel Filter Switch

This parameter displays the input state of the fuel

pressure switch to the ECM. When the large vacuum

pressure is generated in the fuel suction line such as

clogged fuel filter, the scan tool displays Off.

A/C Request Signal

This parameter displays the input state of the air

conditioning (A/C) request to the ECM from the

heating, ventilation, and air conditioning (HVAC)

controls. When the HVAC system is requesting to

ground the A/C compressor clutch, the scan tool

displays On.

A/C Relay Command

This parameter displays the commanded state of the A/

C compressor relay control circuit. On indicates the A/C

compressor relay control circuit is being grounded by

the ECM, allowing voltage to the A/C compressor.

Park/ Neutral Switch

This parameter displays the input state of the neutral

switch to the ECM. When the transmission gear is Park

or Neutral, the scan tool displays Neutral.

Glow Relay Command

This parameter displays the commanded state of the

glow relay control circuit. On indicates the glow relay

control circuit is being grounded by the ECM, allowing

voltage to the glow plugs.

Glow Plug Lamp Command

This parameter displays the commanded state of the

glow indicator lamp control circuit. The glow indicator

lamp should be On when the scan tool indicates

command On. The glow indicator lamp should be Off

when the scan tool indicates command Off.

Brake Switch 1

This parameter displays the input state of the brake

pedal switch 1 to the ECM. When the brake pedal is

depressed, scan tool displays Applied.

Brake Switch 2

This parameter displays the input state of the brake

pedal switch 2 to the ECM. When the brake pedal is

depressed, scan tool displays Applied.

Clutch Pedal Switch

This parameter displays the input state of the clutch

pedal switch to the ECM. When the clutch pedal is

depressed, scan tool displays Applied.

Cruise Main Lamp Command

This parameter displays the commanded state of the

cruise main lamp control circuit. The cruise main lamp

should be On when the scan tool indicates command

On. The cruise main lamp should be Off when the scan

tool indicates command Off.

Cruise Main Switch

This parameter displays the input state of the cruise

main switch to the ECM. When the Cruise Main switch

is pushed, the scan tool displays On.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1681 of 6020

6E-64 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

61. Turn OFF the ignition.

2. Disconnect the FRP sensor harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the FRP sensor (pins 1, 2 and 3

of E-48).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 47, 48, 68 and 69

of E-90).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 7

7 Replace the FRP sensor. Refer to FRP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 11

—

8Repair the short to ground between the ECM (pins

50 and 70 of E-90) and the FRP regulator (pin 2 of

E-50).

Did you compete the repair? —

Go to Step 11

—

91. Check for normal readings at key up for the

following sensor inputs: Use the Scan Tool

Data List or a known good vehicle to

determine nominal values.

• Engine Coolant Temperature Sensor

• Barometric Pressure (BARO) Sensor

• Boost Pressure Sensor

• Intake Throttle Position Sensor

2. Repair the circuit(s) or replace the sensor as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 10

10 1. Other possible causes for the no-start

condition:

• Engine mechanical timing

• Heavily restricted intake or exhaust plugged solid.

• Poor engine compression.

• Water or gasoline contamination in fuel.

2. Repair as necessary.

Did you find and correct the condition? —

Go to Step 11

—

111. Reconnect all previously disconnected

harness connector(s).

2. Turn OFF the ignition for 30 seconds.

3. Attempt to start the engine.

Does the engine start and continue to run? —

Go to Step 12 Go to Step 2

12 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1682 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-65

Circuit/ System Testing Engine Cranks but Does Not Run (2 of 2)

StepAction Value(s)Yes No

1 1. Remove the engine cover.

2. Perform the Injector Force Drive with a scan tool.

3. Command each injector ON and verify clicking noise (solenoid operating noise).

Is there an injector that does not create a clicking

noise (solenoid operating noise), contains an

interrupted noise or abnormal noise when

commanded ON? —

Go to Step 8 Go to Step 2

2 1. Inspect the high pressure side between the

fuel supply pump and the fuel injectors for fuel

leakage. The following components may

contain an external leak.

• Fuel supply pump

• Fuel rail

•Pressure limiter valve

• Fuel rail pressure (FRP) sensor

• Fuel pipe between the fuel supply pump and fuel rail

• Fuel pipe between the fuel rail and fuel injectors

• Each fuel pipe sleeve nuts

Notice: Fuel may leak under the cylinder head

cover from the inlet high pressure line. In such

case, the engine oil level will rise. Inspect for fuel

leakage into the engine oil.

2. Repair any fuel system leaks as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 3

3 1. Check the fuel system line connections

between the fuel tank and the fuel supply

pump for tightness and all fuel hoses for cuts,

cracks and for the use of proper clamps.

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1686 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-69

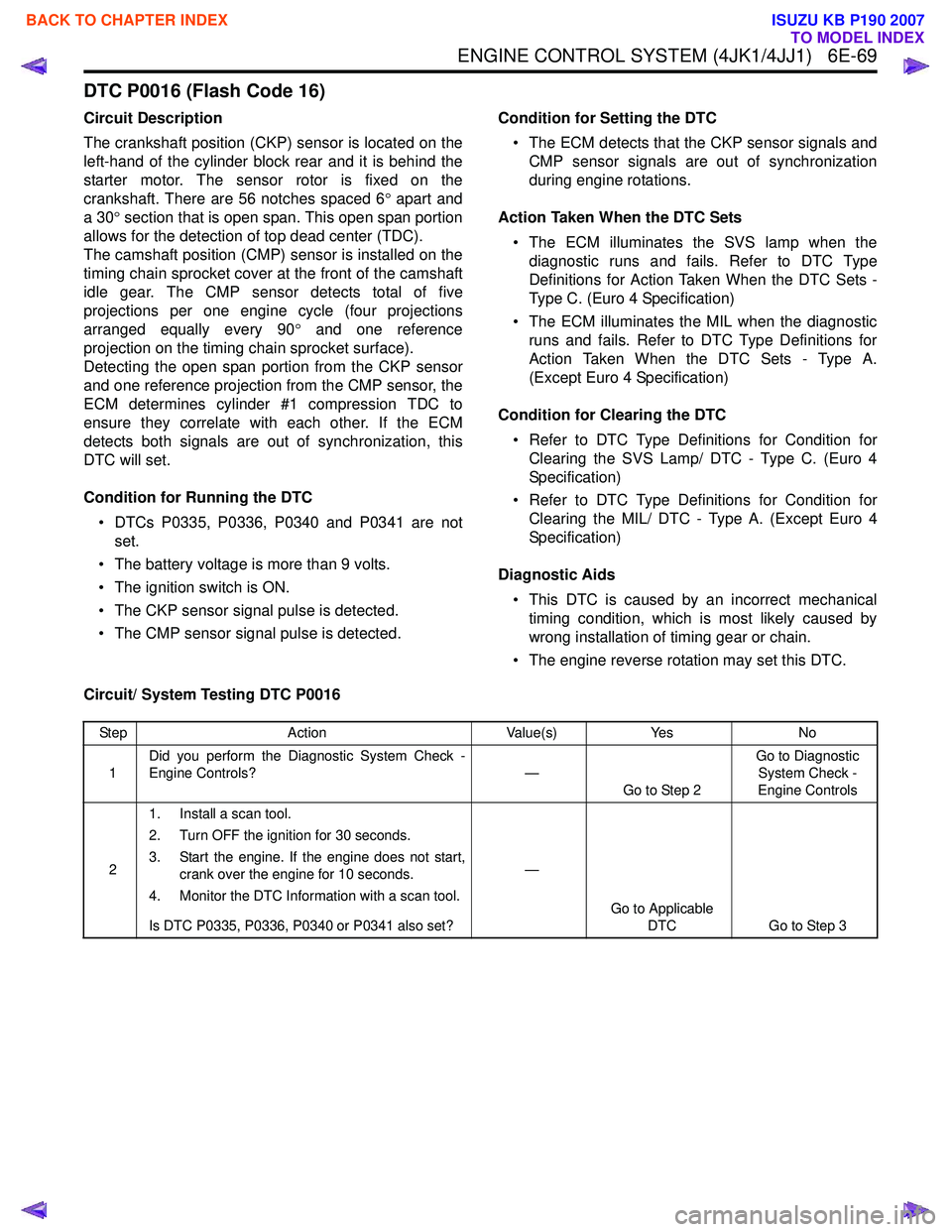

DTC P0016 (Flash Code 16)

Circuit Description

The crankshaft position (CKP) sensor is located on the

left-hand of the cylinder block rear and it is behind the

starter motor. The sensor rotor is fixed on the

crankshaft. There are 56 notches spaced 6 ° apart and

a 30 ° section that is open span. This open span portion

allows for the detection of top dead center (TDC).

The camshaft position (CMP) sensor is installed on the

timing chain sprocket cover at the front of the camshaft

idle gear. The CMP sensor detects total of five

projections per one engine cycle (four projections

arranged equally every 90 ° and one reference

projection on the timing chain sprocket surface).

Detecting the open span portion from the CKP sensor

and one reference projection from the CMP sensor, the

ECM determines cylinder #1 compression TDC to

ensure they correlate with each other. If the ECM

detects both signals are out of synchronization, this

DTC will set.

Condition for Running the DTC • DTCs P0335, P0336, P0340 and P0341 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CKP sensor signal pulse is detected.

• The CMP sensor signal pulse is detected. Condition for Setting the DTC

• The ECM detects that the CKP sensor signals and CMP sensor signals are out of synchronization

during engine rotations.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • This DTC is caused by an incorrect mechanical timing condition, which is most likely caused by

wrong installation of timing gear or chain.

• The engine reverse rotation may set this DTC.

Circuit/ System Testing DTC P0016

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

4. Monitor the DTC Information with a scan tool.

Is DTC P0335, P0336, P0340 or P0341 also set? —

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1687 of 6020

6E-70 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

31. Inspect the crankshaft position (CKP) sensor

and the camshaft position (CMP) sensor for

the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between sensor and sensor rotor or chain sprocket

• Physical damage of sensor rotor or chain sprocket

• Loose or improper installation of sensor rotor or chain sprocket

2. Inspect the engine mechanical timing for the following conditions:

• Incorrectly installed timing gear or chain

• Faulty timing chain tensioner

• Excessive play in the timing chain

• Timing chain that jumped teeth

3. Repair or replace as necessary.

Did you complete the repair? —

Go to Step 4

—

41. Reconnect all previously disconnected

harness connector(s) if disconnected.

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 5

5 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1688 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-71

DTC P0045 (Flash Code 33)

Circuit Description

The position of the turbocharger nozzle is controlled by

the ECM. The ECM utilizes a turbocharger nozzle

control solenoid valve and a boost pressure sensor to

control the turbocharger nozzles. When the engine is

not under load, the turbocharger nozzles are in an open

position, or no boost condition. When the engine is

under load, the ECM commands the control solenoid

valve to close the turbocharger nozzles, thus

increasing the boost. The ECM will vary the boost

dependant upon the load requirements of the engine.

The ECM uses a pulse width modulation (PWM) on the

control circuit to open and control the solenoid valve. If

the ECM detects an open circuit or short circuit on the

solenoid valve circuit, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The ECM detects a low voltage condition on the turbocharger nozzle control solenoid circuit when

the solenoid is commanded OFF.

• The ECM detects a high voltage condition on the turbocharger nozzle control solenoid circuit when

the solenoid is commanded ON. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Test description

The number below refers to the step number on the

Circuit/ System Testing.

4. If the solenoid control circuit between the ECM and

the solenoid is normal, the test lamp changes from

Bright to Dim when commanded from Increase to

Decrease.

Schematic Reference: Vacuum Hose Routing

Diagram and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0045

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the turbocharger nozzle control solenoid valve harness connector.

3. Connect a test lamp between the ignition voltage feed circuit (pin 2 of E-106) and a

known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 4 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1691 of 6020

6E-74 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

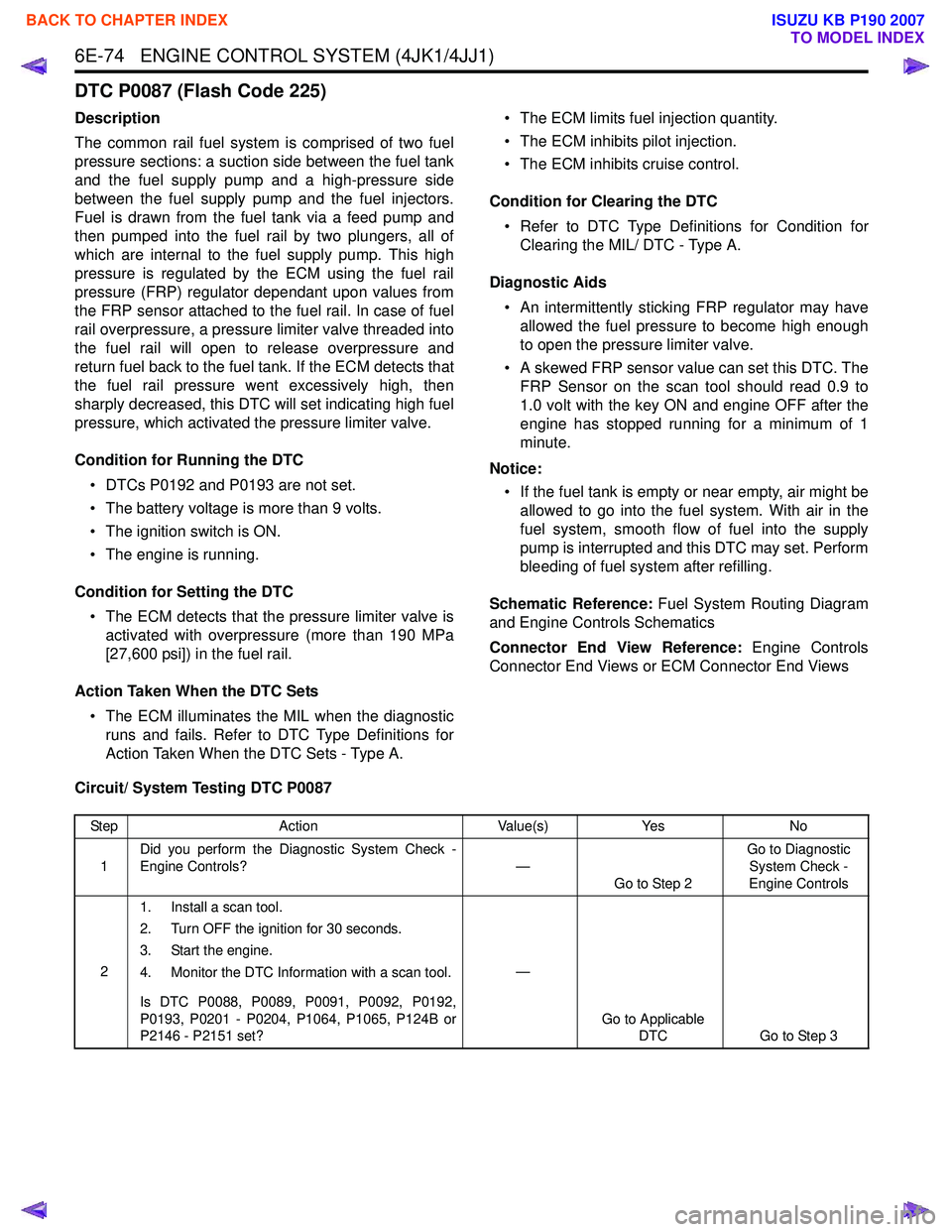

DTC P0087 (Flash Code 225)

Description

The common rail fuel system is comprised of two fuel

pressure sections: a suction side between the fuel tank

and the fuel supply pump and a high-pressure side

between the fuel supply pump and the fuel injectors.

Fuel is drawn from the fuel tank via a feed pump and

then pumped into the fuel rail by two plungers, all of

which are internal to the fuel supply pump. This high

pressure is regulated by the ECM using the fuel rail

pressure (FRP) regulator dependant upon values from

the FRP sensor attached to the fuel rail. In case of fuel

rail overpressure, a pressure limiter valve threaded into

the fuel rail will open to release overpressure and

return fuel back to the fuel tank. If the ECM detects that

the fuel rail pressure went excessively high, then

sharply decreased, this DTC will set indicating high fuel

pressure, which activated the pressure limiter valve.

Condition for Running the DTC • DTCs P0192 and P0193 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC • The ECM detects that the pressure limiter valve is activated with overpressure (more than 190 MPa

[27,600 psi]) in the fuel rail.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A. • The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • An intermittently sticking FRP regulator may have allowed the fuel pressure to become high enough

to open the pressure limiter valve.

• A skewed FRP sensor value can set this DTC. The FRP Sensor on the scan tool should read 0.9 to

1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1

minute.

Notice: • If the fuel tank is empty or near empty, air might be allowed to go into the fuel system. With air in the

fuel system, smooth flow of fuel into the supply

pump is interrupted and this DTC may set. Perform

bleeding of fuel system after refilling.

Schematic Reference: Fuel System Routing Diagram

and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0087

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0088, P0089, P0091, P0092, P0192,

P0193, P0201 - P0204, P1064, P1065, P124B or

P2146 - P2151 set? —

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1692 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-75

31. Turn OFF the ignition.

2. Place the transmission in Neutral and set the parking brake.

3. Start the engine.

4. Accelerate the engine between idle and W.O.T. (accelerator pedal full travel) many

times while observing the DTC Information

with a scan tool.

Does the DTC fail this ignition? —

Go to Step 4 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Wait 1 minute for the fuel pressure to bleed down from the fuel rail.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Observe the Fuel Rail Pressure (FRP) Sensor parameter with the scan tool.

Does the scan tool indicate within the specified

value? 0.9 to 1.0 volt

Go to Step 5 Go to Step 10

5 1. Start the engine.

2. Perform the Cylinder Balance Test with a scan tool.

3. Command each injector OFF and verify an engine speed change for each injector.

Is there an injector that does not change engine

speed when commanded OFF? —

Go to Step 12 Go to Step 6

6 1. Check the fuel system line connections

between the fuel tank and the fuel supply

pump for tightness and all fuel hoses for cuts,

cracks and for the use of proper clamps.

Notice: Air in the fuel system will cause fuel rail

pressure fluctuations especially at high engine

speed and load, which may set this DTC.

2. Start the engine and check for high side fuel system leaks at the fuel supply pump and fuel

rail.

Notice: Fuel may leak under the cylinder head

cover from the inlet high pressure line. In such

case, the engine oil level will rise. Inspect for fuel

leakage into the engine oil.

3. Repair any fuel system leaks as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 7

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1694 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-77

91. Turn OFF the ignition.

2. Disconnect the FRP regulator harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the FRP regulator (pins 1 and 2

of E-50).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 34, 50, 54 and 70

of E-90).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 13

10 1. Turn OFF the ignition.

2. Disconnect the FRP sensor harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the FRP sensor (pins 1, 2 and 3

of E-48).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 47, 48, 68 and 69

of E-90).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 11

11 Replace the FRP sensor. Refer to FRP sensor

Replacement.

Did you complete the replacement? —

Go to Step 14

—

12Important:

Replacement fuel injector must be

programmed.

Replace the appropriate fuel injector that does not

change engine speed when commanded OFF.

Refer to Fuel Injector Replacement/ Fuel Injector

ID Code Data Programming.

Did you complete the replacement? —

Go to Step 14

—

13Important:

The fuel supply pump must be timed to

the engine and adjustment value must be learned

to the ECM.

Notice: Always replace the fuel filter cartridge

when a fuel supply pump is replaced.

Replace the fuel supply pump and fuel filter

cartridge. Refer to Fuel Supply Pump Replacement

and Fuel Filter Cartridge Replacement.

Did you complete the replacement? —

Go to Step 14

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1696 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-79

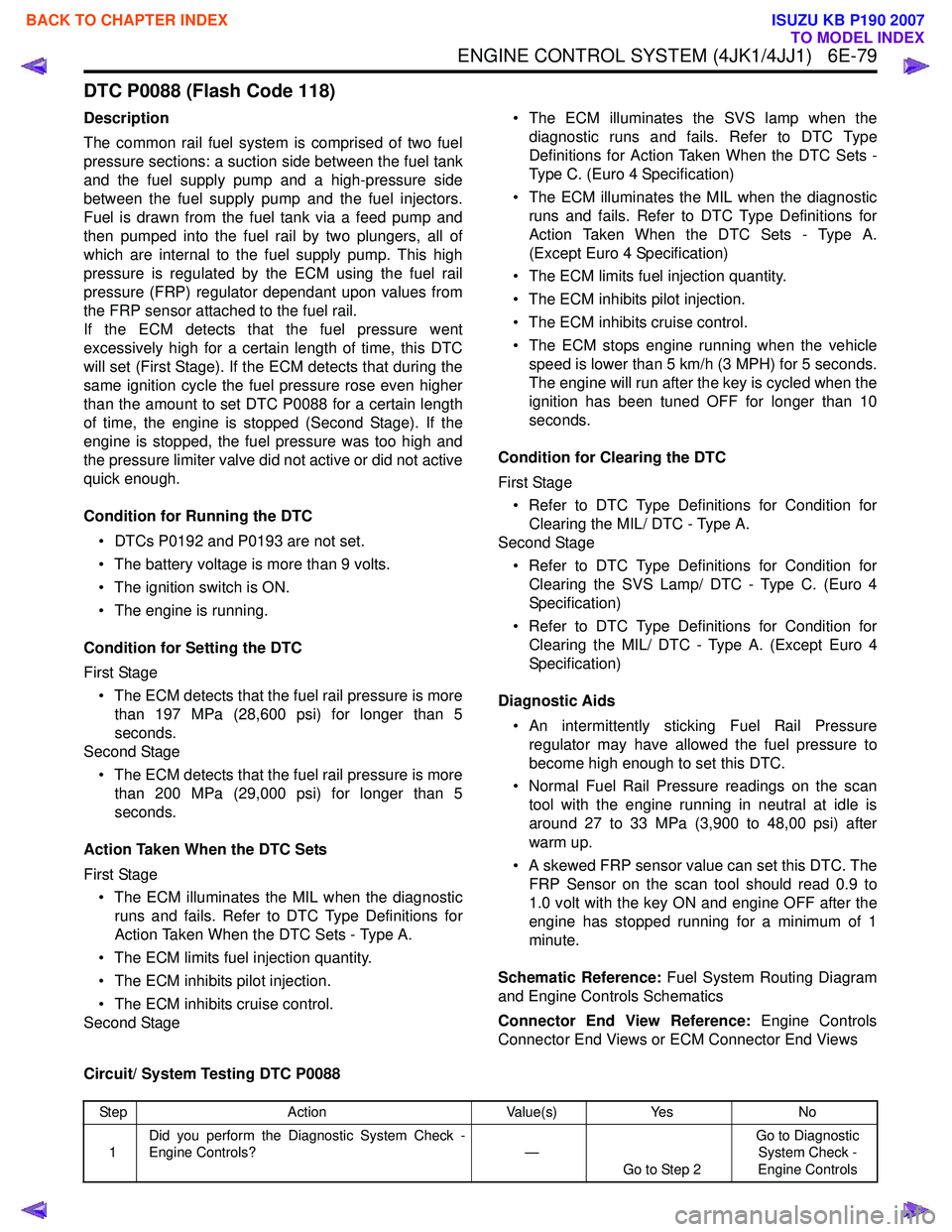

DTC P0088 (Flash Code 118)

Description

The common rail fuel system is comprised of two fuel

pressure sections: a suction side between the fuel tank

and the fuel supply pump and a high-pressure side

between the fuel supply pump and the fuel injectors.

Fuel is drawn from the fuel tank via a feed pump and

then pumped into the fuel rail by two plungers, all of

which are internal to the fuel supply pump. This high

pressure is regulated by the ECM using the fuel rail

pressure (FRP) regulator dependant upon values from

the FRP sensor attached to the fuel rail.

If the ECM detects that the fuel pressure went

excessively high for a certain length of time, this DTC

will set (First Stage). If the ECM detects that during the

same ignition cycle the fuel pressure rose even higher

than the amount to set DTC P0088 for a certain length

of time, the engine is stopped (Second Stage). If the

engine is stopped, the fuel pressure was too high and

the pressure limiter valve did not active or did not active

quick enough.

Condition for Running the DTC • DTCs P0192 and P0193 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

First Stage • The ECM detects that the fuel rail pressure is more than 197 MPa (28,600 psi) for longer than 5

seconds.

Second Stage

• The ECM detects that the fuel rail pressure is more than 200 MPa (29,000 psi) for longer than 5

seconds.

Action Taken When the DTC Sets

First Stage • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Second Stage • The ECM illuminates the SVS lamp when the

diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

• The ECM stops engine running when the vehicle speed is lower than 5 km/h (3 MPH) for 5 seconds.

The engine will run after the key is cycled when the

ignition has been tuned OFF for longer than 10

seconds.

Condition for Clearing the DTC

First Stage • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Second Stage

• Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • An intermittently sticking Fuel Rail Pressure regulator may have allowed the fuel pressure to

become high enough to set this DTC.

• Normal Fuel Rail Pressure readings on the scan tool with the engine running in neutral at idle is

around 27 to 33 MPa (3,900 to 48,00 psi) after

warm up.

• A skewed FRP sensor value can set this DTC. The FRP Sensor on the scan tool should read 0.9 to

1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1

minute.

Schematic Reference: Fuel System Routing Diagram

and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0088

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007